Have you ever wondered about the differences between galvanized iron and galvanized steel? In this article, we’ll dive into the intricacies of these two materials, exploring their unique properties, applications, and corrosion resistance. Our expert mechanical engineer will guide you through the key distinctions, providing valuable insights to help you make informed decisions for your projects.

Galvanized iron and galvanized steel exhibit some differences in material properties, areas of application, and processing capabilities.

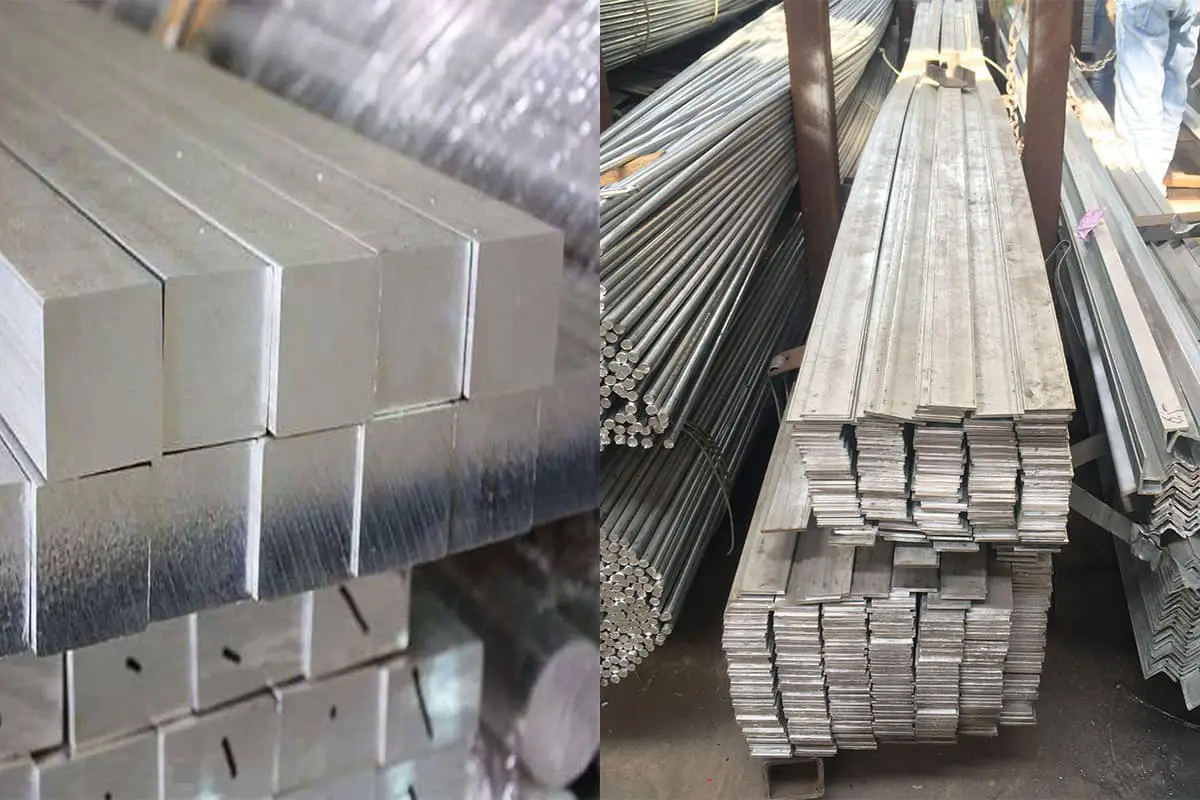

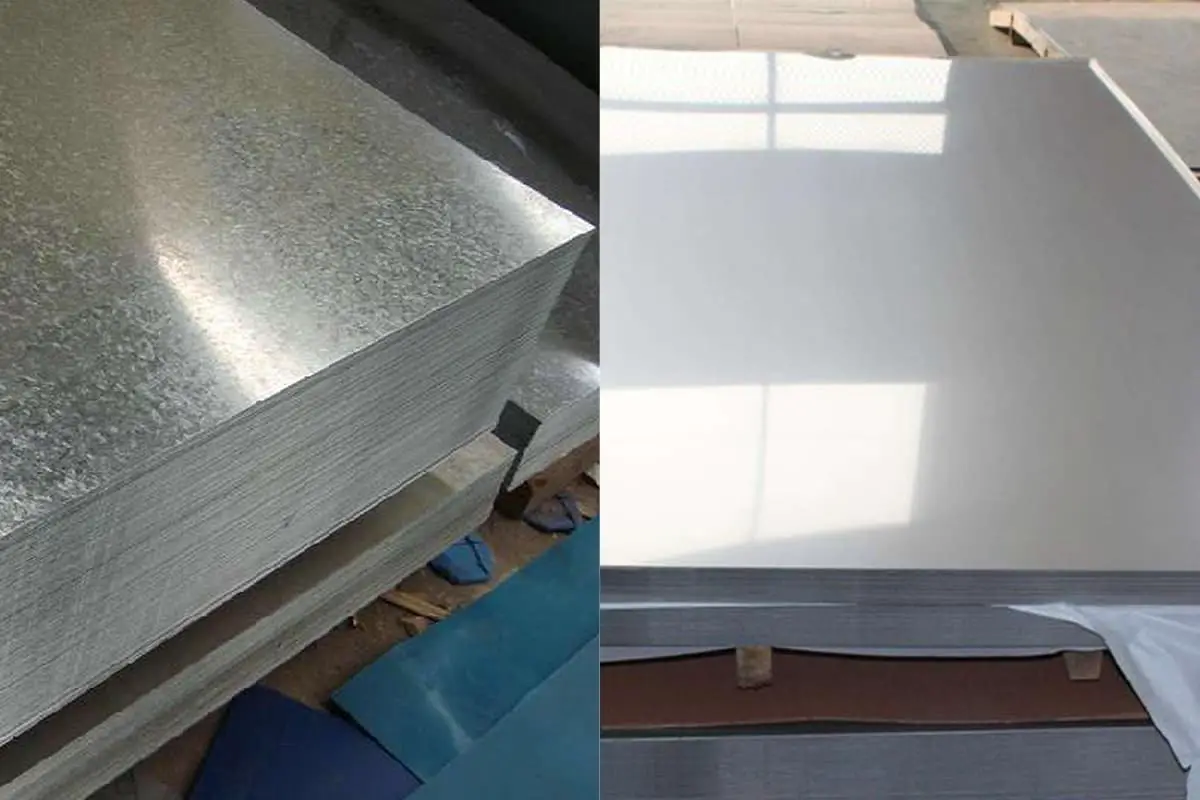

First, in terms of material composition, galvanized iron is a low-carbon steel sheet coated with zinc on the surface; its thickness generally ranges between 0.44 to 1.2 millimeters, with a zinc layer thicker than 0.02 millimeters.

Galvanized steel, on the other hand, is a welded steel plate with a surface hot-dip galvanized or electroplated zinc layer, which can be divided into ordinary electrolytic plates and fingerprint-resistant electrolytic plates. This indicates that galvanized iron is primarily made of low-carbon steel, while galvanized steel may incorporate different types of steel, such as ordinary steel or steel treated in a specific manner.

Second, in terms of corrosion resistance and ductility, galvanized iron is virtually rust-resistant and has strong corrosion resistance and ductility. Galvanized steel plates can effectively prevent steel corrosion, extending their lifespan, and they exhibit excellent paintability, decorativeness, and good formability. This implies that while both have good rust-proof capabilities, galvanized steel plates perform better in terms of decorativeness and formability.

Finally, looking at carbon content, galvanized steel wire holds a carbon content of 0.40-0.80%, while galvanized iron wire has a carbon content of 0.05-0.25%. This difference results in variations in their strength; due to its higher carbon content, galvanized steel wire possesses relatively higher strength.

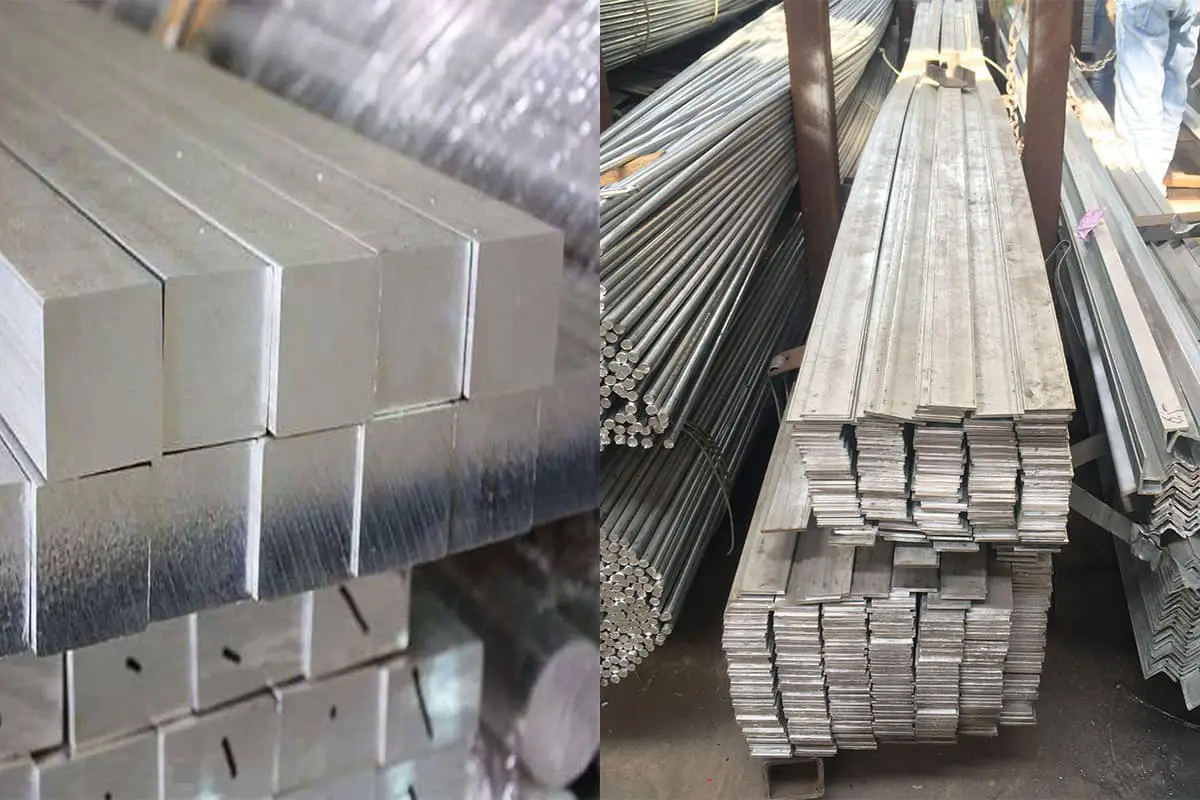

Galvanized iron is a kind of low carbon steel sheet coated with zinc on the surface. Its basic thickness is generally 0.44~1.2 mm, and the thickness of zinc layer is also greater than 0.02 mm.

Galvanized iron sheet can be divided into flat sheet and corrugated (corrugated) sheet.

Ungalvanized sheet is commonly known as black iron sheet.

Galvanized steel plate is a kind of welded steel plate with hot-dip or galvanized zinc coating on the surface.

Galvanized steel plate can be divided into ordinary electrolytic plate and fingerprint resistant electrolytic plate.

Fingerprint-resistant plate is mainly based on the ordinary electrolytic plate for additional fingerprint-resistant treatment, which can resist sweat, and is generally used on parts without any treatment.

The common electrolytic plate can be divided into phosphating plate and passivation plate.

The galvanized iron sheet is basically not easy to rust and has strong corrosion resistance, and has strong ductility.

Galvanized steel plate can effectively prevent steel corrosion, prolong service life, and has excellent painting, decoration, formability, heat conduction and heat reflection.

Galvanized iron sheet is a kind of iron coiled material widely used in industry, manufacturing and other industries. It is often used to manufacture roofs, coils and various containers.

Galvanized steel sheet is widely used in construction, vehicles, household appliances, daily necessities, light industry, agriculture, transportation and other industries.

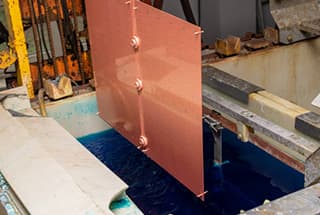

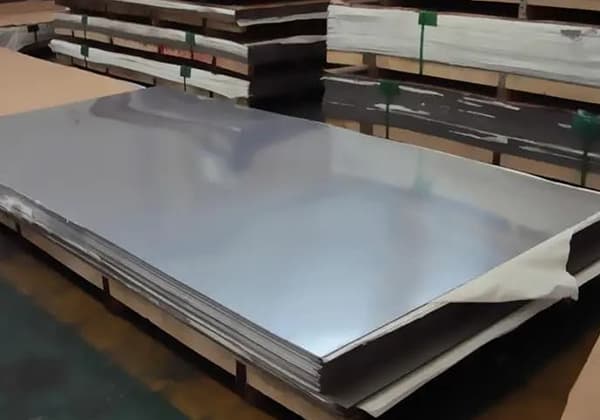

Immerse the sheet steel into the molten zinc bath to make its surface adhere to the zinc sheet steel.

At present, it is also basically produced by a continuous galvanizing process, which can continuously dip the rolled steel plate into the molten zinc plating bath to make galvanized steel plate;

Moreover, this kind of steel plate is basically manufactured by a hot dip method, but it can be heated to about 500 ℃ immediately after it is out of the tank, which is also an alloy coating that can make it produce zinc and iron.

This kind of galvanized sheet also has very good coating adhesion and weldability;

The galvanized steel plate is mainly manufactured by electroplating method, which basically has a particularly good processing performance.

However, the coating is relatively thin and its corrosion resistance is not as good as that of hot-dip galvanized sheet;

Single-sided galvanized steel plate, that is, products that are galvanized on one side only.

It has better adaptability than double-sided galvanized sheet in welding, coating, anti-rust treatment, processing, etc.

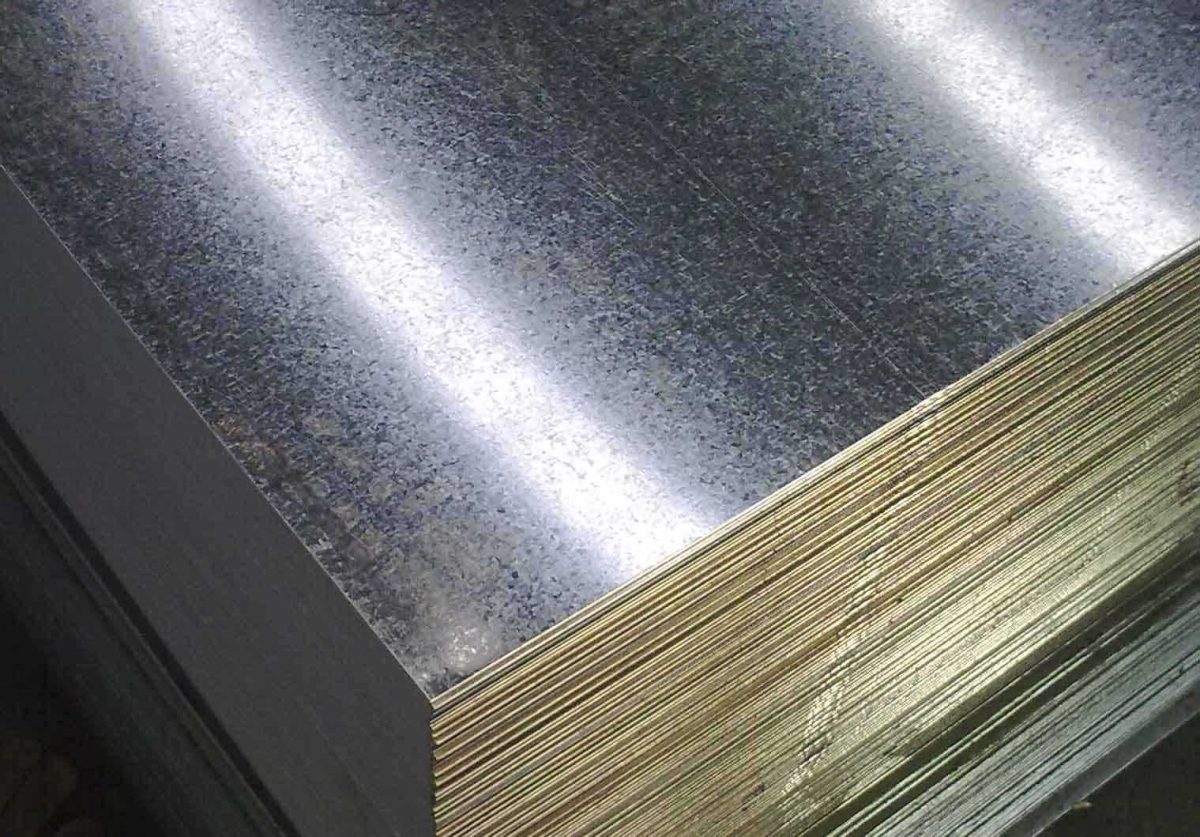

In order to overcome the shortcoming of single side without zinc coating, there is another kind of galvanized sheet coated with thin layer of zinc on the other side, that is, double-sided differential galvanized sheet;

It mainly uses zinc and other metals such as lead and zinc to make alloy and even composite plating steel plate.

This kind of steel plate not only has excellent anti-rust performance, but also has good coating performance.

The comparison of the corrosion resistance properties of galvanized iron and galvanized steel under various environmental conditions primarily depends on the zinc coating on their surface. This zinc layer effectively prevents corrosion, oxidation, and erosion. However, due to the inherent differences in the materials, they exhibit different corrosion resistance properties under various environmental conditions.

For galvanized iron, electroplated galvanized iron wires have a lower zinc content, which makes them prone to rusting in the presence of rainwater or damp conditions. In contrast, hot-dip galvanized iron wires, with a higher zinc layer content, offer better corrosion resistance. This suggests that in damp environments, hot-dip galvanized iron exhibits superior corrosion resistance compared to electroplated galvanized iron.

The situation is slightly different for galvanized steel. The corrosion resistance lifespan of hot-dip galvanized steel grating mainly depends on the thickness of the zinc layer, which can vary greatly under different usage conditions. For instance, in dry air, hot-dip galvanized steel grating demonstrates good corrosion resistance, while in extremely damp conditions, the zinc coating might corrode upon contact with aluminum or stainless steel. Moreover, passivation treatment can significantly enhance the corrosion resistance of galvanized sheets, making them suitable for use under harsh environmental conditions.

The corrosion resistance properties of galvanized iron and galvanized steel under different environmental conditions are influenced by several factors, including the type of galvanization (electroplated or hot-dip), thickness, and whether passivation treatment has been applied. In general dry environments, both offer good corrosion resistance. However, in damp or specific chemical environments, hot-dip galvanized materials typically exhibit higher corrosion resistance, especially when considering passivation treatment. Therefore, the choice of material should be determined based on the specific usage environment and requirements.

What are the differences in strength between galvanized steel wire and galvanized iron wire, and how do they impact their applications?

The difference in strength between galvanized steel wire and galvanized iron wire primarily lies in their carbon content. Steel wire has a higher carbon content, thus possessing greater strength and better toughness, while iron wire has a lower carbon content, making it comparatively weaker and softer. This difference in strength dictates their respective application fields.

Galvanized steel wire, with its high strength, excellent toughness, and corrosion resistance, has a wide range of applications in the automotive, power, energy, and agricultural sectors. Especially in harsh environmental conditions, such as farms and steel wire rope manufacturing, galvanized steel wire is extensively used due to its smooth, clean surface and anti-corrosion properties. Moreover, with the advancement of urbanization, the use of galvanized steel wire in the construction, power, and communications industries is also on the rise.

In contrast, galvanized iron wire, due to its lower strength and softer nature, is more commonly used for lightweight applications in everyday life, such as bundling items. Although the tensile strength standard for galvanized iron wire is 295-540MPa, compared to galvanized steel wire, it falls short in applications requiring higher strength and durability.

The significant difference in strength between galvanized steel wire and galvanized iron wire directly influences their choice of application in different fields. Galvanized steel wire, with its high strength and excellent performance features, plays a crucial role in many important industries and sectors, while galvanized iron wire is more often used in everyday situations where high strength is not a requirement.

When comparing the long-term use costs of galvanized iron and galvanized steel, several factors need to be considered, including initial costs, maintenance expenses, lifespan, and the impact of environmental factors on corrosion rates.

Firstly, looking at the initial costs, the choice of material (iron or steel) in the galvanizing process may lead to some cost differences. However, this discrepancy isn’t significant enough to represent the overall expenditure.

Secondly, maintenance costs are another crucial consideration. Evidence suggests that the maintenance costs for galvanized systems can vary significantly depending on the system. Specifically, hot-dip galvanizing corrosion protection projects excel in long-term economic benefits, especially with rising wages, painting and repair costs will continually escalate, demonstrating the excellence of hot-dip galvanizing.

Thirdly, the lifespan is also a critical measure for assessing cost-effectiveness. Hot-dip galvanizing is more expensive than cold galvanizing because it requires higher energy consumption to form a layer of zinc-iron alloy, which results in a longer lifespan. Furthermore, the lifespan of galvanized steel plates can be affected by environmental factors like sulfur dioxide gas or salt, particularly in industrial areas or coastal regions where corrosion rates are accelerated.

Lastly, the impact of environmental factors on corrosion rates cannot be ignored. For instance, during the rainy season, coatings subjected to long-term exposure to rainwater may accelerate corrosion rates, thereby affecting lifespan.

Although there may be differences in the initial costs of galvanized iron and galvanized steel, from a long-term use cost perspective, hot-dip galvanizing, due to its superior corrosion resistance and longer lifespan, has an advantage in maintenance costs and overall economic benefits. Therefore, considering long-term use costs, hot-dip galvanizing may be a more economical choice. However, the specific selection should still be made based on the actual application scenario and environmental conditions.

When selecting material for a project, it’s essential to consider the specific requirements. Galvanized iron, commonly used for water pipes and general-purpose applications, is known for its good corrosion resistance and high pliability. However, it may not be as suitable for heavy-duty, outdoor, or load-bearing applications.

On the other hand, galvanized steel offers superior strength and durability. This material is often utilized in structural, automotive, and outdoor construction projects due to its robustness and resilience. It’s important to thoroughly assess the project’s demands, such as weight-bearing capacity, exposure to the elements, and longevity, before deciding on the appropriate material.

Both galvanized iron and galvanized steel provide excellent corrosion resistance; however, the cost may vary significantly. Galvanized iron tends to be more affordable than galvanized steel, making it an attractive option for budget-conscious projects. When considering budget constraints, it’s essential to weigh the pros and cons of each material:

In summary, choosing between galvanized iron and galvanized steel depends on the project’s specific requirements and budget constraints. Galvanized iron may be a preferable choice for general-purpose applications, while galvanized steel works best when strength and durability are required.