Steel is fundamental in construction and manufacturing, but choosing the right type can be tricky. Have you ever wondered which is better: galvanized steel or stainless steel? This article breaks down their differences in terms of corrosion resistance, cost, and applications, helping you make an informed decision. Discover the unique benefits and drawbacks of each type, ensuring your projects use the most suitable material. Dive in to learn how these steels compare and what factors to consider when selecting the right one for your needs.

As the name implies, galvanized sheets are steel sheets coated with a layer of zinc, which to some extent provides corrosion resistance. This manufacturing method also helps reduce global zinc consumption.

1. Non-alloy Hot-dip Galvanized Steel Strip

2. Alloy Hot-dip Galvanized Steel Strip

Galvanized sheets involve brushing a layer of zinc on an iron plate for corrosion resistance, including cold and hot galvanizing methods.

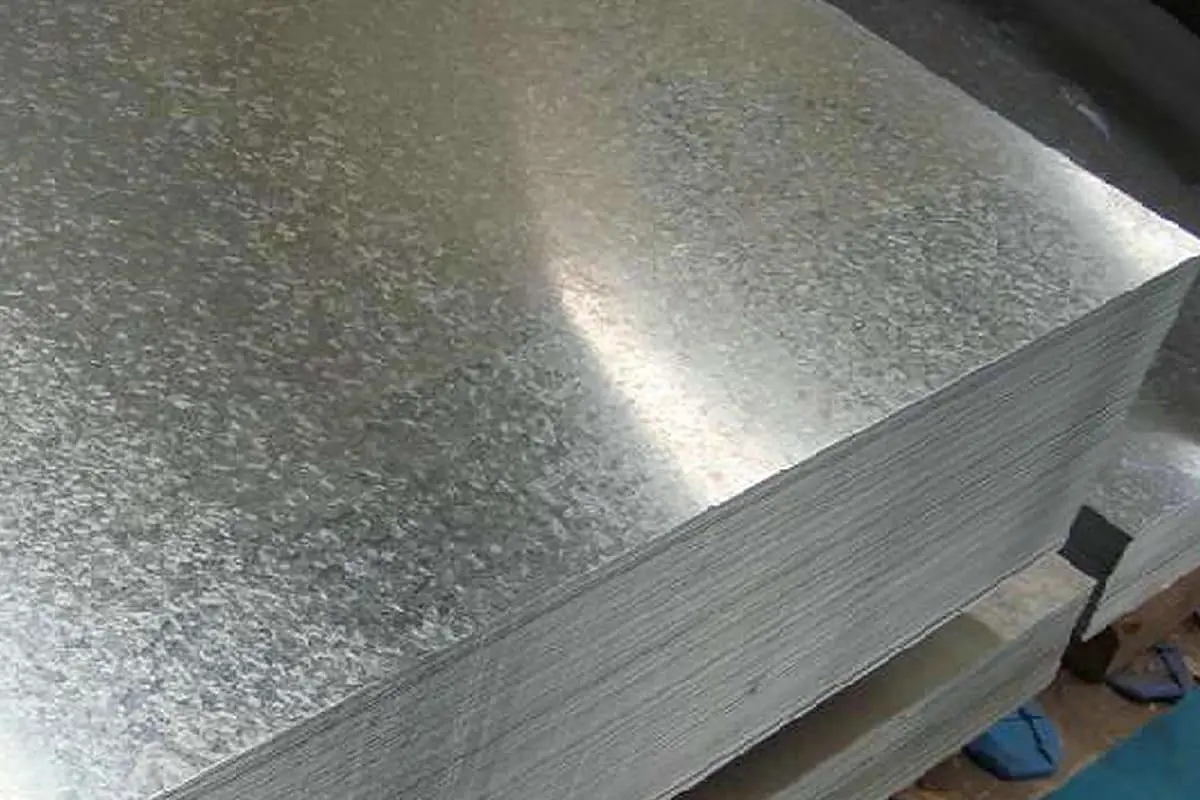

Over time, the surface zinc will fall off, exposing the iron to corrosion. Stainless steel, on the other hand, doesn’t require corrosion protection.

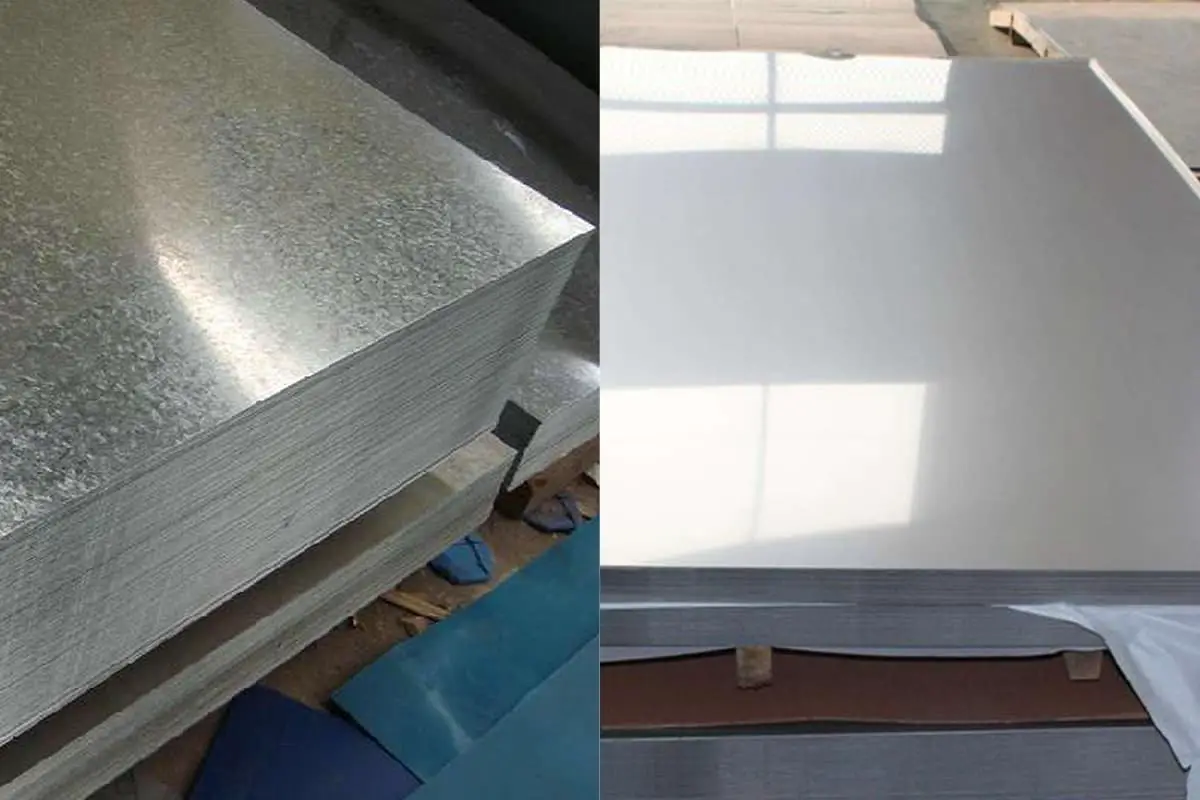

Naturally, it’s more expensive, with prices for stainless steel ranging from 200-300. Only some special materials require 200-300 degree low-temperature tempering.

However, under high temperatures (200 degrees, 300 degrees), the zinc layer on the galvanized sheet will gradually bake off.

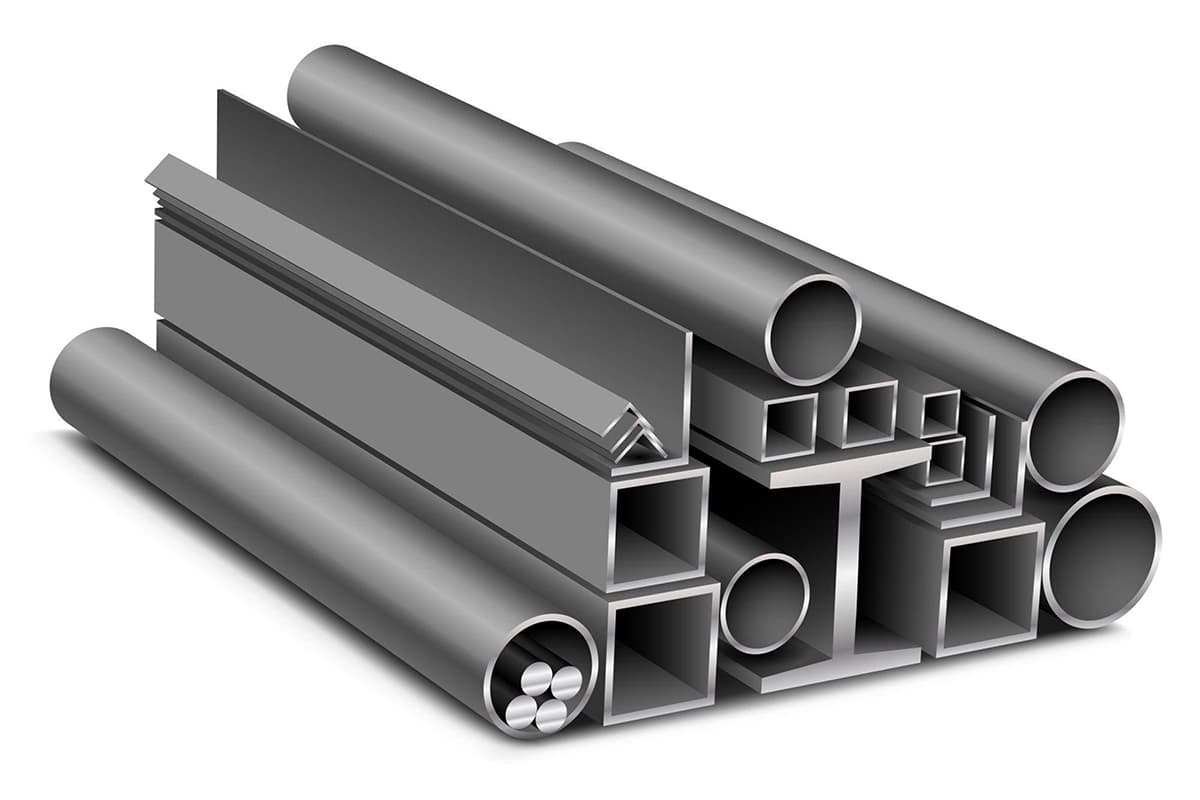

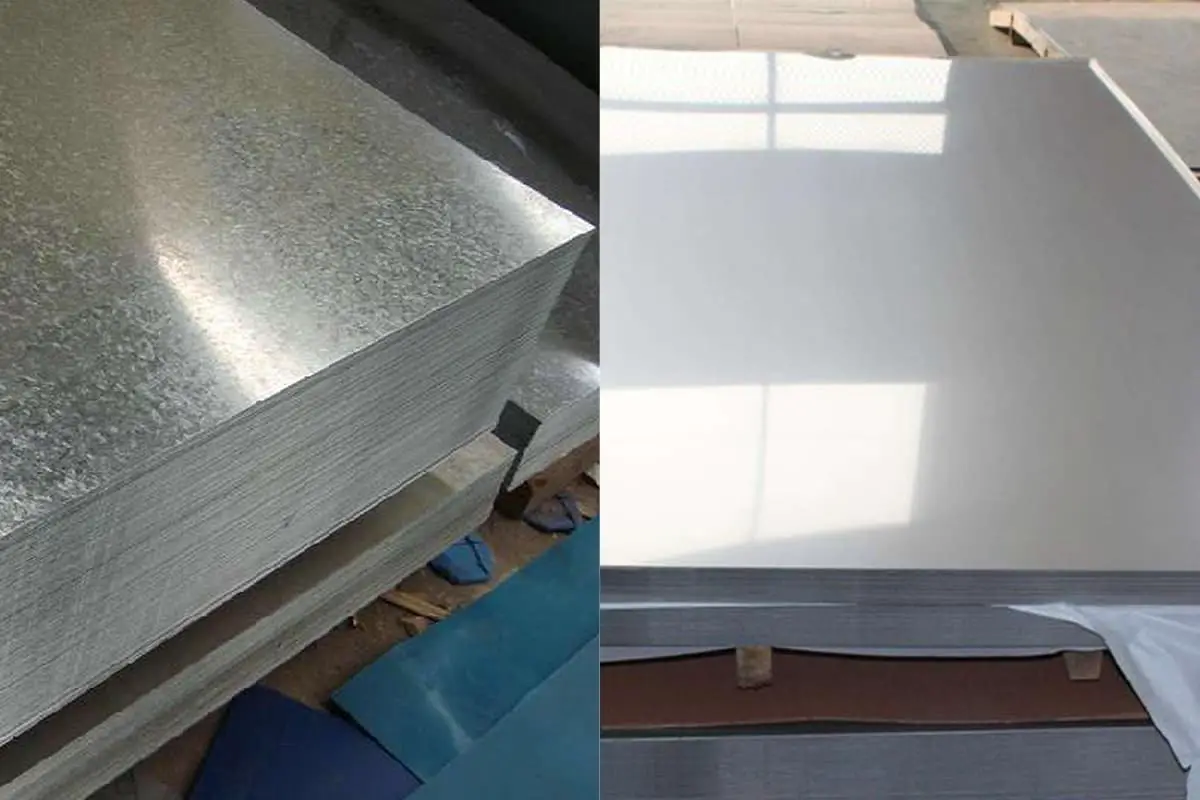

There are many types of stainless steel, while galvanized sheets involve simply electroplating a layer of zinc on the surface of a steel or iron plate. Galvanized sheets are ordinary plates that have been surface treated, while stainless steel sheets are corrosion and acid-resistant alloy plates.

Depending on your purpose, 200-300 degrees isn’t considered high temperature, and a relatively cheap stainless steel 430 plate should be about twice the price of a galvanized sheet of the same specification.

Stainless steel achieves its corrosion resistance by adding trace elements to change the steel composition.

Galvanized sheets, on the other hand, galvanize the surface of ordinary steel sheets, achieving corrosion resistance by sacrificing zinc. 200 and 300 degrees pose no problem for metals; it depends on the ambient atmosphere. There may be some extremely minor effects, but significant changes would take a long time to occur.