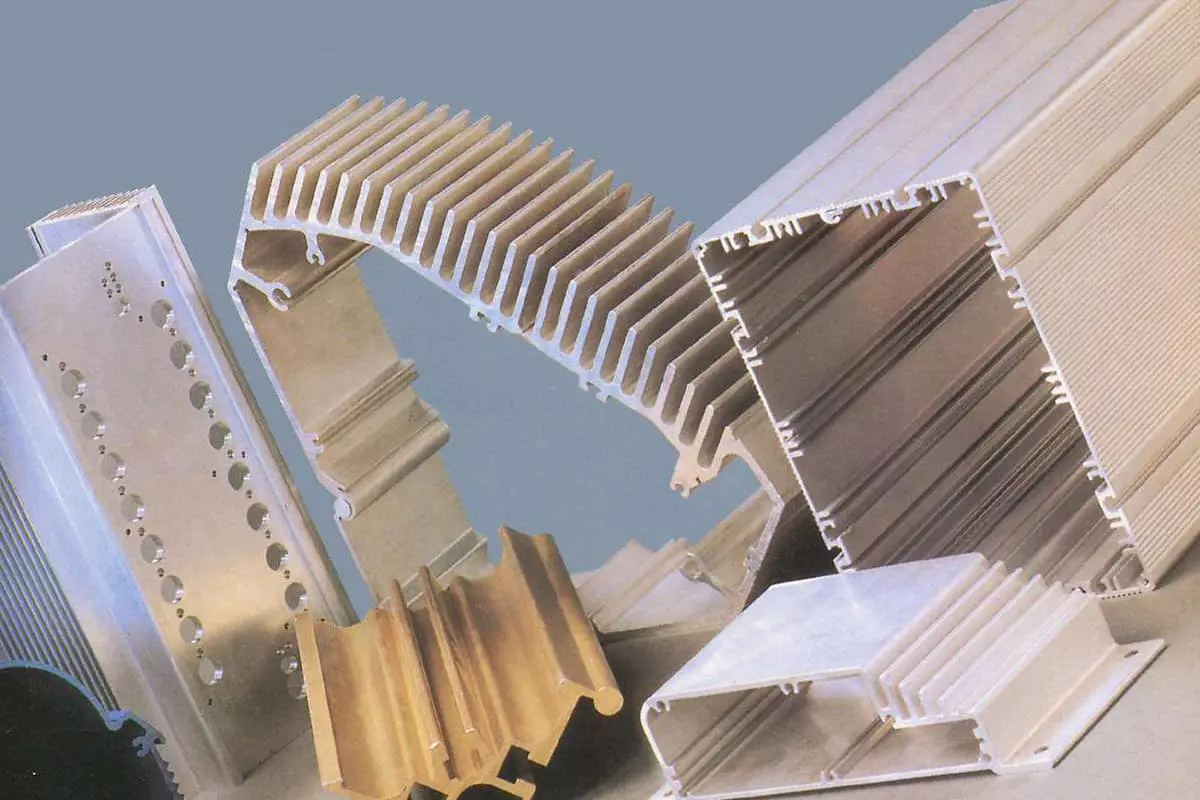

Ever wondered how different aluminum alloys compare in thermal conductivity? This article presents a detailed chart highlighting the thermal conductivity coefficients of various aluminum profiles. From pure aluminum to specific alloys like 6061 and ADC12, you’ll discover essential data that can inform your material choices for engineering projects. Dive in to understand how these properties can impact heat transfer in your applications.

Regarding the thermal conductivity coefficients of various aluminum profiles, the thermal conductivity coefficient of extruded aluminum is as follows:

| Name | Model | Thermal Conductivity (W/m·k) |

| Pure Aluminum | / | 237 |

| Aluminum Alloy | 1050 | 209 |

| Aluminum Alloy | 1070 | 226 |

| Aluminum Alloy | 6061 | 155 |

| Aluminum Alloy | 6063 | 201 |

| Aluminum Alloy | ADC12 | 96.2 |

| Die-Cast Aluminum | A360 | 113 |

| Die-Cast Aluminum | A380 | 96.2 |

Notes:

1. ADC12, compared to ADC10, contains more silicon, has greater strength, superior pressure resistance, and excellent thermal brittleness. Hence, it’s well-suited for casting complex components.

2. The thermal conductivity of plastic is quite low, roughly 1/500-1/600 that of metals.

3. The thermal conductivity of foam plastic is only 0.02-0.046 W/m·k, approximately 1/1500 of that of metals, 1/40 of that of cement concrete, and 1/20 of that of ordinary clay bricks, making it an ideal insulating material.