Are you tired of the rising costs of stainless steel for your projects? This article explores a cost-effective alternative to Stainless Steel 304—SUS443. Learn how SUS443 offers superior corrosion resistance, better thermal conductivity, and significant savings. Dive in to find out how this innovative material can revolutionize your applications!

| Material/Thickness | SUS443/2B | SUS304/2B |

| 0.3 | 19000 | 25100 |

| 0.4 | 18500 | 23600 |

| 0.5 | 17500 | 22800 |

| 0.6 | 16800 | 22500 |

| 0.7 | 16800 | 22400 |

| 0.8 | 16600 | 22200 |

| 0.9 | 16500 | 22100 |

| 1 | 16500 | 22100 |

| 1.2 | 16300 | 21900 |

| 1.5 | 16100 | 21700 |

| 1.8 | 16100 | 21700 |

| 2 | 16000 | 21700 |

| 2.2 | 16000 | 21700 |

| 2.5 | 16000 | 1700 |

| 3 | 16000 | 21700 |

| >3.0 | 17000 | 23200 |

Unit: CNY/Ton.

304 Stainless Steel, commonly referred to as Stainless Steel 304, is one of the most widely used types of stainless steel. To maintain its inherent corrosion resistance, stainless steel must contain at least 12% chromium. In the case of 304 stainless steel, it also includes more than 8% nickel, which enhances its corrosion resistance and formability.

Stainless Steel 304 is prevalent in various applications due to its excellent properties. It is commonly found in:

The international price of nickel, a key component of Stainless Steel 304, is subject to constant fluctuations. Since nickel is a limited resource, its price volatility directly impacts the cost of 304 stainless steel. This rising trend in nickel prices has become a significant factor limiting the development and broader adoption of Stainless Steel 304.

Given the instability in the international market for stainless steel raw materials and the increasing competition, there is a growing demand to reduce material costs. End users are becoming more specific in their requirements for stainless steel materials, seeking alternatives that can offer similar or better performance at a lower cost.

To address these challenges, our company, in collaboration with Japan’s JFE and TISCO, has developed a new product: 21CT, branded as SUS443. This development aims to provide a cost-effective alternative to Stainless Steel 304 without compromising on quality.

The introduction of 21CT (SUS443) represents a significant advancement in the stainless steel industry, offering a viable alternative to Stainless Steel 304. This new material addresses the urgent need for cost reduction while maintaining high performance, making it a valuable solution in the current market landscape.

443 stainless steel, also known as 21CT, contains 21% chromium, which significantly improves its corrosion resistance. This level of chromium content provides corrosion resistance comparable to that of stainless steel 304, and its pitting resistance surpasses that of 304. This makes 21CT an excellent choice for applications requiring high resistance to corrosive environments.

The reduction of impurities such as carbon and nitrogen, coupled with the addition of elements like titanium and copper, further enhances the corrosion resistance of 21CT. Titanium stabilizes the steel, preventing the formation of chromium carbides at grain boundaries, which can lead to intergranular corrosion. Copper improves resistance to certain types of corrosion and enhances the overall durability of the material.

21CT belongs to the ferritic 400 series of stainless steels, specifically identified by the brand number SUS443. Ferritic stainless steels are known for their good mechanical properties and resistance to stress corrosion cracking. 21CT exhibits superior mechanical properties compared to SUS430, making it a robust option for various applications.

One of the significant advantages of 21CT is its cost-effectiveness. Since it does not contain nickel, its price is approximately 30% lower than that of stainless steel 304. This makes 21CT an attractive option for projects where budget constraints are a consideration, without compromising on performance.

21CT offers about 30% higher thermal conductivity compared to stainless steel 304. This characteristic, along with its good magnetic conductivity, makes it particularly advantageous for applications in cooking products and other scenarios where efficient heat transfer is essential.

Due to the inherent characteristics of ferritic stainless steel, components made from 21CT that undergo deep processing are less likely to experience delayed fracture caused by the release of internal stress. As a result, annealing treatment is generally not required, which effectively reduces processing costs and simplifies manufacturing processes.

In summary, 443 stainless steel (21CT) combines excellent corrosion resistance, superior mechanical properties, cost-effectiveness, and enhanced thermal conductivity, making it a highly versatile and valuable material for a wide range of industrial applications.

Stainless Steel 443, also known as 21CT, is a ferritic stainless steel that offers excellent corrosion resistance, good formability, and high-temperature strength. Its unique properties make it suitable for a wide range of applications across various industries. Below is an overview of its primary application fields:

Stainless Steel 443 is widely used in the kitchenware industry due to its corrosion resistance and ease of cleaning. Common applications include:

The appliance industry benefits from the durability and aesthetic appeal of Stainless Steel 443. Common applications include:

In the transportation sector, Stainless Steel 443 is valued for its strength and resistance to corrosion. Common applications include:

The construction industry utilizes Stainless Steel 443 for its durability and aesthetic appeal. Common applications include:

Stainless Steel 443 is also used in various other applications due to its unique properties. Common applications include:

In our company, Stainless Steel 443 materials, primarily in the form of stainless steel plates, are mainly used in the following industries:

Stainless Steel 443 continues to be a versatile and valuable material across multiple industries, providing a combination of durability, corrosion resistance, and aesthetic appeal.

| Steel Type | 21CT | SUS304 |

| Chromium | 21 | 18.2 |

| Nickel | – | 8.1 |

| Molybdenum | – | – |

| Titanium | 0.3 | – |

| Carbon | 0.008 | 0.06 |

| Nitrogen | 0.01 | 0.04 |

| Copper | 0.43 | – |

*21CT increases the chromium content to 21%, thus providing better corrosion resistance, and additionally includes titanium and copper elements.

*Titanium can enhance the resistance to intergranular corrosion and improve weldability.

*Copper can improve resistance to acidic substances.

| Steel Type | 21CT | SUS304 |

| Density(g/cm3) | 7.74 | 7.93 |

| Density(10-6Ω·cm) | 58 | 70 |

| Magnetism | Yes | No |

| Specific Heat 25℃(J/kg·℃) | 440 | 500 |

| Thermal Conductivity 100℃(W/m·℃) | 22.5 | 16.2 |

| Thermal Expansion Rate 20-100℃(10-6/℃) | 10.5 | 17.3 |

| Young’s Modulus (Gpa) | 204 | 193 |

Compared to 304, 21CT has: Lower density, allowing for an approximately 2.5% increase in material area for the same weight, better thermal conductivity, less thermal expansion, magnetism, and excellent properties suitable for use with induction cookers.

| Steel Type | SUS443 | SUS304 |

| Yield Strength (MPa) | 305 | 260 |

| Tensile Strength (MPa) | 483 | 645 |

| Extension Rate (%) | 31 | 60 |

| Average R Value | 1.3 | 1 |

| Hardness (Hv) | 161 | 185 |

| Cone Cup Protrusion (mm) | 38.6 | 37.7 |

| Bendability (Bend Angle 180°) | Good(R=0T) | Good(R=0T) |

The R value is an indicator of the deep drawing performance of the material. The higher the R value, the better the deep drawing performance!

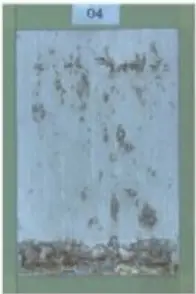

Test result graph for boiling 2 liters of water.

Conclusion: When heating with gas or an induction stove, the thermal conductivity of 443 is superior to that of stainless steel 304!

| Combination | TIG Welding | MIG Welding | Arc Welding |

| Welding of the same type: 21CT and 21CT | □ | □ | □ |

| Welding of different types: 21CT and SUS304 | ■ | □ | □ |

Note: For more detailed welding technical data and welding skills, you can contact our company to obtain them.

| Steel Type | Cyclic Corrosion Testing | Salt Spray Test (NSS) | Exposure Test | Corrosion of Welded Parts | |

| SUS443 |  |  |  |  |  |

| SUS304 |  |  |  |  |  |

Methods to test corrosion resistance:

1. Surface #600 polished stainless steel plate, saltwater spray (5% NaCl, 35℃, 2hr) → dry (60℃, 4hr) → moisten (40℃, 2hr), repeat 30 times.

2. Surface #600 polished stainless steel plate, neutral saltwater spray (5% NaCl, 35℃), 1000 hours.

3. Surface #600 polished stainless steel plate, exposed for 9 months in Chiba Prefecture, Japan, 10 meters from the shore, with sea salt adsorption quantity of 0.25mg.dm-2.day-1.

4. TIG welding, plate thickness is 0.8mm, contact start arc welding, using argon gas for protection, and polished with surface #600 after welding.

Comparison of Stress Corrosion Cracking Tests:

| Steel Type | 304 Stainless Steel | 443 Stainless Steel |

| Presence or Absence of a Break | Breakage occurs within ≤15 hours. | No breakage after 100h test |

| Appearance After Testing |  |  |

Condition: 42% MgCl2U, JIS G 0576 shape bending

Conclusion: 304 stainless steel may undergo stress corrosion cracking, but 443 stainless steel is not at risk of this occurrence.

| EU ROHS Certification | Compliant with the European Union’s environmental protection standards (SGS certified) |

| International Health Certification | Conforms to the requirements of GB-9684-1988 “Hygienic Standard for Stainless Steel Food Utensils and Containers” |

| Germany LFGB Certification | Complies with German food and commodity laws, and meets the requirements for metal release from stainless steel tableware |

| US FDA Certification | Meets the food safety regulatory standards of the United States, and the requirements for metal release from stainless steel tableware |