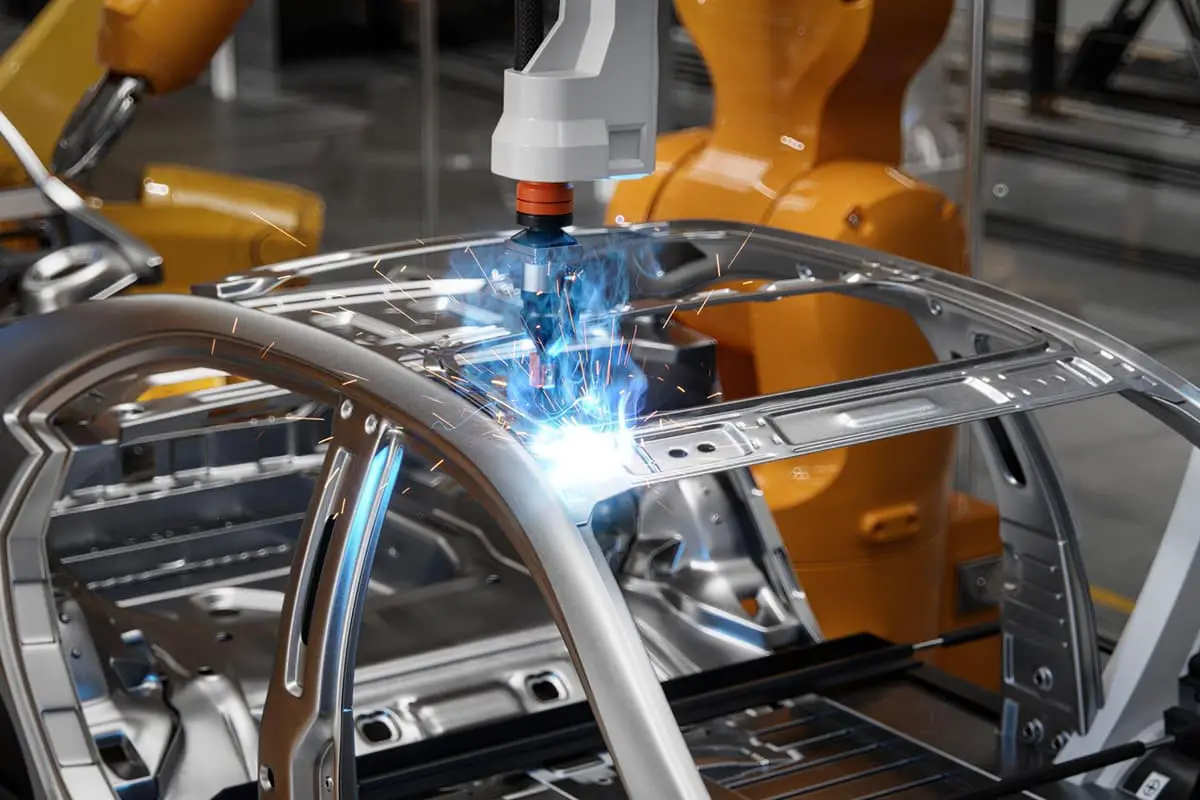

Ever wondered how skyscrapers stand tall or cars stay welded together? This blog uncovers the magic behind electric welding machines. Learn about top manufacturers like Lincoln Electric and Miller Welds, and discover what makes their equipment indispensable in industries. Find out how to choose the best welding machine for your needs.

Electric welding machines play a crucial role in various industries, including construction, automotive, aerospace, and many more. Manufacturers of these machines understand the importance of delivering high-quality, durable, and efficient products to meet the demands of their customers. Some notable companies, like Lincoln Electric and Miller Welds, have become leading names in the industry and earned a reputation for their reliable and innovative welding equipment.

Founded in 1895, Lincoln Electric is a well-established brand with a global presence, offering a wide range of products, including MIG welders, TIG welders, and engine-driven welders. Their commitment to the research and development of welding technologies has helped them maintain a strong industry position. Similarly, Miller Welds provides an extensive selection of welding machines, such as MIG, TIG, Stick, and submerged arc welders, targeting a variety of applications and professional welders.

These top-tier electric welding machine manufacturers ensure their products meet the highest standards, recognizing that skilled welders require dependable and efficient equipment to complete their tasks. As the demand for welding machines continues to grow across various industries, companies like Lincoln Electric and Miller Welds are constantly working towards developing innovative solutions to stay at the forefront of their field.

The electric welding machine industry comprises numerous well-established manufacturers that specialize in producing high-quality welding equipment. These manufacturers offer a diverse range of welding machines catering to various techniques, such as stick, TIG, MIG, and multi-purpose processes. In this section, we will provide an overview of some prominent electric welding machine manufacturers.

Lincoln Electric is one of the leading global manufacturers in the industry, having a substantial presence in North America. They offer a wide array of welding machines, including stick, MIG, TIG, advanced, and multi-purpose machines. Lincoln Electric also specializes in submerged arc welding, engine drives, and wire feeders. They are known for their exceptional quality and reliable equipment.

ESAB Welders is another well-regarded manufacturer with a strong international presence. They provide state-of-the-art welding and cutting solutions for a variety of industries. Their product lineup includes TIG welders, MIG welders, stick welders, and plasma cutters, along with a comprehensive range of welding accessories.

Hobart Welders is a renowned welding equipment manufacturer, specializing in high-performance yet affordable welding machines. Their product range encompasses MIG, TIG, stick, and multi-process welders. Hobart has a strong focus on innovation and dedication to delivering best-in-class welding solutions.

Everlast Welders is a reliable and innovative manufacturer that offers a wide assortment of welding equipment, including TIG, MIG, stick, and multi-process machines. They are known for their emphasis on performance, quality, and value, making their products popular among both DIY enthusiasts and professional welders.

Eastwood is another prominent name in the welding equipment industry, well-known for its versatile welding machines and cutting tools. Their products cater to various industrial segments, and they are committed to delivering high-quality, reliable, and cost-effective solutions.

Several other manufacturers have also made their mark in the electric welding machine industry, including Panasonic Tangshan and Tangshan Kaiyuan Group. These companies are known for their cutting-edge technology and high-quality products in the electric welding machine market.

In conclusion, the electric welding machine market features an array of manufacturers, each offering a diverse range of welding equipment in terms of quality, performance, and price. Professionals and DIY enthusiasts alike can choose from various brands, such as Lincoln Electric, ESAB Welders, Hobart Welders, Everlast Welders, and Eastwood, to find the best-suited welding equipment for their specific requirements.

When selecting an electric welding machine, several critical factors must be considered to ensure you choose the right equipment for your needs. Below is a detailed analysis of these factors:

The motor is the heart of an electric welding machine, and its material significantly impacts performance and durability. A pure copper motor is highly recommended due to its superior properties:

The capacitance of a welding machine affects its durability and performance:

The material of the welding wire core is crucial for efficient welding:

Safety is paramount when operating an electric welding machine:

Consider the specific requirements and materials you will be welding:

Electric welding machines are essential tools in various industries, including construction, automotive, and manufacturing. Choosing the right manufacturer is crucial for ensuring reliability, performance, and safety. Here is a list of the top 10 electric welding machine manufacturers known for their strong market presence, innovation, and quality products.

Tangshan Panasonic, a joint venture between the Japan Panasonic Group and Tangshan Kaiyuan Group, was established in 1994. Over the years, it has grown to become one of the top ten brands in the electric welding machine industry. The company offers a comprehensive range of products and services, including electric welding machines, industrial robots, laser welding systems, and other related services.

Tangshan Panasonic specializes in the manufacturing and distribution of high-quality welding equipment. The company’s product portfolio includes:

With an impressive annual output of 100,000 electric welding machines, Tangshan Panasonic stands out as a professional and reliable manufacturer in the welding equipment sector. To maintain high standards of quality and customer satisfaction, the company has established:

Tangshan Panasonic is committed to delivering superior products and services. By leveraging the expertise of its founding partners and continuously investing in technology and innovation, the company aims to meet the evolving needs of the welding industry and maintain its position as a market leader.

Lincoln Electric, founded in 1895 in the United States, is a renowned manufacturer of welding equipment. The company specializes in the design, development, and production of arc welding products. Their extensive product line is widely utilized across various industries, including pipeline welding, shipbuilding, and stainless steel welding.

The Lincoln welder is celebrated for its ease of operation, durability, and high performance-to-price ratio. These attributes make Lincoln Electric’s products a preferred choice for both professional welders and industrial applications.

Lincoln Electric has established a significant global footprint with 59 production bases in 18 countries. Additionally, their extensive distribution network spans 160 countries worldwide, ensuring that their high-quality welding solutions are accessible to a broad range of customers.

Lincoln Electric’s welding equipment is integral to several key industries:

Founded in 2003, Riland has established itself as a nationally recognized high-tech enterprise. The company specializes in the research and development, manufacturing, sales, and service of inverter welding and cutting equipment, welding automation products, welding accessories, and protective gear.

Riland is a prominent player in the domestic inverter welding equipment industry, with its shares listed on the A-share market. This listing underscores the company’s strong market position and financial stability.

Riland’s sales and service network is extensive, spanning over 60 countries and regions across five continents. This global presence is supported by nearly 100 overseas customers or dealers, showcasing the company’s international appeal and reliability. Domestically, Riland works with over 2,000 dealers, ensuring comprehensive coverage and support within its home market.

Riland’s focus on innovation and quality has been a cornerstone of its success. By continuously investing in research and development, the company ensures that its products meet the highest standards of performance and reliability. This commitment to excellence has earned Riland a reputation as a trusted name in the welding and cutting equipment industry.

Overview

Jasic Technology, established in 2005, is a prominent national high-tech enterprise specializing in the research and development (R&D), production, sales, and service of inverter welding machines, internal combustion power generation welding machines, and comprehensive welding and cutting equipment. In 2011, the company achieved a significant milestone by being listed on the Shenzhen Stock Exchange.

Industry Position

Jasic Technology is recognized as a leading manufacturing enterprise within the domestic welding and cutting equipment industry. The company’s commitment to innovation and quality is underscored by its establishment of four R&D centers across the nation. These centers are pivotal in driving the company’s technological advancements and maintaining its competitive edge.

Technological Achievements

The company has made substantial contributions to the field, securing over 60 core technology patents. These patents reflect Jasic Technology’s dedication to advancing welding and cutting technologies, ensuring that their products remain at the forefront of the industry.

Global Reach

Jasic Technology has developed an extensive sales and service network that spans both domestic and international markets. This global presence enables the company to cater to a diverse customer base, providing high-quality welding and cutting solutions worldwide.

Founded in 1993, Aotai Company has established itself as a national key high-tech enterprise and a global manufacturer of industrial welding and cutting equipment. Over the years, it has become synonymous with innovation and excellence in the field of welding technology.

Aotai Company specializes in a wide range of products and solutions designed to meet the diverse needs of its customers. These include:

Aotai has dedicated significant resources to the research and innovation of inverter technology and welding technology. This focus has positioned the company as a leader in the development and production of industrial inverter welding machines in China. Inverter technology offers numerous advantages, including improved energy efficiency, better control over welding parameters, and enhanced performance, making Aotai’s products highly sought after in the market.

The company’s commitment to continuous improvement and technological advancement has been a driving force behind its success. By staying at the forefront of industry trends and investing in cutting-edge research, Aotai ensures that its products remain competitive and meet the evolving needs of its customers.

Founded in 2001, the company was established through a collaboration between the Times Group, Tsinghua Ziguang, Lenovo Group, Daheng Group, and Sitong Group. This strategic partnership brought together expertise and resources from some of the most influential entities in the technology and manufacturing sectors.

The company specializes in the development, production, and sales of a wide range of welding and cutting equipment. Its product portfolio includes:

The company boasts a robust sales and service network, with over 40 subsidiaries dedicated to sales and after-sales support. This extensive network ensures comprehensive coverage across the entire country, providing customers with reliable and accessible service.

Moreover, the company’s products have a significant international presence, being exported to over 40 countries worldwide. This global reach underscores the company’s commitment to quality and innovation, as well as its ability to meet the diverse needs of customers around the world.

Shanghai Hugong, established in 1958, stands as a prominent research and development (R&D) and manufacturing hub for welding and cutting equipment in China. As a publicly-listed entity on the Shanghai Stock Exchange, it has carved out a significant presence in the welding equipment industry. The company’s product portfolio is diverse, encompassing arc welding equipment, CNC cutting equipment, robotic systems, and laser cutting equipment.

Shanghai Hugong operates under two primary brands: HG and HG Star. Its comprehensive sales and after-sales service network spans the entire country, ensuring robust domestic coverage. Additionally, the company’s products enjoy a global footprint, being exported to numerous countries and regions around the world.

Founded in Sweden in 1904, Esab has established itself as a world-renowned manufacturer of welding and cutting equipment and materials. The company is credited with the invention of the covered electrode, a significant advancement in welding technology that has contributed to its strong reputation in the industry. Esab is celebrated for its professional technology and exceptional customer service.

With over a century of continuous research, development, and production, Esab has made a profound impact on the welding industry. The company’s unwavering commitment to innovation and adherence to strict quality standards have driven its success and industry leadership. Today, Esab’s business operations extend globally, with sales and support teams established in over 80 countries worldwide, ensuring comprehensive service and support for its diverse customer base.

Founded: United States, 1929

Parent Company: ITW Welding Business Group

Miller, established in 1929 in the United States, is a distinguished subsidiary of the ITW Welding Business Group, a globally recognized leader in the manufacturing of welding products. Over the decades, Miller has built a strong reputation for its innovative and reliable welding solutions.

Miller specializes in a comprehensive range of welding equipment and systems, including:

In addition to its product offerings, Miller provides a suite of engineering services to support its customers:

Miller’s electric welding machines are highly regarded in the industrial manufacturing and production sectors. Their product lineup includes:

Founded in 1998, the company is a core subsidiary of the Shanghai General Heavy Industry Group. As a high-tech enterprise, it specializes in the research and development (R&D), manufacturing, sales, and service of electric welding machines. Over the years, the company has established itself as a leader in the welding equipment industry, leveraging advanced technology and innovation to meet the diverse needs of its customers.

The company’s product portfolio is extensive and designed to cater to various welding requirements. The key products include:

In addition to its robust product lineup, the company provides a range of comprehensive services to support its customers:

Welding machines come in various types, each catering to specific welding processes and materials. Understanding the different types of welding machines and their uses is crucial for selecting the right equipment for a particular job. In this section, we will discuss some of the most common types of welding machines, including MIG welders, ARC welders, stick welders, TIG welders, engine-driven welders, and more.

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), uses a continuous wire as an electrode and an inert shielding gas to protect the workpiece from contamination. MIG welders are popular for their ease of use, versatility, and high productivity, making them suitable for a wide range of applications, from automotive repair to heavy metal fabrication.

Also known as stick welders, ARC (Arc Welding) machines employ a consumable electrode coated in flux to create an electric arc between the electrode and the workpiece. Stick welding, or Shielded Metal Arc Welding (SMAW), is a popular choice for many DIY enthusiasts, as well as professional welders, due to its simplicity, low-cost equipment, and adaptability to various materials and job sites.

TIG (Tungsten Inert Gas) welding, or Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode and inert shielding gas, typically argon, to create the weld. TIG welding is known for its precision and clean results, making it ideal for applications such as aerospace, automotive, and high-quality metal fabrication.

These welders are powered by an internal combustion engine, making them ideal for field and remote applications where electricity is not readily available. Engine-driven welders can be found in various configurations, including MIG, TIG, stick, and multi-process systems.

Wire feeders are essential components of many welding machines, particularly MIG and flux-cored welders, as they are responsible for continuously and consistently feeding the wire electrode during the welding process.

As the name suggests, multi-process welding equipment is designed to handle multiple welding processes, such as MIG, TIG, and stick welding. These versatile machines are popular with professional welders and production facilities as they offer flexibility and efficiency in various applications.

Advanced process welding machines, such as the Power Wave® series, incorporate cutting-edge technology to provide greater control, precision, and consistency in welding, especially for high-performance or specialized applications.

These systems are designed to accommodate multiple welders working simultaneously, which can improve productivity and efficiency in large-scale welding operations.

Used in the Submerged Arc Welding (SAW) process, submerged arc devices utilize a granular flux, which covers the weld area and protects it from atmospheric contamination.

Spot welders use electrical current to fuse overlapping metal sheets or components together, typically used in the automotive and sheet metal industries.

Inverter-based welding equipment converts input power to a high frequency, which allows for a more compact and lightweight welding machine. These welders are generally more energy-efficient and offer greater control over the welding process.

In summary, various manufacturers cater to the needs of beginners and hobbyists in the welding industry, offering machines tailored for ease of use and affordability. Aspiring welders and enthusiasts have a plethora of options to choose from when seeking the ideal machine for their needs.

If you have any questions regarding the ranking mentioned above, feel free to leave a message in the comments section.