Have you ever wondered how modern technology achieves such precise and clean welds? In this article, we’ll explore the fascinating world of laser welding machines. You’ll learn how they work, their types, and their incredible applications in various industries. Get ready to uncover the secrets behind these powerful tools!

A laser welding machine is a device that uses high-energy pulse laser to irradiate the workpiece to achieve the purpose of welding. It can accurately weld the workpiece by adjusting the energy of the pulse laser using different laser frequencies and pulse widths.

The laser welding machine is also often referred to as the energy negative feedback laser welding machine, laser cold welding machine, laser argon welding machine, laser welding equipment, and more.

Based on its working mode, it can be classified into various types, such as laser mold welding machine (manual laser welding equipment), automatic laser welding machine, jewelry laser welding machine, laser spot welding machine, optical fiber transmission laser welding machine, galvanometer welding machine, handheld welding machine, and more.

Special laser welding equipment includes a sensor welding machine, silicon steel sheet laser welding equipment, and keyboard laser welding equipment.

Weldable graphics include points, straight lines, circles, squares, or any plane graphics drawn using AutoCAD software.

A laser welding machine is a device that utilizes the characteristics of the laser to accomplish workpiece welding.

Laser welding involves radiating a high-intensity laser beam onto the metal surface. Through the interaction between the laser and the metal, the metal absorbs the laser and converts it into heat energy. This causes the metal to melt and subsequently cool and crystallize, thus resulting in a welded joint.

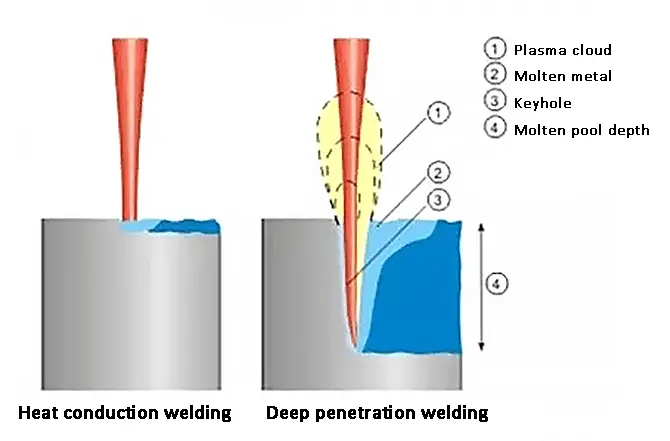

1. Heat conduction welding

When the laser irradiates the material surface, a portion of the laser is reflected, and the remainder is absorbed by the material, causing the light energy to be converted into heat energy, resulting in heating and melting of the material.

The heat from the material surface layer continues to transfer to the depth of the material in the form of heat conduction, ultimately welding the two weldments together.

2. Laser deep penetration welding

When a laser beam with high power density irradiates the material surface, the material absorbs light energy, which is then converted into heat energy.

The material is heated, melted, and vaporized, resulting in the production of a considerable amount of metal steam. As the steam exits the surface, it generates a reaction force that pushes the molten metal liquid around, forming pits.

With continued laser irradiation, the pits penetrate deeper. Once the laser stops irradiation, the molten liquid around the pit flows back, and the two weldments are joined together after cooling and solidification.

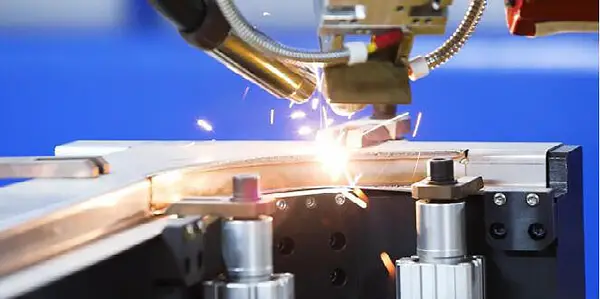

This is a new welding method that is mainly utilized for the welding of thin-walled materials and precision parts, and it can achieve spot welding, butt welding, overlap welding, seal welding, and more.

Laser welding is an efficient and precise welding method that uses a high-energy density laser beam as the heat source. It’s one of the significant applications of laser material processing technology.

In the 1970s, laser welding was mainly used for welding thin-walled materials and low-speed welding. The welding process belongs to the heat conduction type, meaning the laser radiation heats the surface of the workpiece, and the surface heat diffuses internally through heat transfer. By controlling the parameters such as laser pulse width, energy, peak power, and repetition frequency, the workpiece melts and forms a specific molten pool.

Due to its unique advantages, laser welding has been successfully applied to the precision welding of micro and small parts.

A complete laser welding machine mainly comprises five parts.

Part I: laser welding host

The laser welding host mainly produces a laser beam for welding, and it comprises the power supply, laser generator, optical path part, control system, and other components.

In some cases, low-power lasers are typically integrated into the automatic worktable of the laser welding system.

Part II: cooling system

The cooling system provides the cooling function for the laser generator, which is generally equipped with a 1-5 HP water-circulating chiller.

Part III: laser welding automatic worktable or motion system

The laser welding system is utilized to accomplish the automatic welding function by moving the laser beam along the welding track as per specific requirements. There are typically three motion control forms:

The entire system compiles the motion control program using CNC programming to regulate the worktable’s movement as per the requirements. The simplified programming system offers several advantages, such as ease of operation, no need for professional technology or educational foundation, and quick support and understanding.

Common workbench systems on the market include:

Both of them can realize precise welding motion control.

Part IV: tooling fixture

In the process of laser welding, a laser welding fixture is generally employed to secure the welded workpiece and enable it to be repeatedly loaded, unloaded, and positioned. This makes automatic laser welding more manageable.

Thus, the fixture is one of the essential pieces of equipment in laser welding production. Especially during batch production, whether the fixture is adequately designed will directly impact the production efficiency and yield.

Part V: observation system

Generally, the laser welding machine should be equipped with an observation system that can conduct real-time microscopic observation on the workpiece. This observation system is used to facilitate accurate positioning when compiling the welding program and inspecting the welding effect during the welding process.

Common observation systems include a CCD display system or a microscope.

Characteristics of laser welding:

High aspect ratio, small weld width, small heat-affected zone, minimal deformation, fast welding speed, flat and aesthetically pleasing weld, no or minimal treatment required after welding, high weld quality, no pores, accurate control, small focusing light spots, high positioning accuracy, and easy automation realization.

Characteristics of laser welding machine:

The laser welding machine has a high degree of automation and a simple welding process. Its non-contact operation method can meet cleanliness and environmental protection requirements.

Using a laser welding machine to process workpieces can improve work efficiency. The finished workpieces have a beautiful appearance, small welds, large welding depth, and high welding quality. The laser welding machine is widely used in dental denture processing, keyboard welding, silicon steel sheet welding, sensor welding, battery sealing cover welding, and more.

However, the cost of a laser welding machine is high, and the precision of workpiece assembly must also be high. Therefore, there are still limitations in these aspects.

Laser power density

Laser power density is one of the most critical parameters in laser processing.

With high power density, the surface layer can be heated to the boiling point in the microsecond time range, resulting in a significant amount of vaporization. Therefore, high power density is preferable for material removal processing, such as punching, cutting, and engraving.

For low power density, it takes several milliseconds for the surface temperature to reach the boiling point. Before surface vaporization, the bottom layer reaches the melting point, making it easier to form a good melt weld.

Therefore, in conductive laser welding, the power density is in the range of 10^4 ~ 10^6 W/cm2.

Pulse waveform

The pulse waveform is a crucial factor in welding, particularly for sheet welding.

When a high-intensity beam strikes the material surface, some energy on the metal surface is lost due to reflection, and the reflectivity changes with the surface temperature.

The reflectivity of the metal varies significantly during a pulse.

Pulse width

Pulse width is one of the essential parameters in pulse welding.

It differs from material removal and material melting and is also a crucial parameter in determining the cost and volume of processing equipment.

Effect of defocus

Because the power density at the center of the laser spot focus is too high, it’s easy to create holes due to evaporation.

The power density distribution is relatively uniform on each plane away from the laser focus.

There are two defocusing modes: positive defocusing and negative defocusing.

If the focal plane is above the workpiece, it’s positive defocus; otherwise, it’s negative defocus.

According to the geometrical optics theory, when the distance between the positive and negative defocus planes and the welding plane is equal, the power density on the corresponding plane is approximately the same. However, in reality, the shape of the molten pool is different.

When using negative defocusing, greater penetration can be achieved, which is related to the molten pool’s formation process.

Parameter table of laser welding machine

| Diameter | Joint form | Spec. | Joint performance | |||

|---|---|---|---|---|---|---|

| output power/J pulse | Pulse width/ms | Max load/N | Resistance/Ω | |||

| 301 Stainless steel(1Cr17Ni7) |

Φ0.33 | butt-joint | 8 | 3.0 | 97 | 0.003 |

| overlap | 8 | 3.0 | 103 | 0.003 | ||

| cross-shaped | 8 | 3.0 | 113 | 0.003 | ||

| T-shape | 8 | 3.4 | 106 | 0.003 | ||

| Φ0.79 | butt-joint | 10 | 3.4 | 145 | 0.002 | |

| overlap | 10 | 3.4 | 157 | 0.002 | ||

| cross-shaped | 10 | 3.4 | 181 | 0.002 | ||

| T-shape | 11 | 3.6 | 182 | 0.002 | ||

| Φ0.38+Φ0.79 | butt-joint | 10 | 3.4 | 106 | 0.002 | |

| overlap | 10 | 3.4 | 113 | 0.003 | ||

| cross-shaped | 10 | 3.4 | 116 | 0.003 | ||

| T-shape | 11 | 3.6 | 102 | 0.003 | ||

| Φ0.38+Φ0.40 | T-shape | 11 | 3.6 | 89 | 0.001 | |

| Copper | Φ0.38 | butt-joint | 10 | 3.4 | 23 | 0.001 |

| overlap | 10 | 3.4 | 23 | 0.001 | ||

| cross-shaped | 10 | 3.4 | 19 | 0.001 | ||

| T-shape | 11 | 3.6 | 14 | 0.001 | ||

| Nickel | Φ0.51 | butt-joint | 10 | 3.4 | 55 | 0.001 |

| overlap | 7 | 2.8 | 35 | 0.001 | ||

| cross-shaped | 9 | 3.2 | 30 | 0.001 | ||

| T-shape | 11 | 3.6 | 57 | 0.001 | ||

| Tantalum | Φ0.38 | butt-joint | 8 | 3.0 | 52 | 0.001 |

| overlap | 8 | 3.0 | 40 | 0.001 | ||

| cross-shaped | 9 | 3.2 | 42 | 0.001 | ||

| T-shape | 8 | 3.0 | 50 | 0.001 | ||

| Φ0.63 | butt-joint | 11 | 3.5 | 67 | 0.001 | |

| overlap | 11 | 3.5 | 58 | 0.001 | ||

| T-shape | 11 | 3.5 | 77 | 0.001 | ||

| Φ0.65+Φ0.38 | T-shape | 11 | 3.6 | 51 | 0.001 | |

| Copper and tantalum | Φ0.38 | butt-joint | 10 | 3.4 | 17 | 0.001 |

| overlap | 10 | 3.4 | 24 | 0.001 | ||

| cross-shaped | 10 | 3.4 | 18 | 0.001 | ||

| T-shape | 10 | 3.4 | 18 | 0.001 | ||

With the continuous upgrading of laser welding technology, laser welding has undergone a qualitative leap.

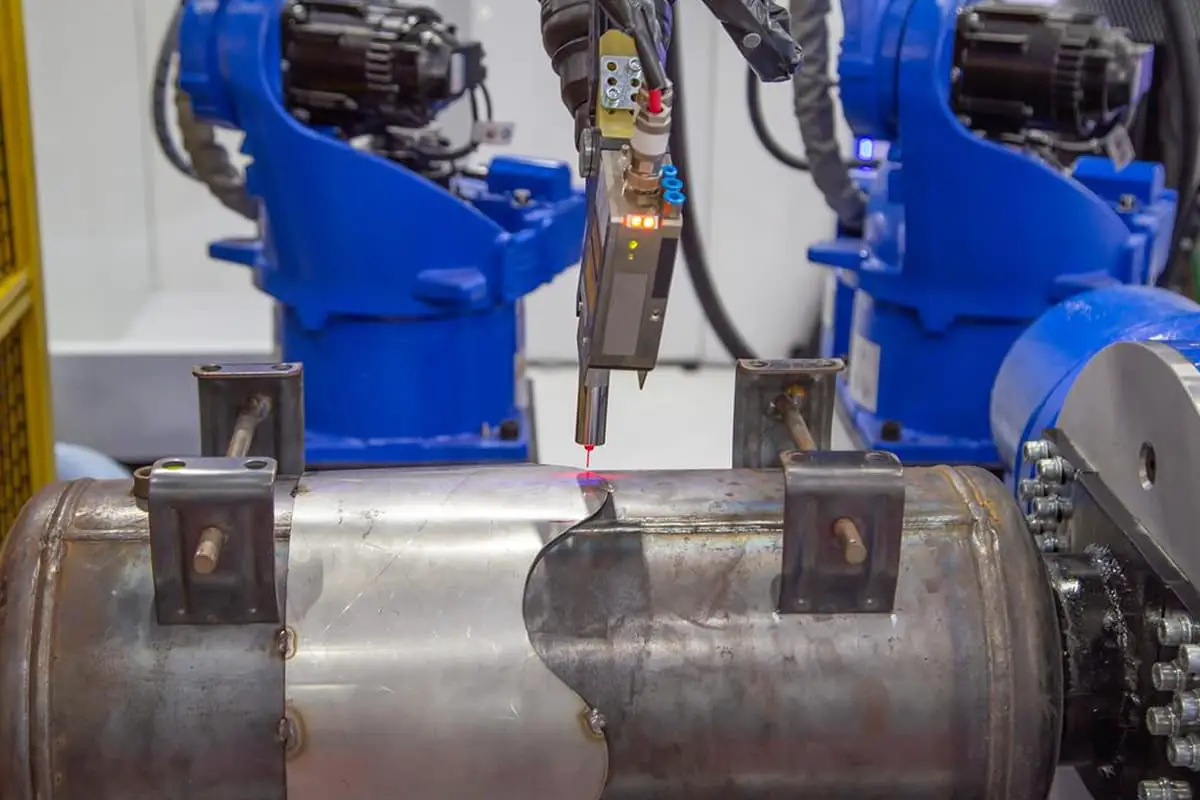

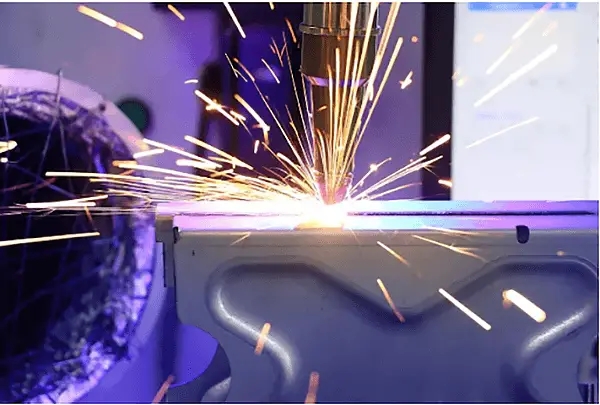

Now, laser welding machines have been utilized in many fields, such as high-tech electronics, automobile manufacturing, precision machining, and more.

As a direction of laser application, laser welding is the combination of current and traditional technology, but it offers different advantages from traditional processing.

1. Good laser beam quality

After laser focusing, the power density becomes high.

The focal spot diameter is small when focusing high-power low-order mode laser.

2. Laser welding has the advantages of high speed, large depth and small deformation

Due to the high power density, small holes are formed in metal materials during laser welding, and the laser energy is transmitted to the deep part of the workpiece through these small holes, with less transverse diffusion.

Therefore, the material fusion depth is significant in the process of laser beam scanning, and the process offers high speed and large welding area per unit time.

3. Laser welding is especially suitable for welding precision sensitive parts

Because the laser welding machine has a large aspect ratio, low specific energy, small heat-affected zone, and minimal welding deformation, it is especially suitable for welding precision and heat-sensitive parts. It can also eliminate the need for post-welding correction and secondary processing.

4. High flexibility of laser welding

Laser welding machines can realize welding at any angle and can weld hard-to-reach parts.

They can also weld various complex workpieces and large workpieces with irregular shapes.

The machines offer great flexibility to achieve welding at any angle.

5. Laser welding can weld difficult materials

Laser welding can be used not only for welding between various dissimilar metal materials but also for welding between titanium, nickel, zinc, copper, aluminum, chromium, niobium, gold, silver, and their alloys, steel, kovar alloy, and other alloy materials.

6. Low labor cost of laser welding machine

Because the heat input of laser welding is very low and the deformation after welding is minimal, a beautiful welding effect can be achieved.

As a result, there is little need for follow-up treatment of laser welding, which can greatly reduce or eliminate the labor-intensive polishing and leveling processes.

7. The laser welding machine is easy to operate

The laser welding machine has the advantages of simple welding equipment, a straightforward operation process, and it is easy to learn and use.

Professional requirements for staff are not high, which can save labor costs.

8. The laser welding machine has strong safety performance

The high-safety welding nozzle can only be triggered when it contacts the metal, and the touch switch has temperature sensing.

There are safety precautions for the special laser generator during operation. It is necessary to wear protective glasses for the laser generator to reduce the risk of eye injury.

9. The working environment of laser welding machines is diverse

The laser welding machine can be used in various complex working environments and can perform welding at room temperature or under special conditions.

For example, laser welding shares many similarities with electron beam welding. Although its welding quality is slightly inferior to electron beam welding, the latter can only be used in a vacuum environment. In contrast, laser welding technology is more advanced and can be used in a wide range of working environments.

10. The welding system is highly flexible and easy to realize automation

However, the laser welding machine also has some limitations. Due to the high cost of laser-related systems, the one-time investment cost will be higher. In addition, the laser welding machine also requires high installation accuracy of weldments, and the position of the light source on commercial workpieces shall not have an obvious deviation.

It can be seen that the ten advantages of laser welding machines are much better than traditional welding methods. In the future, the application of laser welding technology will not be limited to the current electronic, automotive, instrument, and other fields. It will also be more extensive in the military and medical fields, especially in the medical field, which has broad prospects.

Laser welding vs other welding processes

| Comparison items | Laser welding | Electron beam welding | Tungsten inert-gas arc welding | Gas metal arc welding | Resistance welding |

| Welding efficiency | 0 | 0 | – | – | + |

| Large depth ratio | + | + | – | – | – |

| Small heat-affected zone | + | + | – | – | 0 |

| High welding rate | + | + | – | + | – |

| Weld section morphology | + | + | 0 | 0 | 0 |

| Welding under atmospheric pressure | + | – | + | + | + |

| Welding high-reflectivity materials | – | + | + | + | + |

| Use filling material | 0 | – | + | + | – |

| Automatic welding | + | – | + | 0 | + |

| Cost | – | – | + | + | + |

| Operation cost | 0 | 0 | + | + | + |

| Reliability | + | – | + | + | + |

| Assemble | + | – | – | – | – |

Manufacturing

Laser tailor welding technology has been widely used in car manufacturing. According to statistics, there were more than 100 laser tailor welding production lines worldwide in 2000, and the number continues to grow at a high rate.

In Japan, CO2 laser welding is used to replace flash butt welding for the connection of rolled steel coils in the steel industry. In the research of ultra-thin plate welding, such as foil with plate thickness of less than 100 microns, fusion welding cannot be carried out, but YAG laser welding with special output power waveform is successful, which shows the broad future of laser welding.

Japan also successfully developed YAG laser welding for the first time in the world for the maintenance of steam generator tubes in nuclear reactors and carried out gear laser welding technology in China.

Powder metallurgy

With the continuous development of science and technology, many industrial technologies have special requirements for materials that cannot be met by materials manufactured by smelting and casting. Due to the special properties and manufacturing advantages of powder metallurgy materials, they are replacing traditional metallurgical materials in some fields, such as automobile, aircraft, tool and cutting tool manufacturing.

With the increasing development of powder metallurgy materials, the connection between powder metallurgy materials and other parts is becoming more and more prominent, which limits the application of powder metallurgy materials. In the early 1980s, laser welding entered the field of powder metallurgy material processing with its unique advantages, which opened up a new prospect for the application of powder metallurgy materials.

For example, the brazing method commonly used in the connection of powder metallurgy materials could lead to melting and falling off of solder due to low bonding strength and wide heat-affected zone, especially unable to adapt to high temperature and high strength requirements. Laser welding can improve the welding strength and high-temperature resistance.

Automotive industry

In the late 1980s, the kW laser was successfully applied to industrial production. Currently, the laser welding production line has appeared in the automobile manufacturing industry on a large scale and has become one of the outstanding achievements of the automobile manufacturing industry.

As early as the 1980s, European automobile manufacturers took the lead in using laser welding for sheet metal welding, such as roof, body, and side frames. In the 1990s, the United States introduced laser welding into automobile manufacturing, and although it started late, it developed rapidly.

Italy uses laser welding in the welding and assembly of most steel plate components, and Japan uses laser welding and cutting processes in the manufacture of body panels.

High-strength steel laser welding assemblies are increasingly used in the manufacture of automobile bodies due to their excellent performance.

According to the characteristics of large batches and high degrees of automation in the automobile industry, laser welding equipment is developing in the direction of high power and multi-channel.

In terms of the process, Sandia National Laboratory of the United States and Pratt Witney jointly conducted research on adding powder metal and wire in the process of laser welding, and the Bremen Institute of Applied Beam Technology in Germany conducted extensive research on laser welding aluminum alloy body frames.

It is considered that adding filler in the weld is helpful in eliminating thermal cracks and improving welding speed. The developed production line has been put into production in the factory to solve the tolerance problem.

Electronics industry

Laser welding has been widely used in the electronics industry, especially in the microelectronics industry.

Due to its small heat-affected zone, rapid heating concentration, and low thermal stress, laser welding shows unique advantages in the packaging of integrated circuits and semiconductor device shells.

In the development of vacuum devices, laser welding has also been applied, such as molybdenum focusing electrodes and stainless steel support rings, fast heating cathode filament assembly, and more.

The thickness of the elastic thin-wall corrugated sheet in the sensor or temperature controller is 0.05-0.1mm, which is difficult to weld using traditional welding methods.

TIG welding is prone to penetration, plasma stability is poor, and there are many influencing factors. However, laser welding has a good effect and is widely used in this field.

Biomedical science

Laser welding of biological tissues began in the 1970s.

The successful welding of fallopian tubes and blood vessels with lasers, and their advantages, have encouraged more researchers to try to weld various biological tissues and expand it to the welding of other tissues.

Research on laser welding nerves, both domestically and abroad, mainly focuses on laser wavelength, dosage, functional recovery, and the selection of laser solder.

Compared with the traditional suture method, laser welding has the advantages of faster anastomosis speed, no foreign body reaction in the healing process, maintaining the mechanical properties of the welding site, and allowing the repaired tissue to grow according to its original biomechanical properties.

It will be more widely used in biomedicine in the future.

Other areas

In other industries, laser welding is also gradually increasing, especially in the welding of special materials.

Many studies have been carried out in China, such as laser welding of BT20 titanium alloy, HEL30 alloy, and Li-ion battery. Germany has developed a new laser welding technology for flat glass.

Before the 1970s, high-power CW lasers had not been developed, so research focused on pulsed laser welding (PW). Most early laser welding experiments used Ruby pulse lasers with a typical peak output power PM of 5kW for a 1ms pulse, pulse energy of 1-5J, and a pulse frequency of less than or equal to 1Hz.

At that time, although the pulse energy was high, the average output power of these lasers was quite low due to the low working efficiency of the lasers and the properties of the luminous substances. The laser soon became the preferred equipment for spot welding and seam welding due to its high average power.

The welding process was carried out through welding spot lapping, and laser seam welding with real significance was not realized until the development of continuous power waveform lasers with more than 1kW.

With the increasing maturity of digital technology, digital welding machines and digital control technology, such as dynamic grounding technology, have steadily entered the market. National large-scale basic engineering has effectively promoted the development and progress of advanced welding, especially welding automation technology.

The manufacturing of automobiles and parts requires the automation of welding with each passing day. Since the end of the 20th century, the country has gradually promoted the basic welding method of automatic welding – gas-shielded welding – to replace the traditional manual arc welding, which has achieved initial results. It can be predicted that in the future, automatic welding technology will develop at an unprecedented speed.

In the 1990s, the welding industry made the realization of the mechanization and automation of the welding process its strategic goal, which has been implemented in the scientific and technological development of various industries.

It is developing welding production automation, researching and developing welding production lines and flexible manufacturing technology, and developing computer-aided design and manufacturing.

Flux-cored wire has increased from 2% to 20%, and submerged arc welding materials will also continue to grow at the level of 10%.

Among them, the growth rate of flux-cored wire is significantly higher and is expected to exceed that of solid-cored wire in the next 20 years, eventually becoming the leading product of the welding industry.

The development of electronic technology, computer microelectronics, and automation technology promotes the development of welding automation technology.

In particular, the introduction of unit technology such as numerical control technology, flexible manufacturing technology, and information processing technology has promoted the revolutionary development of welding automation technology.

(1) The intellectualization of welding process control systems is one of the core challenges in welding automation and an important area for future research. We need to investigate optimal control methods, including linear and various nonlinear controls. The most representative methods include fuzzy control, neural network control, and expert systems for the welding process.

(2) Welding flexibility technology involves the organic combination of various optical, mechanical, and electrical technologies with welding technology to achieve precise and flexible welding. To improve the level of welding automation, we need to transform traditional welding process equipment with microelectronic technology. Our current research focus is on combining numerical control technology with all kinds of welding machinery and equipment to improve their flexibility. In addition, our research also focuses on combining welding robots and expert systems to achieve automatic path planning, automatic trajectory correction, and automatic penetration control.

(3) The integration of welding control systems involves the integration of humans and technology, welding technology and information technology, and material flow and information flow. By promoting their organic combination, we can greatly reduce the amount of information and real-time control requirements. We need to pay attention to giving full play to people’s response and judgment ability in control and on-the-spot processing, establishing a friendly man-machine interface, and making people and the automatic system harmonious and unified. These factors are crucial in the integrated system.

(4) Our research also focuses on improving the reliability, quality stability, and control of welding power supplies, as well as developing excellent dynamic performance. We aim to develop a high-performance welder that can adjust arc motion, wire feeding, and torch attitude, detect weld slope beginning, temperature field, molten pool state, and penetration, and provide timely welding specification parameters. We also actively develop computer simulation technology for the welding process to help the welding technology evolve from “technology” to “science”, which is an important aspect of welding automation.

Laser welding machine saves time and energy

In any line of work, it’s essential to invent corresponding tools to improve the process flow, save time and energy, and better meet one’s requirements. With the continuous development of technology, there have been great breakthroughs in these aspects, and automatic operation can now be implemented in various industries.

In factories, automation can significantly enhance production and supply efficiency, reduce costs, and increase operation benefits. In welding, it’s crucial to choose appropriate tools to improve operational speed, and the laser welding machine is an excellent choice.

Laser welding can achieve a better production effect

Why can laser welding machines achieve better work efficiency for users?

As a new energy, laser technology provides a stronger working state and enables effective treatment of various materials. Furthermore, new welding methods are used to ensure excellent welding results and to complete operations quickly.

In the future market, people’s living and working speed will continue to accelerate. To achieve better production results and meet the needs of more users, every factory must continuously improve its technology, make breakthroughs, and address any defects and deficiencies to enhance overall performance.

Only by consistently advancing in this direction can products gain a competitive edge, deliver better user experiences, and facilitate effective collaboration between both sides.

Laser welding machine brings more convenience to manufacturers

In my opinion, selecting a laser welding machine in the welding process is a wise choice for manufacturers, as it can enhance work efficiency and provide more convenience.

In the process of operation, each factory can complete its tasks within a specific timeframe, thus improving its overall operational efficiency. It’s also essential to carry out effective welding of large tools and improve the process flow.

Failing to ensure this crucial aspect may waste time and energy during the welding process of significant equipment, which no user wants to experience.

With the continuous maturity and development of laser welding technology, different configurations of laser welding machine equipment also correspond to different effects. However, among many businesses, is it right to choose the more expensive and better laser welding machine equipment? The answer is, of course, no.

So how to choose the most appropriate laser welding machine equipment? Only when we understand it clearly can we know what benefits it brings to us. Let’s talk about the importance of selecting the appropriate laser welding machine now!

Before customers choose laser welding machine equipment, our idea is that the selected equipment can meet our needs, realize our processing effect, and bring benefits to us. Such equipment is what we want.

However, for laser welding machine manufacturers, the price positioning of laser equipment is high-end and low-end. In terms of processing effect, high-end equipment can make the processing effect more complete, and the styles are also various, such as processing multi-materials, metal, and non-metal. The processing effect is also very good, but such equipment is also valuable.

Is it best to choose high-end laser welding machine equipment? Of course not. If your material is aimed at non-metallic materials, there are no metal materials, and the processing effect is not as great as that, it is recommended to choose the general one. Because the more functions, the better the effect of the equipment, the more products processed, and the more expensive the machinery and equipment. In addition, if you don’t use all of its functions when you buy it, you’ll spend money on furnishings, so it’s not worth it.

Only understand what you want to do with this machine and equipment, do the same or several products, and then make choices according to your own needs. Therefore, when choosing laser welding machine equipment, only the right one is the best. The so-called suitability means that the products of merchants can be processed, and the industries with the most applications can meet your requirements. The benefits it brings can meet your requirements. Such equipment is worth more and corresponds to its suitability.

Without saying anything about this problem, it is certain that a high-efficiency and high-quality laser welding machine is definitely worth buying! However, with tens of thousands to hundreds of thousands of laser welding machines on the market, a good laser welding machine can double your work success. So, what should we consider when determining whether the laser welder is worth it?

1. Power

The first consideration is power.

The laser is the core of the laser equipment, and the higher the power, the higher the price. This is because higher power requirements are placed on the laser rod and cooling system.

2. Configuration

The configuration of a laser welding machine involves many aspects. Laser welding machines for different purposes have different configurations, such as mold welding for welding molds, jewelry welding for welding jewelry, vibration mirror welding inside an automatic welding machine, optical fiber transmission laser welding machine, optical fiber continuous laser welding machine, and so on. The equipment configuration is different, and the price also varies.

In addition, automatic welding machines are generally more expensive than manual welding machines because the automatic control system requires supporting automatic configuration such as a CCD camera monitoring system.

3. Requirements for customization

There are also some customized needs, so the price will be higher.

For example, some production processes may require customized automatic fixtures, modified workbenches, or additional functional accessories.

4. Working methods

The laser welding machine must be equipped with a worktable, such as a galvanometer working mode, automatic working mode, spot welding working mode, and handheld working mode.

The worktable belongs to non-standard products and needs to be designed according to customer’s products, so the price is not fixed.

5. Accessories

Imports are usually more expensive than domestically produced products, and domestic prices can vary greatly.

It can be said that the price of accessories can vary greatly.

6. Brand

The brand will also affect the quotation.

The brand is also an aspect that cannot be ignored.

Laser welding machines often cost hundreds of thousands, and have a high technical content and high level of after-sales service, so they must be purchased from formal channels.

It is recommended to find manufacturers for direct sales. A reputable brand’s technology is more mature, the product quality is good, the performance is stable, and the after-sales guarantee is perfect.

Currently, laser welding equipment has been widely used in various industries, including digital products, energy batteries, hardware and plastics, kitchen and bathroom, machinery manufacturing, precision electronics, and craft jewelry.

Although the brands of laser welding machines may vary, their structures are generally similar. So what are the differences among different types of laser welding equipment?

Reasons for the price difference of laser welding machine brands:

1. Manufacturing cost

There are many brands of laser welding machines, each with its own advantages, but their structures are similar.

A laser welding machine is composed of a laser generator, a welding gun head, a control motherboard, an operating system, electrical circuit components, sheet metal shell, and other components.

A piece of good equipment must choose better components, and the equipment composed of good components will be more stable and have higher performance.

The pursuit of a low price will compromise on the quality of the components, reduce the cost, and the corresponding price will be reduced.

2. Technical level

There are many manufacturers of laser welding machines, and the technical level varies.

The technical strength of a manufacturer can be seen from the product composition, commissioning, and after-sales maintenance of the equipment.

The corresponding cost of manufacturers with certain technicians will also increase.

The equipment price of such manufacturers will not be too low, and some manufacturers without core technology will promote the market at a low price.

The principle of “you get what you pay for” is very practical here.

3. After-sales service

Proofread version:

Equipment transactions can involve after-sales problems.

For a laser welding machine, long-term use is bound to have some problems.

How long the production will be delayed if there is a problem with the equipment is a great test of the manufacturer’s after-sales ability.

Excellent after-sales personnel will not only help customers produce better results but also increase the cost of manufacturers.

For manufacturers without after-sales service, this service is less, and the corresponding price will be cheaper.

The development level of the manufacturing industry is one of the factors that reflect a country’s comprehensive strength and can also reflect the range of national economic growth from the side. With the continuous growth of the economy, people’s consumption concepts have also changed, and the demand for product quality and functionality is higher than ever. This requires laser welding equipment manufacturers to constantly improve the manufacturing process, improve the quality, and increase production efficiency to meet market demand and gain recognition from users.

At present, there is an increasing demand for laser welding machine equipment in manufacturing enterprises. This is because laser technology is used for welding processing, offering advantages such as fast welding speed, firm and beautiful welds, no need for secondary grinding treatment, simple operation, automatic batch production and processing, thus greatly improving the work efficiency of product processing and reducing employment costs for enterprises.

Therefore, there is a huge market demand for laser welding machine equipment, and there are many laser welding manufacturers on the market. The quality level of various laser welding equipment is uneven, and the prices range from tens of thousands of yuan to hundreds of thousands of units. Facing many laser equipment manufacturers, many users do not know how to choose.

Let me briefly introduce some factors that need to be referred to when purchasing laser welding equipment.

1. First of all, it is necessary to know whether their own welding needs match the welding function of the manufacturer’s equipment

Such as welding thickness, penetration requirements, etc.

2. The quality of the laser welding machine must be considered

After all, tens of thousands of yuan for a device is not a small amount. It’s best to go to the site for sample welding and understand whether the functional requirements of the device are appropriate before making a purchase.

3. Equipment selection of large brand manufacturers and small brand manufacturers

Some customers believe that the quality of laser welding machines produced by big brand manufacturers must be better than that of small companies. However, in reality, there is no certain standard for this.

Users buy equipment to create value and make profits, and the equipment price of large companies is obviously much higher, which leads to an increase in cost. On the other hand, the equipment of non-large brand companies generally has great discounts in price, the quality is not necessarily worse than that of brand companies, and the cost performance is high, which is also worth considering.

The after-sales service quality of laser welding machine manufacturers is a matter of great concern to many consumers. After purchasing the welding equipment, the manufacturer’s technicians are also required to go to the site for debugging, layout and choosing configuration according to the actual production situation. If there is any problem with subsequent equipment or parts that need to be replaced, the manufacturer should be contacted in time for treatment.

With the rapid development of laser technology, there are many brands of laser welding equipment on the market, but the quality of the products is uneven. This can make it difficult for buyers to know where to start when selecting equipment. How can we choose the most suitable laser welding equipment?

When selecting laser welding machine equipment, we can choose from the following aspects:

1. First determine whether the product is suitable for welding with laser welding technology

When selecting laser welding equipment, we must first determine whether our products are suitable for welding with laser welding equipment. We analyzed the situation of more than 200 customers in the past and found that there are two main types of products that are not suitable for laser welding: the weld is too large (generally more than 0.5mm) and the thickness is too thick (generally more than 5mm).

The most suitable workpiece for laser welding is a thin plate workpiece with good consistency (the thickness is generally less than 3mm), and the weld width does not exceed 10% of the plate thickness. The double swing welding joint is required for the weld slightly exceeding the thickness, but the swing spot will cause laser energy dispersion and affect cutting efficiency.

For workpieces with welds that are too large, we do not recommend customers to use laser welding. Similarly, thick plate laser welding is not recommended for customers at this stage because of high equipment costs and complex adjustment processes.

For example, if the depth of product welding is between 2.5mm-3mm, and the depth of laser welding machine welding exceeds 3mm, it is certainly not suitable. At present, most laser welding equipment manufacturers will provide free proofing services. Before purchasing, customers must let the other party proof the effect to determine whether the use of laser welding equipment can meet their requirements.

Manual welding or automatic welding?

Laser welding is a precision welding technique, which has two main aspects: achieving good welding effects on precision products and having high requirements for the welds of welded products.

If the weld has more than 15 wires, the welding wire must be filled, and only manual welding machines can be used. Conversely, if the weld has less than 15 wires, automation can be achieved. The best scenario is no gap because laser welding is realized by self-melting the sample.

For workpieces with various types, each batch is small, it is too complicated to make tooling, or the workpieces are difficult to locate and weld, and spot welding is most common. In these cases, handheld laser welding can be considered.

Handheld laser welding machines have been very popular in the past two years, but in fact, they are useless and ineffective. Most customers have been deceived by unscrupulous businessmen. Manual laser welding is difficult to control the position of the light spot and focus, and even slight deviations can affect the welding effect. Moreover, the welding consistency of this method is poor, and it is difficult for manual operators to weld continuously for a long time. In addition, the risks associated with manual laser welding are relatively high, and accidents can cause significant harm. Customers must be cautious when choosing handheld laser welding and should not be swayed by welding videos.

Next, let’s talk about automatic laser welding. If the customer’s welding track is complex, has many curve tracks, special-shaped tracks, or several surfaces that need to be welded simultaneously, we recommend using handheld laser welding machines. They are highly flexible and can be clamped in turn, achieve fully automatic welding, and realize multi-machine cooperative welding by cooperating with special tooling and linkage workbench.

If the customer’s workpiece is simple, has many long and straight seams, or requires intersecting line welding of standard pipe fittings, we recommend modular laser welding machines.

2. Select the power of the laser welding machine according to their own product attributes

The laser generator is the core component of laser equipment, and generally, the higher the power, the higher the price. This is because the hardware configuration requires higher power for laser rods and cooling systems. Generally, the greater the welding depth and thickness, the greater the power of the laser welding machine needed.

For a welding depth of 0.5mm, a 200W laser welding machine is suitable. It should be noted that 200W is sufficient for penetration welding and spot welding. For continuous welding, it is better to use a slightly higher laser power as the 200W laser welder can only weld 0.8mm at the deepest. For continuous welding with a welding depth of about 0.5mm, it is better to choose a 250W or 300W laser welding machine. The deeper the welding depth, the greater the power required for the corresponding laser welder.

3. Select the corresponding hardware configuration and the main purpose

The hardware configuration of laser welding equipment involves many fields, and the hardware configuration of laser welding equipment for different purposes varies.

For example, the hardware configuration and price of optical fiber laser welding equipment, welding sheet metal boxes, fillet welding, and overlap welding of stainless steel and carbon steel are different.

The choice of laser power, core diameter, welding joint proportion, manipulator spread, ground rail length, welding process, etc. is determined by factors such as penetration depth, penetration width, tensile force or air tightness requirements, welding length, and weld shape.

4. Make reasonable selections according to cost budget and purpose

Some people choose foreign brands despite the higher price, but in fact, domestic laser welding machine equipment has more advantages. Domestic technology is constantly improving and has already reached international standards. In case of after-sales problems, domestic machines may offer more guaranteed and convenient solutions. Choosing between domestic and foreign brands should depend on your own cost budget and purpose.

After considering the four key factors mentioned above, you should have a better idea of how to choose a laser welding machine that suits your practical demands.