Types of Casting Processes

Casting is a fundamental manufacturing process in which a liquid material is poured into a mold with a hollow cavity of the desired shape and then allowed to solidify. The solidified part is known as a casting, which is ejected or broken out of the mold to complete the process.

There are several types of casting processes, each with its unique characteristics, advantages, and disadvantages. These can be broadly categorized into two main groups: Sand Mold Casting and Special Casting.

1. Sand Mold Casting

Sand mold casting is one of the most common and versatile casting methods. It involves creating a mold from sand and pouring molten metal into the cavity. There are three primary types of sand mold casting:

1.1 Wet Sand Casting

- Definition: Uses sand mixed with water and clay to form the mold.

- Characteristics: The mold is moist when the metal is poured.

- Advantages: Cost-effective, suitable for large castings, and reusable sand.

- Disadvantages: Limited precision and surface finish, potential for moisture-related defects.

1.2 Dry Sand Casting

- Definition: Uses sand that is dried before pouring the molten metal.

- Characteristics: The mold is baked to remove moisture.

- Advantages: Better dimensional accuracy and surface finish than wet sand casting.

- Disadvantages: Higher cost due to the drying process, longer production time.

1.3 Chemical Hardening Sand Casting

- Definition: Uses chemically bonded sand to form the mold.

- Characteristics: The sand is mixed with chemical binders that harden the mold.

- Advantages: High strength molds, excellent dimensional accuracy, and surface finish.

- Disadvantages: More expensive than traditional sand casting, complex handling of chemicals.

2. Special Casting

Special casting processes use different materials and techniques to create molds and castings. These can be divided into two main categories based on the modeling material:

2.1 Natural Mineral Sand-Based Casting

- Investment Casting: Uses a wax pattern coated with refractory material to form a mold. High precision and excellent surface finish but expensive and time-consuming.

- Clay Casting: Uses clay as the primary mold material. Suitable for artistic and decorative items but limited to small-scale production.

- Shell Casting: Involves creating a thin shell of sand and resin around a pattern. Offers good surface finish and dimensional accuracy but is limited to smaller parts.

- Negative Pressure Casting: Uses a vacuum to draw molten metal into the mold. Provides excellent detail and reduces porosity but requires specialized equipment.

- Full Mold Casting: Uses a foam pattern that vaporizes when molten metal is poured. Simple and cost-effective but can produce gas-related defects.

- Ceramic Mold Casting: Uses ceramic materials to create the mold. Suitable for high-temperature alloys and provides excellent surface finish but is expensive.

2.2 Metal-Based Casting

- Metal Mold Casting: Involves using metal molds, also known as dies, to create castings. High precision and surface finish but limited to high-volume production due to mold cost.

- Pressure Casting (Die Casting): Molten metal is forced into a mold under high pressure. Excellent dimensional accuracy and surface finish but limited to non-ferrous metals.

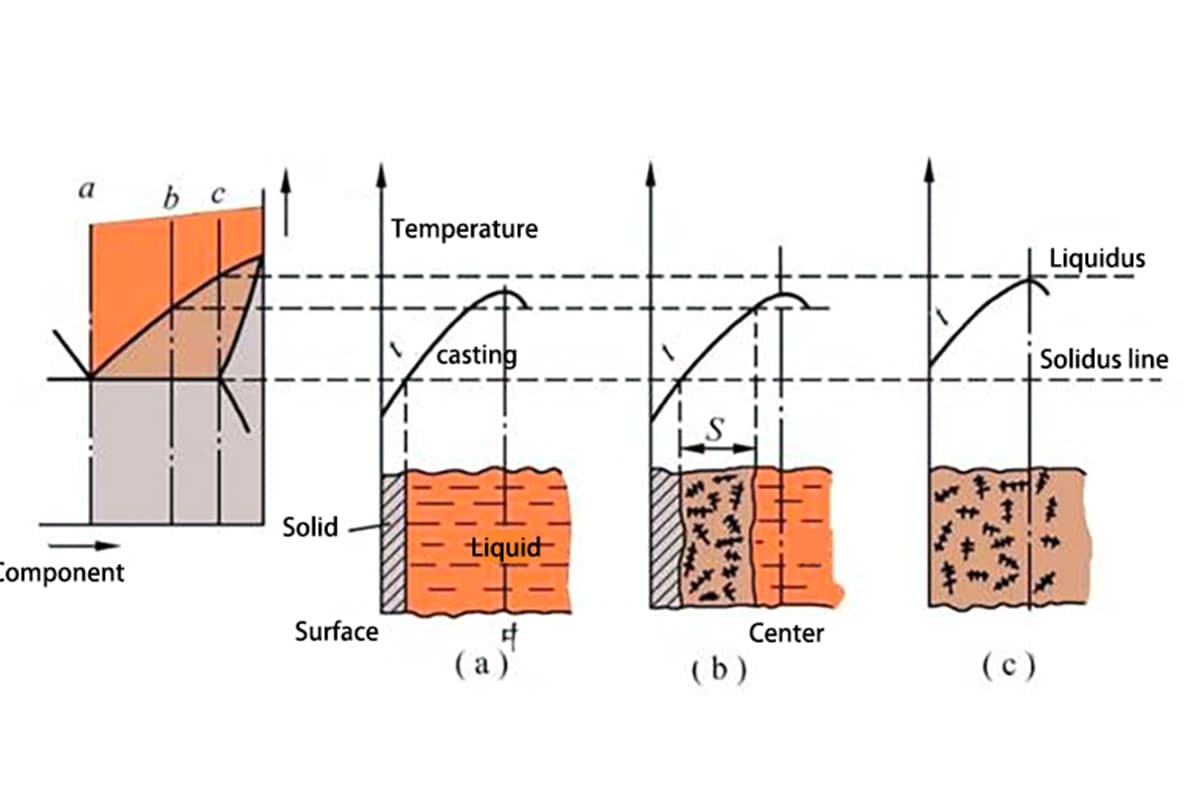

- Continuous Casting: Molten metal is continuously poured into a mold and solidified. Suitable for producing long lengths of material but limited to specific shapes.

- Low-Pressure Casting: Uses low pressure to fill the mold with molten metal. Reduces turbulence and improves quality but requires specialized equipment.

- Centrifugal Casting: Uses centrifugal force to distribute molten metal in the mold. Ideal for cylindrical parts and provides high material density but is limited to specific geometries.

Understanding the various casting processes is crucial for selecting the appropriate method for a specific application. Each process has its unique set of characteristics, advantages, and disadvantages, making them suitable for different types of products and production scales. By exploring these processes in detail, you can make informed decisions to optimize manufacturing efficiency and product quality.

Different Types of Casting Explained

1. Sand Casting

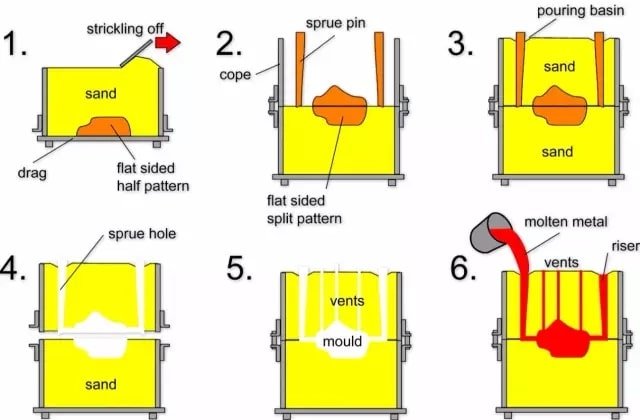

What is Sand Casting?

Sand casting is a versatile and widely used method of producing metal castings by creating a mold from a sand mixture. This process is capable of producing castings from a variety of metals, including steel, iron, and most nonferrous alloys. It is particularly valued for its ability to create complex shapes and intricate inner cavities.

Technological Process

The sand casting process involves several key steps:

- Pattern Making: A pattern, typically made of wood, metal, or plastic, is created in the shape of the desired part.

- Mold Making: The pattern is placed in a container and packed with sand to form a mold. The sand is mixed with a binder to help it retain its shape.

- Core Making: If the casting requires internal cavities, cores made from sand are placed inside the mold.

- Mold Assembly: The mold halves are assembled, and any necessary cores are positioned inside.

- Pouring: Molten metal is poured into the mold cavity through a gating system.

- Cooling: The metal is allowed to cool and solidify within the mold.

- Shakeout: The sand mold is broken apart, and the casting is removed.

- Cleaning: The casting is cleaned to remove any remaining sand, scale, or excess metal.

- Inspection: The casting is inspected for defects and dimensional accuracy.

Sand casting process

Technical Characteristics

Sand casting offers several notable characteristics:

- Complex Shapes: It is well-suited for producing parts with complex geometries and intricate inner cavities.

- Adaptability: Sand casting can be used with a wide range of metals and alloys, making it highly adaptable.

- Cost-Effective: The process is relatively inexpensive, especially for small production runs or custom parts.

- Material Flexibility: It is the only viable process for producing parts or blanks from materials with poor plasticity, such as cast iron.

Applications

Sand casting is widely used in various industries due to its versatility and cost-effectiveness. Common applications include:

- Automotive Industry: Engine blocks, cylinder heads, and crankshafts.

- Aerospace Industry: Structural components and housings.

- Machinery: Gearboxes, pump housings, and valve bodies.

- Construction: Architectural components and fittings.

In summary, sand casting is a highly adaptable and cost-effective method for producing metal castings with complex shapes and intricate details. Its ability to work with a wide range of materials makes it an essential process in many industrial applications.

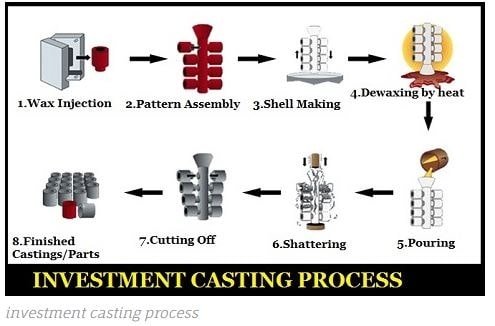

2. Investment Casting

What is Investment Casting?

Investment casting, also known as lost-wax casting, is a precision casting process that involves creating a pattern from a fusible material, typically wax. This pattern is then encased in multiple layers of refractory materials to form a mold. Once the mold is created, the pattern is melted out, leaving a cavity that is free of parting surfaces. The mold is then baked at high temperatures to remove any remaining wax and to strengthen the mold. Finally, molten metal is poured into the cavity to create the final casting.

Technological Process

The investment casting process involves several key steps:

- Pattern Creation: A wax pattern is made, which is an exact replica of the final product.

- Assembly: The wax patterns are attached to a central wax sprue to form a tree-like assembly.

- Shell Building: The assembly is repeatedly dipped into a ceramic slurry and coated with fine sand to build up a thick, hard shell.

- Dewaxing: The ceramic shell is heated to melt and drain away the wax, leaving a hollow mold.

- Preheating: The mold is further heated to remove any residual wax and to prepare it for metal pouring.

- Casting: Molten metal is poured into the preheated mold.

- Cooling: The mold is allowed to cool and solidify.

- Shell Removal: The ceramic shell is broken away to reveal the cast metal part.

- Finishing: The cast part is cut from the sprue, and any necessary finishing operations, such as grinding or machining, are performed.

Investment Casting Process

Advantages

- High Dimensional Accuracy and Geometric Precision: Investment casting produces parts with tight tolerances and intricate details.

- Excellent Surface Finish: The process yields parts with a high surface roughness, reducing the need for additional finishing.

- Complex Shapes: It can cast complex geometries that would be difficult or impossible to achieve with other casting methods.

- Material Versatility: A wide range of alloys can be cast, including those that are difficult to machine.

Disadvantages

- Complicated Procedures: The process involves multiple steps and requires careful control at each stage.

- High Cost: Due to the complexity and labor-intensive nature of the process, investment casting can be more expensive than other casting methods.

Applications

Investment casting is particularly suitable for producing small parts with complex shapes and high precision requirements. It is widely used in industries such as aerospace, automotive, and medical devices. Common applications include:

- Turbine Engine Blades: These parts require high precision and complex geometries.

- Medical Implants: Investment casting can produce intricate and biocompatible components.

- Jewelry: The process is ideal for creating detailed and delicate designs.

- Automotive Components: High-precision parts such as gears and engine components are often investment cast.

Investment casting remains a vital process in modern manufacturing, providing high-quality, precise components for a variety of applications.

3. Clay Mold Casting

Clay mold casting is a traditional casting process that utilizes clay as the primary material to create molds for producing various castings. This method has historical significance and has been used for centuries, particularly in China, where it is recognized as one of the earliest known casting technologies.

Materials and Process

To ensure the clay mold has a strong cohesive force, the clay is mixed with water and various organic and inorganic materials. These materials include:

- Rice Husk and Rice Awn: These agricultural by-products help in binding the clay and improving its structural integrity.

- Horse Dung: Organic matter like horse dung aids in creating a porous structure within the mold.

- Chaff Ash: This material contributes to the mold’s hardness and durability.

Once mixed, the clay undergoes air-drying or sun-drying processes. This drying phase is crucial as it solidifies the mold, making it hard and durable. The resulting clay mold features air outlet pores, which are essential for venting gases during the casting process.

Mold Characteristics

- Surface Texture: The surface of the clay mold is fine and uniform, which helps in achieving a smooth finish on the cast product.

- Internal Texture: The middle texture of the mold is coarser, providing the necessary strength and rigidity.

- Additional Materials: To enhance the mold’s properties, materials such as sand, tank slag, and broken bricks can be added. These additions help in improving the mold’s thermal resistance and overall durability.

Reusability

One of the notable advantages of clay mold casting is the mold’s reusability. The clay mold can be used multiple times, classifying it as a semi-permanent mold. This characteristic makes it an economical and efficient choice for casting processes.

Historical Significance

Clay mold casting holds a prominent place in the history of manufacturing, particularly in China. It represents the ingenuity and resourcefulness of early metallurgists who developed this method to produce a variety of metal objects.

Applications

While modern casting techniques have evolved, clay mold casting is still appreciated for its simplicity and effectiveness in certain applications. It is particularly useful in small-scale production and in areas where traditional methods are preferred.

Clay mold casting is a testament to the enduring legacy of traditional manufacturing techniques. By utilizing readily available materials and simple processes, it has provided a reliable method for producing castings for centuries. Its historical importance and practical benefits continue to make it a valuable casting method in specific contexts.

4. Shell Mold Casting

Shell Mold Casting is a precision casting process that produces high-quality castings using thin shell molds. This method was invented by Johannes Croning in 1943 and was first utilized in Germany in 1944. Since its inception, the technique has been widely adopted by various industries across the globe due to its efficiency and ability to produce intricate and accurate castings.

Process Overview

The Shell Mold Casting process involves several key steps:

- Preparation of the Pattern: A metal pattern, typically made of iron or steel, is heated to a temperature range of 180-280°C.

- Application of Molding Sand: Heat-hardened molding sand, usually phenolic resin-coated sand, is applied to the heated pattern. This creates a thin shell mold with a thickness typically between 6-12mm.

- Curing the Mold: The mold is further heated to solidify the resin-coated sand, providing the necessary strength and stiffness to the shell.

- Assembly of Mold Shells: The upper and lower mold shells are clamped or glued together using resin, forming a complete mold without the need for a traditional sand box.

- Core Making: Cores, if required, can also be made using the same shell molding process. The blowing method is commonly employed to manufacture thin shell cores.

Advantages of Shell Mold Casting

- Precision and Accuracy: The process allows for the production of castings with fine details and tight tolerances.

- Surface Finish: Castings produced using shell molds typically have a superior surface finish compared to those made with traditional sand casting methods.

- Efficiency: The thin shell molds require less material and energy, making the process more efficient and cost-effective.

- Versatility: Shell Mold Casting can be used for a wide range of metals, including ferrous and non-ferrous alloys.

Applications

Shell Mold Casting is widely used in industries where precision and high-quality surface finishes are critical. Common applications include:

- Automotive Industry: Engine components, transmission parts, and other critical automotive parts.

- Aerospace Industry: Precision components that require high strength and reliability.

- Machine Tool Industry: Complex and detailed parts for various machinery.

Shell Mold Casting is a highly efficient and precise casting method that has been instrumental in advancing manufacturing capabilities across various industries. Its ability to produce high-quality, detailed castings with excellent surface finishes makes it a preferred choice for many applications.

5. Ceramic Mold Casting

Ceramic Mold Casting is a sophisticated casting method that utilizes a ceramic slurry to produce high-quality castings. This technique is particularly valued for its ability to create precise and complex shapes with excellent surface finishes. Let’s delve into the specifics of this casting process.

Composition of Ceramic Slurry

The ceramic slurry used in this casting method is composed of:

- Ethyl Silicate Hydrolysate: Acts as a binder.

- Fine Refractory Sands: These include materials such as fused quartz, zircon, and corundum. These sands are chosen for their pure texture and high thermal stability, which are crucial for maintaining the integrity of the mold under high temperatures.

Catalysts for Gelling

To expedite the gelling process of the ceramic slurry, catalysts such as calcium hydroxide or magnesium oxide are often added. These catalysts help in quickly setting the slurry, making the mold ready for subsequent steps in a shorter time frame.

Process Overview

Due to the similarities in composition and appearance between the refractory materials used and traditional ceramics, this process is often referred to as “ceramic type” casting. Ceramic Mold Casting is an advanced technology that has evolved from traditional sand mold casting, offering enhanced precision and surface quality.

Types of Ceramic Mold Casting

There are two primary methods of ceramic mold casting:

1. Mold Production Using a Sand Box

- Application: The ceramic slurry is applied to a molding board.

- Coating: The sand box is coated with the slurry.

- Pouring: The adjusted slurry is poured into the sand box.

- Bonding and Hardening: The mold is allowed to bond and harden.

- Baking: The mold is then baked at high temperatures to form the final casting mold.

This method is particularly useful for creating detailed and intricate castings.

2. Mold Production Using a Bushing

- Gap Filling: The ceramic slurry is poured into the gap between the bushing and the pattern.

- Bushing Material: The bushing can be made of either sand or metal.

- Efficiency: This method is efficient as it saves a significant amount of ceramic slurry.

This technique is widely used in production due to its material efficiency and cost-effectiveness.

Advantages of Ceramic Mold Casting

- Precision: Allows for the creation of complex and detailed shapes.

- Surface Finish: Produces castings with excellent surface finishes.

- Thermal Stability: The high thermal stability of the refractory materials ensures the mold’s integrity at high temperatures.

- Material Efficiency: The use of bushings can significantly reduce the amount of ceramic slurry required.

Ceramic Mold Casting represents a significant advancement in casting technology, offering numerous benefits over traditional methods. Its ability to produce high-precision, high-quality castings makes it an invaluable process in various industrial applications. By understanding the composition, catalysts, and methods involved, manufacturers can effectively utilize this technology to achieve superior casting results.

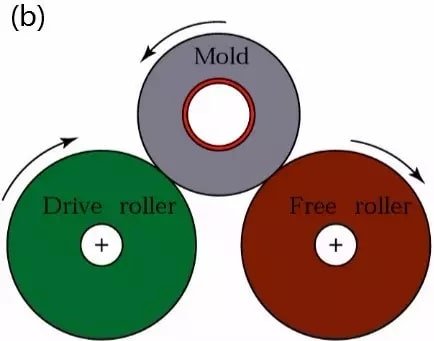

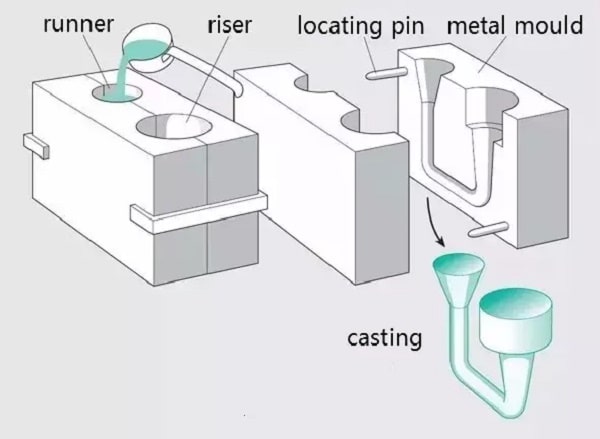

6. Metal Mold Casting

Metal Mold Casting, also known as Hard Mold Casting, is a highly efficient process in which liquid metal is poured into a metal mold to create castings. The mold, typically made from steel or cast iron, can be reused multiple times, often ranging from hundreds to thousands of cycles, making it a cost-effective method for mass production.

Advantages of Metal Mold Casting

- Reusability: The metal molds are durable and can be used repeatedly, reducing the cost per casting over time.

- Precision: Metal molds offer high dimensional accuracy and excellent surface finish, reducing the need for additional machining.

- Production Speed: The process allows for rapid production cycles, which is beneficial for high-volume manufacturing.

Limitations of Metal Mold Casting

Despite its advantages, Metal Mold Casting has certain limitations:

- Material Restrictions: While non-ferrous metals such as aluminum, magnesium, and zinc are commonly used, ferrous metals like cast iron and steel can be more challenging due to their higher melting points and the wear they cause on the molds.

- Complexity of Shapes: The process is best suited for simpler shapes. Complex geometries may require more intricate mold designs, which can be costly and time-consuming to produce.

- Weight Constraints: The weight of the castings is generally limited. Heavier castings can cause excessive wear on the molds and may require special handling and cooling techniques.

- Wall Thickness: There are limitations on the minimum wall thickness that can be achieved. Thinner walls can be difficult to cast uniformly, leading to potential defects and structural weaknesses.

- Initial Cost: The initial cost of creating metal molds is relatively high compared to other casting methods, such as sand casting. This makes it less suitable for low-volume production runs.

Applications

Metal Mold Casting is widely used in industries where high precision and repeatability are crucial. Common applications include:

- Automotive Industry: Production of engine components, transmission parts, and other critical components.

- Aerospace Industry: Manufacturing of lightweight, high-strength parts.

- Consumer Electronics: Production of housings and structural components for electronic devices.

- Industrial Machinery: Components that require high durability and precision.

Metal Mold Casting is a versatile and efficient manufacturing process, particularly well-suited for high-volume production of metal parts with excellent dimensional accuracy and surface finish. However, its limitations in terms of material, shape complexity, and weight must be carefully considered when selecting this method for specific applications.

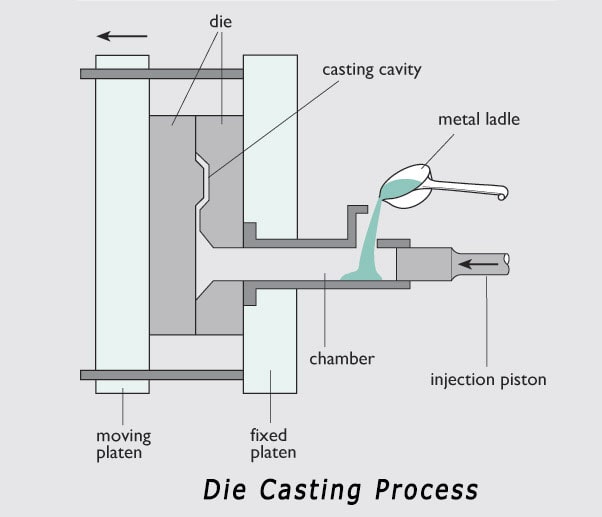

7. Die Casting

What is Die Casting?

Die casting is a manufacturing process in which molten metal is injected into a precision metal mold cavity at high pressure and high speed. The metal cools and solidifies under pressure, forming a casting with precise dimensions and a smooth surface finish.

Technological Process

The die casting process involves several key steps:

- Preparation: The mold is prepared and coated with a lubricant to facilitate the removal of the casting.

- Injection: Molten metal is injected into the mold cavity at high pressure.

- Cooling: The metal is allowed to cool and solidify within the mold.

- Ejection: The mold is opened, and the solidified casting is ejected.

- Trimming: Excess material, such as flash, is removed from the casting.

Advantages

- High Pressure and Fast Flow Rate: The metal liquid is subjected to high pressure and flows rapidly during die casting, ensuring that the mold is filled quickly and completely.

- Good Product Quality: Die castings have stable dimensions, good surface finish, and excellent interchangeability.

- High Production Efficiency: Die casting molds can be reused many times, making the process suitable for high-volume production.

- Economic Benefits: The process is cost-effective for mass production due to its high efficiency and repeatability.

Disadvantages

- Porosity and Shrinkage: Castings are prone to developing fine pores and shrinkage defects, which can affect their mechanical properties.

- Low Plasticity: Die-cast parts have low plasticity and are not suitable for applications involving impact loads or vibrations.

- Mold Life: When casting high melting point alloys, the mold life is reduced, which can limit the production scale and increase costs.

Applications

Die casting was initially used in the automotive and instrument industries. Over time, its applications have expanded to various sectors, including:

- Agricultural machinery

- Machine tool industry

- Electronics industry

- National defense industry

- Computers

- Medical equipment

- Clocks and cameras

- Daily hardware

Die casting remains a versatile and widely used manufacturing process due to its ability to produce complex shapes with high precision and excellent surface quality.

8. Low-pressure Casting

What is Low-Pressure Casting?

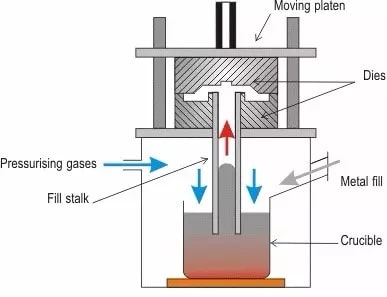

Low-pressure casting is a manufacturing process where liquid metal is made to fill a mold under a low pressure, typically ranging from 0.02 to 0.06 MPa. The metal then crystallizes under this pressure to form a casting. This method is distinguished by its ability to control the pressure and speed of the metal during pouring, making it suitable for a variety of casting molds and alloys.

Technological Process

- Preparation of the Mold: The mold, which can be made of metal or sand, is prepared and positioned.

- Melting the Metal: The metal is melted in a furnace.

- Filling the Mold: The molten metal is injected into the mold from the bottom under low pressure, ensuring a stable and controlled filling process.

- Solidification: The metal solidifies under pressure, forming a dense and high-quality casting.

- Cooling and Ejection: The casting is allowed to cool and is then ejected from the mold.

Technical Characteristics

Adjustable Pressure and Speed

- Versatility: The pressure and speed during pouring can be adjusted, making the process suitable for various casting molds, including metal and sand molds.

- Diverse Applications: It can be used for casting different alloys and producing castings of various sizes.

Bottom-Injection Filling Method

- Stable Filling: By adopting a bottom-injection filling method, the metal liquid fills the mold stably without splashing.

- Gas Prevention: This method helps prevent the presence of gas in the casting.

- Reduced Erosion: It reduces the erosion of the mold walls and core, thereby improving the casting pass rate.

High-Quality Castings

- Dense Structure: The casting solidifies under pressure, resulting in a dense structure.

- Sharp Outline and Smooth Surface: The castings have a sharp outline and smooth surface.

- High Mechanical Properties: The process results in castings with high mechanical properties, making it particularly beneficial for large, thin-walled parts.

Efficiency and Automation

- High Metal Utilization: The process eliminates the need for risers, increasing the metal utilization rate to 90-98%.

- Low Labor Intensity: It is characterized by low labor intensity and good working conditions.

- Simple Equipment: The equipment used is relatively simple.

- Mechanization and Automation: There is a high potential for mechanization and automation, enhancing productivity and consistency.

Application

Low-pressure casting is mainly used in the production of traditional products such as:

- Cylinder Heads

- Hubs

- Cylinder Frames

These components benefit from the high-quality characteristics of low-pressure castings, such as their dense structure and high mechanical properties.

Low-pressure casting is a versatile and efficient method for producing high-quality metal castings. Its ability to control the pressure and speed during pouring, combined with the benefits of bottom-injection filling and solidification under pressure, makes it suitable for a wide range of applications. The process not only improves the quality of the castings but also enhances metal utilization and allows for greater automation, making it a valuable technique in modern manufacturing.

9. Centrifugal Casting

What is Centrifugal Casting?

Centrifugal casting is a casting method where molten metal is poured into a rotating mold. The rotation of the mold generates centrifugal force, which helps fill the mold and solidify the metal. This technique is particularly effective for producing cylindrical parts and components with a high degree of uniformity and density.

Technological Process

- Preparation: The mold is prepared and set to rotate at a specific speed.

- Pouring: Molten metal is poured into the rotating mold.

- Solidification: The centrifugal force distributes the molten metal evenly along the mold walls, where it solidifies.

- Cooling: The casting is allowed to cool and solidify completely.

- Extraction: The solidified casting is removed from the mold for further processing.

Advantages

- Efficient Metal Usage: The pouring system and riser system consume minimal metal, leading to an improved process yield.

- Coreless Production: In the production of long tubular castings, the absence of a core enhances the metal filling ability significantly.

- High Quality: The resulting casting exhibits high density, few defects (such as pores and slag inclusions), and excellent mechanical properties.

- Composite Castings: Manufacturing composite metal castings of barrels and sleeves is relatively easy.

Disadvantages

- Shape Limitations: There are certain limitations when used in the production of special-shaped castings.

- Inner Hole Quality: The diameter of the inner hole of the casting is not accurate, the surface of the inner hole is rough, the quality is poor, and the machining allowance is large.

- Segregation: The casting is prone to specific gravity segregation, which can affect the uniformity of the material.

Applications

Centrifugal casting was initially utilized for producing cast pipes, but it has since been widely adopted in various industries such as metallurgy, mining, transportation, irrigation and drainage machinery, aviation, national defense, and the automotive industry. This process is used to produce steel, iron, and non-ferrous carbon alloy castings.

Common Applications

- Centrifugal Cast Iron Tubes: Widely used in various piping systems.

- Cylinder Liners for Internal Combustion Engines: Essential for automotive and heavy machinery engines.

- Shaft Sleeves: Used in various mechanical systems to reduce wear and tear on rotating shafts.

Centrifugal casting is a versatile and efficient method for producing high-quality cylindrical components with excellent mechanical properties, making it a valuable process in many industrial applications.

10. Gravity Die Casting

What is Gravity Die Casting?

Gravity Die Casting is a casting process where liquid metal is poured into a metal mold under the influence of gravity. The metal is then cooled and solidified to produce a casting. This method is widely used for producing high-quality metal parts with precise dimensions and excellent surface finishes.

Technological Process

- Mold Preparation: The metal mold is preheated and coated with a release agent to facilitate the removal of the casting.

- Pouring: Molten metal is poured into the mold cavity under the influence of gravity.

- Cooling and Solidification: The metal cools and solidifies within the mold.

- Ejection: Once solidified, the casting is removed from the mold.

- Finishing: The casting undergoes finishing processes such as trimming, machining, and surface treatment to achieve the desired specifications.

Advantages

- High Thermal Conductivity and Heat Capacity: The metal mold’s high thermal conductivity and heat capacity result in rapid cooling, leading to a dense casting structure.

- Enhanced Mechanical Properties: Castings produced through gravity die casting have mechanical properties approximately 15% higher than those produced by sand casting.

- Dimensional Accuracy and Surface Finish: The use of metal molds allows for greater dimensional accuracy and lower surface roughness, enhancing quality stability.

- Environmental and Labor Benefits: Minimal or no use of sand cores improves environmental conditions by reducing dust and harmful gases, and lowers labor intensity.

Disadvantages

- Non-Breathable Mold: The metal mold is non-breathable, necessitating measures to evacuate air and gases generated by any sand cores in the cavity.

- Risk of Cracks: The metal mold has no concession, making it prone to cracking during the solidification of the casting.

- High Cost and Long Manufacturing Cycle: Metal molds have a longer manufacturing cycle and higher cost, making them economically viable primarily for mass production.

Applications

Gravity die casting is particularly suitable for the large-scale production of non-ferrous alloy castings, such as aluminum and magnesium alloys, with complex shapes. It is also used for producing iron and steel metal castings and ingots. This method is favored in industries requiring high precision and quality, such as automotive, aerospace, and consumer electronics.By understanding the gravity die casting process, its advantages, and its limitations, manufacturers can better decide when to employ this method for producing high-quality metal components.

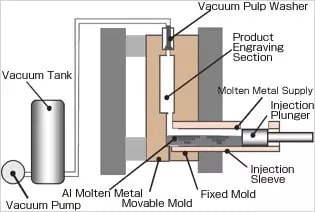

11. Vacuum Die Casting

What is Vacuum Die Casting?

Vacuum die casting is an advanced form of die casting that enhances the mechanical properties and surface finish of cast parts by removing or significantly reducing the pores and dissolved gases within them. This is achieved by extracting gas from the mold cavity during the casting process, which helps in creating denser and more robust castings with fewer defects.

Technological Process

The vacuum die casting process involves several key steps:

- Mold Preparation: The mold is prepared and coated with a release agent to facilitate easy removal of the cast part.

- Vacuum Application: Before the molten metal is introduced, a vacuum is applied to the mold cavity to remove air and gases.

- Metal Injection: Molten metal is injected into the mold cavity under high pressure.

- Solidification: The metal cools and solidifies in the mold, forming the desired shape.

- Part Ejection: The mold is opened, and the cast part is ejected.

Advantages

- Reduced Porosity: Vacuum die casting can eliminate or significantly reduce air holes inside the die casting, leading to improved mechanical properties and surface quality.

- Improved Plating Performance: The reduction of pores enhances the plating performance of the cast parts.

- Lower Back Pressure: By reducing the back pressure in the cavity, lower specific pressure and alloys with poor casting performance can be used.

- Larger Castings with Smaller Machines: It is possible to die-cast larger castings with smaller machines due to the improved filling conditions.

- Thinner Castings: The process allows for the casting of thinner sections, which can be beneficial for certain applications.

Disadvantages

- Complex Mold Sealing Structure: The mold sealing structure in vacuum die casting is complicated, making the mold-making and installation process difficult and costly.

- Control Sensitivity: If the vacuum die casting method is not properly controlled, the benefits may not be significant, leading to potential defects and inefficiencies.

Vacuum die casting is a sophisticated technique that offers significant advantages in terms of reducing porosity and improving the mechanical properties and surface finish of cast parts. However, it requires precise control and a complex mold sealing structure, which can increase costs and complexity. When properly implemented, it can produce high-quality castings that meet stringent performance requirements.

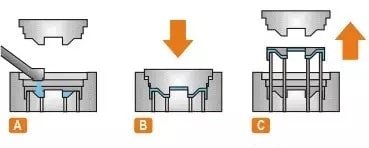

12. Squeezing Die Casting

What is Squeezing Die Casting?

Squeeze casting, also known as liquid metal forging, is a metal forming process that involves solidifying liquid or semi-solid metal under high pressure to produce the final product or blank directly. This process combines the advantages of both casting and forging, offering several benefits including high utilization of liquid metal, a simplified process, and consistent quality. It is an energy-efficient metal forming technology that holds great promise for future applications.

Technological Process

Direct Squeezing Die Casting:

- Spray Paint: Apply a coating to the mold to facilitate the release of the cast part.

- Cast Alloy: Pour the molten or semi-solid alloy into the mold.

- Mold Clamping: Close and secure the mold.

- Pressurization: Apply high pressure to the molten metal.

- Pressure Holding: Maintain the pressure to ensure proper solidification.

- Pressure Relief: Gradually release the pressure.

- Mold Separation: Open the mold.

- Blank Demolding: Remove the solidified part from the mold.

- Resetting: Prepare the mold for the next cycle.

Indirect Squeezing Die Casting:

- Spray Coating: Apply a coating to the mold.

- Mold Clamping: Close and secure the mold.

- Feeding: Introduce the molten or semi-solid metal into the mold.

- Filling: Ensure the mold is completely filled with the metal.

- Pressurization: Apply high pressure.

- Pressure Holding: Maintain the pressure to ensure proper solidification.

- Pressure Relief: Gradually release the pressure.

- Parting: Open the mold.

- Blank Demolding: Remove the solidified part from the mold.

- Resetting: Prepare the mold for the next cycle.

Technical Characteristics

- Defect Elimination: It can eliminate internal pores, shrinkage, and other defects.

- Surface Quality: Produces parts with low surface roughness and high dimensional accuracy.

- Crack Prevention: Prevents the occurrence of casting cracks.

- Automation: Easy to realize mechanization and automation, enhancing production efficiency.

Applications

Squeeze casting can be used to produce various types of alloys, including:

- Aluminum alloy

- Zinc alloy

- Copper alloy

- Nodular cast iron

This versatility makes it suitable for a wide range of industrial applications, from automotive components to aerospace parts.

Squeeze casting is a highly efficient and versatile metal forming process that offers numerous advantages over traditional casting and forging methods. Its ability to produce high-quality parts with minimal defects and its compatibility with various alloys make it an attractive option for modern manufacturing.

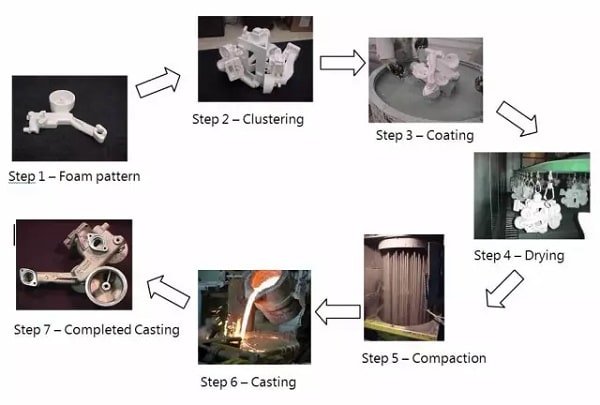

13. Lost Foam Casting

What is Lost Foam Casting?

Lost foam casting, also known as solid casting, is a modern and innovative casting technique that utilizes paraffin or foam models to replicate the desired cast in both size and shape. These models are assembled into a cluster to form a single unit, which is then used in the casting process.

Technological Process

- Pre-Foaming: The process begins with pre-foaming, where expandable polystyrene (EPS) beads are expanded to form foam.

- Foaming Molding: The expanded foam beads are molded into the shape of the desired casting.

- Dip Coating: The foam model is coated with a refractory material to create a shell.

- Drying: The coated model is dried to ensure the refractory coating is solid and stable.

- Modeling: The dried model is placed in a flask and surrounded by dry quartz sand, which is compacted through vibration to support the model.

- Pouring: Liquid metal is poured into the mold, causing the foam model to vaporize and the metal to take its place.

- Falling Sand: After the metal has solidified, the sand is removed.

- Cleaning: The final casting is cleaned to remove any residual sand and refractory material.

Technical Characteristics

- High Precision Casting: Lost foam casting produces high-precision castings with fine surface finishes and intricate details.

- No Sand Core: This method eliminates the need for a sand core, reducing processing time and complexity.

- No Parting Surface: The absence of a parting surface allows for more flexible design and a higher degree of freedom in casting shapes.

- Clean Production: The process is environmentally friendly, producing minimal pollution.

- Cost-Effective: It reduces investment and production costs by simplifying the casting process and minimizing material waste.

Applications

Lost foam casting is highly versatile and can be used to produce a wide range of precision castings with complex structures and varying sizes. It is suitable for various alloys and production batch sizes. Some common applications include:

- Gray Cast Iron Engine Blocks: Utilized in the automotive industry for manufacturing engine components.

- High Manganese Steel Elbows: Used in industries requiring durable and wear-resistant parts.

Lost foam casting is a highly efficient and precise casting method that offers numerous advantages, including high design flexibility, cost savings, and environmental benefits. Its ability to produce complex and high-quality castings makes it an invaluable technique in various industrial applications.

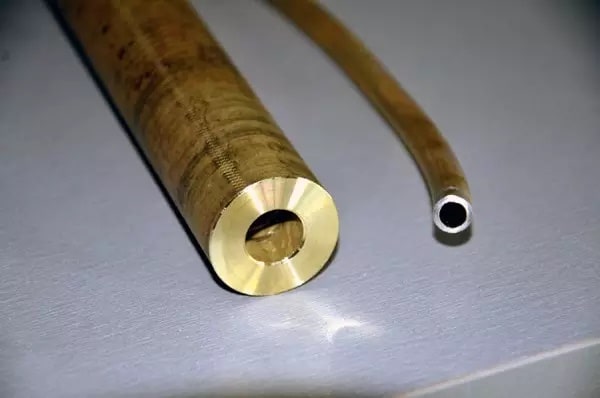

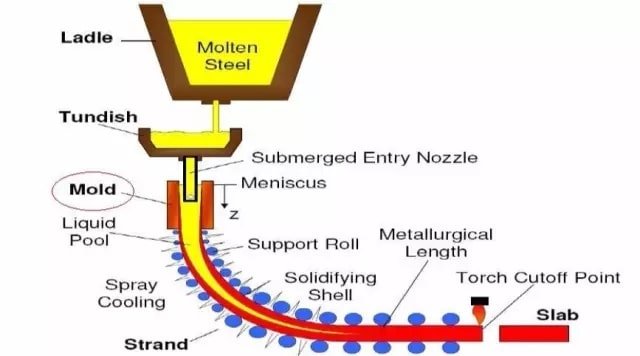

14. Continuous Casting

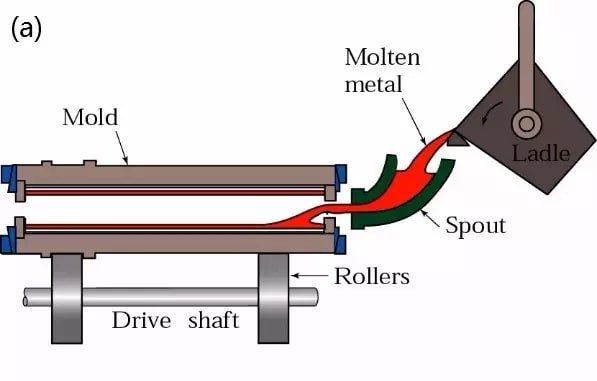

What is Continuous Casting?

Continuous casting is an advanced metallurgical process where molten metal is continuously poured into a specially designed mold called a crystallizer. As the metal solidifies, it is continuously drawn out from the opposite end of the mold. This method allows for the production of castings of indefinite length or specific lengths, making it highly efficient for industrial applications.

Technological Process

The continuous casting process involves several key steps:

- Molten Metal Pouring: The molten metal is poured into the crystallizer.

- Solidification: As the metal flows through the mold, it begins to solidify.

- Extraction: The solidified metal is continuously extracted from the mold.

- Cutting: The continuous casting can be cut into desired lengths as needed.

Technical Characteristics

Continuous casting offers several technical advantages:

- Rapid Cooling: The metal undergoes rapid cooling, resulting in denser crystal structures and uniformity.

- Improved Mechanical Properties: The process enhances the mechanical properties of the cast metal.

- Material Efficiency: It saves metal and increases yield by minimizing waste.

- Simplified Procedures: Continuous casting eliminates the need for traditional modeling and other steps, reducing labor intensity.

- Space Efficiency: The process requires significantly less production space.

- Automation: Continuous casting is easily automated, leading to increased production efficiency through mechanization.

Applications

Continuous casting is versatile and can be used to cast various metals and alloys, including:

- Steel

- Iron

- Copper Alloys

- Aluminum Alloys

- Magnesium Alloys

It is particularly suited for producing long castings with constant cross-sectional shapes, such as:

- Ingots

- Slabs

- Rod Billets

- Pipes

Continuous casting is a highly efficient and technologically advanced process that offers numerous benefits in terms of material properties, production efficiency, and cost savings. Its ability to produce long, uniform castings makes it indispensable in modern metallurgical industries.

The Casting Process: An Overview

Casting is a fundamental and versatile manufacturing technique where solid metal is melted, poured into a mold, and allowed to solidify into a specific shape. This process is integral to modern manufacturing, offering numerous advantages in terms of cost, time, and material efficiency.

Steps in the Casting Process

- Preparation of the Casting Mold:

- Types of Molds: Casting molds can be made from various materials, including sand, metal, ceramic, clay, and graphite. They are classified based on their usage frequency into one-time molds, semi-permanent molds, and permanent molds.

- Importance: The quality of the casting mold is crucial as it directly impacts the quality of the final cast product.

- Melting and Pouring of the Casting Metal:

- Casting Alloys: Common casting metals include cast iron, cast steel, and non-ferrous alloys like aluminum, copper, and lead.

- Process: The metal is melted to meet specific requirements and then poured into the prepared mold.

- Casting Treatment and Inspection:

- Post-Casting Processes: This includes removing foreign matter, sprues, risers, burrs, and cracks. Additional steps may involve heat treatment, shaping, anti-rust treatment, and rough machining.

- Inspection: Ensuring the casting meets the desired specifications and quality standards.

Materials Used in Casting

- Metals: Commonly used metals include copper, iron, aluminum, tin, and lead.

- Mold Materials: These can be sand, metal, or ceramics, depending on the specific requirements of the casting process.

Types of Casting Molds

- Ordinary Casting Molds: Made from raw sand, clay, water glass, resin, and other auxiliary materials.

- Special Casting Molds: Include investment casting, lost foam casting, metal mold casting, and ceramic mold casting. Raw sand types can vary, including quartz sand, magnesia sand, zirconium sand, chromite sand, forsterite sand, kyanite sand, graphite sand, and iron sand.

Technological Process

The casting process can be summarized in the following steps:

- Liquid Metal: The metal is melted into a liquid state.

- Filling: The liquid metal is poured into the mold.

- Solidification Shrinkage: The metal cools and solidifies, often shrinking slightly.

- Casting: The solidified metal is removed from the mold, resulting in the final cast product.

Characteristics of the Casting Process

- Complex Shapes: Capable of producing parts with intricate and complex shapes, especially those with complicated internal cavities.

- Adaptability: Suitable for a wide range of alloys and casting sizes.

- Material Efficiency: Utilizes a wide range of materials, including the ability to remelt waste, leading to low equipment investment.

- Challenges: The process can result in a high scrap rate, low surface quality, and poor labor conditions.

Historical Context

Casting is one of the oldest metalworking processes, with a history spanning approximately 6000 years. This long history underscores its importance and enduring relevance in manufacturing.

Casting remains a cornerstone of modern manufacturing due to its versatility, efficiency, and ability to produce complex shapes. Understanding the intricacies of the casting process, from mold preparation to post-casting treatment, is essential for optimizing production and ensuring high-quality cast products.

How Can I Cast Parts at Home?

Casting parts at home can be a rewarding and practical way to create custom components. Here is a detailed guide to help you get started:

Equipment and Materials Needed

Melting Furnace

- Electric Furnace: For small-scale production, a small-capacity electric furnace is ideal. These furnaces are efficient and provide precise temperature control, making them suitable for both iron and aluminum.

- Kerosene Furnace: Suitable for melting aluminum, kerosene furnaces are an alternative if an electric furnace is not available.

- Note: Iron and aluminum should not be melted in the same furnace due to the difficulty in controlling the material properties. If precise material control is not critical for your project, this may not be a significant issue.

Molds

- Custom Molds: Depending on the parts you want to cast, you will need custom molds. These can be made from various materials, including sand, metal, or silicone, depending on the complexity and precision required.

- Sand: For sand casting, you will need high-quality foundry sand. This sand must be mixed with a binder to hold its shape during the casting process.

- Sand Mixer: While not essential, a sand mixer can significantly improve the consistency and quality of the sand mixture. Manual mixing is possible but may be less efficient.

Modeling Tools

- Pattern: Create a pattern of the part you want to cast. This pattern is used to form the cavity in the sand mold.

- Flask: A container used to hold the sand mold. It typically consists of two parts: the cope (top) and the drag (bottom).

Pouring and Casting

- Crucible: A container made of heat-resistant material used to melt and pour the metal.

- Tongs: For handling the hot crucible safely.

- Protective Gear: Safety is paramount. Wear heat-resistant gloves, an apron, and a face shield to protect against splashes and burns.

Post-Casting Tools

- Cleaning Tools: To remove the pouring riser and smooth out any burrs on the casting. Files, grinders, and chisels are commonly used.

- Shot Blasting Roller: Enhances the surface finish of the casting by removing any remaining sand and smoothing the surface.

Step-by-Step Process

- Prepare the Mold:

- Create a pattern of the part you want to cast.

- Place the pattern in the flask and pack the sand around it, ensuring it is tightly packed.

- Remove the pattern, leaving a cavity in the shape of the part.

- Melt the Metal:

- Place the metal (iron or aluminum) in the crucible and heat it in the furnace until it reaches the melting point.

- Use tongs to handle the crucible and pour the molten metal into the mold cavity.

- Allow to Cool:

- Let the metal cool and solidify in the mold. The cooling time will depend on the size and complexity of the casting.

- Remove the Casting:

- Break away the sand mold to reveal the casting.

- Use cleaning tools to remove the pouring riser and any excess material.

- Finishing:

- Smooth out any burrs or rough edges using files or grinders.

- Optionally, use a shot blasting roller to improve the surface finish.

Safety Considerations

- Always work in a well-ventilated area to avoid inhaling fumes.

- Keep a fire extinguisher nearby in case of emergencies.

- Wear appropriate protective gear to prevent burns and injuries.

By following these steps and using the right equipment, you can successfully cast parts at home. Remember, practice and patience are key to mastering the art of casting.