Have you ever wondered about the differences between various grades of stainless steel? In this blog post, we’ll dive into the world of 304, 304L, 316, and 316L stainless steels. Our expert mechanical engineer will break down their unique properties, compositions, and applications, helping you choose the perfect grade for your project. Get ready to expand your knowledge and make informed decisions about these essential materials.

Stainless steel” is a type of steel that contains less than 2% carbon and more than 2% iron, and is made stronger by the addition of chromium, nickel, manganese, silicon, titanium, molybdenum and other alloying elements. This results in a steel with a corrosion resistance, meaning it does not rust.

“Steel” and “Iron” are different terms, and their properties and characteristics vary. The terms “304,” “304L,” “316,” and “316L” are different grades of stainless steel, each with unique properties and characteristics. It is important to understand these differences to determine the most suitable grade for a particular application.

Steel:

A kind of material that use iron as the main element with carbon content (less than 2%) and other elements.

–GB/T 13304-91 Steel Classification

Iron:

A metallic element with atomic number 26.

Iron materials have strong ferromagnetic properties, excellent plasticity and thermal conductivity.

Stainless steel:

A kind of steel with resistance to air, steam, water and other weakly corrosive media or stainless steel properties.

The commonly used steel grades are 304, 304L, 316, and 316L, which are 300 series steels of austenite.

In the production of stainless steel, different alloys are added, leading to differences in their characteristics. To differentiate them, they are given different steel numbers. The following table of alloying elements is a common reference for different steel numbers in decorative stainless steel.

Chemical composition (mass fraction, %)

| Steel Grade | C | Si | Mn | P | S | Cr | Ni |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | 8-10 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 6-8 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10 | ≤0.05 | ≤0.03 | 17-19 | 4-6 |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.05 | ≤0.03 | 16-18 | 3.5-5.5 |

Performance introduction

304 stainless steel is a widely used and common type of steel that has good resistance to corrosion, heat, low temperature strength, and mechanical properties. It is ideal for stamping and bending processes, as it does not undergo heat treatment hardening and remains non-magnetic. It can be used in temperatures between -196°C and 800°C.

Applicable range

304 stainless steel is commonly used in household goods such as class I and II tableware, cupboards, indoor plumbing, water heaters, boilers, and bathtubs. It is also used in automotive parts, such as windshield wipers and mufflers, and in medical devices, building materials, the chemical industry, the food industry, agriculture, and ship components.

Performance introduction

As a low-carbon steel, 304L has similar corrosion resistance to 304 in its general state. However, after welding or stress-relieving, it has excellent resistance to grain boundary corrosion. It can also maintain good corrosion resistance without heat treatment in a temperature range of 196°C to 800°C.

Applicable range

304L is commonly used in outdoor equipment in the chemical, coal, and petroleum industries that require high resistance to grain boundary corrosion, as well as in heat-resistant parts of building materials and components that are challenging to heat treat.

Performance introduction

Due to the addition of molybdenum, 316 stainless steel has excellent corrosion resistance, resistance to atmospheric corrosion, and high-temperature strength, making it suitable for use in harsh conditions. Its work hardening properties are also excellent (non-magnetic).

Applicable range

Marine equipment, chemical, dye, paper, oxalic acid, fertilizer and other production equipment; camera, food industry, coastal area facilities, ropes, CD rods, bolts, nuts.

Performance introduction

As a low-carbon series of 316 stainless steel, it has the same characteristics as 316, but has excellent resistance to grain boundary corrosion.

Applicable range

Products with special requirements for resistance to grain boundary corrosion.

Enriched with Mo (2-3%), it exhibits exceptional pitting and corrosion resistance, and excellent high-temperature creep strength.

Characteristics and Practical Applications:

| Difference | SUS316(L) |

| Characteristics | –Excellent resistance to crystalline corrosion |

| Usage | –Piping for boilers, marine structures |

Chemical Composition: (Unit: wt%)

| Specification | C | Si | Mn | P | S | Cr | Ni | Other |

| SUS316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0~18.0 | 10.0~14.0 | Mo:2~3 |

| SUS316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0~18.0 | 12.0~15.0 | Mo:2~3 |

Mechanical Properties:

| Specification | YS(Mpa) | TS(Mpa) | EL(%) | Hv |

| SUS316 | ≥205 | ≥520 | ≥40 | ≤200 |

| SUS316L | ≥175 | ≥480 | ≥40 | ≤200 |

Due to the presence of molybdenum, 316 and 316L stainless steels exhibit excellent corrosion resistance and high-temperature strength. With its superior performance compared to 310 and 304 stainless steels, 316 stainless steel is widely used in harsh conditions, including high temperatures and sulfuric acid concentrations between 15% and 85%.

Additionally, its resistance to chloride attack makes it a popular choice for marine environments. With a maximum carbon content of 0.03, 316L stainless steel is ideal for applications that require no post-weld annealing and maximum corrosion resistance.

Chemical composition of 316L stainless steel

Grade: 00Cr17Ni14Mo2

| Material Name | Chemical Composition (Mass Fraction %) | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 |

Chemical composition of 304 stainless steel

Grade: 0Cr18Ni9

| Material Name | Chemical Composition (Mass Fraction %) | |||||||

| C | Si | Mn | P | S | Ni | Cr | N | |

| ≤ | ≤ | |||||||

| SUS304 | 0.07 | 0.75 | 2.00 | 0.035 | 0.030 | 8.0-11.0 | 18.0-20.0 | 0.10 |

1. Corrosion Resistance of 316L

316L stainless steel is a molybdenum-containing type. Its corrosion resistance exceeds that of 304 stainless steel, demonstrating robust resistance during the production of pulp and paper. Furthermore, 316 stainless steel is resistant to marine and corrosive industrial atmospheres.

In terms of heat resistance, 316L stainless steel exhibits good resistance to oxidation in intermittent use under 1600 degrees and continuous use under 1700 degrees.

For the range of 800-1575 degrees, it is advisable not to use 316L stainless steel continuously; however, this steel shows remarkable heat resistance when operated continuously outside this temperature range.

The resistance of 316L stainless steel to carbide precipitation is superior to 316 stainless steel, suitable for use in the aforementioned temperature range.

As a low-carbon version of 316 steel, 316L not only retains the same characteristics as 316 steel but also offers improved intergranular corrosion resistance.

This makes 316L particularly suitable for applications within the 316 steel range that require special resistance to intergranular corrosion.

2. Corrosion Resistance of 304

304 stainless steel exhibits excellent resistance to corrosion and good resistance to intergranular corrosion.

In the case of oxidizing acids, experiments have shown that 304 stainless steel demonstrates strong corrosion resistance in nitric acid solutions with a concentration of ≤65% below boiling temperature.

It also exhibits good corrosion resistance to alkali solutions and most organic and inorganic acids.

A high-alloy steel that is capable of withstanding corrosion in air or chemically corrosive media, stainless steel has an attractive surface and good corrosion resistance.

Without the need for surface treatments such as plating, it leverages the inherent surface properties of stainless steel. This versatile type of steel, commonly referred to as stainless steel, is used in many applications.

The mechanism for rust prevention in stainless steel is that alloy elements form a dense oxide film, isolating oxygen contact and preventing further oxidation. However, stainless steel is not “stainless” in the absolute sense.

The occurrence of rust in 304 material may be due to several reasons:

(1) Presence of chloride ions in the environment.

Chloride ions are widely present, for example in table salt, sweat, seawater, sea breeze, soil, etc. Stainless steel corrodes quickly in an environment with chloride ions, sometimes even faster than common low carbon steel.

Therefore, the environment in which stainless steel is used needs to be considered, and regular cleaning to remove dust and maintain cleanliness and dryness is necessary.

(2) Lack of solution treatment.

If alloy elements are not dissolved into the matrix, the base structure has a low alloy content resulting in poor corrosion resistance.

(3) This type of material, which lacks titanium and niobium, has an inherent tendency for intergranular corrosion.

The addition of titanium and niobium, together with stabilization treatment, can reduce intergranular corrosion.

In the production of pulp and paper, 316 stainless steel has better corrosion resistance compared to 304 stainless steel. It is also resistant to marine and aggressive industrial atmospheres.

Generally, there is little difference in terms of chemical resistance between 304 and 316 stainless steel, although there are differences in certain specific media.

304 stainless steel, being the first developed stainless steel, is more susceptible to Pitting Corrosion (PC) in certain conditions.

The addition of 2-3% molybdenum reduces this sensitivity, leading to the creation of 316. Moreover, extra molybdenum also decreases the corrosion of specific hot organic acids.

316 stainless steel has become the industry standard material for food and beverage industries, however, due to the worldwide scarcity of molybdenum and the higher nickel content in 316, it is more expensive than 304 stainless steel.

Pitting corrosion occurs primarily due to the deposition of corrosion on the surface of stainless steel, resulting from the inability to form a protective layer of chromium oxide due to lack of oxygen.

In most types of aqueous media (distilled water, drinking water, river water, boiler water, seawater, etc.), the corrosion resistance of 304 and 316 stainless steel is almost the same, unless the chloride ion content in the medium is very high, in which case 316 stainless steel is more suitable.

In most cases, the corrosion resistance performance of 304 and 316 stainless steel is not significantly different, but in some cases, there may be a big difference, which requires a specific analysis of each case.

Valve users should have a clear understanding of their requirements, as they will choose the material for their vessel and pipe based on the medium. Recommending materials to users is not recommended.

See also:

316 stainless steel has good oxidation resistance when used intermittently below 1600°C and continuously below 1700°C.

It is best not to use 316 stainless steel continuously within the temperature range of 800-1575°C, but it has good heat resistance when used continuously outside of this range.

316L stainless steel has better resistance to carbide precipitation than 316 stainless steel and can be used in higher temperature ranges.

316 stainless steel need to anneal in the temperature range of 1850-2050oC, then anneal and cool rapidly because it cannot be hardened by overheating.

316 stainless steel has good welding properties and can be welded using all standard welding methods. Depending on the application, a filler rod or electrode of 316Cb, 316L, or 309Cb stainless steel can be used for welding.

For optimal corrosion resistance, post-weld annealing is required for the welded cross-section of 316 stainless steel. However, post-weld annealing is not necessary if 316L stainless steel is used.

1. Weldability of 316L

316L stainless steel is an ultra-low carbon pure austenitic stainless steel with good weldability and resistance to intergranular corrosion.

However, due to the low thermal conductivity and high linear expansion coefficient of stainless steel, significant tensile stress can form in the weld joint during cooling.

This, combined with high heat input and slow cooling speeds, can lead to heat cracking, corrosion cracking, and deformation.

316L stainless steel can be welded using all standard methods. Depending on the application, 316Cb, 316L, or 309Cb stainless steel filler rods or electrodes can be used for welding.

Among the commonly used welding methods, MIG and TIG welding have smaller heat inputs.

The argon gas flow not only protects the high-temperature metal but also has a cooling effect, enhancing the weld’s crack resistance and reducing welding deformation.

For 316L stainless steel, post-weld annealing treatment is not required (austenitic stainless steel generally does not undergo stress relief annealing after welding). The main reasons are:

1) Austenitic stainless steel has excellent plasticity and toughness, so there’s no need to restore its properties through post-weld stress relief annealing.

2) The temperature range of 450~850°C is the sensitization temperature for austenitic stainless steel.

Long-term heating in this range can degrade its corrosion resistance. If the weld contains ferrite, it may also lead to 475°C brittleness and sigma phase brittleness.

The stress relief annealing treatment after welding falls within this temperature range (except for solid solution and stabilization treatments).

In special cases, post-weld stress relief annealing treatment is needed:

1) To stabilize the geometry of equipment parts, it is necessary to eliminate welding residual stress.

2) If the equipment operates in an environment prone to stress corrosion, it is necessary to eliminate tensile residual stress.

2. Weldability of 304 Stainless Steel

Austenitic stainless steel, represented by 18%Cr-8%Ni steel or 304 stainless steel, does not generally require pre-heating or post-welding heat treatment. It exhibits good welding performance.

However, high-alloy stainless steel with a high nickel and molybdenum content tends to crack during welding.

Other problems include σ phase embrittlement (Fe-Cr intermetallic compound), ferrite-induced low-temperature brittleness, corrosion resistance reduction, and stress corrosion cracking.

After welding, the joint typically demonstrates good mechanical properties, but carbides of chromium on the grain boundaries in the heat-affected zone can lead to a chromium-depleted layer, which is prone to intergranular corrosion.

To avoid these issues, use grades with low carbon (C≤0.03%) or grades with added titanium or niobium.

To prevent high-temperature cracking of the welded metal, it’s commonly considered effective to control the δ ferrite in the austenite, with a general recommendation of maintaining at least 5% δ ferrite at room temperature.

For steel primarily used for corrosion resistance, opt for low carbon and stabilized grades, and apply appropriate post-weld heat treatment.

For steel primarily used for structural strength, post-weld heat treatment should be avoided to prevent deformation and embrittlement from precipitated carbides and the occurrence of δ phase.

| Type | UTS N/mm | Yield N/mm | Elogation % | Hardness HRB | Comparable DIN number | |

|---|---|---|---|---|---|---|

| wrought | cast | |||||

| 304 | 600 | 210 | 60 | 80 | 1.4301 | 1.4308 |

| 304L | 530 | 200 | 50 | 70 | 1.4306 | 1.4552 |

| 316 | 560 | 210 | 60 | 78 | 1.4401 | 1.4408 |

| 316L | 530 | 200 | 50 | 75 | 1.4406 | 1.4581 |

In all types of steels, austenite has the lowest yield strength. Hence, in terms of mechanical properties, austenite is not the most suitable material for use in valve stems.

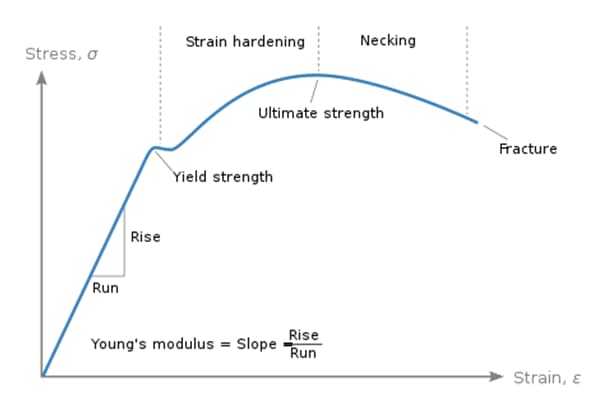

This is because, to ensure a specific strength, the diameter of the stem must be enlarged. The yield strength cannot be increased through heat treatment, but can be increased through cold forming.

Comparison of Mechanical Properties between 316L and 304 Stainless Steels

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation Rate (%) |

| ≥ | |||

| 0Cr18Ni9(304) | 520 | 205 | 35 |

| 00Cr17Ni14Mo2(316L) | 480 | 175 | 35 |

1. The primary chemical difference between 316L and 304 is that 316L contains Molybdenum (Mo).

Adding Molybdenum to austenitic stainless steel enhances its heat strength and creep strength, improving its resistance to pitting and intergranular corrosion.

Molybdenum can passivate the steel surface in both reductive and highly oxidative salt solutions, enhancing the steel’s corrosion resistance and preventing pitting in chloride solutions.

Including Molybdenum improves resistance to reductive acids and pitting, while reducing carbon content enhances resistance to intergranular corrosion and improves weldability. The addition of Molybdenum better prevents pitting.

304 is classified as low carbon stainless steel, whereas 316L is ultra-low carbon stainless steel.

Lower carbon content can reduce the occurrence of intergranular corrosion. However, both 304 and 316L are sensitive to chloride ions.

The resistance of 304 to chloride ions is significantly weaker than that of 316L, so 316L is generally chosen for environments with high chloride content.

2. The difference between 316L and 304 is substantial, primarily concerning intergranular corrosion.

304 is categorized as low carbon stainless steel, while 316L is ultra-low carbon stainless steel. The higher the carbon content, the weaker the steel’s resistance to intergranular corrosion. Therefore, 316L outperforms 304 in resisting intergranular corrosion.

3. 316L stainless steel has a maximum carbon content of 0.03, making it suitable for applications requiring post-welding annealing and maximum corrosion resistance.

Broadly speaking, 316L has better corrosion resistance and intergranular corrosion resistance than 304. In terms of weldability, due to its low carbon content and other combined factors, 316L outperforms 304.

Regarding mechanical properties, 304’s strength is higher than 316L. In machining capability, 316L exhibits superior cutability.

Due to the widespread use of austenite, a false perception has been created that all stainless steels are non-magnetic.

It is generally understood that austenite is non-magnetic and hardened forged steels are indeed so.

However, 304 that has undergone cold forming may be somewhat magnetic. On the other hand, 100% austenite cast steel is non-magnetic.

The corrosion resistance of austenite comes from the protective layer of chromium oxide that forms on the surface of the metal.

If the material is heated to high temperatures of 450°C to 900°C, the structure of the material changes, and chromium carbide is formed along the crystal edge, preventing the formation of a protective layer of chromium oxide at the edge of the crystal and resulting in a reduction in corrosion resistance.

This corrosion is called ‘intergranular corrosion.’

To combat this corrosion, 304L and 316L stainless steels were developed with a lower carbon content, meaning there is no chromium carbide and no intergranular corrosion.

It should be noted that a higher sensitivity to intergranular corrosion does not mean that non-low-carbon materials are more susceptible to corrosion, and this sensitivity is also higher in high chlorine environments.

Note that this phenomenon is due to high temperatures (450°C – 900°C), often caused by welding.

For a conventional butterfly valve with a soft seat, there is no need to use low-carbon stainless steel as we do not weld on the valve plate, even though most specifications call for 304L or 316L stainless steel.

Why does stainless steel still rust?

When brown rust spots appear on the surface of a stainless steel pipe, it can be surprising, as many people have the misconception that stainless steel does not rust.

However, stainless steel can corrode under certain conditions, as it has the ability to resist atmospheric oxidation, but also has the ability to corrode in mediums containing acid, alkali, and salt.

The corrosion resistance of stainless steel varies depending on its chemical composition, the state of protection, the conditions of use, and the type of environmental medium.

For example, 304 steel pipes have excellent corrosion resistance in a dry and clean atmosphere, but they can quickly rust in a seaside area with sea spray containing large amounts of salt.

On the other hand, 316 steel pipes perform well in these conditions. It is important to note that not all stainless steel is resistant to corrosion and rust in all environments.