Cracks in fasteners can compromise structural integrity and safety in engineering applications. Detecting these cracks early is crucial. This article delves into both traditional and modern non-destructive testing (NDT) methods, highlighting techniques like wavelet analysis and electromagnetic pulses. Readers will learn about the latest advancements in crack detection technologies and their practical applications, ensuring the reliability and durability of fasteners in various industries.

This article provides a summary of the current state of crack detection technologies, including their advantages and limitations, as well as hot topics and future development directions. It is based on existing fastener crack detection methods, with a focus on wavelet analysis and electromagnetic pulse nondestructive testing.

Fasteners are extensively utilized in various engineering fields such as machinery, construction, bridges, and oil production. As the basic component of large structures, fasteners are susceptible to various defects, including cracks, corrosion, pits, and human-induced damage during operation.

Crack defects pose a significant threat to the safety and reliability of structures and institutions, making crack detection an essential aspect of structural evaluation. Crack detection involves identifying and evaluating cracks in mechanical structures to determine their location and extent.

With the advancement of modern machinery manufacturing, electronics, and computer technology, non-destructive testing (NDT) has significantly improved, leading to the development of advanced crack detection techniques.

This article provides an overview of traditional crack detection methods and focuses on the modern NDT methods based on wavelet analysis and electromagnetic (eddy current) pulses. Additionally, it highlights the current hot topics and future development directions in crack detection techniques for fasteners.

There are numerous traditional crack detection techniques, which can be categorized into two groups: conventional and unconventional detection methods.

Conventional detection methods encompass eddy current testing, penetrant testing, magnetic particle testing, radiation testing, and ultrasonic testing. Unconventional detection methods, on the other hand, include acoustic emission testing, infrared testing, and laser holographic testing.

At present, conventional testing methods are widely used for simple crack detection in engineering fields such as machinery, construction, and oil production. The methods used vary depending on the institution.

For instance, ultrasonic testing is primarily used to inspect metal plates, pipes, bars, castings, forgings, and welds, as well as concrete structures like bridges and housing constructions. X-ray testing is mainly used to inspect castings and welds in industries such as machinery, weapons, shipbuilding, electronics, aerospace, petrochemical, and others. Magnetic particle testing is mainly used for the inspection of metal castings, forgings, and welds. Penetration testing is primarily used for the inspection of castings, forgings, weldments, powder metallurgy parts, and non-ferrous and ferrous metal products made of ceramic, plastic, and glass. Eddy current detection is mainly used for flaw detection and material sorting of conductive pipes, rods, and wires.

For the crack detection of fasteners, ultrasonic testing and eddy current detection can be used. For example, an experimental study found the best eddy current detection parameters for small cracks in fasteners. The results of the study showed that the best detection parameters had a linear relationship between the small crack eddy current detection parameters and phase signal, which is important in improving the accuracy of small crack detection in bars and selecting the eddy current detection parameters for external fasteners. However, eddy current detection has more interfering factors and requires special signal processing techniques.

Another method used for crack detection is the Lamb wave propagation energy spectrum structure crack detection method, which is known for its strong penetrating ability, high sensitivity, and speed and convenience. However, it has limitations such as blind spots and blockages, which can result in missed close cracks. The method is also challenging to characterize the defects found quantitatively and qualitatively.

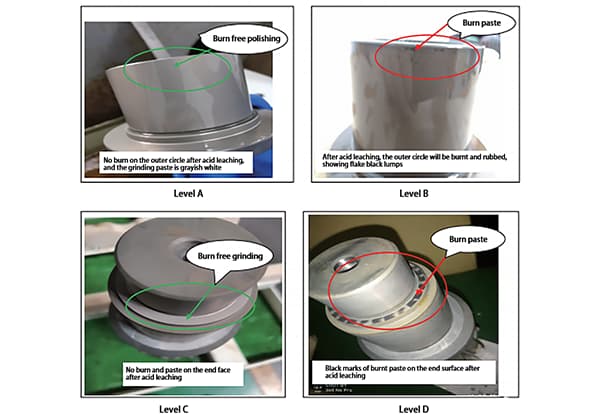

For most fasteners, magnetic particle testing and fluorescent flaw detection methods are used. These methods are relatively efficient, but they consume manpower and material resources and can damage human health. Additionally, missed inspections often occur due to human factors.

When conventional testing methods fail to detect cracks in fasteners, unconventional testing methods can be employed as an alternative.

Three commonly used unconventional crack detection methods include:

1) Acoustic emission technology.

Acoustic Emission technology is widely recognized as the most advanced method for crack detection in pressure-bearing equipment. It has been used successfully in the safety assessment of pressure vessels and pipelines, as well as in the detection of cracks in aerospace and composite materials. In the field of rotating machinery crack diagnosis, it has been used primarily to detect cracks in rotating shafts, gears, and bearings.

One of the key advantages of Acoustic Emission is that it is a dynamic detection method, using energy emitted from the object being tested rather than from external nondestructive testing equipment like ultrasonic or radiographic testing. This makes it highly sensitive to defects and capable of detecting and evaluating the status of active defects in the entire structure.

However, there are also some disadvantages to consider. Acoustic emission detection is greatly affected by the material being tested, and can be disrupted by electrical and mechanical noise in the testing environment. Additionally, the accuracy of the detection can be limited by low positioning accuracy, and the information obtained from the crack identification is often limited.

2) Infrared detection.

Infrared Non-Destructive Testing (NDT) technology is widely used in a variety of industries, including power equipment, petrochemical equipment, mechanical processing, fire detection, crop analysis, and the detection of defects in materials and components.

One of the major advantages of Infrared NDT is that it is a non-contact testing technology that is safe, reliable, harmless to humans, and highly sensitive. It has a wide detection range, fast speed, and does not impact the object being tested. It also has a high spatial resolution over long distances.

However, there are also some disadvantages to consider. The detection sensitivity of infrared is dependent on the thermal emissivity of the test piece, and can be affected by surface interference and background radiation. The resolution of the original specimen is poor, making it difficult to accurately measure the shape, size, and position of defects, particularly when they are small or buried deeply.

Additionally, the interpretation of test results is complex and requires reference standards, and operators need to be trained to use the technology effectively.

3) Laser holographic detection.

Laser holographic detection is primarily utilized for the inspection of various structures, such as honeycomb structures, composite materials, solid rocket motor shells, insulation layers, coating layers, and propellant grain interfaces for defect detection. It is also used for the assessment of printed circuit board solder joint quality and the detection of fatigue cracks in pressure vessels.

This method offers several advantages, including ease of use, high sensitivity, no special requirements for the tested object, and the ability to perform quantitative analysis of defects.

However, one of its disadvantages is that deeply buried debonding defects can only be detected when the debonding area is substantial.

Additionally, laser holographic detection typically requires a dark room environment and strict vibration isolation measures, making it less suitable for on-site testing and possessing certain limitations.

With advancements in science and technology, there has been a growing demand for more advanced crack detection methods in various engineering fields, such as machinery, construction, and oil production. This has led to the emergence of new technologies for crack detection.

Signal processing and electromagnetic (eddy current) pulse non-destructive testing are two of the commonly used and effective new technologies for detecting cracks. These methods offer efficient and reliable solutions for identifying cracks in various applications.

With the advancement of signal processing technology, several crack detection methods based on signal processing have emerged, including time-domain, frequency-domain, and time-frequency-domain methods such as Fourier transform, short-time Fourier transform, Wigner-Ville distribution, Hilbert-Huang transform (HHT), and blind source separation.

Of these methods, wavelet analysis is the most widely used and representative.

Crack identification methods using wavelet analysis can be divided into two categories:

① Time Domain Response Analysis Method:

This method includes using the singular points of the decomposition map in the time domain, the change of wavelet coefficients, and the energy change after wavelet decomposition. The aim of this method is to identify the moment when crack damage occurs.

② Spatial Response Based Analysis Method:

This method uses the spatial position of the spatial axis instead of the time axis of the time domain response signal for wavelet analysis, with the spatial domain response as the input. This method allows for the determination of the location of the crack.

While the wavelet method itself can only determine the moment when damage occurs or the location of the damage, the former has more applications. To identify small cracks, wavelet analysis should be combined with other methods.

Electromagnetic technology combines multiple functions such as ultrasonic detection, eddy current imaging, eddy current array, and pulsed eddy current detection to form advanced new technologies for electromagnetic inspection.

Common crack detection technologies include pulsed eddy current testing, pulsed eddy current thermal imaging, dual-probe non-destructive testing using pulsed eddy current and electromagnetic acoustic transducer (EMAT), and metal magnetic memory testing technology.

Pulsed eddy current testing involves exciting a coil with a pulse current, analyzing the time-domain transient response signal induced by the detection probe, and quantitatively detecting cracks by selecting the peak value, zero-crossing time, and peak time of the signal.

Research by Yang Binfeng and others at the National University of Defense Technology has shown that pulsed eddy current can quantitatively detect cracks of different depths with just one scan. Some researchers use harmonic coils as an alternative technology for pulsed eddy current testing.

However, the peak value of the pulsed eddy current signal is easily affected by other factors such as the lift-off effect and the detection ability of the pulsed eddy current probe can also impact crack detection.

Pulsed eddy current imaging instruments use coils as inspection sensors, while some use Hall sensors. In recent years, super quantum interference instruments have begun to be used in the field of non-destructive inspection.

Pulsed eddy current thermal imaging technology eliminates the lift-off effect in other detections and ensures accurate imaging results. Some researchers use YNG laser beams with a Gaussian beam shape on the surface of metal sheets, using pulsed eddy current and electromagnetic acoustic transducer detection technology. They identify cracks by detecting a sudden change in the ultrasonic waveform or a sudden increase in frequency components when the laser beam irradiates the crack.

Currently, the research on fastener crack detection is limited to traditional detection methods. In order to advance detection technology and address practical application problems, the focus of crack damage identification is mainly on two aspects: statistical identification methods considering the impact of uncertainty and the identification of fastener micro-cracks.

The uncertainty of crack damage detection requires the use of statistical inference methods to address the system identification problem. With the advancement of damage identification research, the study of damage identification methods based on probabilistic statistical theory has deepened, with current main application areas being system identification and pattern recognition.

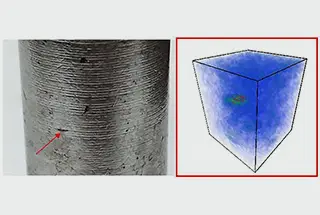

There are currently methods for detecting microcracks in fasteners, such as microcrack detection based on ICT technology and laser ultrasonic casting based on laser-assisted heating, but both have limitations. For example, microcrack detection based on ICT technology may struggle to distinguish details if the gray value in the collected image is not much different from the background gray value, affecting image quality and making image acquisition difficult. Additionally, it is uncertain to extract the spatial range containing all the microcracks when using VG Studio MAX software. The limitation of the laser-assisted heating method based on laser ultrasonic projection is that it is complicated to operate and cannot be used in harsh environments, so it still needs further development.

As the social economy continues to develop, the requirements for fastener crack detection methods are becoming increasingly demanding. These methods must meet the needs of real-time online detection, be highly sensitive, simple to operate, and resistant to external interference, and be able to work in harsh environments. They must also quickly and accurately detect the location, size, width, depth, and development trend of cracks, display test results in images that can be analyzed, and offer fast detection speed, high efficiency, and intuitive results.

Extensive research has been conducted on the identification of fastener crack damage, but the current damage identification methods and indicators are limited to traditional detection methods. Given the cost of testing equipment, the environment in which they are used, and human factors, the detection of multiple cracks and microcracks in fasteners is a current area of research interest.

The development direction of fastener crack detection is to achieve rapid positioning, accurate quantification, improve detection accuracy and reliability, and achieve fast and effective crack detection.