Have you ever considered the unsung heroes holding our machines together? In this article, we’ll explore the fascinating world of mechanical connections, from the humble rivet to the mighty weld. As an experienced mechanical engineer, I’ll guide you through the strengths, limitations, and applications of each method. By the end, you’ll appreciate the vital role these connections play in our engineered world.

In the 19th and 20th centuries, many significant steel structures were riveted, such as the Eiffel Tower and automobile skeletons. In the late 20th century, a considerable number of structures were welded, including automobile skeletons. However, some structures needed to be both lighter and stronger, such as airplane fuselages and steel bridges, and these use the screw connection technique.

From the perspective of bearing force, riveting has better shear bearing capacity but poorer tensile bearing capacity. Bolted connections can bear both tension and shear strength. Welding can also bear tension and shear strength but is susceptible to tearing.

Bolted connections are detachable joints, while riveting and welding are not. This makes bolted connections preferable for structures requiring maintenance or part replacement.

In terms of quality assurance, bolted connections are better than riveting, which is better than welding. Welding is the least easy to check the quality, which is why civil aviation aircraft use less welding.

Welding has the greatest impact on material properties, causing significant residual stress and deformation. This is tolerable for bridges and cars but not ideal for aerodynamic shapes such as aircraft surfaces.

From the perspective of cost, bolted connections are more expensive than riveted and welded connections. They also add extra weight, making them less desirable in some applications.

For dissimilar material connections (such as aluminum and titanium, composite and titanium, different series of aluminum alloys), welding is not a good choice. Different materials are commonly joined in airplanes, so the range of applications is seriously affected by welding.

Bolted connections and welding are more likely to be used in civil engineering due to their reliability and cost-effectiveness. Bolts offer the best reliability, especially high-strength bolt friction-type connections, which provide excellent control and lower costs.

Bolted connections are easier to handle in field construction environments. They do not require the heating processes of riveting and welding, making them more controlled. Additionally, bolted connections can be inspected more easily, ensuring higher quality and consistency.

Bolted connections maintain structural integrity under large deformations and dynamic loads, making them suitable for bridges that face various stresses over time. The use of high-strength bolts ensures that the connections remain robust and durable.

PS1: Weld defects are relatively difficult to control, resulting in inconsistent fatigue properties.

PS2: Hot riveting, especially with larger titanium rivets, is also commonly used in airplanes.

Supplementary explanation: Each connection technique is advancing and has given rise to different types.

For example, riveting can be divided into single-sided riveting and self-piercing riveting.

Self-pierce riveting is currently used more in the automotive industry, and the equipment is expensive.

Single-sided riveting is mainly used in situations where the structure is not open and is a low-end application in the packaging industry.

There are more advanced riveting techniques on airplanes that are difficult to localize.

New technologies, such as welding, laser welding, and stirring friction welding, are also being used in the aerospace industry.

Laser welding has a small heat-affected zone and small deformation.

The mechanism of stirring friction welding has not been studied clearly and differs from other welding methods.

Therefore, the previous view of welding being used for automobiles and riveting for airplanes is no longer accurate.

Regarding bridges, I don’t know much, but intuitively speaking, most of these large-scale structures consider cost factors and are not sensitive to weight, and often do not use the latest technological methods.

If we only consider the mechanical properties of the connection method itself, without taking into account the complexity of fabrication and on-site construction, bolted connections and welding are more likely to be used in civil engineering due to their reliability and cost-effectiveness.

Bolts have the best reliability, especially high-strength bolt friction-type connections. In engineering, it is always preferred to use more controllable technology with smaller dispersion, which is conducive to achieving lower costs and higher reliability. Therefore, high-strength bolt friction-type connections are currently an ideal method for such engineering requirements.

Traditional hot riveting requires heating the rivet before installation, which can be cumbersome in the field. The natural cooling process (annealing) is difficult to control, leading to variable strength and reliability. Modern techniques like self-piercing riveting alleviate some of these issues but come with high equipment costs.

In civil engineering, steel structures are generally thicker and larger, and the rivets used are not the same as the cold rivets. They need to be heated first, and then the straight end is beaten into a grip with a riveter.

Here are two more pictures, now you should understand how the rivets of the Waibaidu Bridge and the Eiffel Tower were hit!

Heating > Installation > Forging and forming

In civil engineering, steel structures are generally thicker and larger, and the rivets used are not the same as cold rivets.

They need to be heated first, and then the straight end is beaten into a grip with a riveter.

In this process, the rivet has actually undergone two processes: heat treatment and forging.

Under modern industrial conditions, most of the heat treatment and forging are done in metallurgical and mechanical processing factories.

The starting temperature of the heat treatment and the speed of heating and cooling need to be controlled. The forging is also completed with high-precision dies.

In the field processing environment, it is evident that neither of them can be well-controlled at a low cost.

For most on-site installations of civil engineering, after the rivet is formed, the temperature is lowered in the outdoor natural environment. This process is actually “annealing.

Annealing reduces the strength of steel and increases ductility.

However, it is different from the factory heat treatment in which the steel is heated in an electric furnace with a thermometer, and the temperature is controlled by an automatic control device.

Engineers do not like the uncontrolled annealing that occurs naturally in the field.

The rivets are naturally annealed in the component, and it is impossible to know exactly how much the strength will be reduced and how much residual stress will remain.

Even if it encounters some accidents, such as rain or strong wind, it will even cause “quenching,” which is the opposite of “annealing”.

The final performance of this kind of hot rivet is highly variable.

To ensure the overall reliability of the project, the strength of the rivet will not be fully utilized, which will increase the number of rivets required, resulting in waste and complicated design.

In addition, the construction is cumbersome, and each rivet needs to be heated before use. Now, such hot rivets are not used much in the civil engineering field.

On-site welding is affected by environmental factors, leading to potential defects such as cracks, bubbles, slag inclusion, and incomplete penetration. Quality control is challenging, requiring skilled labor and sophisticated inspection techniques. Welding also introduces significant residual stresses and material deformations, which can compromise structural integrity.

It used to be thought that welding is a very simple thing, but when taking courses in steel structure and reading a little information, the truth was not. The welding process involves too many things, which makes it a very large and complicated matter. The whole process is a large collection of various physical and chemical reactions.

Welding can be a specialized profession, and it is not just welding in a higher vocational or technical school, but also a major in a research university. Many software such as MARC and NASTRAN have developed welding modules to simulate the welding process. Even in the field of civil engineering, there are still a large number of scholars studying the influence of welding on structure, which shows the complexity of welding. Welding will melt the materials in the connection area, and the materials near the connection area will also withstand high temperatures.

Therefore, under the conditions of civil engineering site construction, because the temperature is higher than that of rivets, the residual stress caused by cooling and recrystallization can even reach the yield strength of the material. The heat treatment effect on the surrounding area is uncontrollable, the strength and toughness of the surrounding materials will change. At the same time, the welding process is not only a physical change but also reacts with the surrounding gas and welding flux to produce some residue.

On-site welding is generally manual welding, and it is inevitable that errors will occur, resulting in defects such as undercuts, false welds, and welds. These kinds of faults can have a significant impact on structural rigidity and fatigue performance.

Not all materials can be easily welded, especially in the on-site construction environment. For instance, aluminum has high requirements in the factory, and the scene is even more challenging. Although steel is the most commonly used material in civil engineering, its weldability varies widely. High-strength and alloy steel usually have poor weldability due to different materials, the high melting point of oxides in aluminum, too fast cooling, and reactions during welding.

In the factory environment, materials such as steel can be welded by argon arc welding and other welding techniques that require more equipment. However, the construction site is limited by the simple environment, and arc welding is generally used, making it unrealistic to weld such materials.

Even though the raw materials are high-strength steels or ordinary steels, they are obtained through various cold and hot processing in the factory environment. As a result, it is almost impossible to weld on-site welds with the same properties.

Bolted connections are more manageable on-site due to the elimination of heating processes. However, precise alignment of bolt holes is crucial, and misalignment can lead to additional labor and material costs. High-strength bolt friction-type connections require meticulous surface preparation and controlled tightening to ensure proper frictional force.

Compared to riveting and welding, bolting is much more controlled in the field construction environment without a heating process that could cause uncontrolled heat treatment.

Both components and bolts are produced in a factory environment, so the consistency of the product is quite good, and they can be screwed on-site. Pressure-bearing joints are similar to rivets, but the strength and consistency of the bolt are better than that of a rivet.

Frictional joints are not the same, and there is an involved issue with field construction – frictional control. Friction is influenced by contact surface pressure and surface roughness, but shear-twist bolts, torque wrenches, and surface preparation techniques can now solve this problem.

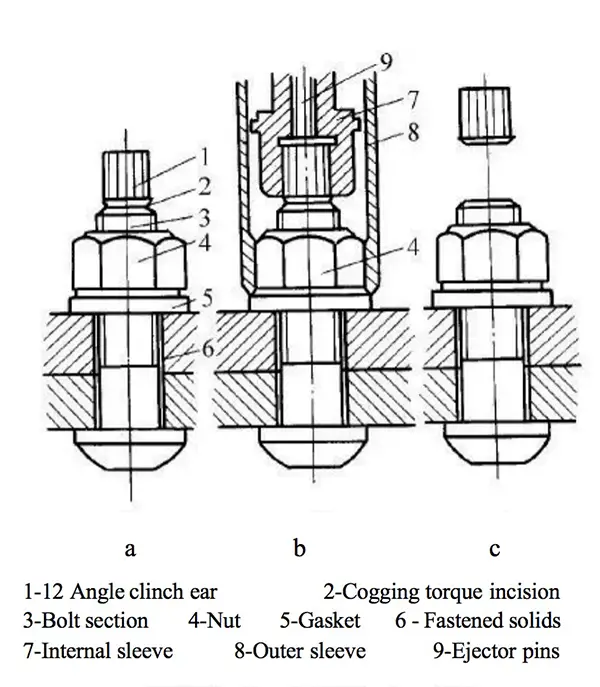

The shear-twist bolt has a rounded head similar to a rivet at one end, without angles, and the bolt is screwed through a spline (or plum head) at the other end. There is a fine neck between the spline and the bolt, and the spline is twisted off when the torque generated by the friction between the component and the bolt reaches the torsional limit of the neck.

The torque wrench can be used to tighten large hexagonal bolts to achieve the same effect as shear-twist bolts. It won’t be too hard to twist because someone has a cold today, nor will it be too exciting because someone is going to the next door tonight (if the bolts are too tight, they will break).

Surface treatment can be done in the factory by sandblasting or applying antirust paint after sandblasting.

Using the friction-type connection, the force transfer between members is through friction, so the connection performance is basically equal to the member itself. It is most in line with the design concept, and strength, stiffness, and fatigue performance are guaranteed.

Diagram of how to use the wrench

Do you think I want to cheer for bolt connections? NO!

Anyone who has installed steel structures on site knows how frustrating bolt connection installations can be.

The bolt holes may not match the bolt for various reasons (manufacturing error, welding deformation, and force deformation…), and it is not uncommon for the bolts to be off by one millimeter.

Reinhardt’s sledgehammer is used to drive the shear pin into the hole and make the hole match.

However, the two components did not fit together, and the bolts could not be tightened.

On-site drilling and correction may weaken the component too much.

Sometimes repair welding or steel sleeve repair is required, which is very troublesome.

In many cases, connecting plates cannot be directly connected between components, and don’t forget to cut off the spline that has been twisted off the bolts.

All of this adds up to a significant increase in material usage.

Bolts are more expensive than ordinary Q345\Q235 by weight, so the price of bolted connections is too high.

There is no such trouble in welding, and it can be welded directly without too much difference in position.

Another advantage of welding is that it is fast.

At the same time, the welding torch can not only be used to connect but also to cut, allowing for quick correction of construction errors.

Most of the time, welding can be done directly between members without the need for additional plates and with less material.

The strength of steel that can be welded by arc welding is generally not very high, and the weld strength can be higher than that of the base material.

In addition, the welding area fully encompasses the entire component, leaving sufficient safety margins and reliability.

Therefore, welding is a common method during on-site installation because it is convenient.

However, various methods cannot be applied when it is not possible to obtain the required stable quality in a particular environment at a sufficiently low cost.

The reason for the unstable quality of on-site welding is that the external environment is not controllable, and human operation cannot be reliable.

Therefore, if welding is moved to a factory environment, the results are very different.

Automatic welding machines, closed workshops, and processes such as straightening, grinding, and heat treatment after welding help adjust welding deformation and reduce residual stress.

In addition, large-scale flaw detection equipment can help detect the quality of welds and repair them.

So, the best way to produce some non-standard components in a factory environment is still welding.

Riveting can also be improved by using better technologies, such as the heating process.

In the past, charcoal furnaces were used, but now electric furnaces have appeared that use the principle of eddy current heating to quickly heat the rivet.

Because the rivet is heated and then cooled down, it will put considerable pressure on the plate and can compress the plate.

Moreover, because the rivets themselves are relatively good in toughness, they are sometimes used for structures that are subjected to dynamic loads. It is still necessary to continue to use rivets to repair some old steel bridges.

For example, the picture below is selected from the Guangzhou Daily’s news about repairing Haizhu Bridge.

Due to the bulky nature of civil engineering, the use of hot rivets is declining in the field. However, cold rivets (such as pull rivets) are still useful when connecting light skins and thin plates as they are lighter and use less material than bolts.

Additionally, thin plates are not easy to weld and cold rivets are suitable for connecting different types of materials, particularly for connections requiring less strength. In civil engineering, they are typically used to connect thin-walled steel and profiled steel plates, which are very thin components. A common example is temporary fences on construction sites.

So, which way to connect has to be considered:

Each type of connection has its own scope in the application.

There are still many uses for rivets in the fields like aerospace, but that’s not my area, and it is the time for other aerospace folks to introduce more.

Riveting was commonly used in ship construction prior to World War II but is now obsolete. Despite its obsolescence in the shipbuilding industry, riveted joints are still used in modern aircraft construction, but they are very different from the riveted joints used in pre-World War II ships.

Due to the need to reduce empty weight, the majority of aircraft materials used are aluminum and composites. Aluminum is not easy to weld, while composites cannot be welded. Considering that the aircraft must also be waterproof, riveting is the best option for aircraft construction.

Bolted connections are mostly used in inland construction (buildings, bridges, cranes, and deck-mounted facilities on ships/ocean platforms). Bolted structures are easy to remove but are not watertight, and the bolts themselves are prone to rust (water can build up in the grooves of the bolts).

Welding is essentially the only method of joining components used in the marine industry today (completely replacing riveting), and is also used in land-based construction. Compared with bolted connections, welding has the advantage of impermeability. Compared with riveting, welding has the advantage of fast speed, and the quality of contemporary welding technology is more reliable. The disadvantage is that it is not easy to disassemble, and the components must be blown up or cut off when dismantling, which damages the reusability of raw materials.

In addition to the slow construction speed, the riveted hull structure before World War II can be compared to a soda cracker, and the new Titanic built with modern welded technology can be compared to a piece of plasticine.

The key to any large metal structure is actually the connection point of the components!

This is true whether it is a ship, airplane, vehicle, or rocket.

Two connected boards cannot be stronger than a one-time composite board.

Regarding welding: One should not completely rely on the welding results in the factory.

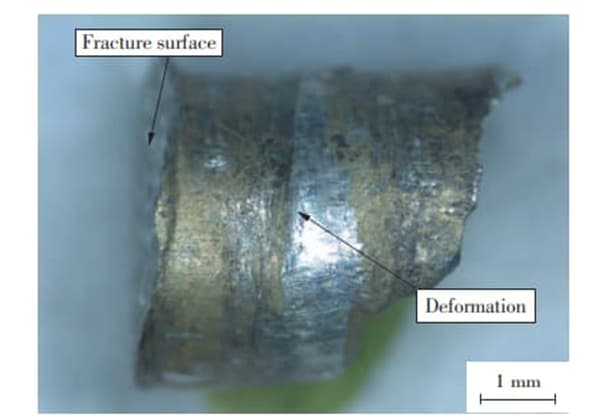

Even if the welding material is stronger than the parent material, the parent material on the boundary line will still be weakened after welding. Remember!

Example

Let me take an actual project as an example (I enjoy learning through practical examples), using a steel structure factory building with a portal steel frame as an example.

Due to the high cost and difficulty of using riveting for ordinary steel structure buildings, let’s discuss welding and bolting.

Our requirements for a plant with a crane are as follows:

Let’s start with the connection between the steel column of the door steel and the foundation.

The column base is divided into rigid connections and hinge joints.

For power equipment, we tend to make a rigid connection because the dynamic load of the crane, especially the horizontal braking load, can easily cause overall instability.

We can weld or bolt the column base, but welding is not very easy to do.

Because the column foot is connected to the foundation under the column, if it is fully welded, it is easy to cause problems such as an insufficient weld seam, and it is difficult to ensure the stability of the column during the welding process.

Are you afraid of looking at the welding rod in your hand while pouting your ass and looking at the dangling pillar?

Secondly, let’s talk about the beam-column joints. This doesn’t matter.

As long as they are rigidly connected, both bolts and welding are acceptable, but the welds are prone to rust, so the steel structure manufacturers have to be reliable.

If the bolt holes are slightly off, you might cry in a minute.

Once again, the wind-resistant pillar must be hinged.

So don’t hesitate, take the bolt and give it a stab.

Lastly, if one day the factory fails (boss don’t hit me), how easy is the bolt connection? Two people can screw three factories in one day and sell them at night.

In summary, if the connection needs to be a hinged connection, use bolts.

If it’s a rigid connection, the choice between welding and bolted connections depends on the situation, the difficulty, and the skill level of the welders.

Bolted connections are easier and require lower skill, but they have higher requirements for the manufacturer in terms of precision and quality control.

Welded connections can save money but have higher requirements for material toughness and skill of the welders.

After finishing the work, the inspection unit will be asked to conduct an inspection, but the manufacturer is likely to be unhappy if there are mistakes and may even offer a discount.

However, if you are confident in your bolted connections and think that the government may demolish the land of your factory, you can use the bolt connection to ask for compensation for the factory, and then find a new piece of land to build on.

Opinion A

I just finished evaluating basic research on process equipment and I’ll share my thoughts.

The biggest problem with both riveting and bolting is that they conflict with the larger goal of weight reduction.

Bolts also have a problem with slipping wires and loosening.

Both riveting and bolting have the advantage of simple principles and proven technology.

There are many types of welding, including friction welding, stir welding, and laser arc welding.

The advantage of welding is that weight reduction can be achieved.

The disadvantage is that some metal materials have poor weldability and are prone to cracking and deformation.

Welding of the same material and different materials requires different welding techniques.

In addition to the process, the manufacturing of automated welding equipment is also difficult.

Opinion B

Welding

Advantages: Suitable for various shapes, saves steel, can be automated, and has high production efficiency.

Disadvantage: Quality is strongly influenced by welding consumables and handling.

Riveting

Advantages: Reliable force transmission connection, toughness, good plasticity, quality is easy to check, commonly used in structures subject to dynamic load.

Disadvantages: Scrap steel and extra work involved.

Bolts are divided into common bolts and high-strength bolts.

Common bolts are easy to handle and should not shear.

High-strength bolts contain the advantages of both ordinary bolts and riveted joints and can now be used instead of riveted joints.

Opinion C

Riveted parts with defects can be easily observed, making it useful in aerospace, shipbuilding, bridges, and other fields.

Welding has high efficiency and strength, making it widely used in machinery, equipment, and automobile manufacturing.

Bolt connections are convenient for disassembly, making them mainly used in the assembly process. For example, welding in airplane windows is troublesome for maintenance, and welding during flight is risky.

Riveting can make defects found during maintenance easy to repair. For example, riveting metal structural parts of a car chassis can compromise production efficiency and strength.

In the National Stadium (Bird’s Nest) project, welding all parts creates concentrated stress in certain areas and makes construction inconvenient due to large amounts of welding in high altitude locations. The most reliable solution is to make “branches” in the factory and assemble them on-site.

A riveting teacher repaired a riveted bridge built by the Japanese by heating the rivets with gas welding, then smashing them with a sledgehammer when they were cold.

Repairing a cracked weld inside a bridge is difficult as the entire bridge cannot be torn down and re-welded.

Opinion D

The response provided only addresses two points, while the advantages of riveting are not clear.

Bolting offers good toughness and ductility in both the connecting plate and bolts.

It maintains its bearing capacity even under large deformations and has strong seismic resistance.

It is easy to observe when the node load is exceeded.

The weld’s toughness is not as good, especially at low temperatures, which makes it prone to brittle damage.

During construction, bolting construction may not be as convenient as welding, but the quality of construction is easy to control.

Welding, especially field welding, can produce defects such as cracks, bubbles, slag, welding leakage, unmelted and penetration welding.

It has high requirements for welding personnel and is difficult to observe the construction quality.

The technical content of common ultrasonic nondestructive testing is higher than high-strength bolt torque testing, and has higher equipment and labor costs.

Opinion E

Based on my own intuition, let me discuss some concepts.

The riveting process is the simplest. The rivet itself is a casting, and the riveting can be achieved by only drilling holes in the object. The disadvantage is that the rivet can be deformed and collapsed if given a large enough longitudinal impact.

The screw process is more complicated because not all screws are self-worked. The thread of the screw itself needs to be made by a lathe, and the hole on the joint also needs a machine tool to engrave the negative pattern. Compared to riveting, screws are stronger when facing direct impact. However, screws may become loose over time if the joint is subjected to prolonged reciprocating vibration, and the threaded surface of the screw is particularly prone to rust.

The welding process is the most complex. In terms of advantages, welding not only splices but also fuses the materials. Therefore, welding should be better than the previous two types in terms of strength, water tightness, air tightness, and electrical conductivity.

Opinion F

Disadvantages of welding:

Deformation can be severe, as the high temperature of welding leads to stress concentration at the weld. Therefore, many high-precision, high-requirement surface connections use threads and adhesive bonding.

It is difficult to inspect. After welding, special testing equipment is needed to detect any defects, which can increase costs.

Site constraints can also be an issue.

It is difficult to disassemble. If a welding mistake is made, the joint must be cut and re-welded.

It has good connection performance and is practical for welding large equipment with varying shapes and sizes of materials.

It has good rigidity, overall performance, and sealing.

Opinion G

Bolts can be easily removed, but they take up space and add weight, so they are used sparingly if they don’t need to be removed. Welding requires equipment and working hours, and not all materials can be welded. Riveting is becoming less common.

Opinion H

Stationary objects, such as bridges, towers, and construction screws, are commonly riveted or welded, while moving objects or parts are welded or riveted together due to the fact that movement can loosen screws. It is not feasible to check every screw before every flight.

Welding is the most stable option because both riveted and screwed joints connect two parts by friction, which is unsuitable if there is a force in the direction of translation between the two parts. Welding fuses two components into a single unit.

If there is a force in the direction of translation between two parts, it is possible to consider fixing them with screws if they are backed by each other. For example, if one part has grooves and the other part has convex rails, they can be fixed with screws if they match each other. The principle is to convert the frictional force of translation into pressure against the mount, improving the bearing force and stability greatly.

Opinion I

Riveted joints are a broad category, and bolts are one of the most common types. Bolting or high-strength riveting can provide greater strength than welding, but the downside is the higher cost. Airplanes use riveted links that are stronger and lighter than regular screw links, such as bom screw and huck screw, etc. Since airplanes require high safety standards, they cannot be welded and must use riveting. High-speed trains do not require such high standards, so they typically use welding. Cars have even lower standards and can use welding, although some car manufacturers like Land Rover have made cars with full bodies of aluminum and riveted like airplanes, but they are extremely expensive.

Bridges are not my specialty, but for some special requirements, such as the need to keep the bridge lightweight while using high-strength steel, welding may not be possible due to the poor welding performance of high-strength steel. Additionally, there may be corrosion resistance requirements near the seashore, and since corrosion-resistant steel is also difficult to weld, riveting is often used to ensure safety.

In recent years, welding technology has seen significant advancements that address some of its traditional drawbacks:

Maintenance and repair considerations also play a critical role in the selection of connection methods:

The field of structural connections is continually evolving, with ongoing research and development aimed at improving the strength, durability, and efficiency of various methods:

The selection of riveted, bolted, or welded connections in structural engineering is a complex decision influenced by mechanical properties, construction conditions, quality control, maintenance requirements, and cost. While each method has its advantages and disadvantages, advancements in technology and materials are continually enhancing their applicability and performance. For large-scale structures like bridges, bolted connections offer a reliable and maintainable solution, balancing the needs for strength, durability, and ease of inspection. As the industry evolves, hybrid and innovative techniques will further optimize the efficiency and effectiveness of structural connections, ensuring safer and more resilient constructions.