Have you ever wondered about the difference between iron and steel? In this blog post, we’ll dive into the fascinating world of metallurgy to unravel the mystery. Join us as we explore the unique properties and applications of these essential materials, guided by the insights of an experienced mechanical engineer. Get ready to discover the science behind the metals that shape our world!

Do you ever wonder about the difference between iron and steel? If so, I will provide a detailed explanation.

To understand the difference, it’s important to note that iron is a chemical element, while steel is an alloy made from a combination of elements, including iron and carbon.

Are you still feeling confused?

It’s true that elements alone cannot create things. In reality, the iron that is commonly used is actually an alloy, specifically a ferrocarbon alloy made up of iron and carbon.

The difference between iron and steel lies in their carbon content.

Iron can be divided into two types: pig iron and wrought iron, which are distinguished by their carbon content. The table below provides a comparison of their differences.

Iron and steel carbon content table

| Name | Wrought iron | Steel | Pig iron |

| Carbon content | <0.02% | 0.02%-2.11% | 2.11%-4.3% |

Iron with a carbon content less than 0.02% is referred to as wrought iron, while iron with a carbon content between 2.11% to 4.3% is called pig iron. Steel falls in between these two categories.

The carbon content impacts the performance of iron. The higher the carbon content, the harder the iron will be, but it will also become more brittle. On the other hand, iron with a lower carbon content will be softer and have better ductility.

Related reading: Pig Iron vs Wrought Iron

Wrought iron is a type of pure iron that is refined from pig iron. It has a carbon content of less than 0.02% and is also known as wrought iron or pure iron.

Wrought iron is soft, pliable, and ductile, making it possible to draw it into wire with low strength and hardness. Additionally, it is easy to forge and weld.

Wrought iron has several uses due to its properties. For example, it has high magnetic permeability, making it a suitable material for electromagnetic applications, including various iron cores.

Additionally, wrought iron is also used as a deep drawing material as it can be molded into complex shapes, as seen in many beautiful handicrafts.

Pig iron, on the other hand, is hard, durable, and has good casting properties, but it is brittle and cannot be forged.

Depending on the form of carbon in pig iron, it can be further divided into white iron, gray iron, and ball cast iron.

White iron is a type of pig iron in which carbon mainly exists in the form of iron carbide. Its section is white in color. This type of pig iron is hard and brittle and is commonly used as a raw material for steelmaking.

When carbon exists in the form of flake graphite, the fracture appears gray, and this type of pig iron is known as cast pig iron.

Due to the softness and lubricating properties of graphite, cast pig iron has good cutting and wear resistance, as well as casting properties. However, it lacks sufficient tensile strength, so it cannot be forged or rolled and is only suitable for manufacturing items such as machine tool beds and iron pipes.

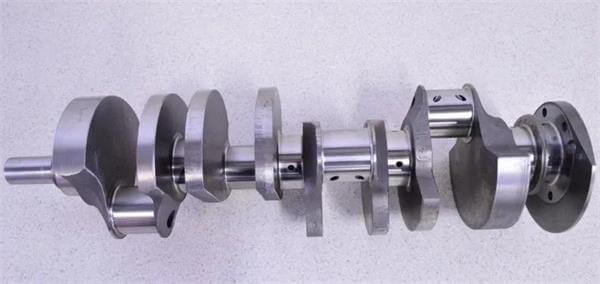

When carbon exists in the form of spherical graphite, it has significantly improved mechanical properties compared to gray iron and is comparable to steel.

Ball cast iron has excellent casting, cutting, and wear resistance properties, as well as some elasticity. It is widely used to make crankshafts, gears, pistons, and other advanced castings, as well as various mechanical parts.

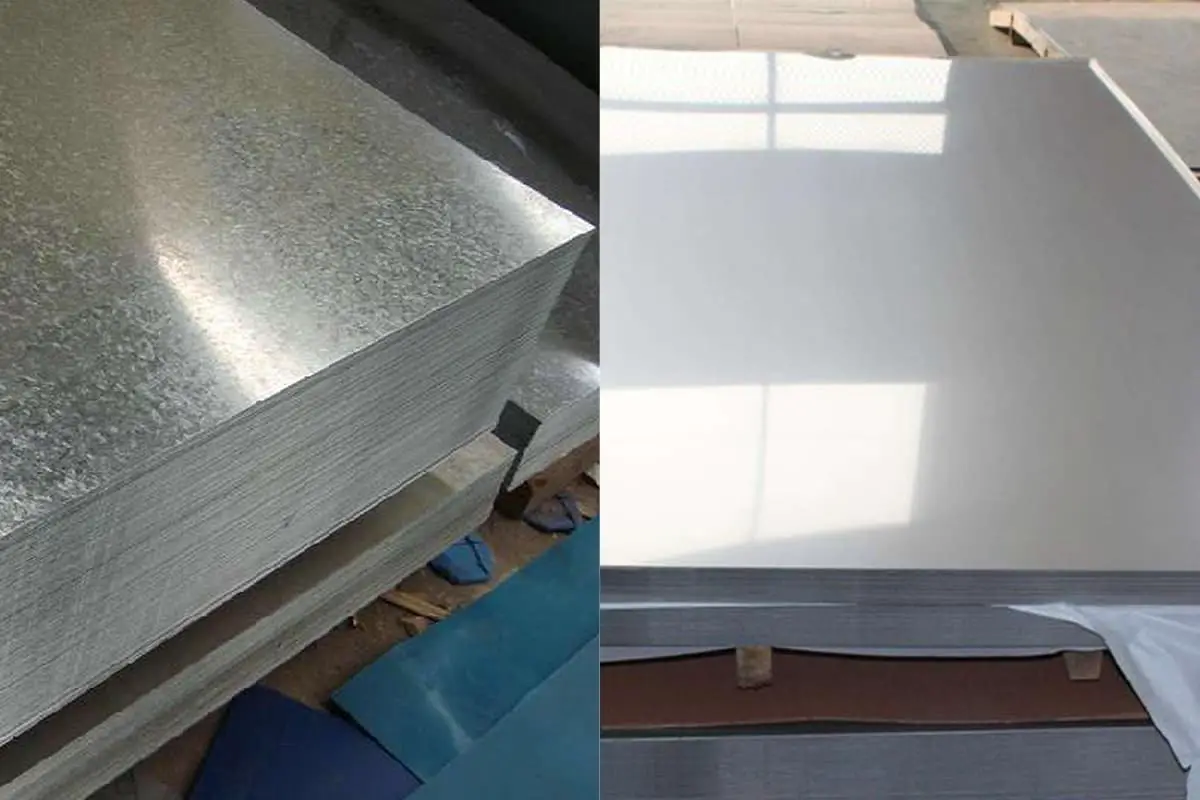

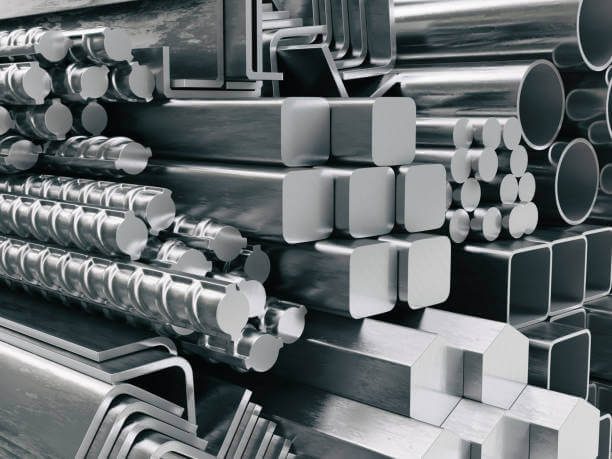

Steel is the most commonly used form in our daily life. Steel is an alloy that falls between pig iron and wrought iron and is commonly referred to as carbon steel.

Carbon steel not only has good plasticity, but also possesses exceptional physical and chemical properties, such as high strength, good toughness, high temperature resistance, corrosion resistance, easy processing, impact resistance, and ease of refining. These properties make carbon steel widely used.

Based on the carbon content, carbon steel can be further divided into low carbon steel, medium carbon steel, and high carbon steel.

Related reading: Types of Steel

As the carbon content increases, the hardness of carbon steel also increases, while its toughness decreases.

Steel is produced from pig iron by a steelmaking plant through high-temperature calcination and other processes. The carbon and oxygen in the steel react to produce carbon dioxide, reducing the carbon content in the iron and transforming it into steel.

To meet a wider range of needs and improve the performance of steel, alloy elements such as chrome, manganese, and nickel are added to carbon steel during the smelting process, resulting in what is known as alloy steel. This includes chrome steel, manganese steel, chrome manganese steel, and chrome nickel steel.