Have you ever wondered what those numbers on sheet metal mean? In this article, we’ll dive into the world of sheet metal gauge and demystify this essential aspect of metalworking. As an experienced mechanical engineer, I’ll share my insights on how gauge affects your projects and provide a comprehensive guide to help you make informed decisions when selecting materials. Get ready to learn everything you need to know about sheet metal gauge!

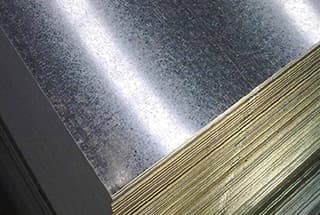

Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the thickness of metal sheets, plates, and wire. This measurement is crucial for determining material properties such as strength, formability, and weight, which directly influence its suitability for various industrial applications.

In sheet metal fabrication, gauge thickness inversely correlates with the gauge number; as the gauge number increases, the material thickness decreases. For instance, 14-gauge steel is thicker than 20-gauge steel. This counterintuitive relationship stems from historical manufacturing processes and has persisted in modern metalworking practices.

Understanding sheet metal gauge is essential for engineers, fabricators, and designers as it impacts several critical factors:

While gauge remains a common industry term, many modern manufacturers are transitioning to direct decimal measurements (in inches or millimeters) for more precise specifications. This shift aligns with global standardization efforts and enhances accuracy in computer-aided design (CAD) and computer-numerical control (CNC) manufacturing processes.

Gauge numbers inversely correlate with sheet metal thickness: as the gauge number increases, the metal thickness decreases. For instance, 8-gauge sheet metal is substantially thicker than 16-gauge. It’s crucial to recognize that gauge measurements are not universally standardized across different metal types. This means that 16-gauge steel, aluminum, and brass will each have distinct thicknesses despite sharing the same gauge number.

Key Points About Sheet Metal Gauges:

For precise material specifications, always refer to a comprehensive sheet metal gauge table that includes decimal and metric equivalents for various metals. This ensures accurate material selection and helps prevent costly errors in design and fabrication processes.

This comprehensive chart illustrates the correlation between gauge numbers and the corresponding thickness of steel sheets in both imperial (inches) and metric (millimeters) units.

The gauge system, widely used in metal fabrication, provides a standardized method for specifying sheet metal thickness.

For example, 3-gauge steel, commonly used in heavy-duty industrial applications, has a substantial thickness of 0.2391 inches (6.07 mm). In contrast, 16-gauge steel, frequently employed in automotive body panels and HVAC ductwork, measures 0.0598 inches (1.52 mm) thick.

| GAUGE (Ga.) | Steel | Galvanized Steel | Stainless Steel | Aluminum | Electrical Steel |

|---|---|---|---|---|---|

| in (mm) | in (mm) | in (mm) | in (mm) | in (mm) | |

| 3 | 0.2391 (6.07) | – | – | – | – |

| 4 | 0.2242 (5.69) | – | – | – | – |

| 6 | 0.1943 (4.94) | – | – | 0.162 (4.1) | – |

| 7 | 0.1793 (4.55) | – | 0.1875 (4.76) | 0.1443 (3.67) | – |

| 8 | 0.1644 (4.18) | 0.1681 (4.27) | 0.1719 (4.37) | 0.1285 (3.26) | – |

| 9 | 0.1495 (3.80) | 0.1532 (3.89) | 0.1563 (3.97) | 0.1144 (2.91) | – |

| 10 | 0.1345 (3.42) | 0.1382 (3.51) | 0.1406 (3.57) | 0.1019 (2.59) | – |

| 11 | 0.1196 (3.04) | 0.1233 (3.13) | 0.1250 (3.18) | 0.0907 (2.30) | – |

| 12 | 0.1046 (2.66) | 0.1084 (2.75) | 0.1094 (2.78) | 0.0808 (2.05) | – |

| 13 | 0.0897 (2.28) | 0.0934 (2.37) | 0.094 (2.4) | 0.072 (1.8) | – |

| 14 | 0.0747 (1.90) | 0.0785 (1.99) | 0.0781 (1.98) | 0.0641 (1.63) | – |

| 15 | 0.0673 (1.71) | 0.0710 (1.80) | 0.07 (1.8) | 0.057 (1.4) | – |

| 16 | 0.0598 (1.52) | 0.0635 (1.61) | 0.0625 (1.59) | 0.0508 (1.29) | – |

| 17 | 0.0538 (1.37) | 0.0575 (1.46) | 0.056 (1.4) | 0.045 (1.1) | – |

| 18 | 0.0478 (1.21) | 0.0516 (1.31) | 0.0500 (1.27) | 0.0403 (1.02) | – |

| 19 | 0.0418 (1.06) | 0.0456 (1.16) | 0.044 (1.1) | 0.036 (0.91) | – |

| 20 | 0.0359 (0.91) | 0.0396 (1.01) | 0.0375 (0.95) | 0.0320 (0.81) | – |

| 21 | 0.0329 (0.84) | 0.0366 (0.93) | 0.034 (0.86) | 0.028 (0.71) | – |

| 22 | 0.0299 (0.76) | 0.0336 (0.85) | 0.031 (0.79) | 0.025 (0.64) | 0.0310 (0.787) |

| 23 | 0.0269 (0.68) | 0.0306 (0.78) | 0.028 (0.71) | 0.023 (0.58) | 0.0280 (0.711) |

| 24 | 0.0239 (0.61) | 0.0276 (0.70) | 0.025 (0.64) | 0.02 (0.51) | 0.0250 (0.64) |

| 25 | 0.0209 (0.53) | 0.0247 (0.63) | 0.022 (0.56) | 0.018 (0.46) | 0.0197 (0.50) |

| 26 | 0.0179 (0.45) | 0.0217 (0.55) | 0.019 (0.48) | 0.017 (0.43) | 0.0185 (0.47) |

| 27 | 0.0164 (0.42) | 0.0202 (0.51) | 0.017 (0.43) | 0.014 (0.36) | – |

| 28 | 0.0149 (0.38) | 0.0187 (0.47) | 0.016 (0.41) | 0.0126 (0.32) | – |

| 29 | 0.0135 (0.34) | 0.0172 (0.44) | 0.014 (0.36) | 0.0113 (0.29) | 0.0140 (0.35) |

| 30 | 0.0120 (0.30) | 0.0157 (0.40) | 0.013 (0.33) | 0.0100 (0.25) | 0.011 (0.27) |

| 31 | 0.0105 (0.27) | 0.0142 (0.36) | 0.011 (0.28) | 0.0089 (0.23) | 0.0100 (0.25) |

| 32 | 0.0097 (0.25) | – | – | – | – |

| 33 | 0.0090 (0.23) | – | – | – | 0.009 (0.23) |

| 34 | 0.0082 (0.21) | – | – | – | – |

| 35 | 0.0075 (0.19) | – | – | – | – |

| 36 | 0.0067 (0.17) | – | – | – | 0.007 (0.18) |

| 37 | 0.0064 (0.16) | – | – | – | – |

| 38 | 0.0060 (0.15) | – | – | – | 0.005 (0.127) |

Unit: inch, mm

| Gauge No. | Thickness (in. ) | Thickness ( mm) |

| 7/0 | 0 | — |

| 6/0 | 0 | — |

| 5/0 | 0 | — |

| 4/0 | 0 | — |

| 3/0 | 0 | — |

| 2/0 | 0 | — |

| 1/0 | 0 | — |

| 1 | — | |

| 2 | — | |

| 3 | 0.2391 | 6.0731 |

| 4 | 0.2242 | 5.6947 |

| 5 | 0.2092 | 5.3137 |

| 6 | 0.1943 | 4.9352 |

| 7 | 0.1793 | 4.5542 |

| 8 | 0.1644 | 4.1758 |

| 9 | 0.1495 | 3.7973 |

| 10 | 0.1345 | 3.4163 |

| 11 | 0.1196 | 3.0378 |

| 12 | 0.1046 | 2.6568 |

| 13 | 0.0897 | 2.2784 |

| 14 | 0.0747 | 1.8974 |

| 15 | 0.0673 | 1.7094 |

| 16 | 0.0598 | 1.5189 |

| 17 | 0.0538 | 1.3665 |

| 18 | 0.0478 | 1.2141 |

| 19 | 0.0418 | 1.0617 |

| 20 | 0.0359 | 0.9119 |

| 21 | 0.0329 | 0.8357 |

| 22 | 0.0299 | 0.7595 |

| 23 | 0.0269 | 0.6833 |

| 24 | 0.0239 | 0.6071 |

| 25 | 0.0209 | 0.5309 |

| 26 | 0.0179 | 0.4547 |

| 27 | 0.0164 | 0.4166 |

| 28 | 0.0149 | 0.3785 |

| 29 | 0.0135 | 0.3429 |

| 30 | 0.012 | 0.3048 |

| 31 | 0.0105 | 0.2667 |

| 32 | 0.0097 | 0.2464 |

| 33 | 0.009 | 0.2286 |

| 34 | 0.0082 | 0.2083 |

| 35 | 0.0075 | 0.1905 |

| 36 | 0.0067 | 0.1702 |

| 37 | 0.0064 | 0.1626 |

| 38 | 0.006 | 0.1524 |

| 39 | — | |

| 40 | — |

Galvanized steel thickness varies slightly from standard steel. For example, 10-gauge galvanized steel is 0.1382 inches (3.51 mm) thick.

| Gauge No. | Thickness (in. mm) | ||

|---|---|---|---|

| 7/0 | (0000000) | — | |

| 6/0 | (000000) | — | |

| 5/0 | (00000) | — | |

| 4/0 | (0000) | — | |

| 3/0 | (000) | — | |

| 2/0 | (00) | — | |

| 1/0 | (0) | — | |

| 1 | — | ||

| 2 | — | ||

| 3 | — | ||

| 4 | — | ||

| 5 | — | ||

| 6 | — | ||

| 7 | — | ||

| 8 | 0.1681 | 4.2697 | |

| 9 | 0.1532 | 3.8913 | |

| 10 | 0.1382 | 3.5103 | |

| 11 | 0.1233 | 3.1318 | |

| 12 | 0.1084 | 2.7534 | |

| 13 | 0.0934 | 2.3724 | |

| 14 | 0.0785 | 1.9939 | |

| 15 | 0.071 | 1.8034 | |

| 16 | 0.0635 | 1.6129 | |

| 17 | 0.0575 | 1.4605 | |

| 18 | 0.0516 | 1.3106 | |

| 19 | 0.0456 | 1.1582 | |

| 20 | 0.0396 | 1.0058 | |

| 21 | 0.0366 | 0.9296 | |

| 22 | 0.0336 | 0.8534 | |

| 23 | 0.0306 | 0.7772 | |

| 24 | 0.0276 | 0.701 | |

| 25 | 0.0247 | 0.6274 | |

| 26 | 0.0217 | 0.5512 | |

| 27 | 0.0202 | 0.5131 | |

| 28 | 0.0187 | 0.475 | |

| 29 | 0.0172 | 0.4369 | |

| 30 | 0.0157 | 0.3988 | |

| 31 | 0.0142 | 0.3607 | |

| 32 | 0.0134 | 0.3404 | |

| 33 | — | ||

| 34 | — | ||

| 35 | — | ||

| 36 | — | ||

| 37 | — | ||

| 38 | — | ||

| 39 | — | ||

| 40 | — | ||

Stainless steel follows a similar gauge system but has unique thickness values. For example, 10-gauge stainless steel is 0.1406 inches (3.57 mm) thick.

| Gauge No. | Thickness (in. mm) | ||

|---|---|---|---|

| 7/0 | (0000000) | 0.5 | 12.7 |

| 6/0 | (000000) | 0.46875 | 11.90625 |

| 5/0 | (00000) | 0.43775 | 11.11885 |

| 4/0 | (0000) | 0.40625 | 10.31875 |

| 3/0 | (000) | 0.375 | 9.525 |

| 2/0 | (00) | 0.34375 | 8.73125 |

| 1/0 | (0) | 0.3125 | 7.9375 |

| 1 | 0.28125 | 7.14375 | |

| 2 | 0.26563 | 6.74688 | |

| 3 | 0.25 | 6.35 | |

| 4 | 0.23438 | 5.95313 | |

| 5 | 0.21875 | 5.55625 | |

| 6 | 0.20313 | 5.15938 | |

| 7 | 0.1875 | 4.7625 | |

| 8 | 0.17188 | 4.36563 | |

| 9 | 0.15625 | 3.96875 | |

| 10 | 0.14063 | 3.57188 | |

| 11 | 0.125 | 3.175 | |

| 12 | 0.10938 | 2.77813 | |

| 13 | 0.09375 | 2.38125 | |

| 14 | 0.07813 | 1.98438 | |

| 15 | 0.07031 | 1.78594 | |

| 16 | 0.0625 | 1.5875 | |

| 17 | 0.05625 | 1.42875 | |

| 18 | 0.05 | 1.27 | |

| 19 | 0.04375 | 1.11125 | |

| 20 | 0.0375 | 0.9525 | |

| 21 | 0.03438 | 0.87313 | |

| 22 | 0.03125 | 0.79375 | |

| 23 | 0.02813 | 0.71438 | |

| 24 | 0.025 | 0.635 | |

| 25 | 0.02188 | 0.55563 | |

| 26 | 0.01875 | 0.47625 | |

| 27 | 0.01719 | 0.43656 | |

| 28 | 0.01563 | 0.39688 | |

| 29 | 0.01406 | 0.35719 | |

| 30 | 0.0125 | 0.3175 | |

| 31 | 0.01094 | 0.27781 | |

| 32 | 0.01016 | 0.25797 | |

| 33 | 0.00938 | 0.23813 | |

| 34 | 0.00859 | 0.21828 | |

| 35 | 0.00781 | 0.19844 | |

| 36 | 0.00703 | 0.17859 | |

| 37 | 0.00664 | 0.16867 | |

| 38 | 0.00625 | 0.15875 | |

| 39 | — | ||

| 40 | — | ||

Aluminum’s gauge thicknesses differ significantly from steel and stainless steel. For example, 10-gauge aluminum is 0.1019 inches (2.59 mm) thick.

| Gauge No. | Thickness (in. mm) | ||

|---|---|---|---|

| 7/0 | (0000000) | 0.65135 | 16.54439 |

| 6/0 | (000000) | 0.58005 | 14.73324 |

| 5/0 | (00000) | 0.51655 | 13.12034 |

| 4/0 | (0000) | 0.46 | 11.684 |

| 3/0 | (000) | 0.40964 | 10.40486 |

| 2/0 | (00) | 0.3648 | 9.26592 |

| 1/0 | (0) | 0.32486 | 8.25144 |

| 1 | 0.2893 | 7.34822 | |

| 2 | 0.25763 | 6.5438 | |

| 3 | 0.22942 | 5.82727 | |

| 4 | 0.20431 | 5.18947 | |

| 5 | 0.18194 | 4.62128 | |

| 6 | 0.16202 | 4.11531 | |

| 7 | 0.14428 | 3.66471 | |

| 8 | 0.12849 | 3.26365 | |

| 9 | 0.11443 | 2.90652 | |

| 10 | 0.10189 | 2.58801 | |

| 11 | 0.09074 | 2.30485 | |

| 12 | 0.08081 | 2.05252 | |

| 13 | 0.07196 | 1.82781 | |

| 14 | 0.06408 | 1.62773 | |

| 15 | 0.05707 | 1.44953 | |

| 16 | 0.05082 | 1.29083 | |

| 17 | 0.04526 | 1.14953 | |

| 18 | 0.0403 | 1.0237 | |

| 19 | 0.03589 | 0.91161 | |

| 20 | 0.03196 | 0.81181 | |

| 21 | 0.02846 | 0.72293 | |

| 22 | 0.02535 | 0.64381 | |

| 23 | 0.02257 | 0.5733 | |

| 24 | 0.0201 | 0.51054 | |

| 25 | 0.0179 | 0.45466 | |

| 26 | 0.01594 | 0.40488 | |

| 27 | 0.0142 | 0.36055 | |

| 28 | 0.01264 | 0.32108 | |

| 29 | 0.01126 | 0.28593 | |

| 30 | 0.01003 | 0.25464 | |

| 31 | 0.00893 | 0.22677 | |

| 32 | 0.00795 | 0.20193 | |

| 33 | 0.00708 | 0.17983 | |

| 34 | 0.0063 | 0.16012 | |

| 35 | 0.00561 | 0.1426 | |

| 36 | 0.005 | 0.127 | |

| 37 | 0.00445 | 0.11311 | |

| 38 | 0.00397 | 0.10071 | |

| 39 | 0.00353 | 0.08969 | |

| 40 | 0.00314 | 0.07986 | |

Brass sheets have their own gauge measurements, with 10-gauge brass being 0.1019 inches (2.59 mm) thick.

| Gauge No. | Thickness (in. mm) | ||

|---|---|---|---|

| 7/0 | (0000000) | 0.65135 | 16.54439 |

| 6/0 | (000000) | 0.58005 | 14.73324 |

| 5/0 | (00000) | 0.51655 | 13.12034 |

| 4/0 | (0000) | 0.46 | 11.684 |

| 3/0 | (000) | 0.40964 | 10.40486 |

| 2/0 | (00) | 0.3648 | 9.26592 |

| 1/0 | (0) | 0.32486 | 8.25144 |

| 1 | 0.2893 | 7.34822 | |

| 2 | 0.25763 | 6.5438 | |

| 3 | 0.22942 | 5.82727 | |

| 4 | 0.20431 | 5.18947 | |

| 5 | 0.18194 | 4.62128 | |

| 6 | 0.16202 | 4.11531 | |

| 7 | 0.14428 | 3.66471 | |

| 8 | 0.12849 | 3.26365 | |

| 9 | 0.11443 | 2.90652 | |

| 10 | 0.10189 | 2.58801 | |

| 11 | 0.09074 | 2.30485 | |

| 12 | 0.08081 | 2.05252 | |

| 13 | 0.07196 | 1.82781 | |

| 14 | 0.06408 | 1.62773 | |

| 15 | 0.05707 | 1.44953 | |

| 16 | 0.05082 | 1.29083 | |

| 17 | 0.04526 | 1.14953 | |

| 18 | 0.0403 | 1.0237 | |

| 19 | 0.03589 | 0.91161 | |

| 20 | 0.03196 | 0.81181 | |

| 21 | 0.02846 | 0.72293 | |

| 22 | 0.02535 | 0.64381 | |

| 23 | 0.02257 | 0.5733 | |

| 24 | 0.0201 | 0.51054 | |

| 25 | 0.0179 | 0.45466 | |

| 26 | 0.01594 | 0.40488 | |

| 27 | 0.0142 | 0.36055 | |

| 28 | 0.01264 | 0.32108 | |

| 29 | 0.01126 | 0.28593 | |

| 30 | 0.01003 | 0.25464 | |

| 31 | 0.00893 | 0.22677 | |

| 32 | 0.00795 | 0.20193 | |

| 33 | 0.00708 | 0.17983 | |

| 34 | 0.0063 | 0.16012 | |

| 35 | 0.00561 | 0.1426 | |

| 36 | 0.005 | 0.127 | |

| 37 | 0.00445 | 0.11311 | |

| 38 | 0.00397 | 0.10071 | |

| 39 | 0.00353 | 0.08969 | |

| 40 | 0.00314 | 0.07986 | |

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for accurate material selection and processing. Here’s a comprehensive guide:

When using a gauge chart, always confirm the metal type, applicable standard, and required tolerances for your specific application. For critical components, it’s advisable to specify thickness directly in decimal measurements rather than gauge numbers to avoid potential misinterpretations. Keep in mind that actual material thickness may vary slightly due to manufacturing tolerances, so verifying with a micrometer or caliper is recommended for precision work.

The concept of “gauge” as a thickness measure emerged during the American Industrial Revolution, driven by wire manufacturers’ need to quantify their products. Initially, they employed a gravimetric method, which, while simple, led to complications when customers ordered wire without specifying diameters.

To resolve this issue, wire craftsmen developed a system based on the number of drawing operations performed on the wire. This innovative approach became the foundation of the gauge measurement system. Each drawing process reduced the wire’s diameter, establishing an inverse relationship between the gauge number and wire thickness: higher gauge numbers indicated thinner wires.

Steel mills later adopted a similar principle for rolled plates, finding it more practical to weigh rather than measure thickness directly. They began selling steel plates based on unit area weight, with thinner plates weighing less per square foot. This weight-based approach naturally aligned with the gauge number system used in the wire industry, leading to its adoption for specifying steel plate thickness.

The gauge system’s evolution reflected the industrial landscape of the 18th and 19th centuries, characterized by a lack of standardized practices in the United States. Manufacturers initially developed their own standards, which gradually converged into more consistent industry-wide measures. This process culminated in the establishment of unified standards such as the Standard Wire Gauge (SWG), the Manufacturer’s Standard Gauge (MSG) for steel sheets, and the American Wire Gauge (AWG) for non-ferrous metals.

Wire drawing technology played a crucial role in shaping the gauge system. Craftsmen sought to maximize wire diameter reduction while working within the constraints of material deformation limits. Through iterative process optimization, the wire industry determined the optimal number of drawing passes, resulting in the characteristic exponential decay curve observed in gauge number progressions.

It’s crucial to understand that gauge numbers correspond to different thickness values across various metals. For instance, 21 gauge translates to 0.0329 inches (0.84mm) in standard steel, 0.0366 inches (0.93mm) in galvanized steel, and 0.028 inches (0.71mm) in aluminum. This variation underscores the importance of specifying both gauge number and material type in technical communications and manufacturing processes.

The gauge system, despite its historical roots and some inherent complexities, remains widely used in modern metalworking industries. It serves as a testament to the ingenuity of early industrialists and continues to influence material specification practices in sheet metal fabrication, wire production, and related fields.

Understanding sheet metal gauge is crucial for professionals in metal fabrication and manufacturing. Proper gauge selection directly impacts project success, influencing factors such as material strength, formability, and cost-effectiveness. By leveraging accurate gauge charts and maintaining open communication with suppliers, engineers and fabricators can make informed decisions that optimize material performance and manufacturing efficiency.

Key considerations when working with sheet metal gauges include: