Have you ever wondered what separates a motor controller from a motor driver? Motor controllers manage the speed, direction, and torque of motors, making them essential in electric vehicles and automation. In contrast, motor drivers convert input signals to power the motor. This article dives into their key differences, explaining how each component contributes to efficient motor operation. Explore the distinct roles they play and learn how they work together to enhance performance in various applications.

The motor controller is an integrated circuit that controls the direction, speed, angle, and response time of a motor through active work.

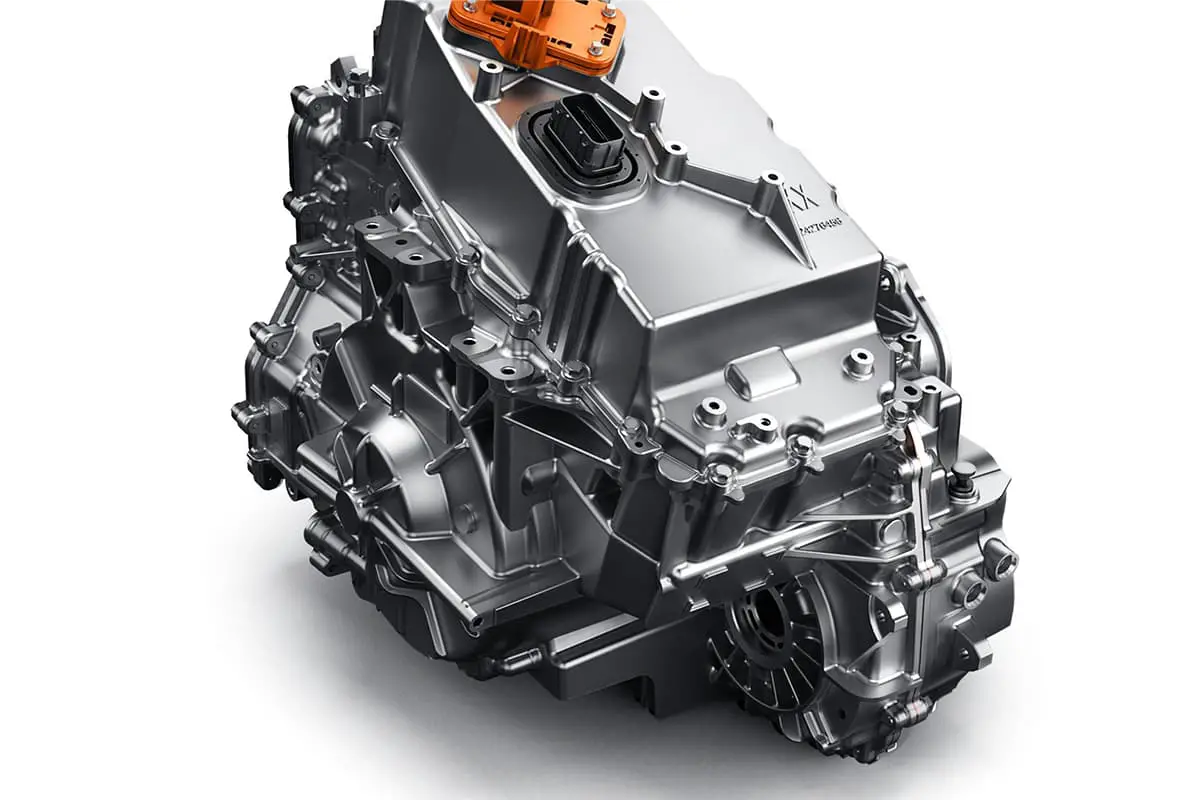

In electric vehicles, the motor controller plays a vital role in converting the electric energy stored in the power battery into the electric energy required to drive the motor, based on the instructions received from the gear, throttle, and brake. This enables the controller to control the driving state of the electric vehicle, including start-up, operation, forward and backward speed, climbing force, and also assist in braking by storing part of the energy in the power battery.

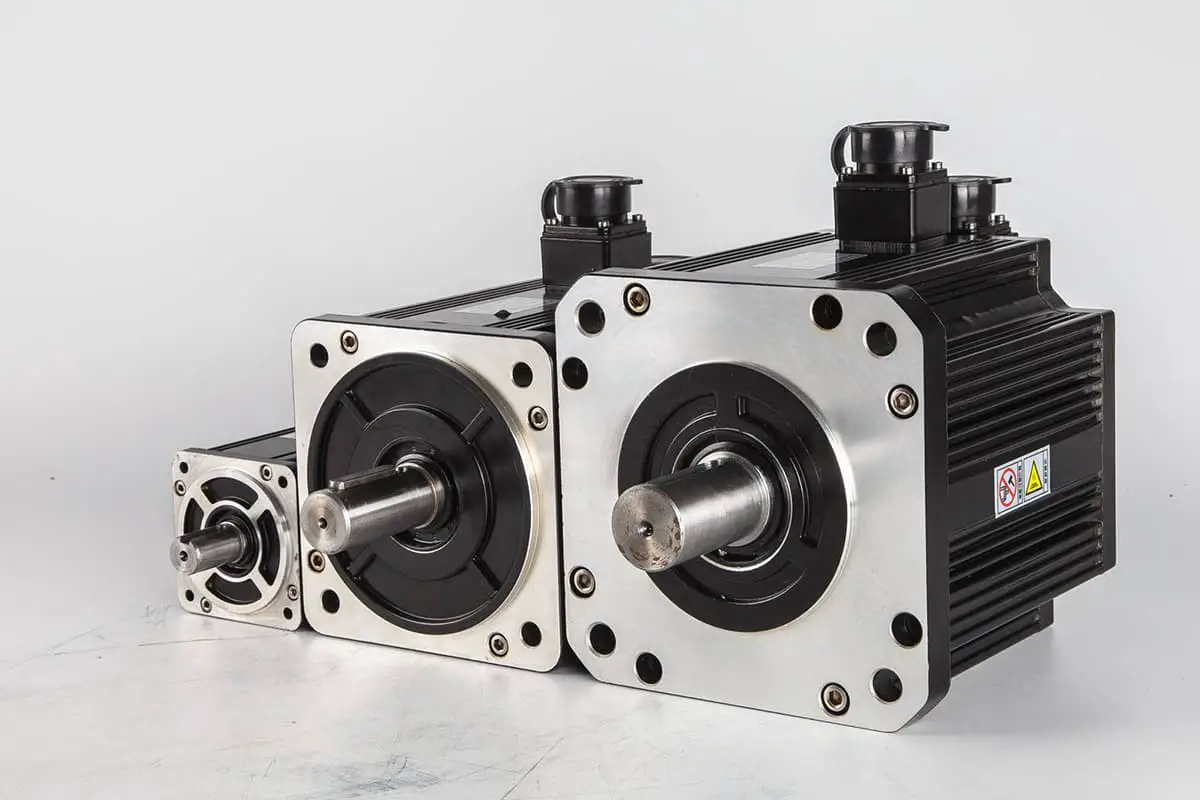

Therefore, the motor controller is considered one of the key components of electric vehicles.

By combining with the stepper motor driver and stepper motor, a CNC programmable stepper motor controller can form an efficient stepper motor control system that can control the time-sharing operation of three stepper motors. This controller adopts computer programming language and offers a variety of instructions, including input, output, and counting. It has the advantage of flexible programming, wide adaptability, and can be used in various control automation fields.

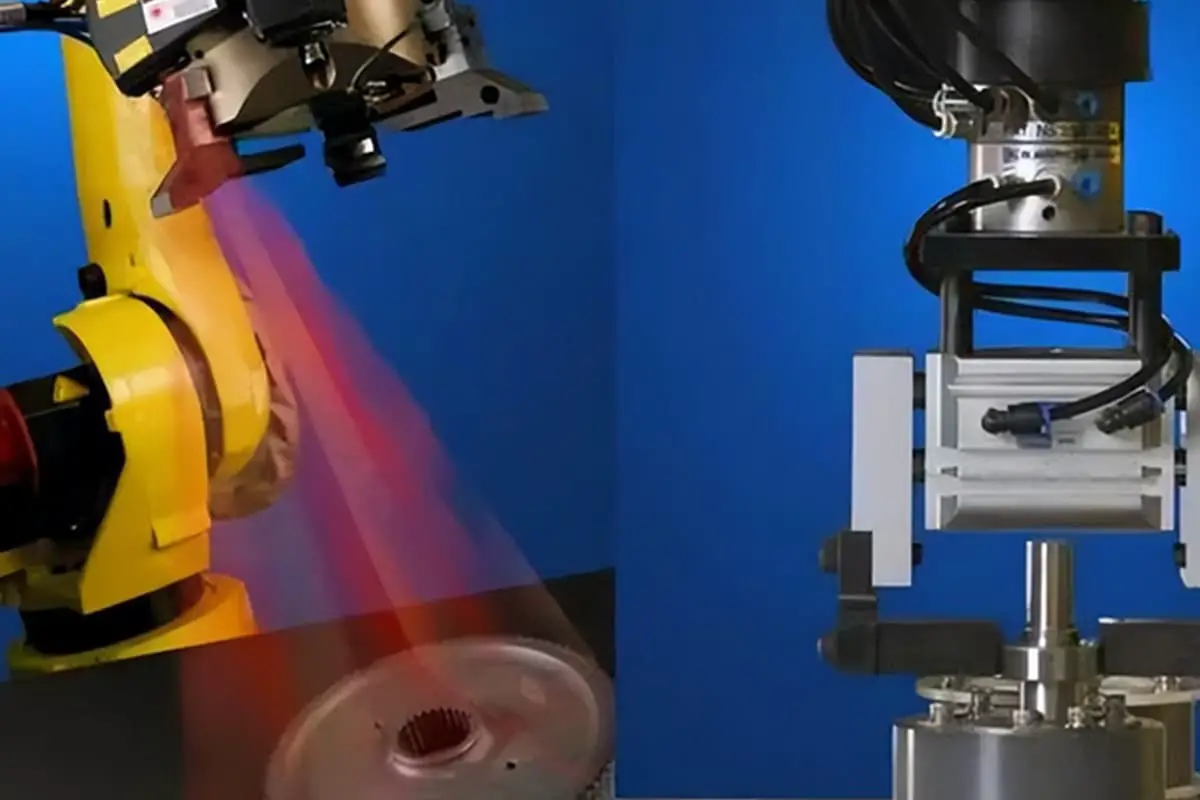

A motor driver and a motor controller are both integral to motor operations but serve different functions. A motor driver is a hardware device or circuit that powers the motor by converting input signals into the necessary voltage and current. In contrast, the motor controller is a more complex device, often including a driver, that manages all aspects of the motor’s operation, such as speed control, direction, and torque regulation. Both are necessary for optimal motor performance.

Controller:

A controller is a master command device that controls the start, speed regulation, braking, and reverse of a motor. It achieves this by altering the wiring of the main circuit or control circuit and changing the resistance value in the circuit based on a predetermined sequence.

Stepper motor driver:

A stepper motor driver is an actuator that converts an electric pulse into angular displacement.

Controller:

A controller is composed of a program counter, instruction register, instruction decoder, timing generator, and operation controller. It serves as the “decision-making body” that issues commands and coordinates the operation of the entire computer system.

Stepper motor driver:

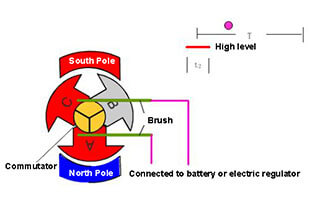

When a stepper motor driver receives a pulse signal, it drives the stepper motor to rotate a fixed angle (known as the “step angle”) in the specified direction. The rotation occurs step by step at a constant angle.

Controller:

An electromagnetic suction cup controller operates using an AC voltage of 380V, which is reduced by a transformer, rectified by a rectifier, and converted into 110V DC before entering the suction cup through the control device. This magnetizes the suction cup. During demagnetization, the reverse voltage line is connected, and the controller achieves the demagnetization function.

Stepper motor driver:

The angular displacement of a stepper motor can be accurately controlled by adjusting the number of pulses. This enables precise positioning of the motor. Additionally, the speed and acceleration of the motor rotation can be controlled by adjusting the pulse frequency, thereby achieving speed regulation and precise positioning.