Have you ever considered the hidden dangers lurking in oxygen pipelines? In this article, we dive into the critical process of degreasing oxygen pipelines, essential to prevent explosive hazards. You’ll learn about the importance of oil removal, the steps involved in degreasing, pickling, and passivation, and the safety measures necessary for handling these materials. This guide ensures that your oxygen pipeline operations remain safe and efficient.

Everyone knows that oxygen pipelines must be oil-free and degreased. Today, we will discuss the method of degreasing oxygen pipelines. Degreasing, by definition, is the removal of oil stains from the internal and external surfaces of the pipe.

It is a crucial step in the construction of oxygen pipelines. If there is any oil contamination inside the oxygen pipe, an explosion can easily occur when it comes into contact with pure oxygen.

Oxygen pipelines generally use seamless steel pipes made of 20# steel or stainless steel. For pipes made of stainless steel, only degreasing treatment is needed.

However, for pipes made of 20# steel, not only degreasing but also pickling, neutralization, and passivation treatment are required.

During construction, the degreased pipe ends must be promptly sealed to prevent secondary contamination. Before handing over for use, they must be thoroughly cleaned with oil-free compressed air.

Carbon steel pipes should be degreased before pickling since grease is not soluble in acid. If pickling is done first, it will not remove the oil stains or the rust under the oil stains.

The dip method is commonly used for degreasing and pickling seamless steel pipes during construction. During dipping, the liquid level should be at least 50mm above the external surface of the pipe.

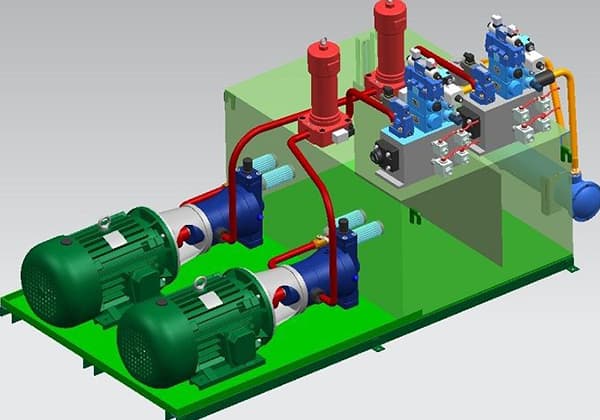

Given that oxygen pipelines undergo degreasing, pickling, and passivation treatment, four tanks are usually prepared based on the actual pipe diameter. These are the degreasing tank, pickling tank, neutralizing tank, and passivation tank.

The process flow of degreasing and pickling for oxygen pipelines is as follows: degreasing → water rinsing → pickling → water rinsing → neutralization → passivation → water rinsing → drying.

The degreasing solution formula is: each liter of solution contains 20g to 30g of sodium hydroxide, 35g to 50g of sodium nitrate, and 3g to 5g of sodium silicate.

The operating process requires: a liquid temperature of 70℃ to 80℃, and a soaking time determined by the amount of oil on the pipe surface, usually between 10 and 40 minutes.

Steam can be used for heating.

The degreased items should be inspected using any of the following methods:

Rinse thoroughly with clean water at a pressure of 0.8MPa.

Pickling uses an acid solution to remove the oxide skin and rust on the surface of the seamless steel pipe.

The oxides of iron (Fe3O4, Fe2O3, FeO, etc.) react with the acid solution to form salts that are soluble in the acid solution and are thus removed. Sulfuric acid and hydrochloric acid are most commonly used for pickling. The sulfuric acid solution formula is: the concentration of sulfuric acid is 5% to 10%.

The operational requirement is: a temperature of 60℃ to 80℃ and a soaking time of 5 to 20 minutes. The hydrochloric acid solution formula is: the concentration of hydrochloric acid is 5% to 20%.

The operational requirement is: a temperature of 20℃ to 50℃ and a soaking time of 5 to 20 minutes.

After the pipe is pickled, check that the surface rust is completely removed and that the metal luster is exposed. It is considered qualified if this is the case.

Rinse thoroughly with clean water at a pressure of 0.8MPa.

The neutralization solution formula is: NH4OH diluted to a pH value of 10 to 11. The operational requirement is: soak at room temperature for 3 minutes.

After pickling, water rinsing, and bleaching, the metal surface is very clean and highly activated, and it is very susceptible to corrosion. Therefore, passivation treatment must be carried out immediately to form a protective film on the cleaned metal surface to slow down corrosion.

The passivation solution formula is: the concentration of NaNO2 is 8% to 10%; the concentration of NH4OH is 2%. The operational requirement is: soak at room temperature for 10 minutes.

Rinse with purified water at a pressure of 0.8MPa until clean.

Drying must be done using clean, oil-free, dry air or nitrogen.

Wipe and inspect with white filter paper. If there are no traces of oil on the paper, it is considered qualified. After passing the inspection, seal both ends of the pipe with plastic cloth and tape.

Carbon steel pipes treated in this way have clean and shiny inner walls and can remain rust-free for about 2 months; if stored well, this period can be extended. This method can also be applied to carbon steel pipe fittings.

For stainless steel pipes that only require degreasing, aside from the aforementioned degreasing methods, the wipe-down technique can also be utilized for larger diameter pipes.

When using the wipe-down method, cotton yarn is not recommended; instead, cloths, silks, or glass fiber fabrics that are less likely to shed fibers should be used.

For longer pipes, clean iron wires can be used to attach cloth strips, performing bidirectional drag-and-wipe to remove the oily contamination from the inner wall of the pipe.

After degreasing, a careful inspection of the surface of the degreased component is mandatory to prevent the attachment or fall of organic textile fibers. Once inspected and deemed satisfactory, the pipe ends should be sealed immediately.

According to the largest valve’s volume, a custom-made degreasing container can be created from steel plates (or a simple modification of an iron drum used to store carbon tetrachloride).

After removing the rust and dirt from its inner wall, it should be wiped clean with a white cloth.

Stainless steel pipe fittings and valves requiring degreasing should be wiped clean with a dry, white cloth (Note: it is recommended to use a high-quality white cloth that does not shed fibers), strung together using iron wire or thin steel wire ropes, and placed into the created container.

Fill the container with carbon tetrachloride to soak the stainless steel pipe fittings and valves. Avoid overfilling; ideally, maintain a distance of 200mm between the liquid level and the top of the container to prevent spilling of carbon tetrachloride, causing pollution or personal injury.

Since carbon tetrachloride is toxic and evaporates easily, the operator should stand upwind while filling to prevent inhaling and consequently being poisoned.

Then, cover the container, soak for 1-2 hours, remove the pipe fittings and valves, wipe dry the inner and outer surfaces with silk cloth, and let them air-dry naturally.

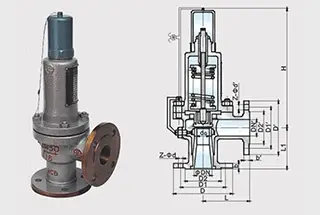

After passing inspection, pipe fittings and valves should be individually wrapped and sealed in plastic. Before degreasing valves, grind and pressure-test them, then disassemble to remove rust and other debris before immersing in a carbon tetrachloride solvent for 1 to 1.5 hours.

Bolts and metal gaskets should be degreased using the same method. Valve bodies that are not convenient for immersion can be wiped clean.

Non-metal gaskets should be soaked in carbon tetrachloride for 1.5 to 2 hours during degreasing, then hung in a well-ventilated area or within a ventilation device to be individually blown dry until no solvent odor remains.

For asbestos fillings within valves, burn at around 300°C for 2-3 minutes (do not use a smoking flame), then soak in a specified coating.

Before construction, technical staff must brief construction personnel about safety and techniques. Tools, measuring instruments, and other devices used for degreasing, inspection, and installation must be pre-degreased according to the requirements of the degreased parts.

Use without degreasing is not allowed. Safety measures for degreasing and pickling should follow relevant regulations of the “Petrochemical Construction Safety Technical Regulations”, and degreasing and pickling work should be performed in a well-ventilated outdoor area.

Personal protection should be reinforced during work, including wearing work clothes, rubber gloves, masks, protective glasses, rain boots, aprons, and when necessary, a gas mask.