Have you ever wondered how to effectively remove rust from steel surfaces? In this blog post, we’ll dive into the world of rust and derusting, exploring the various grades of steel surfaces and the best methods to restore them to their former glory. As an experienced mechanical engineer, I’ll share my insights and practical tips to help you tackle this common issue with confidence.

This standard outlines the criteria for visually evaluating the extent of rust and the quality of rust removal on the surface of steel prior to painting.

It applies to steel surfaces that have undergone rust removal through spraying or jetting, manual or power tool methods, and flame rust removal. It is also relevant for the evaluation of rust removal grade on cold-rolled steel surfaces.

This standard is equivalent to ISO8501-1:1988 “Preparation of Steel before Application of Paints and Related Products – Visual Assessment of Surface Cleanliness – Part 1: Rust Grades and Derusting Grades of Uncoated Steel and Steel after Overall Removal of the Original Coating.”

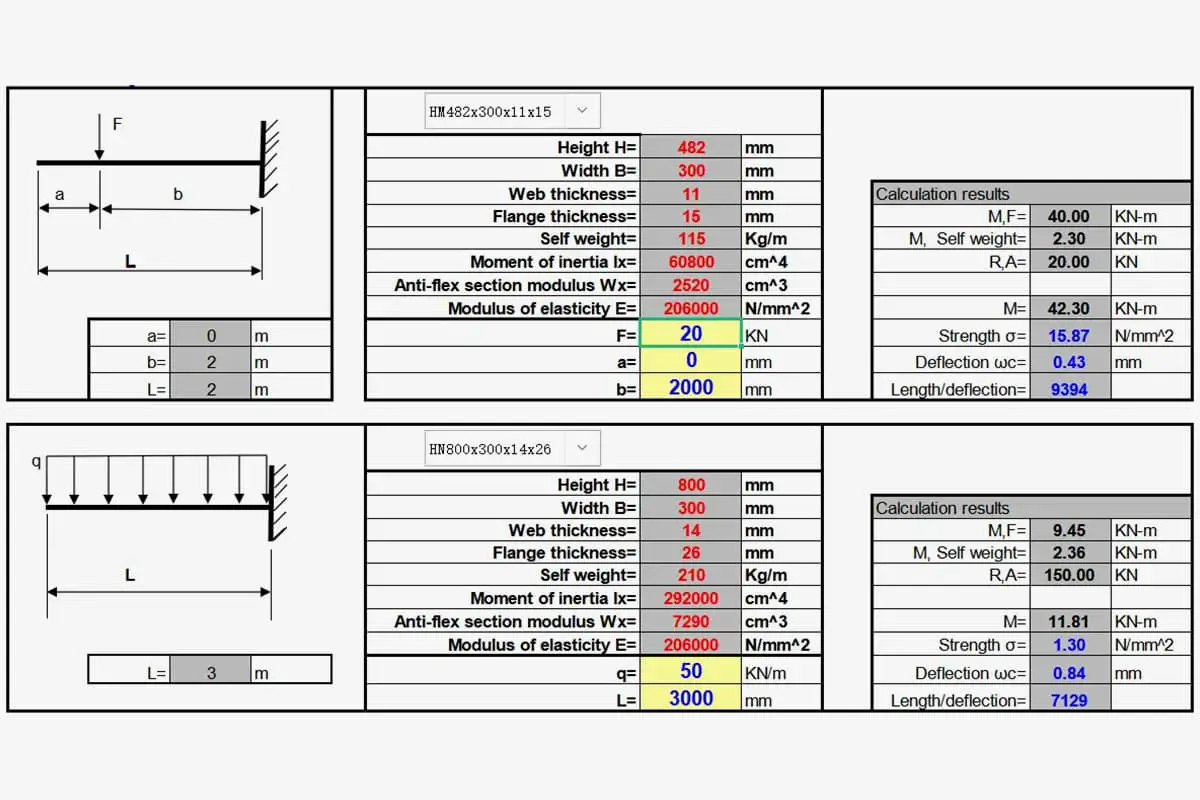

1.1 This standard categorizes the initial level of rust on uncoated steel surfaces into four “rust grades” and assesses the quality of rust removal on uncoated steel surfaces and those that have been completely stripped of their original coating into several “rust removal grades.”

The rust grade and rust removal grade of the steel surface will be determined through a combination of written descriptions and photographs of representative samples.

1.2 This standard evaluates the rust grade and rust removal grade based solely on the visual appearance of the steel surface.

When making these evaluations, direct observation with the naked eye under moderate lighting conditions should be used, without the aid of magnifying glasses or other instruments.

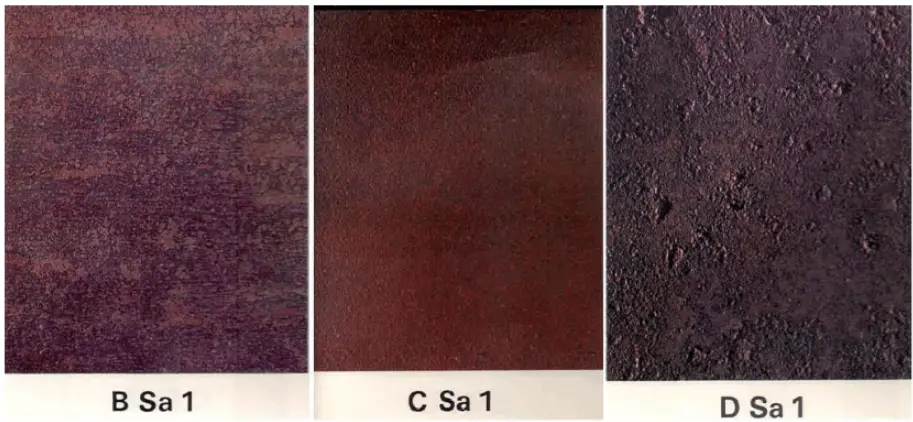

The four rust grades of steel surfaces are designated as A, B, C, and D. These grades are defined as follows:

A. The steel surface is completely covered with an oxide layer and is virtually free of rust.

B. The steel surface has some rust and some oxide scales have come off.

C. The oxide layer on the steel surface has come off due to corrosion or can be scraped off and there is a small amount of pitting corrosion.

D. The oxide layer on the steel surface has been completely stripped off due to corrosion and there is widespread pitting corrosion.

3.1.1 The rust removal grade of the steel surface is indicated by the letters “Sa”, “St”, or “FI”, representing the method used for rust removal.

If the letter is followed by an Arabic numeral, it indicates the extent to which the scale, rust, paint coating, and other attachments have been removed.

3.1.2 For detailed descriptions of the rust removal grade of the steel surface, refer to sections 3.2, 3.3, and 3.4.

Note:

(1) In this chapter’s definitions of rust removal grades, the term “attachment” encompasses items such as welding slag, welding spatter, and soluble salts.

(2) In this chapter, if the “oxide skin, rust, or paint coating” can be removed from the steel surface using a metal putty scraper, it is considered not firmly attached.

3.2.1 The letter “Sa” is used to denote spray or shot derusting.

3.2.2 Before applying spray or shot derusting, a thick rust layer must be removed, as well as any visible grease and dirt. After rust removal, the steel surface should be thoroughly cleaned of any floating ash and debris.

3.2.3 This standard includes four grades of rust removal for steel surfaces that have undergone spray or shot derusting:

Sa1 Mild spray or shot derusting:

The steel surface should be free of any visible grease or dirt and must not have any loose oxide skin, rust, paint coating, or other attachments.

Refer to photos BSa1, CSal, and DSa1 for reference.

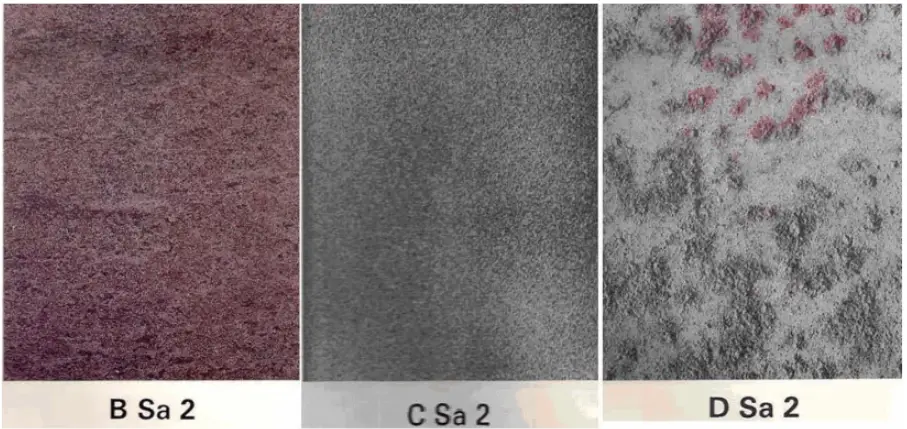

Sa2 Complete Spray or Blast Rust Removal:

The steel surface should be free of visible grease and dirt, and the attachments such as scale, rust, and paint coating must have been thoroughly removed. Any residues should be firmly attached to the surface.

Refer to photos BSa2, CSa2, and DSa2 for reference.

Sa2 1/2 Extensive Spray or Shot Rust Removal:

The steel surface should be completely free of visible attachments such as grease, dirt, oxide skin, rust, and paint coating. Any residual traces should only be slight spots or stripes.

Refer to photos ASa2 1/2, BSa2 1/2, CSa2 1/2, and DSa2 1/2 for reference.

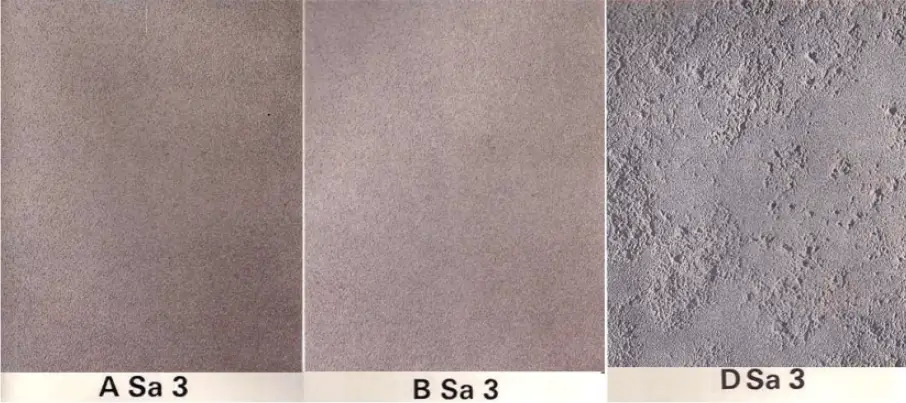

Sa3 Spray or Jetting to Achieve a Clean Steel Surface:

The steel surface should be completely free of visible attachments such as grease, dirt, oxide skin, rust, and paint coating. The surface should have a uniform metal color.

Refer to photos ASa3, BSa3, CSa3, and DSa3 for reference.

3.3.1 Use manual and power tools, such as blades, manual or power wire brushes, power sandpaper trays, or grinding wheels, to remove rust, which is indicated by the letter “St”.

3.3.2 Prior to derusting with manual and power tools, the thick rust layer should be removed, and visible grease and dirt should also be cleared.

After the rust removal process using manual and power tools, the steel surface should be thoroughly cleaned of any floating dust and debris.

3.3.3 For steel surfaces that have been derusted by hand and power tools, this standard has two derusting grades. The grades are described as follows:

St2 Thorough Manual and Power Tool Derusting

The steel surface should be free of visible grease and dirt and any loose oxide skin, rust, paint coating, or other attachments.

Please refer to photos BSt2, CSt2, and DSt2 for reference.

St3 Very Thorough Manual and Power Tool De-Rustification

The steel surface must be free of visible grease, dirt, loose oxide skin, rust, paint coatings, and any other attachments. The rust removal must be more comprehensive than St2, resulting in a metallic luster on the exposed parts of the substrate.

Refer to photos BSt3, CSt3, and DSt3 for reference.

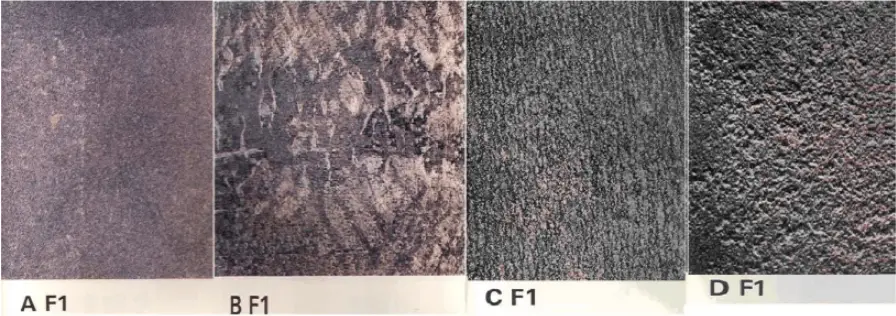

3.4.1 The process of flame derusting is indicated by the letter “FI”.

3.4.2 Prior to flame derusting, the thick layer of rust must be removed.

Flame derusting must encompass not only the steel surface, but also any products attached to it after the flame heating operation and cleaned with a power wire brush.

3.4.3 The level of derusting achieved through flame derusting is defined as follows:

The steel surface should be free of oxide scale, rust, paint coatings, and other attachments. Any remaining traces should only be in the form of surface discoloration, appearing as shadows of varying colors.

Refer to photos AFI, BFI, CFI, and DFI for visual reference.

4.1 The evaluation of the rust grade and rust removal grade of the steel surface shall be conducted in good lighting conditions, either under scattered sunlight or with artificial lighting of equivalent brightness. The inspector must have normal vision.

4.2 The steel surface being inspected must be visually compared to the corresponding photographs as outlined in Chapter 5. The photographs should be taken as close to the steel surface as possible.

4.3 When determining the corrosion grade, the evaluation result shall be taken from the photograph corresponding to the most severely rusted grade.

When determining the rust removal grade, the evaluation result shall be taken from the photograph closest in appearance to the steel surface.

Note:

(1) The visual evaluation results of the rust grade of a steel surface can be impacted by several factors, including:

a. The type of abrasives and tools used for rust removal, whether through spraying, jetting, manual, or power tool methods;

b. The rust condition of the steel surface that falls outside of the standard corrosion grade;

c. The steel’s inherent color;

d. The varying roughness due to different levels of corrosion;

e. Irregularities in the surface, such as dents;

f. Tool-inflicted scratches;

g. Uneven lighting conditions;

h. Shadows caused by the angle at which abrasives impact the surface during rust removal through spraying or projection.

(2) The rust grade of a coated steel surface should be visually assessed.

Only photos featuring rust grade symbols C and D (e.g. DSt21/2 and CSt21/2) can be used for this purpose.

The selection of either DSt21/2 or CSt21/2 will depend on the degree of pitting present on the steel surface.

5.1 This standard includes 28 photos that depict typical samples of steel surface rust grades, which are in accordance with the international standard ISO 8501-1:1988.

In the event of any disputes, the photos in ISO 8501-1 shall serve as the basis for arbitration.

5.1.1 There are 4 photos that illustrate the corrosion grades and are marked with A, B, C, and D.

5.1.2 There are 24 photos that demonstrate the derusting grades achieved through spray or projection derusting, manual and power tool derusting, and flame derusting. These photos are marked with symbols indicating the original rust grade before and after rust removal, such as BSa21/2.

5.2 Fourteen photos of spray or shot derusting depict the steel surface condition after dry spray derusting using quartz sand abrasive.

Please note that the steel surface after derusting may exhibit different colors when other types of abrasives are used for spray or shot derusting.

5.3 This standard does not include photos of ASa1, ASa2, ASt2, and Ast3.