Ever wondered which companies lead the way in China’s machine tool industry? This article introduces the top 10 boring machine manufacturers, detailing their histories, innovations, and contributions to the field. From SMTCL’s advanced technologies to DMTG’s global collaborations, discover how these industry giants are shaping the future of precision machining. Expect to learn about their flagship products, key achievements, and strategic goals in revolutionizing the sector.

Shenyang Machine Tool founded in 1993 and with roots going back to 1933, stands as a key player in the Chinese machine tool sector. Listed on the Shenzhen Stock Exchange (stock code: 000410), this company represents the merger of four industry pioneers, including the esteemed Shenyang First Machine Tool Factory.

The company specializes in producing high-quality machine tools, including diverse lathes and machining centers, known for their precision and durability. Shenyang Machine Tool has consistently innovated, especially notable since 2010, by integrating advanced technologies and new materials like the LZA4205 microcrystalline alloy in CNC turrets, which has significantly boosted product quality and cost-effectiveness.

Apart from manufacturing, Shenyang Machine Tool provides extensive services in the SMTCL lathe machine spare parts arena, offering everything from sales and maintenance to consulting and training. These services are tailored to enhance customer experience and value in selecting and utilizing machine tool parts.

The company is also a central figure in the Shenyang CNC Machine Tool Industrial Park, a state-of-the-art manufacturing hub that consolidates nine major enterprises. This strategic initiative highlights Shenyang Machine Tool’s commitment to leading the global machine tool industry through innovation and quality.

Founded in 1935 and a subsidiary of China General Technology Group, Dalian Machine Tool Company Limited is a premier developer and manufacturer of CNC machine tools, flexible manufacturing systems, and complete sets of automation equipment. Renowned for its expertise in CNC technology, the company has established itself as an important base for the industrialization of functional components in China.

With its origins as Dalian Machine Tool Factory, the company has evolved through mergers and acquisitions, including the integration of several state-owned machine tool enterprises in the Dalian area in 1995 and the joining of the Dalian Combination Machine Tool Research Institute in 2000. Post-2002, Dalian Machine Tool Group acquired international entities, such as the American Ingersoll Production Systems, and established joint ventures with partners from the US, Germany, Japan, Switzerland, and South Korea.

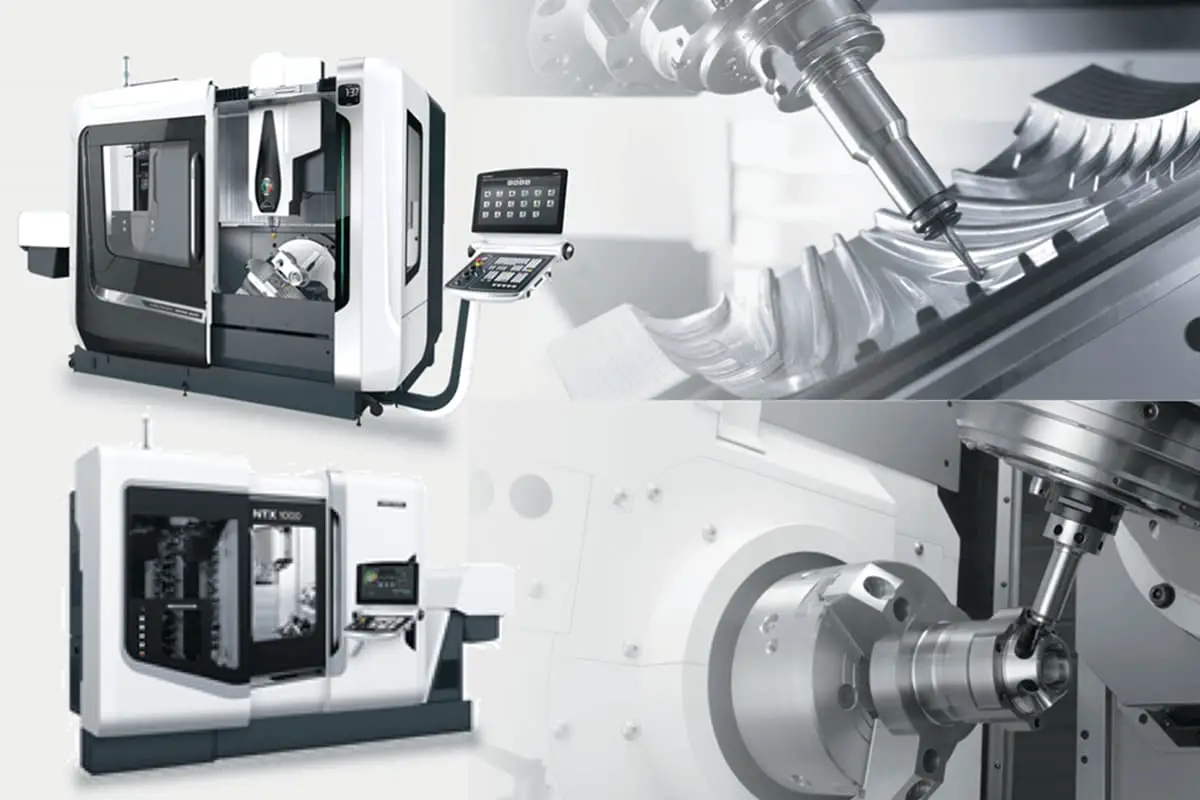

Supported by national policies to revitalize the Northeast’s old industrial base, the company has constructed two modern production bases in Dalian Port and Wafangdian, leading the nation in the comprehensive manufacturing scale of CNC machine tools and functional components. Its product suite, which includes CNC flexible machine tools, intelligent manufacturing units, five-axis machining centers, and high-speed precision centers, maintains a leading domestic position with some reaching international standards.

Over 80 years, Dalian Machine Tool has supplied over 500,000 units to industries such as automotive, rail transportation, and mining, with a presence in over 100 countries. The company is committed to equipping China’s manufacturing sector and offers an extensive network for sales and services, ensuring customer satisfaction through prompt delivery and responsive after-sales support. Dalian Machine Tool is dedicated to fulfilling market demands with an integrated approach to marketing and service, striving to build strong partnerships and a bright future with its customers.

Founded in 1965, Qinchuan Machine Tool Group Co., Ltd. (Stock Code: 000837) has established itself as a leading manufacturer of precision CNC machine tools and complex instruments in China. As a renowned system integrator and key component supplier in the high-end equipment manufacturing sector, Qinchuan’s product range includes advanced CNC lathes, machining centers, cylindrical grinders, gear processing machines, thread grinders, precision measuring instruments, and complex CNC tooling.

Qinchuan is recognized as the backbone of China’s machine tool industry and a hub for innovation and technological advancement, housing multiple entities such as Baoji Machine Tools and Hanjiang Machine Tools. With a focus on original innovation in core technologies for industrial mother machines, the company has received numerous accolades, including national science and technology awards and recognition for its “Qinchuan” trademark as a well-known Chinese brand.

The company’s commitment to “equipping China and reaching the world” is reflected in its strategic development goals, which include leading in high-end manufacturing, supporting core components, breaking through in intelligent manufacturing and CNC technologies, and actively undertaking national R&D projects. With a clear “5221” development target, Qinchuan strives to become a world-class provider of system integration services and a key supplier of crucial components in the field of high-end equipment manufacturing.

Established in 1937, Jinan Second Machine Tool Group Co., Ltd. (Jinan No.2 Machine Tool) has grown into a prominent manufacturer of stamping equipment, renowned for its extensive scale in forging machinery and large heavy-duty metal cutting machine tools. With over 5,000 employees and a sprawling 1.23 million square meter campus, the company has played a pivotal role in China’s industrial development by producing the nation’s first gantry planer in 1953 and mechanical press in 1955, earning it the titles “Home of the Gantry Planer” and “Cradle of the Mechanical Press.

Jinan No.2 Machine Tool is not only a backbone enterprise in China’s machine tool industry but also among the “Eighteen Arhats” of the sector. This state-owned enterprise offers a comprehensive range of products, including forging equipment, CNC metal cutting machine tools, automation equipment, casting machinery, and CNC cutting devices. These products cater to key industries such as automotive, aerospace, rail transit, energy, shipbuilding, metallurgy, mold, construction machinery, and more, with exports to 67 countries and regions.

The company has developed over 600 products, many of which were the first of their kind in China, providing vital support to various industries. As one of the world’s top three CNC stamping equipment manufacturers, Jinan No.2 Machine Tool holds the majority market share in China for large and heavy-duty mechanical presses, supplying hundreds of large stamping production lines and heavy-duty presses to the domestic automotive industry and other sectors.

Recognized by the State Council for its significant contributions to the field of major technical equipment, Jinan No.2 Machine Tool is a pillar of industry, offering a broad spectrum of services including pre-sales, after-sales, machine tool refurbishment, spare parts supply, and external collaboration on castings, forgings, welded parts, and machined components. Its product lines are diverse, with specifications ranging from 60t to 5000t for various machinery such as mechanical presses, production lines, large multi-position presses, CNC hydraulic presses, and CNC bending machines. The company’s automation equipment, casting machinery, and environmental building material devices maintain rapid growth, showcasing the most extensive product range and specifications in the national machine tool industry. Since 1997, the company has supplied over ten stamping production lines to renowned global automotive companies and has been exporting heavy machinery presses with full intellectual property rights to the high-end U.S. market since 2001. Jinan No.2 Machine Tool is a foundational enterprise for China’s automotive industry and a global leader in its field.

Founded in 1950, Qiqihar No.1 Machine Tool Plant, now known as Qiqihar Heavy CNC Equipment Co., Ltd., is a cornerstone in China’s machine tool industry. Recognized as a “Little Giant” by the Ministry of Industry and Information Technology, this enterprise leads with its high-grade heavy CNC machine tools, enjoying a robust brand influence within the national equipment manufacturing sector.

The company’s flagship products include vertical and horizontal lathes, focusing on heavy-duty machine tools. Its diverse portfolio comprises over 600 varieties across 10 major categories, including heavy deep-hole drilling and boring machines, roll lathes, and vertical grinding machines. Many of these products have filled domestic gaps and are exported to over 30 countries and regions, including Europe, the Americas, Japan, and South Korea.

Qiqihar Heavy CNC Equipment holds the status of a first-class measurement enterprise and is recognized by the Ministry of Science and Technology as a national high-tech enterprise. With a state-level enterprise technology center and an R&D team led by experts with special government contributions and academic leaders in the machine tool industry, the company is dedicated to innovation.

Adhering to the philosophy of “Lean Manufacturing and Winning by Quality,” the company strives to exceed customer expectations, serving as a process advisor and providing integrated solutions for mutual benefit. Committed to innovation-driven development, Qiqihar Heavy CNC Equipment is transitioning towards intelligent and service-oriented transformation, aiming for high-quality corporate development.

Established in 1949, Beijing No.1 Machine Tool Co., Ltd. (BMT) is a state-owned enterprise renowned for its high-end CNC machine tools. The company excels in producing a comprehensive range of integrated and intelligent machine tool solutions. BMT’s expansive product line includes ultra-heavy gantry milling machines, heavy-duty vertical lathes, floor-type boring and milling machines, CNC inverted lathes, and turning-milling compound machine tools, among others.

Headquartered in the Zhongguancun Science Park in Shunyi, Beijing, BMT oversees several subsidiaries, including international brands like Waldrich Coburg in Germany and C.B. Ferrari in Italy. The company shares the same age as the People’s Republic of China and adheres to a spirit of excellence and manufacturing prowess, underpinned by technological innovation. With a national-level enterprise technology center and a CNAS-certified testing and calibration laboratory, BMT has received multiple national awards for its contributions to high-grade CNC machine tools and manufacturing equipment.

BMT’s products are extensively used in industries such as automotive, shipbuilding, power generation, rail transport, mold-making, and machinery, demonstrating versatility and a commitment to fulfilling the diverse needs of its clients. Through its mission to deliver lasting returns to shareholders, respect for its employees, and value creation for customers, BMT is dedicated to being the backbone of the equipment industry and strives to become a globally competitive machine tool manufacturer and service provider.

BMT’s focus on customer service is exemplary, reflecting its ambition to continuously improve and innovate for mutual success with its stakeholders. With its advanced technology and strong international partnerships, BMT is determined to elevate China’s manufacturing prowess on the world stage.

Founded in 1950 and now a subsidiary of China General Technology Group, Qiqihar No. 2 Machine Tool (Group) Co., Ltd. (formerly Qiqihar No. 2 Machine Tool Factory) is a renowned industrial enterprise specializing in the production of heavy and super-heavy CNC machine tools and large-scale complete forging and pressing equipment. With over 70 years of development, the company has become a leading backbone enterprise in China’s heavy machinery sector.

The company’s offerings are categorized into four main product lines: metal cutting machine tools, metal forming machine tools, specialized equipment, and technical services. Their products include heavy CNC floor-type boring and milling machines, CNC vertical and horizontal lathes, mechanical presses, and customized machine tools. They also offer industrial services such as machine tool modification, remanufacturing, machining, and technical consultancy.

Qiqihar No. 2 Machine Tool’s equipment serves critical industries including civil aviation, shipbuilding, automotive, metallurgy, and rail transportation. The company has supplied over 2,000 major pieces of equipment to key domestic enterprises, contributing significantly to the national industrial infrastructure.

The company boasts a skilled workforce of over 4,500 employees, including those with advanced technical titles and degrees. It occupies a space of 450,000 square meters with a factory area of 160,000 square meters. The company is equipped with 1,928 pieces of production equipment, including 1,005 metal cutting machine tools and 225 large precision machines, some of which are of international advanced level.

Qiqihar No. 2 Machine Tool has achieved many firsts in the country’s history, including the development of China’s first CNC milling machine in 1958. The company has produced over 60,000 machine tools, with over 1,000 units weighing over a hundred tons each, filling numerous gaps in the national industry. Its “Qiqihar” brand is recognized as a “China Famous Trademark” and stands as one of the most trusted machine tool brands in the country.

Founded in 1936, the General Technology Group Kunming Machine Tool Co., Ltd. (previously known as the Central Machinery Factory) has grown into a cornerstone of China’s large precision machine tool manufacturing. Situated at 23 Ciba Road, Kunming, Yunnan, with a workforce of 940 and total assets of 1.3 billion yuan, the company spans across 264,000 square meters, with a built-up area of 140,000 square meters.

Over the years, Kunming Machine Tool has developed and manufactured an extensive range of products, including the KIKI Smart Series, KITI Series, KHC-AUTO Series, and several more series up to the THM/TGK and KiMi Series. Their portfolio features a variety of precision machine tools, such as horizontal boring and milling machines, floor-type boring and milling machines, gantry milling and boring machines, coordinate boring machines, horizontal machining centers, and essential machine tool components.

Leveraging a rich history of innovation that includes the creation of China’s first horizontal boring machine in 1945 and the first coordinate boring machine in 1958, Kunming Machine Tool has consistently maintained its commitment to excellence. With a focus on manufacturing and sales, the company has cemented its position as a leader in the industry, recognized for its quality and technological advancements, like winning the National Quality Gold Award for their T42100 coordinate boring machine in 1980.

The company, now a part of the General Technology Group, continues to expand its legacy in precision machine tool manufacturing, ensuring that its products meet the evolving demands of both domestic and international markets.

Founded in 1965, Baoji Machine Tool Group has established itself as a premier developer and manufacturer of CNC machine tools in China. As an essential base for CNC machine tool research, production, and intelligent manufacturing, the company is leading the industry with its intelligent machine tools, flexible machining units, intelligent manufacturing units, and automatic production lines.

With a mission to craft high-quality Chinese machine tools through dedication and smart manufacturing, Baoji Machine Tool Group operates with a management philosophy that blends intelligent guidance with dual-driving forces of craftsmanship and global service. The company boasts 12 subsidiaries, a total asset value of 2 billion yuan, a workforce of 3,500, an annual production of 20,000 machine tools, revenues of 3 billion yuan, and an export trade generating 30 million USD.

Baoji Machine Tool Group excels in innovation, having developed a comprehensive R&D and manufacturing system that integrates talent, technology, and brand. Its product portfolio includes over 200 varieties and 400 specifications across 14 major categories, serving sectors like automotive, aerospace, engineering machinery, agricultural machinery, and educational institutions. The company has undertaken over 30 national key projects and the “Brain Replacement Project,” and operates five global marketing and service centers, positioning itself as an influential supplier in the intelligent development of the industry’s supply chain.

With a strong focus on talent development, the company has implemented a “High-Skill Talent Quality Improvement Project,” creating a multi-tiered talent development pathway from technical experts to “Baoji Craftsmen.” This strategy has cultivated a multi-level team of skilled craftspeople and innovators.

Baoji Machine Tool Group is dedicated to second-level development and the optimization of CNC systems and robots, collaborating on the creation of a new generation of intelligent machine tools. By integrating advanced manufacturing technology with big data and cloud platforms, the company is accelerating its transformation into intelligent manufacturing and aims to establish a digital factory by 2024.

The company has earned numerous accolades, including national awards and recognition for its contribution to quality, innovation, and integrity within the machine tool industry. As it moves forward, Baoji Machine Tool Group is committed to high-quality development, customer-centricity, market and product transformation, and the establishment of a high-end R&D and manufacturing base for complex turning and milling centers, striving to become a top-tier supplier of high-end equipment.

Wuhan Heavy Duty Machine Tool Group Co., Ltd., a subsidiary of China North Industries Group Corporation, stands as a monumental enterprise in China’s machine tool industry, heralding an extensive range of heavy and super-heavy machine tools. This company, which was one of the 156 key projects during China’s First Five-Year Plan, has evolved into a leading CNC heavy and super-heavy machine tool research and development base following a comprehensive relocation and transformation.

The company boasts a workforce of over 3,000 employees, including more than 600 engineering and technical experts, seven of whom are national-level specialists. With a product portfolio encompassing over 400 varieties across more than 50 series, including heavy and super-heavy vertical and horizontal lathes, floor-type milling and boring machines, gear hobbing machines, and specialized equipment for sectors such as mining and railways, the company has fully embraced the integration of numerical control and multifunctionality.

The enterprise has made significant contributions to China’s manufacturing sector by developing high-end CNC machine tools with proprietary intellectual property rights, thus supporting national major projects. It has undertaken various national and provincial research projects, earning numerous awards for its innovative products, such as the DL250 super-heavy CNC horizontal boring machine and the CKX5680 CNC seven-axis five-linkage turning and milling compound machine. Moreover, the company has set and revised 36 heavy machine tool standards and accumulated over 120 national patents.

The Wuhan Heavy Duty Machine Tool Group is committed to a strategy that emphasizes the integration of machine tools and specialized machinery, aiming to build comprehensive industry, value, and service chains. By focusing on high-end, intelligent, and niche equipment, the company aspires to be a world-class systems integrator and provider of key components in the high-end equipment manufacturing sector, driven by innovation and sustainable development.