Have you ever wondered about the giants of the CNC machine industry? In this fascinating blog post, we’ll take a deep dive into the world of CNC manufacturing, exploring the top 10 global players that are shaping the future of precision engineering. Our expert analysis will provide valuable insights into their cutting-edge technologies, market dominance, and the impact they have on various industries. Get ready to be captivated by the innovation and excellence that define these industry leaders!

Recently, CCID Consulting released the 2022 ranking of the top 10 CNC Machine Manufacturers globally, including the best 10 CNC machine brands.

MAZAK from Japan secured the first position with $5.28 billion, followed by German company TRUMPF in the second position with $4.24 billion, and DMG MORI in the third position with $3.82 billion.

The remaining companies in the top 10 list are MAG, AMADA, OKUMA, MAKINO, GROB, HAAS, and EMAG.

The top 10 list is dominated by companies from Japan, Germany, and the United States. Japan and Germany each have four companies, while the US has two in the top 10 list.

Before we dive into the top 10 list, let’s learn more information about CNC machine tools.

MAZAK is a well-known manufacturer of machine tools worldwide, established in 1919.

The company specializes in a wide range of CNC-related products, including lathes, lathe-mill cutting centers, vertical and horizontal machining centers, CNC laser systems, FMS flexible production systems, CAD/CAM systems, CNC devices, and production support software.

MAZAK’s products are highly recognized in the industry for their precision and high speed and are extensively used across various industries, including automobiles, machinery, electronics, energy, and the medical field.

The company has a robust global presence, with nine manufacturing facilities located in Japan, the United States, the United Kingdom, Singapore, and China.

Additionally, it has established over 30 technology centers in more than 60 locations worldwide and over 80 customer support bases, in conjunction with its worldwide Technical Centers.

With the ongoing development of manufacturing technology, automation, and digital technology, MAZAK continues to enhance and expand its offerings to customers globally.

TRUMPF was founded by Christian Trumpf in Stuttgart, Germany, in 1923.

Initially, the company manufactured flexible shafts, but it eventually evolved into the TRUMPF Group.

During the 1960s, TRUMPF began working in the laser field, which resulted in the development of an industry-leading laser in the 1980s.

Incorporating laser technology into its product line has driven over 30 years of continuous growth and development.

Today, the TRUMPF Group specializes in producing a wide range of products, including various types of lasers and laser processing machine tools, as well as CNC punching and bending machines.

As a global leader in technology and market share in the industrial laser and laser system industry, the TRUMPF Group offers a diverse range of products, such as laser cutting machines, including plane and 3D models, punching machines, bending machines, welding robots, laser welding equipment, laser tube cutting machines, printing systems, 3D printing systems, punching laser machines, material storage systems, and automation devices.

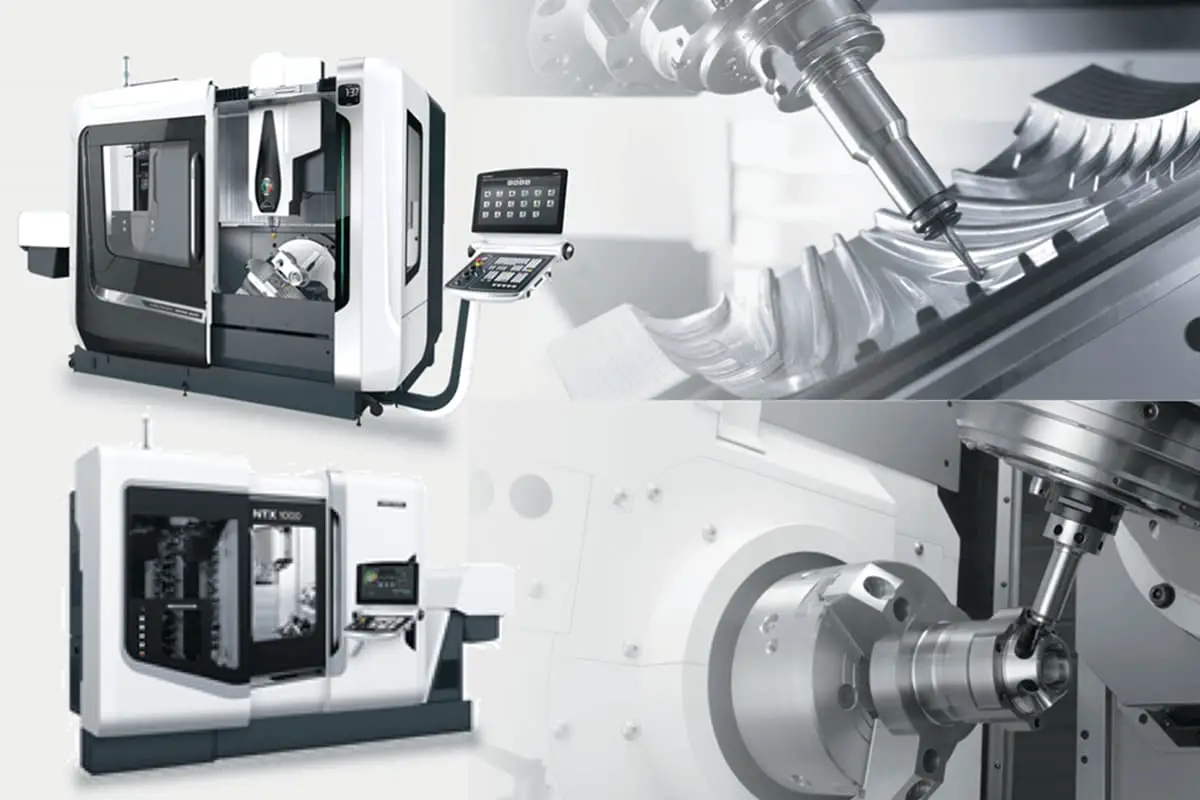

DMG MORI is a well-known name in the industry. The company was formed by the merger of the German DMG and the Japanese Mori Seiki, creating a new global leader in CNC machine tools.

As a leading manufacturer of CNC machine tools, DMG MORI is a key player in high-end manufacturing, both in China and worldwide.

Its cutting-edge vertical, horizontal, and multi-axis lathe-mill cutting centers, as well as ultrasonic/laser machining centers, represent the latest technical advancements in the machine tool industry.

DMG MORI is dedicated to producing innovative and high-tech CNC machine tools, including CNC turning centers, milling centers, advanced processing technologies (ULTRASONIC/LASERTEC), software solutions, and automation systems.

The company offers a full range of industrial services, including machine tool maintenance and accessories, energy-saving solutions, and other services throughout the machine tool’s lifecycle.

MAG is a globally recognized machine tool and automation system company that provides complete and custom machining solutions, primarily for the durable goods industry.

The company is associated with numerous well-known brands such as Berlinger, Cincinnati, Klaus Whelo, Exero, Fadao, Giddings Louis, Hessup, Honsberg, Wheelock, and Witsch Frank Wait, and is renowned for its excellent process technology and custom production solutions.

MAG caters to a wide range of industries, including aerospace, automobiles, heavy machinery, oil fields, rail transit, solar energy, wind turbine production, and general processing.

The company has manufacturing and technical support facilities worldwide, offering a broad range of products and technologies, such as turning, milling, gear hobbing, grinding, honing, system integration, composite machining, repair, industrial control systems, software, tools, oils, and core components.

As a leading supplier in the industry, MAG is widely recognized for its advanced process technology and personalized solutions.

In 1946, Isamu Amada founded Amada Seisakusho, initially specializing in sheet metal machinery and cutting products.

In 1955, the company developed and began selling a bandsaw disk named “Contour.”

In 1965, it acquired the Torc-Pac brand in the United States and the Promecam brand in France, which it sold under the Amada name.

This led to a period of rapid growth for the brand and established its reputation as a world-class provider in the sheet metal industry.

Today, Amada is highly regarded in countries such as Japan, the US, and Europe for its wide range of sheet metal processing machinery, which includes nearly a thousand advanced and high-performing products.

The company’s development of an intelligent automatic sheet metal processing center in the 1990s was a significant milestone in the world’s sheet metal industry and earned the highest award for technological invention in Japan.

Amada’s main products are CNC punching machines, bending brakes, shearing machines, laser cutting machines, and other sheet metal processing machinery, as well as associated dies, spare parts, and cutting products.

Okuma is a globally recognized company and Japan’s largest manufacturer of machine tools, including the largest producer of gantry machining centers worldwide.

With over a century of experience in the industry, it is also one of the largest CNC machine tool manufacturers worldwide.

For more than 100 years, Okuma has been producing various CNC lathes, turning centers, vertical and horizontal machining centers, gantry machining centers, and CNC grinders.

Its annual production exceeds 7,000 sets, and in 2006, its sales reached 170 billion yen, which is equivalent to approximately 1.5 billion US dollars.

Okuma exports half of its products worldwide. The company’s products are known for their high rigidity, efficient cutting, precision, longevity, and ease of use, receiving wide acclaim from customers globally.

The company was founded by Mr. Tsunezo Makino in 1937 with a specialization in producing Type 1 vertical milling machines.

In 1958, Makino achieved a significant milestone by developing Japan’s first CNC milling machine, followed by the creation of Japan’s first machining center in 1966.

Makino primarily focuses on designing and producing three-axis and multi-axis linkage CNC machine tools, CNC systems, servo devices, components, and other related products.

The company is also engaged in research and development, including producing application software, and providing technology and maintenance services for its products.

Over the years, Makino Asia has grown into a comprehensive manufacturing company that encompasses manufacturing, research and development, product design, and business management.

Our company’s operations involve advanced processing, manufacturing, and assembly, and our product range includes the F and E series machining centers, EDAF and EDGE series EDM machines, DUO series, and the latest U3 wire cutting machine tools.

GROB, which was founded in 1926 in Munich, Germany, has its headquarters located in Mindelheim, Germany.

It is one of the world’s largest machine tool manufacturers, offering a wide range of products that includes standard machines, complex production systems, assembly cells, cutting lines, and fully automated assembly lines.

GROB is always at the forefront of innovation when it comes to its processes and technologies.

GROB specializes in complete turnkey engine components and is a global system integrator that has a broad range of processes, technologies, resources, and cultures.

To bring its cutting-edge technology to all areas, GROB engineers have developed a 5-axis simultaneous machining center, which has already gained widespread market recognition.

The company’s G-module technology and expertise in the automotive industry have been successfully applied to the design and technology of the G350 and G550.

Innovative achievements, such as non-hydraulic machine tools and turning-milling machining centers, have quickly gained success in the highly competitive general-purpose machine tool market.

As a result, the G550 has quickly become the leader in its product series.

HAAS Automation is among the largest manufacturers of CNC machine tools in the world. Its only manufacturing facility is situated in Oxnard, California, covering an area of over 100,000 square meters.

In 2006, HAAS produced more than 12,500 CNC machine tools annually.

Gene Haas introduced the Haas VF-1 vertical machining center, which set the industry standard for high-quality and high-value CNC processes.

This vertical machining center is equipped with a high-performance vector-driven spindle, high-torque brushless servo motors to power each axis, and a solid casting structure that provides added stability.

The machine tool configuration offers a wide range of applications, including 40 and 50-taper gear-driven models for high torque and heavy cutting, as well as SS models (featuring coaxial direct drive spindles) for high-speed machining.

The origins of EMAG can be traced back to 1867, when the company was founded in Bautzen, Saxony, as a manufacturer of cast iron and machine tools.

In 1952, the company relocated to a site between Stuttgart and Ulm, near Salach, where it remains to this day.

After the relocation, the company began producing lathes.

Today, EMAG offers a comprehensive technology portfolio that provides customers with machine tools and production systems for processing disk parts, shaft parts, and box parts.

EMAG’s technology solutions include a range of machines such as lathes, grinding machines, gear hobbing machines, laser welding machines, and machining centers to provide the optimal production solution for any application.

With its advanced intelligent automation technology, EMAG helps customers streamline their equipment, improve efficiency, save costs, and drive the growth of their businesses.

The machine tools and production systems manufactured by EMAG Leipzig Maschinenfabrik GmbH are widely used in industries such as petroleum, automotive and its supporting industries, machinery manufacturing, and aerospace.

Since becoming part of the EMAG Group, the Leipzig facility has leveraged the combined technologies and experience of both companies to continuously develop and produce machine tools based on the EMAG series, targeting its own customer base.