Imagine a world where CNC machines can diagnose their own problems, program themselves, and achieve unprecedented levels of precision and speed. This is the future of the CNC machine tool industry. This article explores six major trends transforming the sector, from multifunctional capabilities to intelligent systems, and what these innovations mean for the future of manufacturing. Get ready to discover how these advancements will revolutionize production processes and enhance efficiency in ways previously unimaginable.

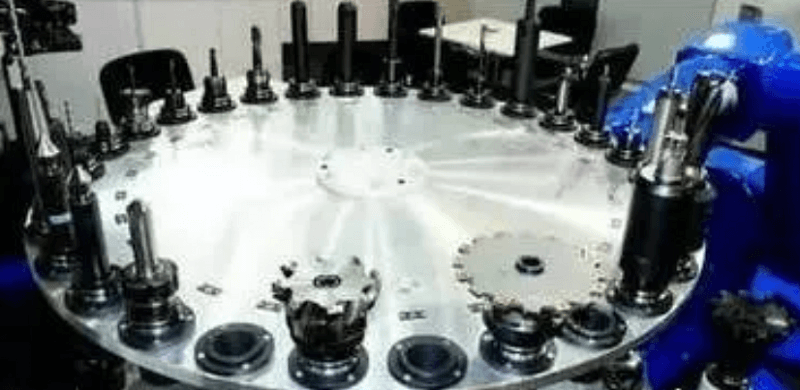

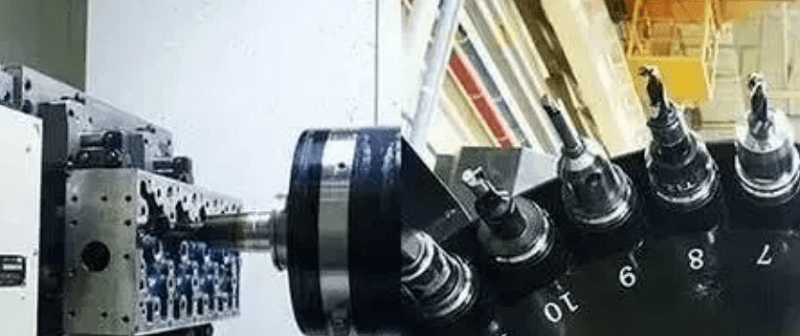

Modern CNC machines are equipped with an automatic tool changer, with a tool magazine capacity of up to 100 or more, enabling various machining centers to perform milling, boring, drilling, turning, reaming, tapping, and other processes on the same machine simultaneously. Additionally, advanced CNC machines also utilize multi-spindle and multi-face cutting capabilities.

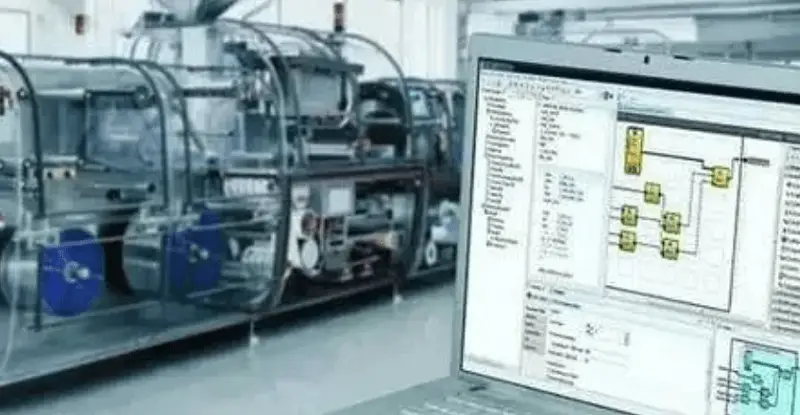

The CNC system enables data communication between CNC machines and can directly control multiple machines.

Speed and accuracy are two critical factors in CNC machines, impacting machining efficiency and product quality.

The CNC system employs a high-frequency, high-precision processor to enhance the basic computing speed of the system. Additionally, the use of ultra-large-scale integrated circuits and multi-processor structures improves the data processing capability of the system, specifically the speed and accuracy of interpolation operations.

The linear motor is used to drive the linear servo feed of the machine table, offering exceptional speed and dynamic response.

The implementation of feed-forward control technology significantly reduces tracking hysteresis error, thereby improving the accuracy of corner-cutting during machining.

Modern CNC machine tools are incorporating adaptive control technology, allowing the system to adjust working parameters in real-time based on changes in cutting conditions. This enables the machining process to maintain optimal conditions, resulting in higher accuracy, reduced surface roughness, and longer tool life, as well as improved production efficiency.

The CNC system has self-diagnosis and self-healing capabilities, which allow it to continuously monitor and check the system and connected equipment. In the event of a failure, the system will trigger a failure alarm to indicate the location and cause of the problem, and take appropriate action such as shutting down. It may also automatically switch to a spare module to maintain unmanned operation.

To meet the increasing demand for troubleshooting capabilities, the trend is towards the use of artificial intelligence expert diagnostic systems.

With advancements in computer application technology, the use of CAD/CAM interactive automatic programming is becoming increasingly common in the field of CNC technology. This involves using a CAD drawing of the machining pattern and having the computer calculate and post-process the tool path data to automatically generate the NC part machining program, effectively integrating CAD and CAM.

The CIMS technology now allows for fully automated CAD/CAPP/CAM programming. Unlike the CAD/CAM system, the programming process parameters are directly obtained from the CAPP database within the system without human intervention.

The reliability of CNC machines is a major concern for users. To address this, CNC systems use more integrated circuit chips and utilize large or ultra-large scale integrated circuits to reduce the number of components and improve reliability.

By using hardware and software to adapt to various control functions, and by using modular, standardized, and generalized hardware structures, it becomes easier to improve production and quality control.

Automatic startup diagnostics, online diagnostics, and offline diagnostics help in troubleshooting and alarming of hardware, software, and external devices in the system. Alarm alerts allow for prompt troubleshooting, and fault-tolerant technology and “redundant” design for important parts allow for self-healing. Various testing and monitoring technologies are also used to automatically protect against production overtravel, knife damage, interference, power failure, and other accidents.

The trend towards miniaturization in digital control systems has made it easier to integrate mechanical and electrical components. The system now utilizes ultra-large-scale integrated components and multi-layer printed circuit boards, and utilizes three-dimensional installation methods to allow for high-density electronic component installation, reducing the overall size of the system. The use of new color LCD thin displays, instead of traditional cathode ray tubes, has further miniaturized the CNC operating system. This makes it possible to mount the system directly onto machine tool equipment, making it more user-friendly for CNC machine operation.