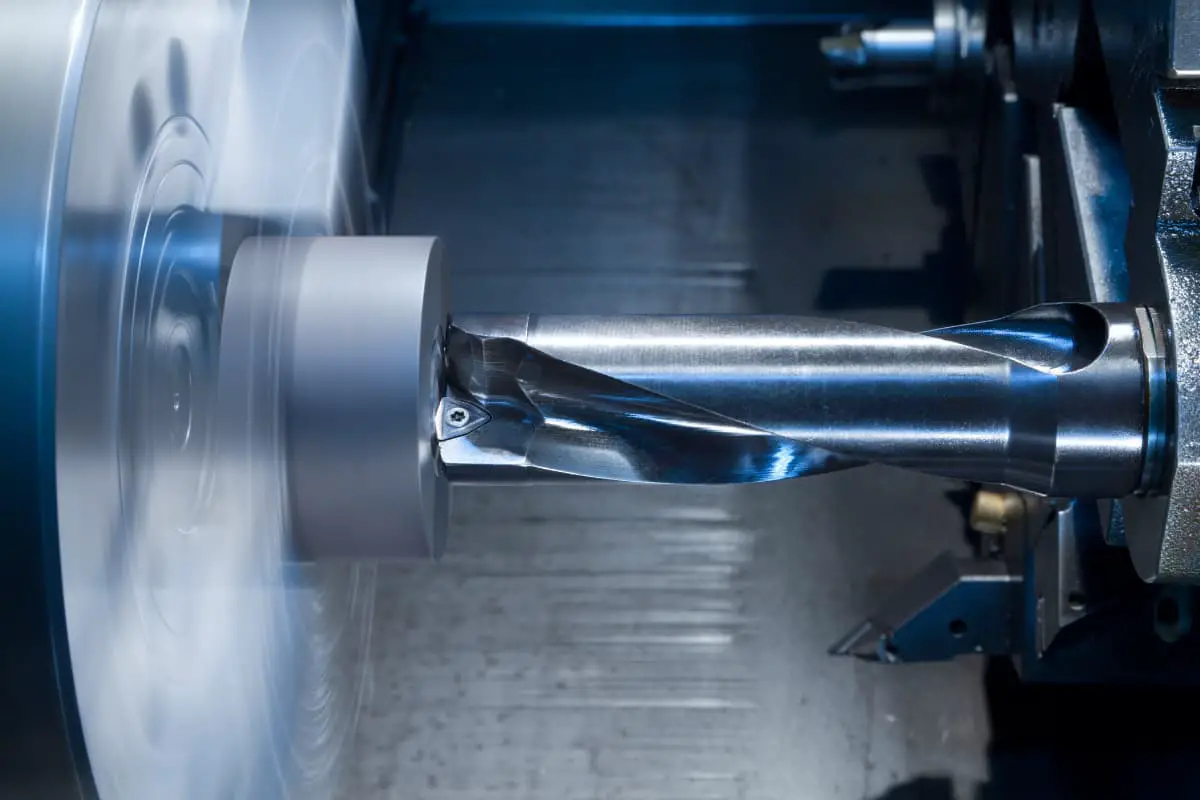

Ever wondered why metal cutting techniques differ and how they affect your projects? This article explores six essential metal cutting methods, detailing their unique characteristics and applications. By understanding these differences, you’ll be better equipped to choose the right technique for your specific needs, ensuring efficiency and precision in your work. Dive in to discover key insights into steel, stainless steel, cast iron, non-ferrous metals, heat-resistant alloys, and hardened steel.

In the metal cutting process, there are various types of workpiece materials. These materials have distinct cutting formation and removal characteristics, and it is important to understand these properties in order to effectively cut the materials.

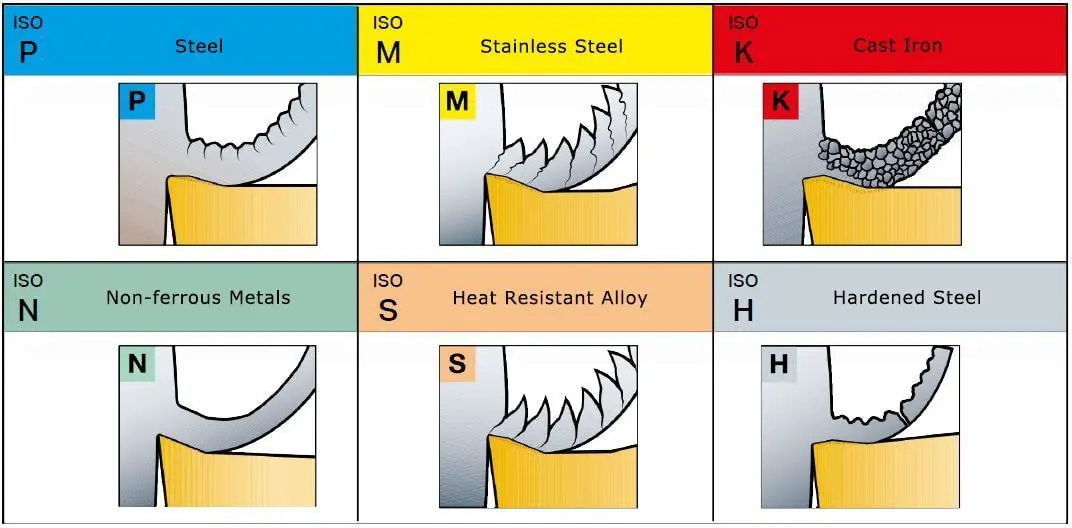

According to the ISO standard, metal materials are classified into six groups, each with its own specific processing properties. In this article, we will provide a comprehensive overview of each group.

The six categories of metal materials are:

(1) P-Steel

(2) M-Stainless Steel

(3) K-Cast Iron

(4) N-Non-Ferrous Metals

(5) S-Heat Resistant Alloy

(6) H-Hardened Steel

Cutting characteristics of different materials

What is steel?

Steel is a widely used material in the metal cutting industry. It is an alloy primarily composed of iron (Fe) and is produced through a smelting process. Steel can be either non-hardened or hardened through a quenching and tempering process, resulting in a hardness level of up to 400HB.

Non-alloy steel has a low carbon content of less than 0.8% and contains no other alloying elements besides iron. On the other hand, alloy steel contains a carbon content of less than 1.7% and additional alloying elements such as nickel (Ni), chromium (Cr), molybdenum (Mo), vanadium (V), and tungsten (W) are added to enhance its properties.

| ISO | MC | Material |

|---|---|---|

| P | P1 | Non-alloy steel |

| P2 | Low alloy steel (alloy element ≤ 5%) | |

| P3 | High alloy steel (alloy element > 5%) | |

| P4 | Cast steel |

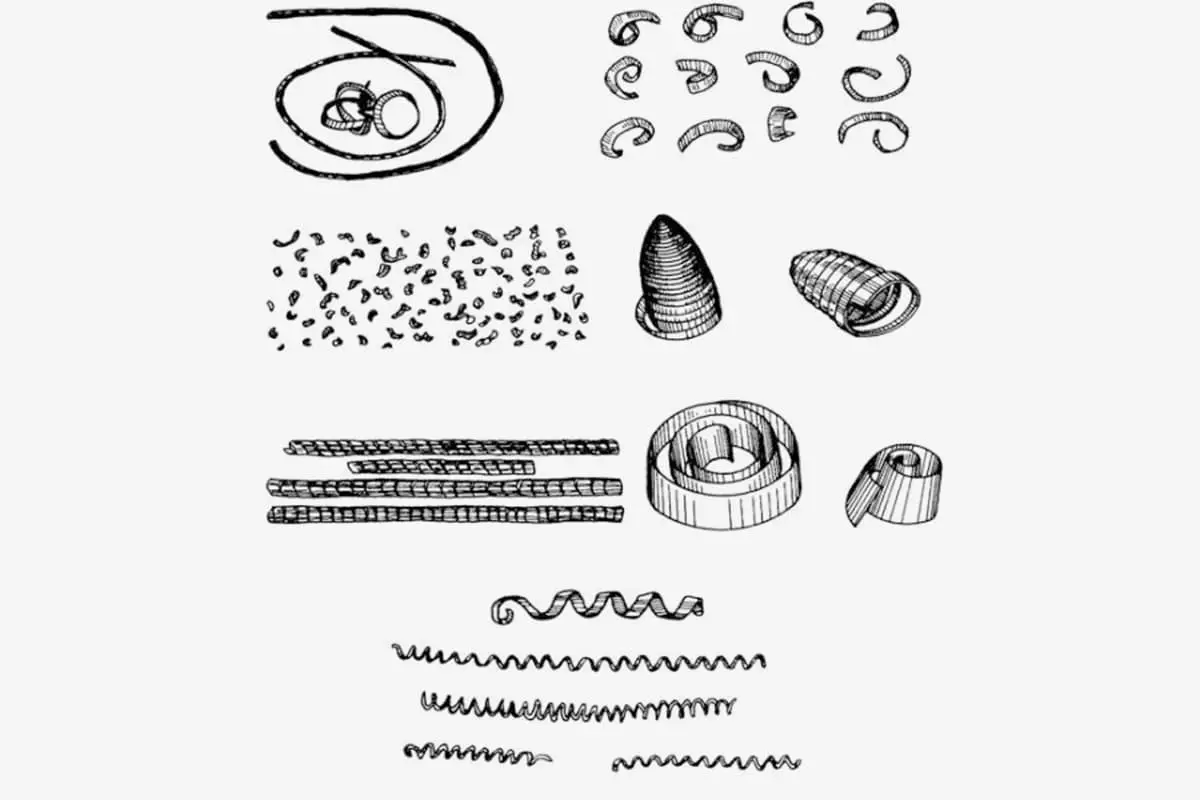

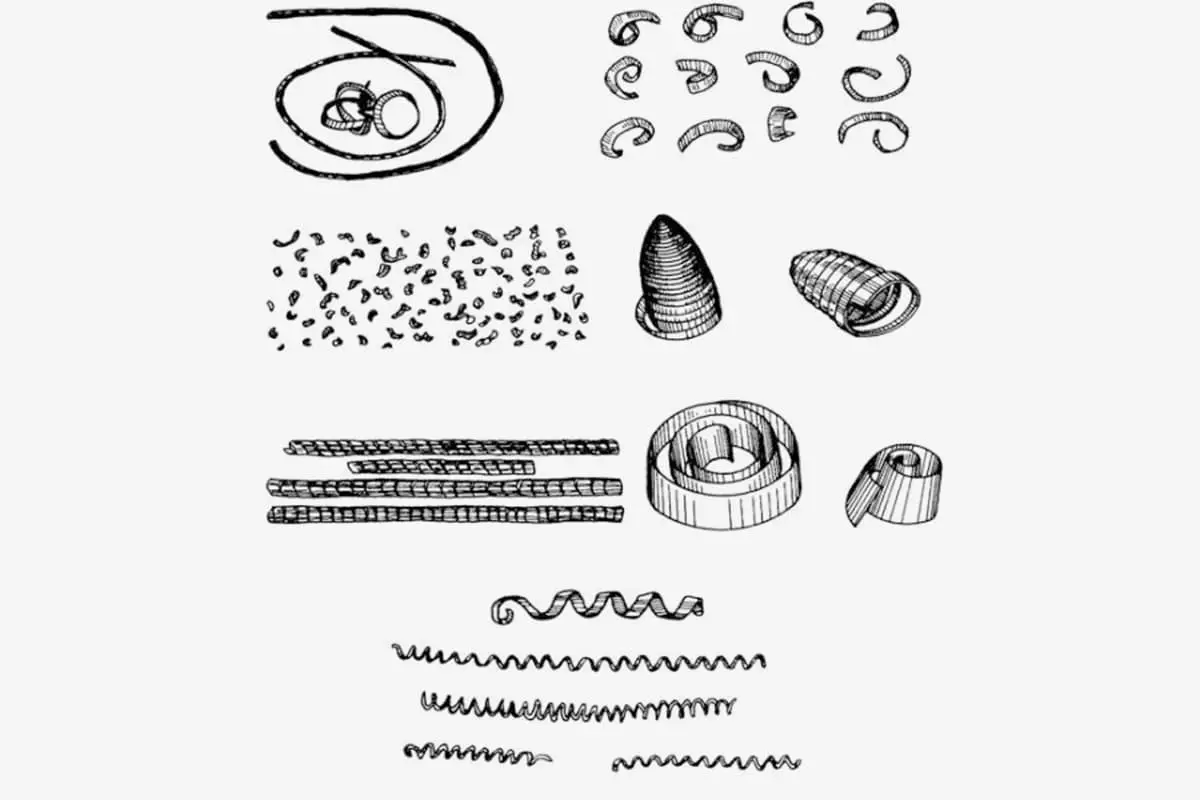

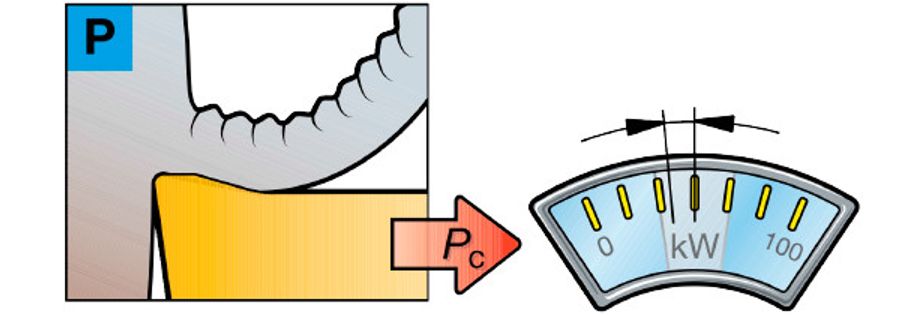

Within the metal cutting field, the P group is the largest material group, encompassing a broad range of industrial applications. The material in this group is typically characterized by the formation of long chips and the ability to produce continuous, uniform chips. The specific chip form is largely dependent on the carbon content of the material.

Materials with a low carbon content are typically tough and viscous, while those with a high carbon content are brittle.

Processing characteristics:

What is stainless steel?

| ISO | MC | Material |

|---|---|---|

| M | P5 | Ferritic/martensitic stainless steel |

| M1 | Austenitic stainless steel | |

| M2 | Super austenitic stainless steel, Ni≥20% | |

| M3 | Duplex stainless steel (austenitic/ferritic) |

The Group M materials are widely used in industries such as oil and gas, pipe fittings, flanges, pharmaceuticals, and processing.

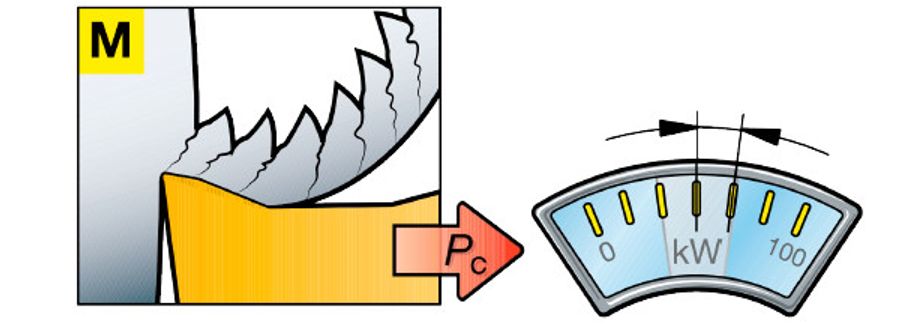

These materials have a tendency to produce an irregular, flaky chip and have a higher cutting force compared to normal steel. There are several different types of stainless steel, and their chip breaking performance (which can range from easy to almost impossible to break) depends on the properties of the alloy and heat treatment.

Processing characteristics:

What is cast iron?

| ISO | MC | Material |

|---|---|---|

| K | K1 | Malleable cast iron |

| K2 | Gray cast iron | |

| K3 | Ductile iron | |

| K4 | Vermicular graphite cast iron | |

| K5 | Austempered ductile iron |

The K group materials are primarily used in the automotive, machine manufacturing, and iron-making industries.

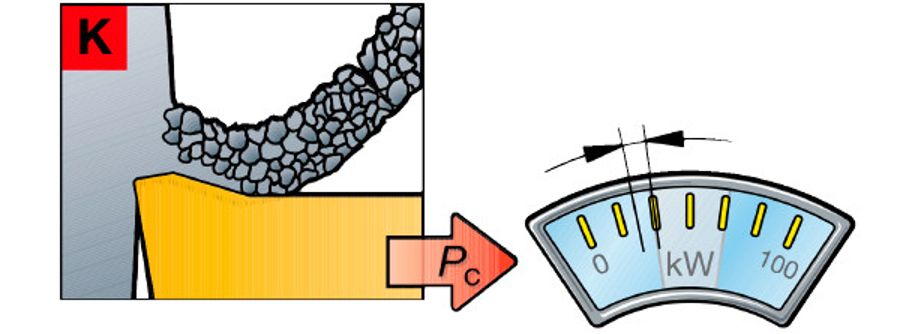

The chip formation of these materials can vary from fine powdery chips to long chips. The power required to process this group of materials is typically low. It is important to note that grey cast iron, which typically produces fine powdery chips, differs significantly from ductile cast iron, which often resembles steel in terms of chip formation.

Processing characteristics:

What is non-ferrous metals?

| ISO | MC | Material |

|---|---|---|

| N | N1 | Alloy based on non-ferrous metals |

| N2 | Magnesium based alloy | |

| N3 | Copper base alloy | |

| N4 | Zinc-based alloy |

Related reading: Ferrous vs Non-ferrous Metals

The N group is dominated by the aircraft manufacturing and aluminum alloy wheel industries.

While the power required per cubic millimeter is low, it is important to accurately calculate the maximum power needed in order to achieve high metal removal rates.

Processing characteristics:

What is heat resistant alloy?

Heat Resistant Alloys (HRSA) consist of a range of high alloyed materials based on iron, nickel, cobalt, or titanium.

These materials are classified into three groups: iron-based, nickel-based, and cobalt-based. They are used in working conditions such as annealing, solution heat treatment, aging treatment, rolling, forging, and casting.

HRSA materials are characterized by their high alloy content, with cobalt providing better heat resistance and a higher tensile strength than nickel. Additionally, higher cobalt content also results in increased corrosion resistance.

| ISO | MC | Material |

|---|---|---|

| N | S1 | Iron-based alloy |

| S2 | Nickel-based alloy | |

| S3 | Cobalt based alloy | |

| S4 | Titanium based alloy | |

| S5 | Tungsten-based alloy | |

| S6 | Molybdenum based alloy |

Materials that are difficult to process, commonly referred to as S-materials, are primarily used in industries such as aerospace, gas turbines, and generators. These materials have a wide range of applications, but they typically require a high cutting force.

Processing characteristics:

What is hardened steel?

| ISO | MC | Material |

|---|---|---|

| H | H1 | Steel (45-65HRC) |

| H2 | Chilled cast iron | |

| H3 | Tungsten chromium cobalt alloy | |

| H4 | Ferro-TiC |

Hardened steel in Group H finds application in various industries, including automotive, machine manufacturing, and mold business. During the cutting process, the steel typically produces continuous red hot chips due to the high temperatures involved. This elevated temperature helps to reduce the kc1 value and is essential in addressing application challenges.

Processing characteristics: