Have you ever considered the fascinating world of tin materials and their varied uses? This article explores the four main types of tin: foil, powder, granules, and profiles, detailing their unique applications across industries from electronics to food packaging. You’ll learn about each type’s specific properties and the growing demand driven by technological advancements and market needs. Dive in to understand how these materials shape our everyday products and the challenges faced in their production and consumption.

Tin materials can be divided into four categories: tin foil, tin powder, tin granules (beads, balls), and tin profiles (rods, plates, sheets, strips).

There are three allotropes of tin: white tin, grey tin, and brittle tin.

Tin foil finds extensive use in diverse fields such as medicine, chemical industry, light industry, food, art supplies, and handicraft production. Its applications include advanced dry capacitors, decoration and decoration materials, microwave oven insulation, packaging for food and alcohol, and usage in folk religious activities.

Tin foil’s flexibility, non-extrusion, anti-corrosion, and waterproof properties make it suitable for packaging barrel lining of flame retardant, floor glue, synthetic paint, and other organic chemical raw materials.

Tin foil is also used as a preform in special welding processes. However, currently, the production of tin foil is mainly done by hand, resulting in products that are narrow in breadth, uneven in thickness, and poor in strength. As a result, they are only suitable for handmade flower binding technology products, mainly used in religious ceremonies.

Currently, most of the tin foil (approximately 2000 tons/year) is exported to Taiwan, Hong Kong, Southeast Asia, and other areas with large overseas Chinese populations. However, in recent years, particularly since the 1990s, the domestic economy has experienced rapid growth, leading to a surge in the use and consumption of tin foil.

Unfortunately, the varieties produced domestically are limited in scope and cannot satisfy the needs of users. Therefore, there is a high demand for imported tin foil, which is primarily machine-made, large-sized, and high-grade.

It is estimated that the worldwide production of machine-made foil with mechanical strength, brightness, finish, and thickness (approximately 40μ) is approximately 5000 tons. The major tin foil producers globally include Germany, the United States, the United Kingdom, the Netherlands, Spain, Australia, and others.

From the current production and consumption of tin foil:

On one hand, the application and demand for tin foil have further expanded. On the other hand, the emergence of substitutes and increased consumption of alternatives, such as low-cost aluminum foil and polyethylene film packaging materials, have led to a decline in the consumption of tin foil. As a result, the total consumption of tin foil has not significantly improved.

However, in the long run, tin foil has advantages and market needs that aluminum foil does not possess, such as brightness, non-oxidizing, non-toxic, corrosion resistance, and good resonance performance. With the continuous improvement of industrial level and quality of life, the production of high-quality, large specification tin foil products has broad market prospects in China.

Tin powder finds extensive use in various applications such as electroplating, powder metallurgy structural parts, porous materials, friction materials, metal ceramics, diamond grinding wheels, metal graphite brushes, clutch brake patches, special coatings, flares, rubber, plastics, and other organic chemical additives, and organic synthetic reducing agents.

Currently, the demand for tin powder is more than 500 tons annually. Furthermore, with the continued development of the powder metallurgy industry, the consumption of tin powder is expected to increase at a rapid pace.

2)Tin particles and tin balls find extensive use in flux, organic synthesis, chemical production, alloy manufacturing, and assembling multiple groups of integrated circuits in the electronic industry.

They serve as reagents and reducing agents for the determination of arsenic and phosphate, and also in the production of tin plated products.

Tin granules are essential raw materials in the tin plating process, and they should be smooth, uniform, and bright for optimal results.

Tin profiles find wide application in the welding and electroplating industries, particularly in the electronic industry.

In China, they represent the largest category of tin imports, with an annual import volume of around 10,000 tons.

These profiles come in numerous varieties, specifications, and models, such as diamond bars, octagonal bars, star bars, anode plates, and round tubes of varying specifications.

The cost of these products is high, and their value addition exceeds 20% of the raw material cost.

1) Tin rods (rods) are mainly used in two ways:

Typically, tin-lead alloy bars serve as raw material for the production of solder wires in the electronics industry. To obtain solder wires of various specifications, these alloy bars require further processing and stretching.

On the other hand, pure tin bars are utilized as anode bars in the electroplating of tin plates.

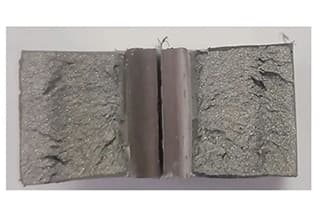

2) Tin plates can be divided into two categories:

There are two types of tin plates used in different applications. One is the tin anode plate used for tin plating, while the other is used for civilian purposes, mainly in the food industry or large hotels, where pure tin plates serve as the panel or console for food processing.

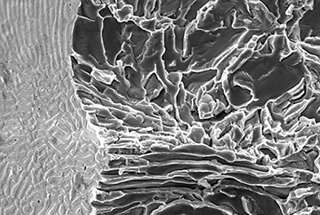

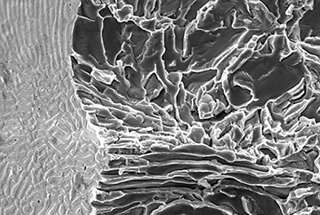

In Japan, during the production of tinplate, the tin anode plate serves as the insoluble anode, which means that it does not change during the electroplating process. This differs from the common electroplating process, which uses a soluble anode. In the latter, the anode plate dissolves during the production process.