For different types of steam turbine generator units, the shapes of both dynamic and static components are intricate and variable, and their deformation (amplitude) cannot be described by a simple function of dynamic stress. Consequently, it is incorrect to determine the fatigue of these components solely based on the vibration amplitude. Despite this, some insights […]

For different types of steam turbine generator units, the shapes of both dynamic and static components are intricate and variable, and their deformation (amplitude) cannot be described by a simple function of dynamic stress.

Consequently, it is incorrect to determine the fatigue of these components solely based on the vibration amplitude.

Despite this, some insights can be gleaned from the statistical analysis of a large number of unit operational experiences.

As far as the bearing amplitude of the steam turbine generator is concerned, there are three meanings as follows:

It is common on-site that the unit vibrates excessively at the rated speed.

For units with a rated speed of 3000 RPM, prolonged operation at the working speed can lead to excessive vibration.

Some units may experience frequent starting and stopping when passing the rotor’s critical speed.

If the vibration is caused by low-frequency oil film oscillation and subharmonic resonance in the generator bearing, it may not cause significant harm in the short term.

However, if it is a fundamental frequency vibration, it can lead to serious and harmful accidents at the rated speed, such as significant shaft bending and damage to the shafting.

If the vibration occurs at the critical speed of the high-pressure rotor in the turbine, it can also result in shaft bending accidents.

Furthermore, if the vibration occurs at the critical speed of the low-speed generator rotor, even if there is no noticeable damage to the generator, the unbalanced rotor can lead to an increase in the vibration of the high-pressure rotor at the critical speed, causing and exacerbating shaft rubbing and ultimately inducing a shaft bending accident.

These three types of vibrations are generally referred to as excessive vibration, strong vibration, and large vibration, respectively.

In terms of component fatigue caused by vibration, only excessive vibration and strong vibration are relevant, as large vibrations cannot occur during long-term operation of the unit.

If the vibration is the fundamental frequency, even if it is only present for a short time, it can result in a major vibration accident before component fatigue takes place.

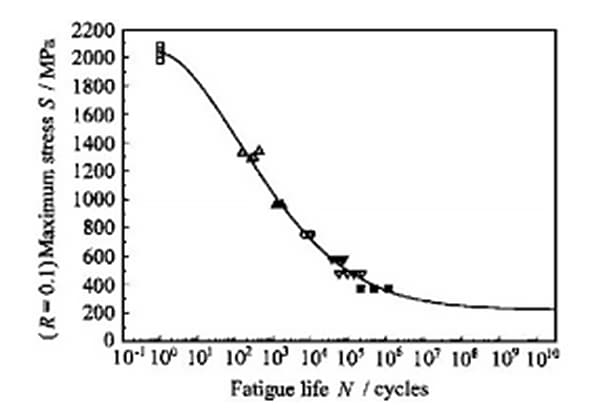

According to statistics gathered from extensive unit operation experience over a long period of time, the fatigue of components due to vibration is directly related to the amplitude value. The following rules have been established:

1. For any component of the unit, regardless of shape or structure, when operating at a speed of 3000 r/min, if the vibration frequency is less than or equal to the fundamental frequency and the maximum amplitude of bearings or components in three directions is less than 120 micrometers, these components will not experience fatigue damage during long-term operation.

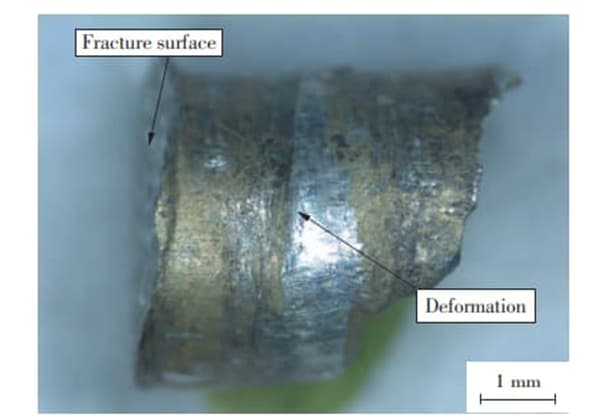

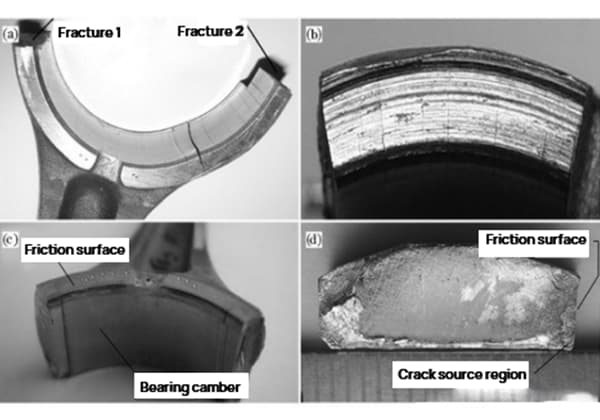

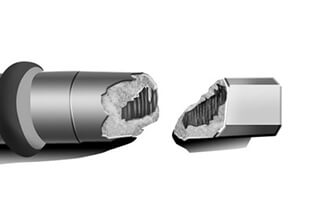

2. For parts with high stiffness, such as bearing pedestals, if the maximum amplitude in one direction exceeds 150 micrometers, fatigue damage will occur at joints with other parts during long-term operation, such as the fixing screws for the bearing pedestal and secondary grouting.

3. For parts with low stiffness, such as the end cover of a generator mirror where the pipe is not directly connected to the bearing seat, if the vibration in one direction exceeds 250 micrometers, fatigue damage will occur at the connection between these parts and parts with high stiffness after long-term operation, such as the connection between the pipe and the bearing seat.