Have you ever wondered how hot it gets during laser welding? Laser welding can produce temperatures from 100 to 3000 degrees Celsius, making it versatile enough to weld a wide range of materials. This article explores how laser welding’s adjustable temperature settings can effectively handle different materials’ melting points. Discover how this technology can benefit your welding projects by providing precise control over heat and efficiency. Dive in to understand the science and applications behind laser welding temperatures.

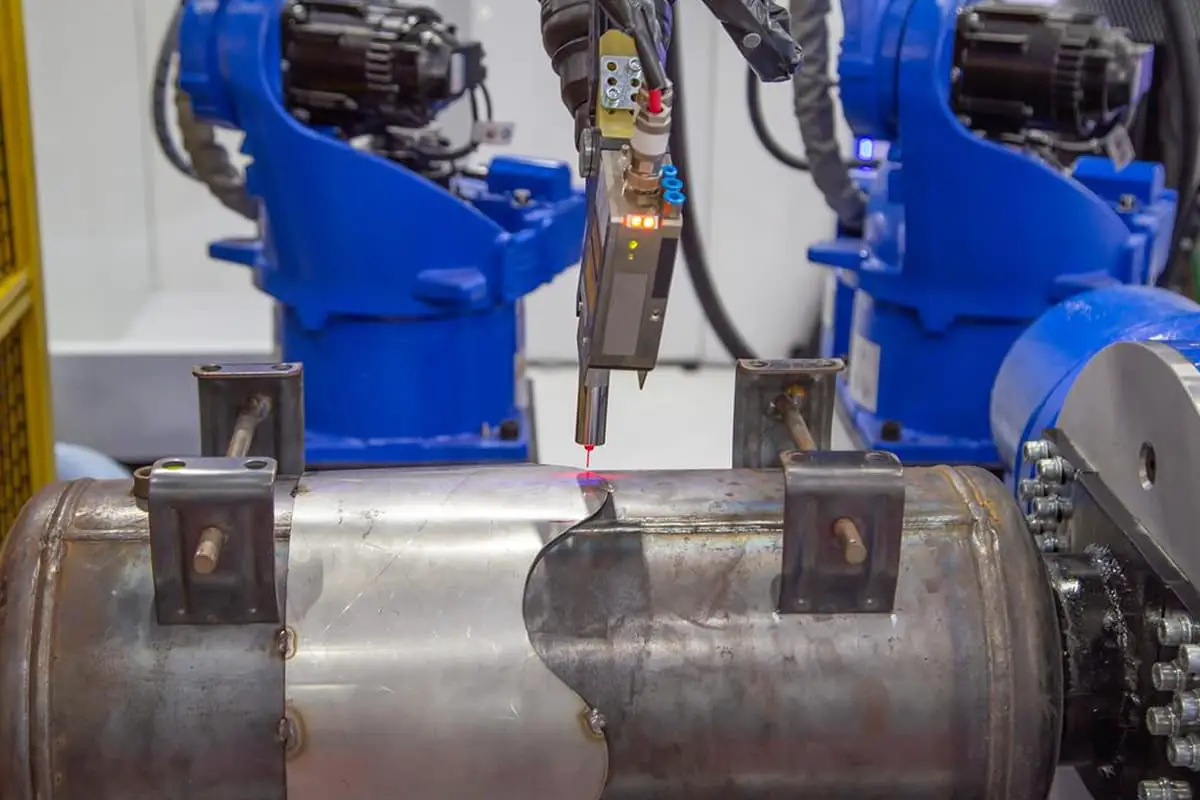

What is the temperature of laser welding?

The temperature can reach up to 3000 degrees.

The temperature can be adjusted manually through parameters.

In traditional welding, the temperature is fixed, but in laser welding, the temperature can be increased or decreased through manual control.

The temperature range is between 100 degrees and 3000 degrees, which is high enough to weld all types of materials.

To weld a material, the temperature must reach just above its melting point.

As a result, the melting temperature of the material is a limiting factor in conventional welding, and not all materials can be processed in every welding process.

Only electric welding can produce a limited range of spot heat intensity on its electrode.

Laser beam welding, on the other hand, offers maximum flexibility in terms of welding temperature in all welding processes.

An overview of common materials and their melting points highlights the range of materials that can be processed through laser beam welding:

It is possible to attain higher temperatures during laser beam welding.