Have you ever wondered how handheld laser welding machines are revolutionizing the manufacturing industry? In this blog post, we’ll explore the intricacies of these cutting-edge tools and how they’re transforming the way we create and repair metal components. Our expert mechanical engineer will guide you through the benefits, applications, and key features of handheld laser welding machines, providing valuable insights that will keep you at the forefront of this exciting technology.

According to preliminary understanding, most stainless steel products are produced through argon arc welding and other conventional welding methods.

Although these methods can fulfill 80% of production requirements, they can result in defects in the welding products such as undercut, incomplete penetration, dense porosity, and cracks.

These defects not only reduce the joint’s strength, but also serve as the source of crevice corrosion.

The welding process requires not only the welder’s technical proficiency but also the high cost of flux, which increases production costs. Additionally, the post-welding processing steps are very slow.

Moreover, the working steps of processing after welding are very slow.

To address these issues, handheld fiber laser welding machines were introduced.

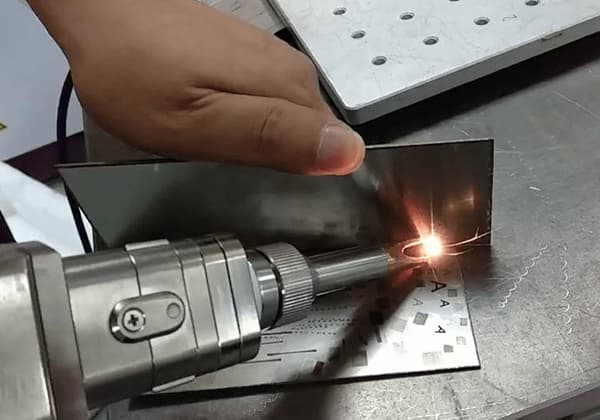

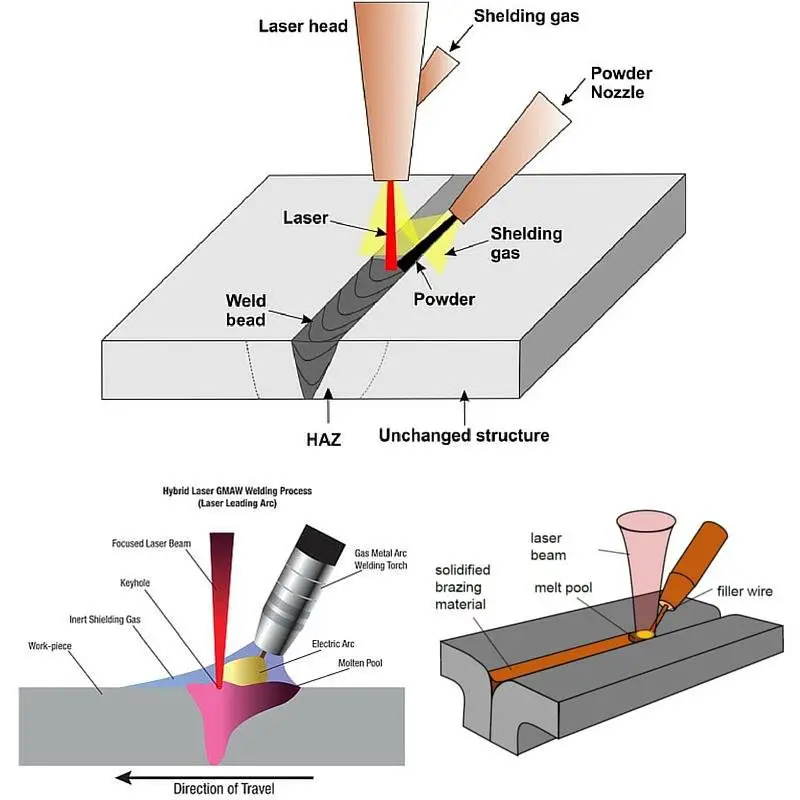

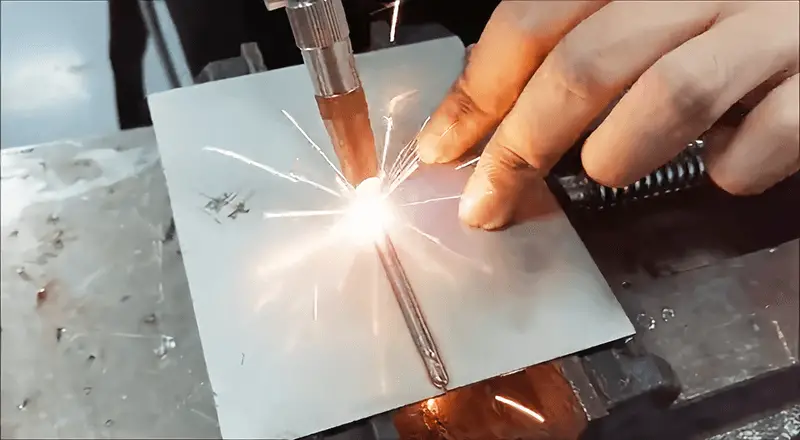

Handheld laser welding technology uses laser beams as the energy source to impact the welding joint and achieve welding.

It is a new welding method that has good welding performance, low deformation, and is widely used in the processing and welding of various metals.

The handheld laser welding machine has the advantages of ease of use, beautiful welding appearance, fast welding speed, and the absence of consumables.

It can perfectly replace traditional processes such as argon arc welding and electric welding for welding thin stainless steel sheets, iron sheets, galvanized sheets, and other metal materials.

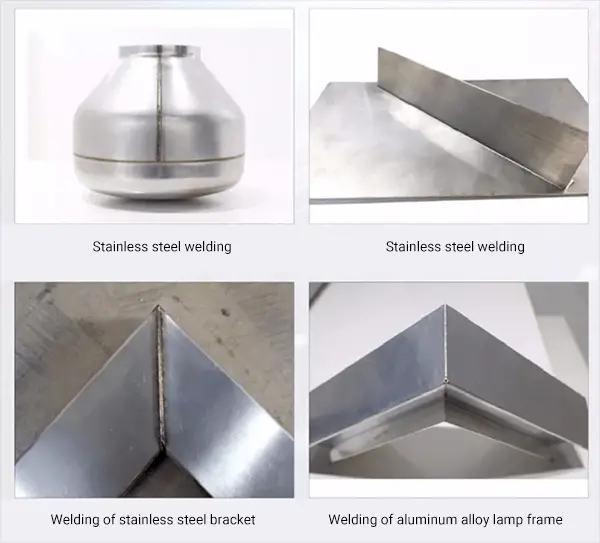

Handheld laser welding machines can be used in a variety of industries that require complex, irregular welding processes, such as cabinets, kitchens, stairs, elevators, shelves, ovens, stainless steel doors and windows, guardrails, distribution boxes, and stainless steel homes.

The handheld laser welding machine has a fast welding speed, which is 2 to 10 times faster than traditional welding methods, and can save at least two welders per year.

The welding seam after laser welding is smooth and attractive, reducing the need for post-weld grinding, saving time and cost.

The laser-welded workpieces are free from deformation and welding scars and have a strong welding bond. Additionally, the handheld laser welding machine requires fewer consumables and has a long lifespan.

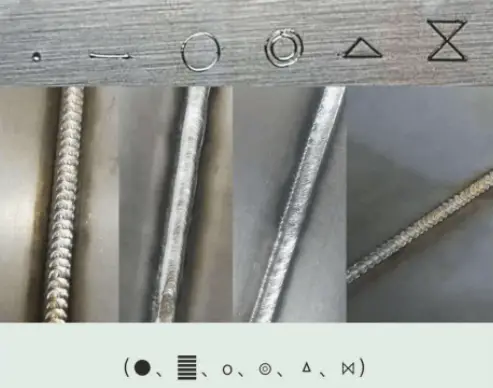

The machine is capable of welding various graphics, including points, lines, circles, squares, or any 2D shapes created using AutoCAD software.

The handheld laser welding machine is a new generation of laser welding equipment that uses non-contact welding techniques.

There is no need to apply pressure during operation, as it works by directly shining a high-energy laser beam onto the material surface.

This interaction between the laser and material melts the material, which then cools and solidifies to form the weld.

The handheld fiber laser welding machine fills a gap in the laser equipment industry by revolutionizing the traditional laser welding mode, replacing fixed optical paths with handheld flexibility.

This makes it possible to weld outdoors and at longer distances. The heat-affected area during welding is small, preventing workpiece deformation, blackening, or traces on the reverse side.

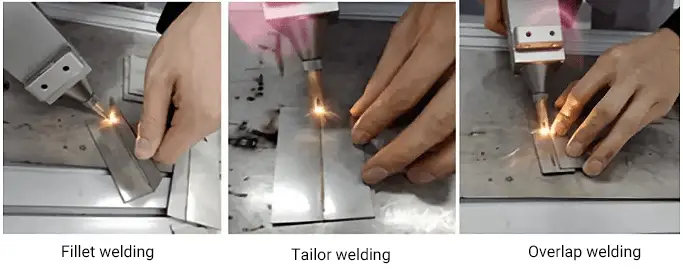

Furthermore, the welding depth is substantial and the welding is strong, making it possible to perform a variety of techniques, including thermal conductivity welding, continuous deep penetration welding, spot welding, butt welding, overlap welding, seal welding, seam welding, and more.

With simple operation, beautiful welds, fast welding speed, and no consumables, the handheld laser welding machine can replace traditional argon arc welding for metal materials such as thin stainless steel, iron, and galvanized plates.

It is mainly used for welding large workpieces at long distances, overcoming the limitations of traditional laser welding machines.

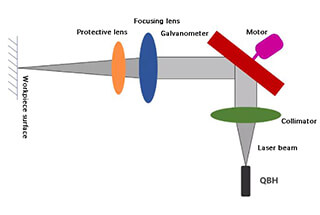

The working principle of a handheld laser welding machine is to use high-energy laser pulses to heat up specific small areas of the material. This energy is transferred through heat and guided into the material’s interior, causing the material to melt and form a molten pool.

The laser heat source has a high energy density and can concentrate a significant amount of energy on a small spot. This results in fast welding speeds, minimal welding deformations, and the ability to connect thin plates.

When the laser power density is high (>106w/cm2), the metal quickly heats up and reaches its boiling point, causing the surface temperature to rapidly rise and the metal to vaporize. This generates additional stress and makes the molten metal sag downward, creating a small pit under the laser spot.

As the laser continues to heat up the material, the laser beam is injected directly into the pit’s bottom, forming a “small hole”.

The small hole’s depth is determined by the balance between the metal vapor’s recoil pressure, the liquid metal’s surface tension, and gravity.

When the spot density is high, the small hole will run through the entire plate thickness, forming a deep penetration weld.

The small hole moves in the welding direction with the light beam relative to the workpiece, and the metal in front of the small hole melts, flows to the rear, and solidifies to form the weld.

This method is mainly used for welding thin-walled materials and precision parts, and can achieve various types of welding such as spot welding, butt welding, overlap welding, and seal welding.

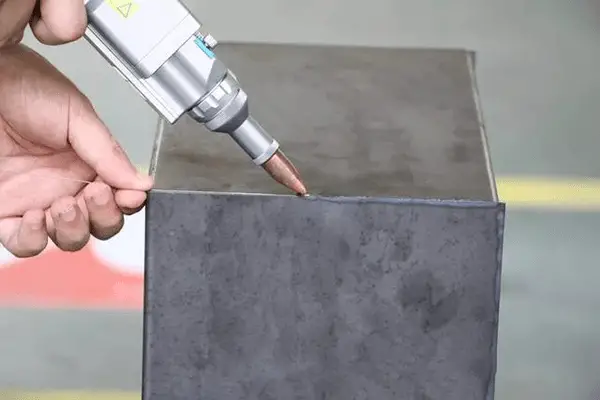

The handheld laser welding machine is designed for welding on long-distance and large workpieces.

During the welding process, the affected area by heat is kept minimal, thereby avoiding any deformations, blackening, and bead formation on the workpiece.

This machine offers a deep and sturdy weld with complete melting, resulting in no depression between the raised portion of the molten material and the matrix structure.

The handheld laser welding machine boasts several advantages over traditional welding methods.

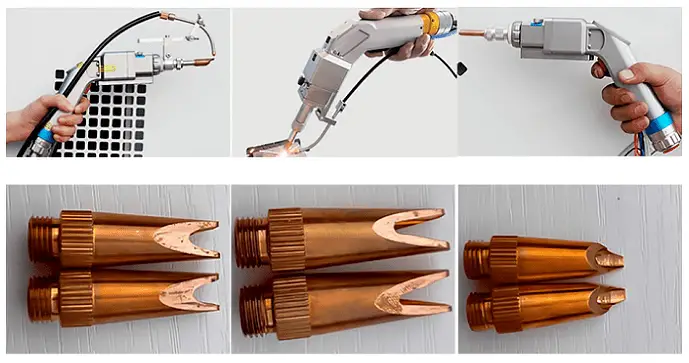

Firstly, the hand-held welding joint is selected, which eliminates the restrictions posed by the workspace.

The welding head can either be fixed or moved along with the workpiece for welding.

Furthermore, the welding head is equipped with a 5m imported optical fiber and has the ability to rotate in all directions, making it convenient and easy to operate.

This machine is suitable for outdoor welding and offers greater flexibility compared to traditional welding methods.

With the ability to weld at any angle and part of the workpiece, it is ideal for spot welding on complex welds and various devices.

The hand-held laser welding machine has the advantage of being able to perform any welding task with ease and simplicity.

Performance comparison between laser welding and traditional welding

| Material | Depth-width ratio | Power density (W/cm2) | Thermal deformation | Welding quality |

| Metal, Non-metal | <10 | 10K-100M | Min | High quality; Single side welding reduces weight and has high welding strength |

| Metal | <2 | 100-1M | Remarkable | Double-sided welding increases weight and low welding strength |

| Metal | <2 | 1K-100K | Remarkable | Large weld joint; Increased weight and low welding strength |

| Metal, Non-metal | <30 | 1M-100M | Min | High quality; However, the process is complex and requires vacuum and degaussing |

Hand-held laser welding technology is renowned for its ease of operation, attractive welds, fast welding speed, and the absence of consumables.

Furthermore, it is capable of perfectly replacing traditional welding processes, such as argon arc welding and electric welding, for the welding of thin stainless steel, iron, and galvanized plates, among other metal materials.

The hand-held design of the laser welding machine is essential in its practical application, making it the best choice for workshops that deal with small-scale processing or non-large-scale welding.

The diverse and flexible shapes of the welding products from small workshops can be fully met with manual laser welding.

The handheld laser welding machine employs a handheld welding gun instead of a fixed light path, revolutionizing the previous working mode of laser welding machines.

This operation mode not only facilitates the welding of products such as molds, advertising signs, and kitchenware, but also allows for outdoor laser welding.

The hand-held laser welding system can be widely used in the complex and irregular welding processes of various industries, including cabinets, kitchens, elevators, shelves, ovens, stainless steel door and window railings, distribution boxes, and stainless steel homes, among others.

Stainless steel, aluminum, copper, gold, and silver jewelry can be welded, as well as a wide range of hardware, such as triangle valves, stainless steel sinks, water pipe fittings, stainless steel pipe tees and elbows, floor drains, door handles, and door locks.

Wide Welding Range:

The handheld welding machine comes equipped with 5m-10m original optical fiber, which eliminates the limitations of workbench space and enables welding to be performed outdoors and remotely.

Convenient and Flexible Use:

The handheld laser welding machine features a mobile pulley for comfortable grip and the ability to adjust the station at any time, without a fixed station. This makes it suitable for a variety of work environments and scenes.

Multiple Welding Methods:

The handheld laser welding machine is capable of welding at any angle, including overlap welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, and more.

It can handle welding on complex and irregularly shaped large workpieces.

Good Welding Effect:

Handheld laser welding is a hot melt welding process that offers higher energy density compared to traditional welding methods, resulting in a superior welding effect.

The welding area is minimally impacted by heat and is not easily deformed or blackened.

The welding depth is large, the melting is sufficient, and the weld is firm and reliable, with a strength that can reach or even exceed that of the base metal itself.

No Polishing Required:

Traditional welding often requires polishing to ensure a smooth surface without roughness.

Handheld laser welding, on the other hand, provides a continuous and smooth weld without fish scales, scars, or the need for subsequent grinding.

No Consumables Needed:

Unlike traditional welding that requires welding wire, handheld laser welding can be completed easily and reduces material costs in production and processing.

Multiple Safety Alerts:

The touch switch is only effective when the welding nozzle comes into contact with metal.

The light is automatically locked once the workpiece is removed and the touch switch features temperature sensing, ensuring high safety levels for the operator during work.

Reduced Labor Costs:

Compared to arc welding, the processing cost of handheld laser welding can be reduced by up to 30%.

The operation is simple and easy to learn, requiring a low technical threshold for operators, who can be trained quickly to achieve high-quality welding results.

With the advancement of the economy and the enhancement of welding technology, there are numerous welding methods available for individuals to select from.

Unlike traditional welding equipment, more and more consumers are opting for laser welding machines in the modern manufacturing industry.

So, is laser welding really that good? To help you comprehend the features of this product better, I would like to highlight the differences between laser welding and traditional welding.

Can laser welding take the place of traditional welding? Let’s examine the welding methods individually.

Low-temperature welding in traditional welding is a combined welding process, where the solder is heated by a flame torch and melted in the gap between the metals to be joined.

Typically, the welded joint needs to be buried and preheated.

This method is cumbersome and has several drawbacks, such as being prone to deformation, solder joint breakage, corrosion, etc.

As of now, it is seldom used.

The handheld fiber laser welding machine operates in a handheld welding mode, offering flexibility and convenience, with a longer welding range. The fixed light path is replaced with a handheld welding gun.

The handheld fiber laser welding machine is primarily used for laser welding on large workpieces at a long distance. During welding, the heat-affected area is minimal, preventing deformation, blackening, and marking on the back of the workpiece.

Additionally, the welding depth is substantial, the weld is strong, and the melting is adequate, with no depression on the convex part of the dissolved material or the matrix structure of the solution pool.

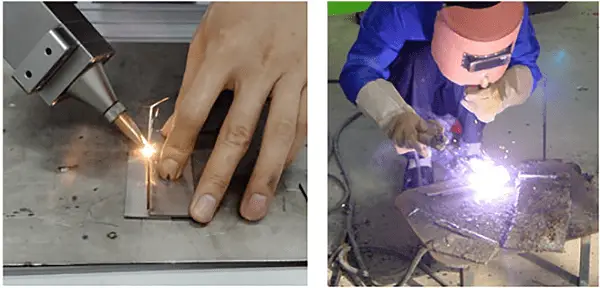

What distinguishes hand welding from traditional welding? The first defining feature of laser welding is that it minimizes workpiece deformation and there is virtually no joint gap.

The ratio of depth to width is high, with a ratio of 5:1 for high-power devices and a maximum of 10:1.

The weld strength is high, welding speed is fast, the weld seam is narrow, and the surface finish is usually good, eliminating the need for post-weld cleaning, leading to a more aesthetically pleasing appearance than traditional welding.

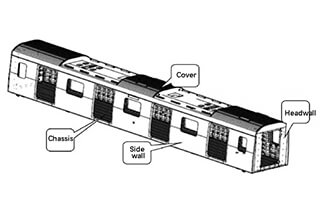

Laser welding can weld inaccessible parts and has the capability for non-contact remote welding. However, laser welding is limited to thin plates as it does not have enough penetration and cannot be used for welding the chassis and frame.

This can be achieved through spot welding, but the welding joint of spot welding requires stacking two thin plates together, resulting in a 15mm laminate that not only affects the appearance but also increases the weight of the vehicle.

While laser welding is currently the most advanced body welding technology, it is not feasible for the entire vehicle to adopt laser welding.

Laser welding is a non-contact method that does not require pressure during the operation process. It is fast, efficient, and has a large depth with minimal residual stress and deformation. The welding can be performed at room temperature or in special conditions, such as a closed space, and the equipment is simple and does not emit X-rays.

It can be used to weld refractory materials, such as high melting point metals, and even non-metallic materials such as ceramics and plexiglass. Its flexibility in welding special-shaped materials makes it ideal for non-contact, long-distance welding of inaccessible parts.

By focusing the laser beam, small spots can be achieved, and because it is not affected by magnetic fields and can be accurately positioned, it is suitable for micro-welding in the assembly of micro and small workpieces in mass automatic production.

The laser beam can be split easily in time and space, and can be transferred to multiple workstations via switching devices, allowing for multi-beam simultaneous processing and multi-workstation processing for more precise welding.

As a non-contact process, there are no tool loss or replacement problems, and no need for electrodes, avoiding the issue of electrode pollution or damage.

Laser welding can be automated for high-speed welding and can be controlled by digital or computer means.

Ordinary employees with some basic computer knowledge can operate it, unlike traditional welding machines that require experienced technicians. This saves a significant amount of cost for the enterprise.

Can laser welding replace traditional welding? The answer is yes, as laser welding has more advantages than traditional welding in three key areas.

Laser welding is 2-10 times faster than traditional welding and can save at least two welders per year through the use of a single machine. It requires no special technical skills and can be easily operated by general workers with a simple, intuitive design.

No additional training or guidance is necessary, enabling beautiful welded products to be created without assistance.

The final welded workpiece will be flat, smooth, and aesthetically pleasing, with no need for grinding, polishing, or extensive post-processing. This simplifies the polishing process and saves both time and cost.

What are the advantages of the handheld laser welding machine compared with the traditional welding method?

Simple Operation: The handheld laser welding machine can be used without extensive training, reducing the cost of training.

Fast and Efficient with a Wide Processing Range: The laser welding machine is highly efficient and fast, producing smooth and beautiful welds, reducing the need for subsequent grinding processes.

Weldable Material Range: The machine can weld various materials such as stainless steel, iron, galvanized, and aluminum plates.

No Limitations on Workpiece Shape and Processing Environment: The machine can produce small solder joints and small heat-affected areas. It does not require a welding workbench and occupies limited space. It is flexible, fast, and can be used in remote operations without being limited by the environment.

Low Maintenance Cost: With the handheld laser welding equipment and its accessories, the welding operation can be completed, and the cost of replacements is low.

High Cost-Performance: The manual handheld laser welding machine is not only for handheld laser welding operations but also for high-precision mold welding repairs using an erection platform. It is the preferred high cost-performance welding production equipment for small-scale manufacturers.

Energy Consumption: Compared to traditional arc welding, a handheld laser welding machine can save about 80% to 90% of electrical energy and reduce the processing cost by about 30%.

Welding Effect: Handheld laser welding can effectively weld dissimilar steel and dissimilar metals. The advantages include high speed, low deformation, and a small heat-affected zone. The resulting weld joint is clean, flat, without or little air holes, and without contamination. The machine is capable of micro-welding and precision welding.

Subsequent Processes: Due to its low heat input during the welding process, a handheld laser welding machine minimizes deformation of the workpiece and results in a beautiful weld surface that requires minimal or no post-treatment. This significantly reduces the labor cost associated with large-scale polishing and leveling processes.

Welding Process for Dissimilar Parts: Argon Arc Welding: This is a type of spot welding, where the workpiece is joined with a welding scar and overlap. The heat input is high, and the workpiece requires significant post-treatment, such as polishing, to remove the scar. An auxiliary welding wire is also necessary.

Handheld Laser Welding: In this process, a continuous laser light is used, without direct contact with the workpiece. The laser produces high temperature light that instantly melts the metal, creating a molten pool. The gas is evenly filled into the weld and cools it. The result is an instantly hot or cold weld with minimal heat effect, creating a beautiful weld without any scars. Depending on the customer’s requirements, the welding part may not need further grinding.

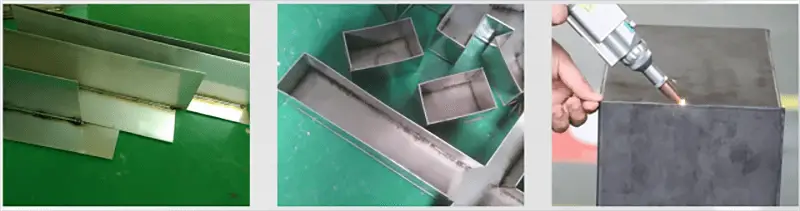

Welding of stainless steel square tube

Thickness Requirements:

Argon arc welding is not suitable for welding thin plates, as it has a high heat effect and cannot weld sheet metal less than 1mm.

Handheld laser welding, on the other hand, is suitable for welding thin plates within 3mm, while the argon arc welding method should be used if the thickness of the sheet metal is over 4mm.

Suitable Process and Function:

Argon arc welding is appropriate for stiffeners or fasteners, such as the welding of 4mm+ plate or pipe, bed body.

It is suitable for reinforcement and bearing purposes that do not require accuracy and beauty. It is capable of dot welding, stacking thickness, and strengthening the workpiece itself, and does not need to focus on appearance.

The added value of the product is also different in this case, and there is no need to choose laser welding.

Handheld laser welding is appropriate for parts that require a beautiful appearance, support parts, and structural parts.

In case of Missing or False Welding:

Argon arc welding: if repeat spot welding is done on the original welding workpiece, there will be pits. The more the welding is repaired, the more likely it is to collapse, resulting in high costs, especially for large parts.

Handheld laser welding: on the other hand, allows for flexible welding repairs and the workpiece can be welded accordingly. Welding wire can also be filled according to actual demand, and slight polishing can be done later.

welding with filler wire

Thermal Effects:

Argon Arc Welding: generates high heat and slow heat dissipation, causing the welding spot to be red hot.

Handheld Laser Welding: has no heat effect and fast heat dissipation.

Mobility:

Argon Arc Welding: comes with a motor box (gun body) that is 3 meters long and not easy to move.

Handheld Laser Welding: has a cable length of 5-20 meters, making it easy to move.

Risk Factor:

Argon Arc Welding: generates large sparks that can splash onto the body and face.

Handheld Laser Welding: is risk-free due to the use of laser protective glasses, with no sparks.

Worker Requirements:

Handheld Laser Welding: is easy to operate and requires only 3 hours of training for ordinary workers to start welding.

Efficiency Comparison:

Handheld Laser Welding is 10 times faster than Argon Arc Welding.

Welding Load or Tension:

Different powers corresponding to different thicknesses can be combined with welding thickness and power to achieve full penetration of the workpiece.

The penetration welding will be stronger than the material itself as it is cut off after being heated and becomes more wear-resistant after the second heating and forging.

Customers can make their own tensile test samples, and they may find that the welding place is not broken while the non-welding place breaks first.

Swing head handheld laser welding machine

Welding Temperature: The maximum welding temperature can reach 4000°C, and the heat can be controlled and dissipated instantly, resulting in minimal heat effect.

Single and Double-Sided Welding: Typically, the strength of single-sided welding is not as strong as double-sided welding. The surface of double-sided welding is heated more evenly, resulting in a better appearance and less heat effect and deformation. If you want to achieve greater strength in single-sided welding, the process must be slowed down, resulting in more heat and greater heat effect.

Handheld laser welding vs argon arc welding vs solid YAG welding table

| Type | Argon arc welding | Solid YAG welding | Handheld laser welding | |

|---|---|---|---|---|

| Welding quality | Heat input | Large | Small | Small |

| Workpiece deformation/undercut | Large | Small | Small | |

| Weld seam forming | Fish scale pattern | Fish scale pattern | Smooth | |

| Subsequent treatment | Polish | Polish | / | |

| Operation | Welding speed | Slow | Medium | Fast |

| Operation difficulty | Large | Small | Small | |

| Environmental protection and safety | Personal hazard | Large | Small | Small |

| Environmental pollution | Large | Small | Small | |

| Use cost | Consumables | Welding rod | Laser crystal, xenon lamp | / |

| Energy consumption | Small | Large | Small | |

| Area covered | Small | Large | Small | |

It is easy to operate and can be used by ordinary employees without incurring high training costs. It boasts high efficiency, large welding capacity, fast welding speed, and produces delicate and beautiful welds, reducing the need for subsequent grinding processes.

This technology can be utilized to weld a variety of metal materials such as stainless steel, iron, galvanized, and aluminum plates. With a small welding spot and minimal heat-affected area, no welding workbench is required, saving floor space.

The handheld laser welding equipment can easily complete welding tasks when equipped with a handheld laser welding joint, and replacement of accessories is cost-effective.

As an important supporting technology for green remanufacturing, laser processing technology has clear advantages over traditional methods.

Due to its high speed, precision, low energy consumption, and other benefits, it is widely used in crucial areas of the national economy such as microelectronics and electrical appliances, automobiles, aerospace, machinery manufacturing, printing and packaging, and others.

As a powerful tool in achieving the goal of intelligent manufacturing, laser welding technology is one of the crucial applications of laser processing.

Handheld laser welding is particularly important for complex and irregular welding processes without fixtures, such as sheet metal, chassis, water tanks, distribution boxes, cabinet kitchens, stainless steel door and window railings, etc.

Although handheld laser welding is a relatively new technology, it has already replaced traditional argon arc welding and electric welding in the welding of thin metal materials such as stainless steel plates, iron plates, and aluminum plates in the above mentioned applications.

Additionally, the growth of the laser welding industry has been further accelerated in recent years due to the rapid expansion of the new energy vehicle market, particularly in the production of power batteries.

Handheld laser welding is becoming increasingly popular and recognized by the market, making it a promising new area in the laser market. Industry experts predict that after handheld laser welding equipment has been standardized, it will be widely used in crucial industries such as rail transit, aerospace, automobile manufacturing, and the medical industry.

With the advancement of technology, the handheld laser welding machine has become increasingly sophisticated. The fourth-generation laser welding machine is now available on the market.

The welding power is adjustable, and the size and width of the weld can be adjusted according to the materials being welded, providing great convenience and cost savings.

The laser used is a well-known brand, known for its high efficiency, stable light output, and up to 100,000 hours of service life. Additionally, the handheld laser welding machine has a sleek design that has been well-received by users.

The machine’s operation is simple, with a 10-meter optical fiber cable connecting the welding gun to the main body, allowing for flexible welding in a wide range, even in outdoor settings.

The handheld laser welding machine offers more flexibility and operability than traditional fixed welding methods and can save up to 80-90% of electric energy compared to arc welding.

It can also reduce processing costs by about 30% compared to arc welding. The operation of the machine is simple, requiring only a half-hour of training to get started, making it easy to learn and quick to start using.

The technical threshold for operators is low, saving on labor costs. It is so simple to use that even girls can easily control it.

In conclusion, the handheld laser welding machine is easy to use and has won high praise in the welding industry.

The utilization of handheld laser welding equipment significantly reduces the preparation work required for workpieces and the technical expertise needed from the welding operator.

Business owners welding stainless steel products only need to adjust the welding parameters based on the thickness of the stainless steel plate, without the need for any additional welding wire or consumables.

The handheld laser welding machine boasts strong penetration ability and provides neat and durable welds. It requires less laser power for welding stainless steel doors and windows, handrails, and other stainless steel products, making it easier to use.

The welding head of the handheld laser welding machine is equipped with 5m of imported optical fiber, making it flexible and convenient for outdoor welding.

The operation mode of the handheld welding gun allows for welding at any angle or part of the workpiece, with dual optical path intelligent switching and uniform time-division light energy distribution.

It’s suitable for spot welding of various complex welds and devices, and can be easily automated by combining it with a manipulator for even greater flexibility and convenience.

This handheld laser welding machine is suitable for welding various materials such as stainless steel and carbon steel, and can be used in a variety of industries, including kitchens, household appliances, advertising, mold-making, stainless steel doors and windows, crafts, household products, furniture, and automotive parts, among others.

Despite the growing popularity of handheld laser welding systems in the market, there are still some challenges to be addressed. Most of the handheld laser welding machines available from equipment manufacturers utilize continuous fiber lasers with power levels ranging from 200W to 1500W.

However, for safety reasons, the welder must undergo extensive training, and the laser must not be directed at people or surrounding objects, as it can cause severe burns or even fires.

Furthermore, although the welding process is directed towards the workpiece, it still generates high-brightness reflections, so the operator must wear special protective light goggles.

If these issues are addressed, the handheld laser welding system will gain more recognition and the market demand could grow rapidly.

1. Application in the kitchenware industry

Handheld kitchenware laser welding equipment can save approximately 80% to 90% of electric energy. It also offers a cost reduction of around 30% compared to arc welding.

Additionally, this equipment is capable of welding dissimilar steel and dissimilar metals and can easily achieve mechanization and automation.

2. Application in the sheet metal processing field

In the field of sheet metal processing, laser welding has clear advantages compared to traditional argon arc welding.

These advantages include higher efficiency, minimal thermal deformation, a more attractive appearance, increased strength, no need for post-weld polishing, the ability to perform seamless butt welding, bending, stamping, and cutting.

3. Application in stainless steel bathroom processing field

In the field of welding stainless steel sanitary ware, handheld laser welding offers seamless splicing of fittings such as faucet and sink outlets with bright and attractive welding seams.

The process allows for 360-degree welding of right-angle fillets, making it convenient and easy to operate.

The basic operation environment of the product is as follows:

| Voltage | Three-phase five wire 380V ± 10% 50 / 60Hz AC |

| Power supply capacity | Not less than 5KW |

| Setting environment | Smooth, without vibration and impact |

| Working environment temperature | 10℃~40℃ |

| Working environment humidity | <70% |

| Weight (excluding package) | 300kg |

Warning:

Prior to using the laser, ensure a proper grounding connection.

The product does not come with built-in components, all maintenance must be conducted under the guidance of the company’s technical staff.

To prevent electric shock, do not tamper with the label or remove the cover. Any damage to the product will not be covered under warranty.

The laser’s output head is connected to an optical cable. Carefully inspect the output head to avoid contamination from dust or other debris.

When cleaning the output lens, use specialized lens paper.

Abnormal operation may cause damage to the laser if not used according to the instructions in this manual.

It is forbidden to install the output head while the laser is in use.

Do not gaze directly into the output head. When operating the machine, make sure to wear proper laser protection.

Precautions

(1) Before connecting the laser welding machine to the AC power supply, it is important to make sure that the correct 380V AC voltage is used. Failure to do so can cause irreparable damage to the laser.

(2) Operating the laser outside of the control or adjustment methods specified in this manual can also result in damage.

(3) Maintaining a clean output lens is crucial for good collimation of the laser output. Any damage to the lens will result in irreparable damage to the laser.

(4) When not in use, it is important to cover the collimator with its protective cap and not to touch the lens at the output end. If cleaning is necessary, special lens paper and alcohol should be used.

(5) Any loss of laser power due to incorrect operation, as specified above, will not be covered under the warranty.

Technical parameters of handheld laser welding machine

| Model | ||

|---|---|---|

| Optical characteristics | Testing environment | |

| Rated output power (W) | 1000-2000 | |

| Working mode | Continuous / modulation | |

| Output spot | Rotary motor ring variable multi spot | |

| Power regulation range (%) | 10~100 | |

| Central wavelength (nm) | 1080 | Rated output power |

| Output power instability | <3% | Rated output power; Continuous operation time: ≥ 5hrs; Working temperature: 25 ℃ |

| Modulation frequency (Hz) | 50~5k | Rated output power |

| Red light indicates output power (mW) | 0.5~1 | |

Optical output characteristics of output head

| Beam quality (BPP, mm•mrad) | <2 | Rated output power |

|---|---|---|

| Numerical aperture | 0.2 | |

| Fiber core diameter (μm) | 50 | 25, 100, 200 Optional |

| Output fiber length (m) | 10-15 |

Electrical properties

| Working voltage | Three phase five wire system 380V±10% 50/60Hz AC |

| Maximum power consumption (W) | 5000 |

| Control mode | Hyper terminal /RS-232/AD |

Other features

| Dimensions (W×H×D) | |

| Weight (kg) | <300 |

| Temperature range of working environment (℃) | 10~40 |

| Humidity range of working environment (%) | <70 |

| Storage temperature (℃) | -10~60 |

| Cooling mode | water cooling |

1) Cooling system water temperature setting:

2) Coolant requirements:

Purified water should be used as the cooling water and it is recommended to also drink purified water.

To avoid clogging in the chiller’s water caused by mold growth, it is suggested to add 10% ethanol when adding pure water.

When the equipment’s ambient temperature is between -10℃ and 0℃, a 30% ethanol solution should be used and replaced every two months.

If the ambient temperature of the equipment is below -10℃, a double system chiller with heating function must be utilized and continuous operation of the cooling system must be ensured.

Other requirements of the cooling system:

If the laser is not used for an extended period, it is important to drain the cooling water inside the cooling system and the laser to prevent irreparable damage to the laser equipment.

| It is important to set the water temperature of the cooling system correctly in accordance with the ambient temperature. If the water temperature is set too high, it may cause the laser to malfunction. On the other hand, if the water temperature is set too low, condensed water may form in the laser or its output head, resulting in irreparable damage to the laser equipment. |

| Before starting the laser, it is important to ensure that the cooling system is functioning properly and that the water temperature has reached the appropriate level. (In summer: 29 ± 0.5°C; In winter: 25 ± 0.5°C) |

Installation precautions

(1) Position the equipment in a horizontal location and secure it as needed.

(2) Before turning on the power, make sure the power supply is stable (220-380V AC ± 10%, 50/60Hz) and the grounding wire is in good condition.

(3) Connect all power and control lines while the power is off.

(4) Connect the cooling system to the laser and output head following the water inlet and outlet identification.

(5) Inspect the laser output head and clean it if necessary before installing it in the equipment. If dust is found on the output head, do not install and operate the laser until it has been cleaned.

(6) Handle the Yellow/metal armored protective sleeve with care during jumper installation, avoiding damage to the optical fiber by not stepping on it, squeezing it, or over-bending it.

(7) When installing or removing the laser output head, handle it with care and avoid vibration.

(8) Maintain a clean surrounding environment during the installation of the jumper output head to avoid pollution of the output head. For example, avoid using electric fans for heat dissipation in the summer when it is hot to prevent large amounts of dust in the air.

(9) The minimum bending radius of the laser transmission fiber should not be less than 20 cm during transportation and storage when the laser is not in use. When the laser is in the output state, the minimum bending radius should not be less than 30 cm.

| All the control lines of the laser should be connected while the power is off to avoid any potential damage to the laser caused by electrically charged installation of the control lines. |

| The laser output fiber should be kept in a relaxed position as much as possible, and twisting of the output fiber is prohibited. If the diameter of the fiber is too small, it can cause damage to the laser output. |

| In the process of installing and removing the laser output head, handle it with care and avoid any vibration. Before assembling the laser output head, ensure that the optical lens and cutting head cavity are clean and free of any pollutants. Take good care of the protective cap of the output head to prevent contamination. Otherwise, the protective cap can cause indirect contamination of the output head. |

(1) The device offers three new beam shapes and six beam shapes for selection, allowing for customization to meet the needs of different beam shapes for internal and external corner welding, flat welding, and angle welding.

(2) The Qilin double pendulum allows for adjustable energy density, effectively welding within a range of 0.2 to 5mm.

| No. | Model | Advantages |

| 1 | Spot | Small spot, strong energy, suitable for penetration welding and cutting. |

| 2 | Line | The width of the welding can be adjusted, and it is capable of penetrating thicker plates to a certain extent. This makes it suitable for external corner welding, tailor welding, and wire-feeding welding. |

| 3 | Circle | The diameter can be adjusted, resulting in a uniform distribution of energy density. The benefits of using high-frequency welding for thin plates are clear. |

| 4 | Double O | The adjustable diameter serves the primary purpose of reducing hollow spots, enlarging the spot size, and ensuring more uniform light radiation across the plate. This feature makes it suitable for all types of angle welding. |

| 5 | Triangle | The adjustable width helps reduce hollow spots and ensures that the three sides of the plate receive equal heating. Additionally, incorporating wire feeding welding allows for a reduction in frequency and produces a fish scale shaped welding spot, which is a significant improvement over single swing welding joints. |

| 6 | 8 style | Building upon a triangular design, the light spot is increased further, allowing for multiple heating of the plate. This feature makes it suitable for use in large-width welding. |

Laser Head Status Not Displayed:

No Conductive State Display or Intermittent Light Output During Welding:

Gas Cannot Be Controlled:

Protective Lens Easily Burns:

Welding Torch Head Overheated:

Touch Screen Parameters Cannot Be Modified:

Cleaning the Welding Gun Head:

Replacing the Protective Lens:

Handling the Welding Gun Head:

Using the Product:

Warning

Maintenance:

The circuit board is dead

Unit maintenance

Please blow the condenser for a long time:

Water Tank Maintenance:

Power Supply Maintenance:

Safety precautions

Before First Installation and Power-On, Carefully Check Wiring and Voltage for Correctness

The personnel responsible for the unit’s installation must ensure proper installation to prevent electric leaks, water leaks, or fire. If the unit needs to be removed and reinstalled, it is recommended to contact a professional.

Do Not Switch the Unit by Pulling Out the Power Plug through the Controller’s Switch System. Excessive current could burn the plug and trip the circuit, posing a safety hazard.

Ensure that the power supply is securely connected and the wire insulation is intact. Loose or broken wires could lead to electric shock, short-circuits, or fire.

Avoid putting foreign objects such as fingers or sticks into the unit’s air outlet, as this could cause damage to the unit or personal injury.

Provide adequate ventilation during operation of the unit.

Do not stand on or place objects on the unit.

Do not operate the unit with wet hands, as this could lead to electric shock.

The unit must be properly grounded. The ground wire should not be connected to the gas pipe, water pipe, or telephone line, as poor grounding could result in electric shock.

Ensure that a current protection device is installed to prevent electric shock.

If any unusual phenomena (such as a burning smell) are observed, immediately cut off the power supply and contact the economic department for solutions.

The operator of the handheld laser welding machine must undergo professional training, understand the use of the system indicator lights and buttons, and be familiar with basic equipment knowledge.

Before operating the handheld laser welding machine, check that the detection work trunking and wires are not damaged or exposed.

It is strictly prohibited to place sundries or tools on the robot body, external shaft, gun cleaning station, or water cooler.

It is also strictly prohibited to place any flammable or liquid objects in the operating room. The temperature in the operating room should not exceed 25°C, and there should be no leaks.

Conduct regular tests and inspections.

The welding machine uses forced air cooling and can easily attract dust from the surrounding area and accumulate inside the machine.

To prevent this, use clean and dry compressed air to regularly clean the dust inside the welder.

Check the power wiring connections regularly.

During annual maintenance and inspection, replace any faulty parts, repair the casing, and reinforce any insulation deterioration parts.

Regularly check and replace the conductive nozzle and clean and replace the spring hose.

Inspect the insulating rings as well.

The above-mentioned regular maintenance and inspections can minimize the occurrence of welding faults.

Although they may require some time and effort, they will prolong the service life of the welding machine, increase its operating efficiency, ensure its performance, and enhance safety.

Moreover, safety precautions must not be overlooked during the use of the hand-held laser welding machine.

Welding speed significantly affects the energy absorbed by the weld per unit of time, thereby influencing the weld’s penetration depth and width, as well as its appearance. This brief overview discusses the impact of welding speed on weld quality, providing a reference for process adjustments.

The speed primarily affects penetration depth and width, mainly relating to the linear energy density. Generally, as the laser welding speed increases, the fused area and width decrease. This can be understood as the increase in laser welding speed leading to a reduced dwell time of the laser on the surface of the workpiece. With the shorter laser dwell time, the heat conduction area decreases, resulting in a smaller fusion zone and heat-affected zone.

Furthermore, welding speed affects the appearance of the weld, often resulting in a rough, “V-shaped” fish scale pattern on the surface, with discoloration and minimal to no reinforcement, resulting in an unfilled weld.

Table Handheld Laser Welding Thickness & Speed Chart (800W-1500W)

| Metals | Thickness (mm) | Welding form | 800W welding efficiency (mm/s) | 1000W welding efficiency (mm/s) | 1500W welding efficiency (mm/s) |

| Stainless steel | 1 | Butt welding | 45 | 55 | 70 |

| Stainless steel | 2 | Butt welding | 16 | 35 | 45 |

| Stainless steel | 3 | Butt welding | / | 18 | 35 |

| Stainless steel | 4 | Butt welding | / | / | 15 |

| Carbon steel | 1 | Butt welding | 40 | 48 | 62 |

| Carbon steel | 2 | Butt welding | 12 | 23 | 35 |

| Carbon steel | 3 | Butt welding | / | 18 | 25 |

| Carbon steel | 4 | Butt welding | / | / | / |

| 1-3 series aluminum alloy | 1 | Butt welding | 32 | 40 | 70 |

| 1-3 series aluminum alloy | 2 | Butt welding | / | 20 | 35 |

| 4-7 series aluminum alloy | 1 | Butt welding | 18 | 35 | 60 |

| 4-7 series aluminum alloy | 2 | Butt welding | / | / | 25 |

Note: The above performance parameters are standard test data, and due to the complexity of practical applications, there may be differences in the data.

Improper speed selection can lead to defects in laser welding, which is a continuous process of melting and solidification. As the welding speed increases, the cooling rate of the molten metal also increases. This accelerated solidification makes it difficult for the metal to spread, resulting in humping defects. These humps increase as the welding speed rises, indirectly limiting the welding speed.

Solutions to Humping Prevention:

1. Utilize lasers with a smaller core diameter or select collimating focusing heads to reduce the spot size, concentrating the energy more effectively.

The mechanism is as follows: lasers with a smaller spot diameter can shorten the distance between the laser heat source and the liquid metal flow convergence point, facilitating the spread of liquid metal and suppressing humping;

2. Employ a dual-beam laser approach with one beam ahead of the other, or use ring-shaped spots, multi-wavelength fiber semiconductor composite welding, which can significantly increase the maximum welding speed without causing humping by over 40% compared to single-beam laser speeds.

Typically, one of the two laser beams is responsible for preheating and post-processing, and the other for melting depth. This reduces the cooling rate of the liquid metal around the keyhole, decreases the temperature gradient, lowers the surface tension of the liquid metal around the keyhole, and enhances the spreading ability of the liquid metal, thereby preventing humping.

If you want to find reliable laser welding machine manufacturers, you can refer to this post.