Imagine welding with precision so fine it’s almost futuristic. Laser welding machines are transforming industries by offering superior accuracy and minimal heat damage. From the automotive to the medical field, these machines are revolutionizing manufacturing processes. In this article, explore how various sectors are leveraging this advanced technology for better performance and efficiency. Get ready to uncover the remarkable applications and benefits of laser welding machines across multiple industries.

The advent of laser welding machines has provided another option for those in the market for welding equipment, but it has also introduced new challenges. Many individuals may be hesitant to switch from traditional welding methods, making it difficult for them to choose between a traditional welding machine and a laser welding machine.

The source of this hesitation is often a lack of knowledge about laser welding machines.

For laser welding machines, people often ask:

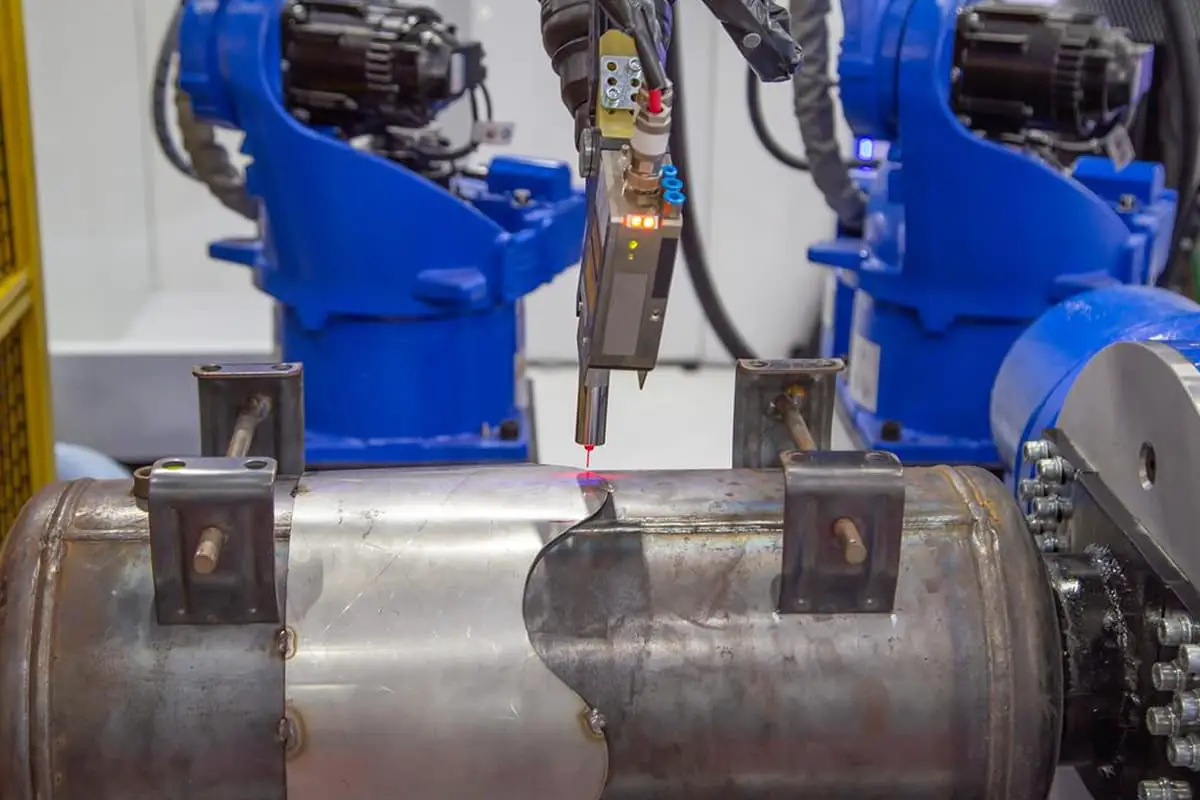

Laser welding machines use high-energy laser pulses to heat a small area of the material. The energy of the laser is transferred through heat, melting the material and forming a specific molten pool.

This is a new welding method, mainly used for welding thin-walled materials and precision parts. It can be used for spot welding, butt welding, overlap welding, seal welding, and more.

Laser welding machines have several key characteristics:

Laser welding machines are also known as energy feedback laser welding machines, laser cold welding machines, laser argon welding machines, and laser welding equipment.

As technology continues to advance, traditional welding methods are no longer suitable for meeting the special requirements of materials in industrial technology. This is why laser welding machines are widely used, as they offer a low bonding strength and a small heat-affected zone. They are gradually replacing traditional welding methods in many industries.

The following industries use laser welding machines in their applications:

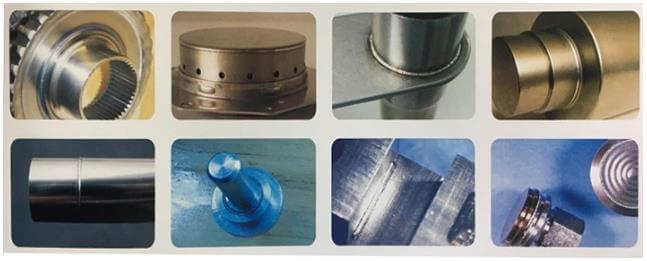

Other industries such as domestic hardware, kitchenware, sanitary ware, stainless steel door handles, electronic components, sensors, clocks, precision machinery, communications, handicrafts, and others, as well as the automobile hydraulic tappet industry, use laser welding machines due to their high strength requirements.

In conclusion, almost all of these industries utilize laser welding machines in their operations.

The advantages of a laser welding machine include high energy concentration, no pollution, small welding spots, a wide range of weldable materials, high applicability, efficiency, and speed.

In addition, the following types of products are well-suited for laser welding:

Recently, YAG laser processing technology has adopted optical fiber transmission technology, making laser welding technology more widely available and applicable. For example, a laser beam will not shift when passing through an electromagnetic field and can weld in vacuum, air, and some gas environments, and can even stop welding through glass or materials transparent to the beam.