What’s the difference between aluminum alloys 2A12, LY12, and 2024? These materials are key in aerospace and other high-load applications, but each has distinct properties and uses. This article compares their chemical compositions, mechanical properties, and typical applications, providing clear guidance on selecting the right alloy for your needs. By reading further, you’ll understand the strengths and limitations of each alloy, helping you make informed decisions for your projects.

LY12, now usually called 2A12, is equivalent to 2024. It is mainly composed of Al-Cu-Mg system with the following chemical composition:

Note:

(1) The properties of the elements in the combination are expressed as the highest percentage, unless a range or minimum value is listed.

(2) In order to establish appropriate numerical limits, observation or calculated values obtained from analysis are based on standard rules (ANSI Z25.1) to represent a clear range.

(3) Unless it is a non-alloy, the amount of elements specified in the alloy is usually indicated in the analysis report. However, if there is suspicion of the presence of other elements or the overabundance of some elements during the analysis process, further analysis should be carried out until confirmed.

(4) The aluminum content in non-alloy aluminum that has not been refined is equal to the total amount of other metals and the difference with 100% pure aluminum – the difference is about 0.01% or slightly more (the second decimal place after the percentage).

(5) It can contain up to 0.20% zirconium and titanium.

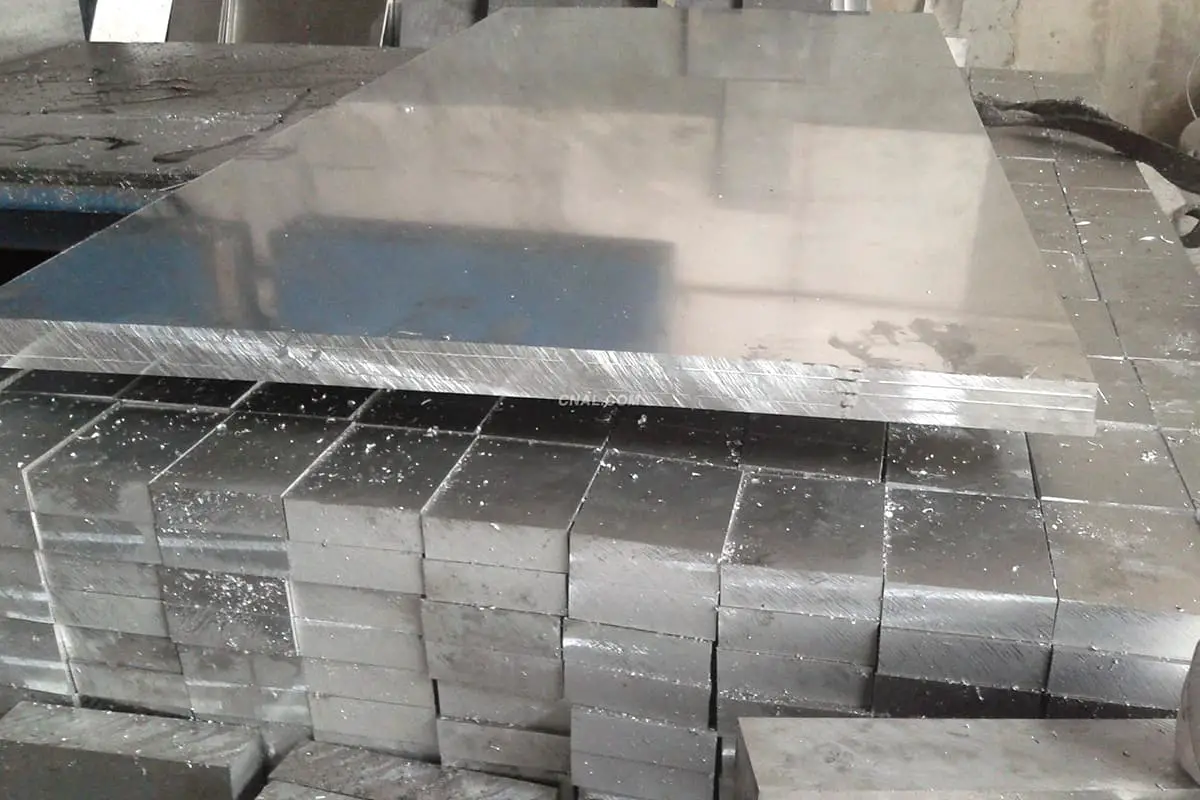

The common plate standard is AMS-QQ-A-250/4 (non-clad) and AMS-QQ-A-250/5 (clad), mainly used for aircraft structures, rivets, missile components, truck wheel hubs, propeller components, and other structural parts.

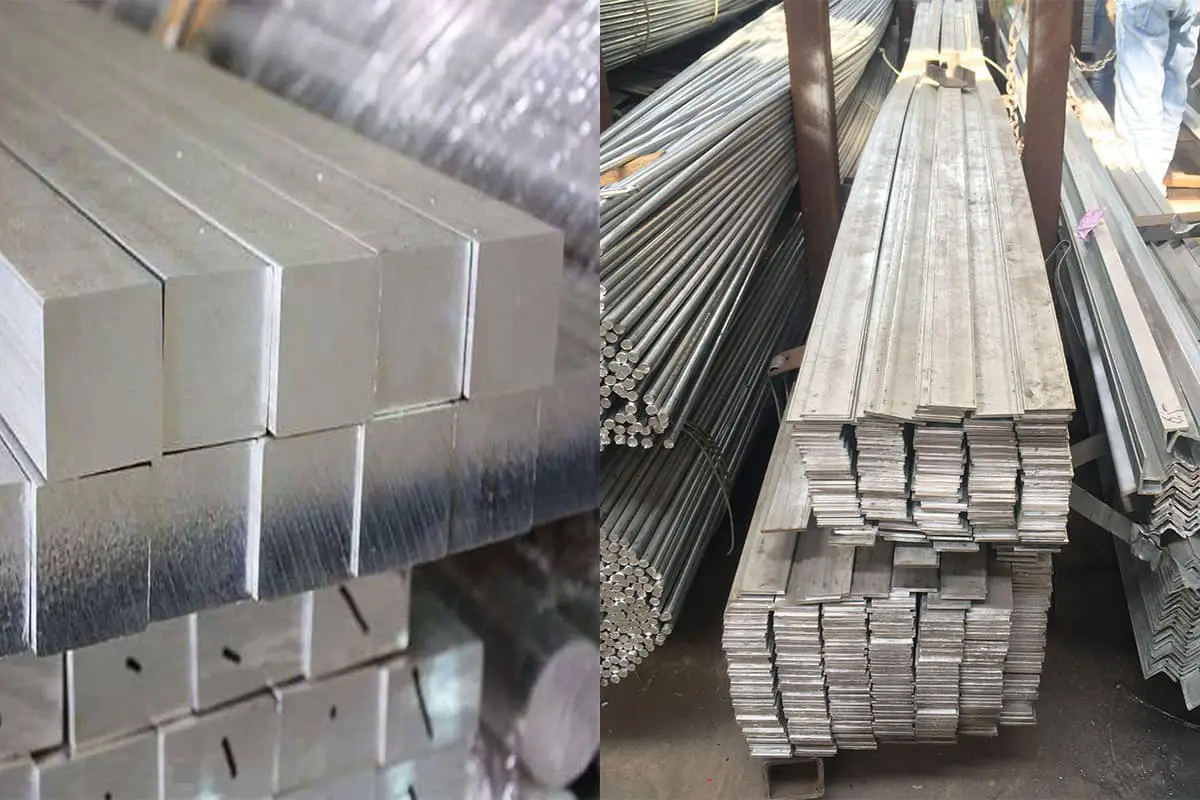

Sample size: bar diameter (square bar, hexagonal bar inscribed circle diameter) ≤ 22.

Standard: JIS H4000-1999

Chemical composition:

Mechanical properties:

Tensile strength (σb) ≥ 390 MPa

Yield strength (σ0.2) ≥ 245 MPa

Sample size: all wall thicknesses

Note: Pipe material, at room temperature, longitudinal.

Main characteristics and application scope:

This is a high-strength hard aluminum that can be strengthened by heat treatment. Its plasticity is moderate in quenched and tempered states. It has good resistance spot welding, but there is a tendency to form intergranular cracks when gas welding.

After quenching and cold working hardening, the alloy still has good machinability, while its machinability is poor after annealing. Its corrosion resistance is not high, so it is often treated with anodizing and painting or surface-coated with aluminum to improve its corrosion resistance.

It is mainly used to make various high-load parts and components (excluding stampings and forgings), such as skeleton parts, skin, partitions, ribs, spars, rivets, and other parts working below 150°C on aircraft.

Standard: GB/T 3191-1998

Chemical composition:

Note: Individual element: ≤ 0.05%; Total: ≤ 0.10%

Characteristics and application range:

2A12 aluminum alloy is a high-strength hard aluminum that can be strengthened by heat treatment.

It has moderate plasticity in annealed, quenched and tempered, and hot states. It has good resistance spot welding, but there is a tendency to form intergranular cracks when gas welding or argon arc welding.

After quenching and cold working hardening, the alloy still has good machinability, while its machinability is poor in the annealed state. Its corrosion resistance is not high, so it is often treated with anodizing and painting or surface-coated with aluminum to improve its corrosion resistance.

It is mainly used to make various high-load parts and components (excluding stampings and forgings), such as skeleton parts, skin, partitions, ribs, spars, rivets, and other parts working below 150°C on aircraft.

Mechanical properties of 2A12 aluminum alloy:

Note: The longitudinal mechanical properties of the bar at room temperature.