Have you ever wondered how a simple piece of steel can transform into a robust cabinet? In this article, we’ll explore the fascinating nine-fold profile, its applications, and the bending process. Learn how this innovative design enhances cabinet strength and efficiency.

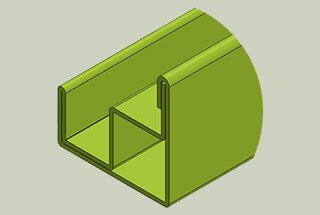

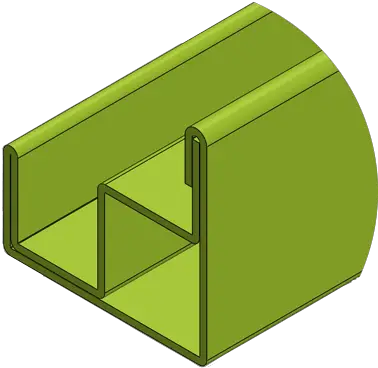

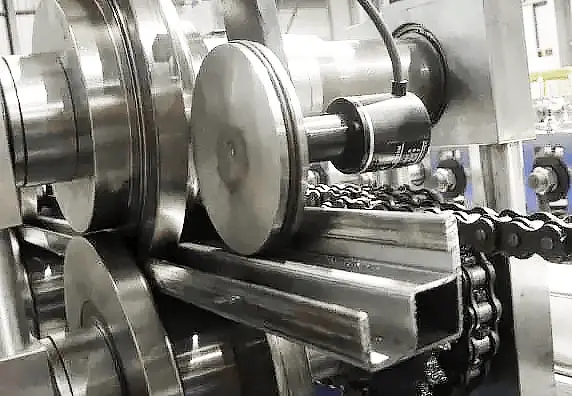

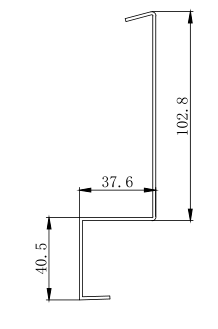

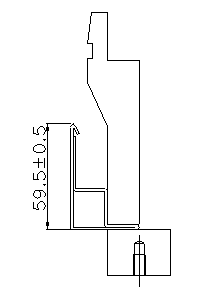

The nine-fold profile gets its name from the nine bends in the column and beam structure. It is made from cold-rolled steel plate that has been rolled by a roll forming machine.

Before detailing the process of using a press brake machine to bend a nine-fold profile, let’s first discuss the use of the nine-fold profile.

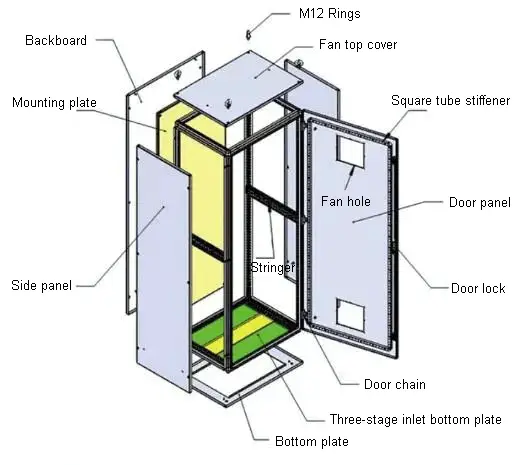

The nine-fold profiles are primarily used for cabinet production. The cabinets made from these profiles have a closed column and beam structure, providing higher strength compared to traditional open beam and C profile structures. They offer high force, low cost, take up minimal space, and are highly favored by users. The technology for processing these cabinets was developed by Rittal Company in Germany and has since been copied by Chinese domestic enterprises.

Materials of nine-fold profile cabinet:

The materials used for the nine-fold profiles include national standard cold-rolled steel plates and high-grade stainless steel, such as SUS304L for the food and beverage industry, SUS316L for the medical and pharmaceutical industry, and SUS201 as an economical stainless steel option.

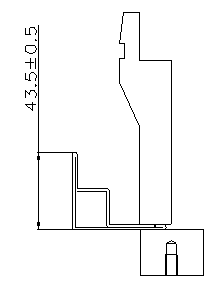

The thickness:

Surface treatment of the cabinet with nine-fold profile:

The steel plates for the cabinet body, base, and door undergo 12 international standard pre-treatment processes, including pickling, phosphating, dewaxing, washing, and purification. After these processes, the surface is coated with plastic and can be painted in any color as required. Stainless steel is typically treated with double-sided drawing.

Standard components of a nine-fold profile cabinet include:

Typically, the nine-fold profile can be purchased rather than made by the sheet metal shop. In special circumstances, sheet metal fabricators can also bend their own profiles.

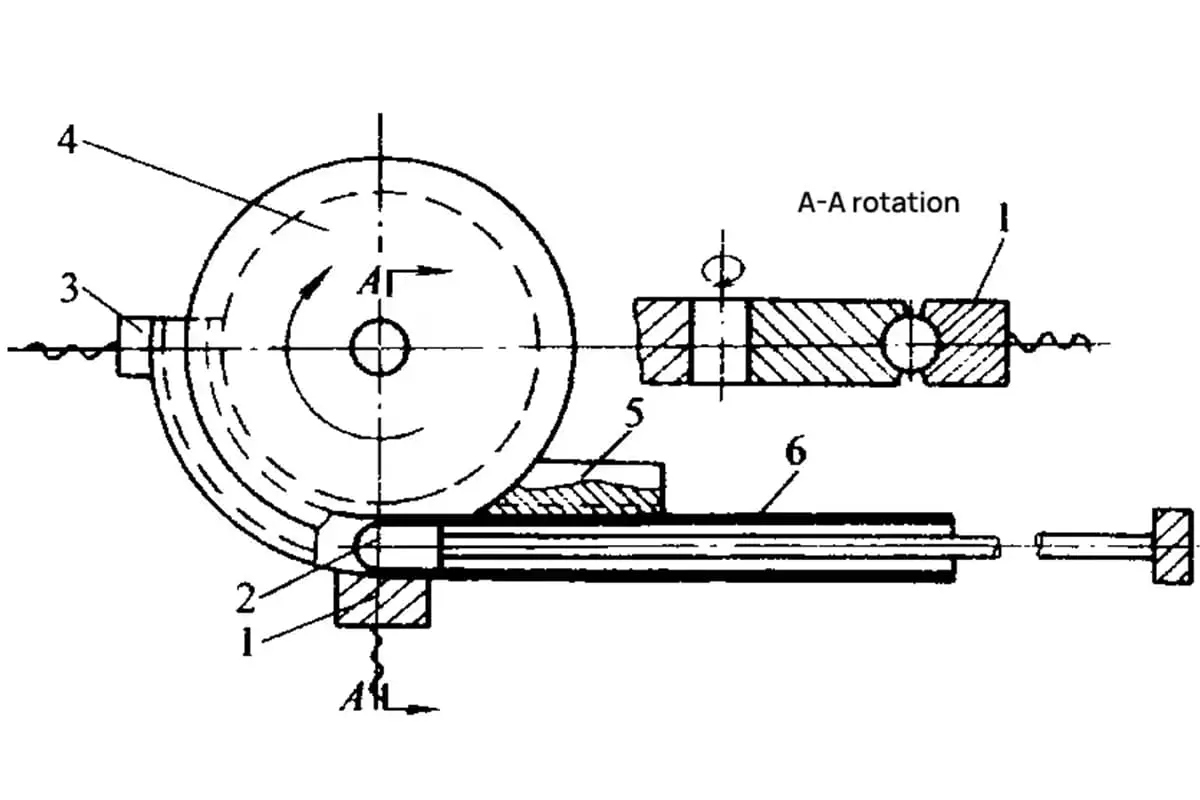

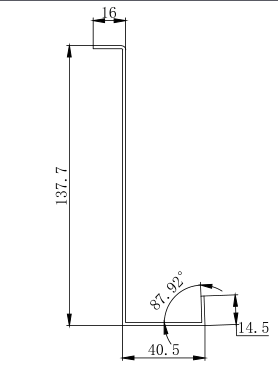

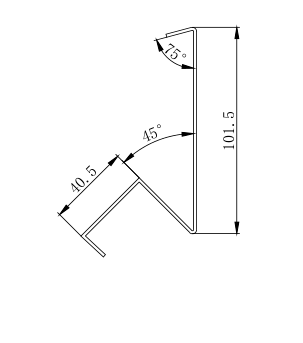

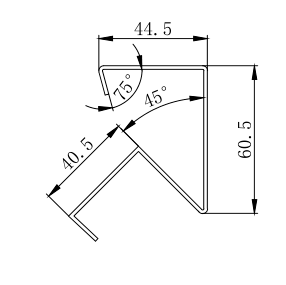

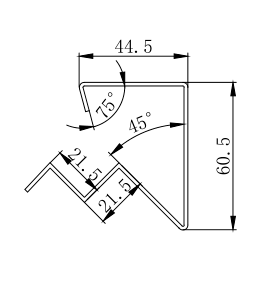

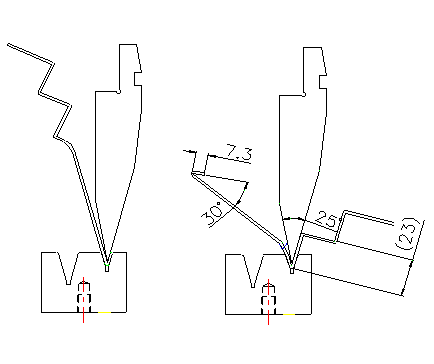

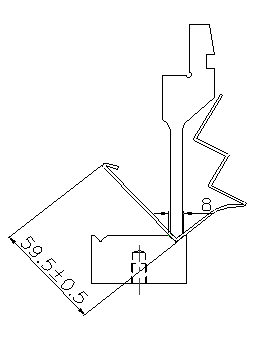

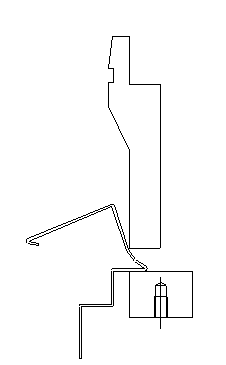

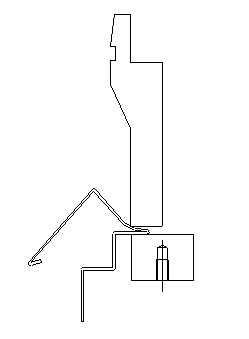

The following are two methods to bend a nine-fold profile.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

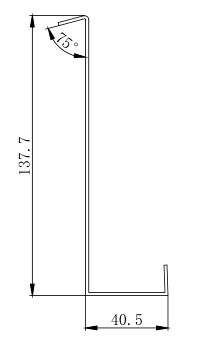

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Step 10

Step 11