Have you ever struggled with calculating the right bend allowance for your sheet metal projects? In this blog post, we’ll dive into the world of bend allowances and explore how to use a bend allowance calculator to streamline your workflow. As an experienced mechanical engineer, I’ll share my insights and break down the concepts behind this handy tool. Get ready to learn how to achieve precise bends and save time on your next project!

For new press brake operators who may not be familiar with the intricacies of calculating bend allowance, a bend allowance calculator can be an invaluable tool. This calculator simplifies the process, ensuring accurate results and making daily work more efficient.

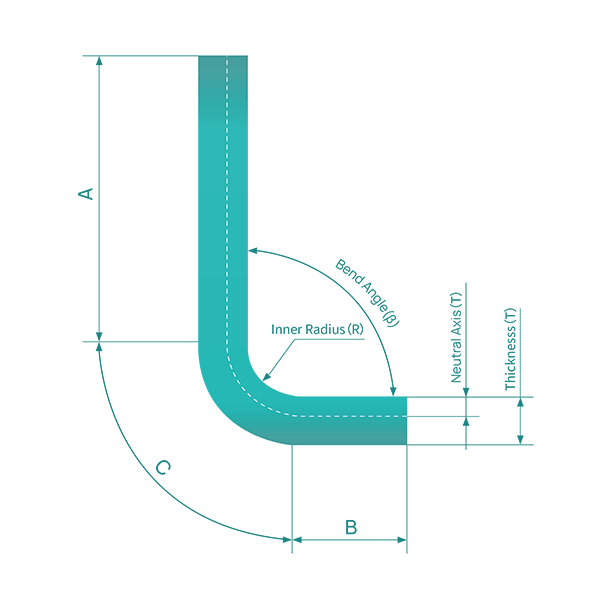

To use the bend allowance calculator effectively, operators need to input the following parameters:

Related calculator:

Further reading:

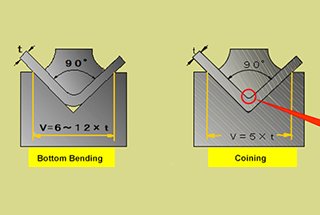

Bend allowance is the additional material length required when bending sheet metal to achieve the desired final dimensions after forming. It compensates for the stretching and compression that occurs in the material during the bending process.The bend allowance varies based on several factors:

Bend allowance values are typically determined through a combination of empirical data, mathematical calculations, and practical experience. Experienced sheet metal designers and engineers have developed bend allowance tables and formulas over years of repeated testing and verification.

By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent dimensions. This is crucial for creating accurate flat patterns and ensuring that the bent part fits and functions as intended.

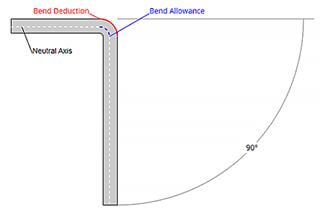

Bend allowance and bend deduction calculations are essential methods used to determine the length of sheet metal raw materials in their flat form, ensuring the desired size of the bent part is achieved. Understanding these calculations is crucial for precision in sheet metal fabrication.

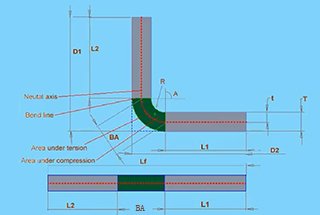

Bend Allowance Calculation Method:

The bend allowance (BA) is the amount of material that is added to the total length of the flat sheet to account for the material that will be used in the bend.

The following equation is used to determine the total flattening length when the bend allowance value is used:

Lt = A + B + BA

Where:

Bend Deduction Calculation Method:

The bend deduction (BD) is the amount of material that is subtracted from the total length of the flat sheet to account for the material that will be used in the bend.

The following equation is used to determine the total flattening length when using the bend deduction value:

Lt = A + B – BD

Where:

In addition to the bend allowance and bend deduction methods, other techniques can be used to determine the flat length of sheet metal raw materials. These include:

| Material | Thickness | Bending angle | V opening | Inner radius | Bends Allowance |

|---|---|---|---|---|---|

| SPCC | 0.5 | 90 | V4 | 0.5 | 0.95 |

| 100 | 0.73 | ||||

| 135 | 0.3 | ||||

| 175 | 0.03 | ||||

| SPCC | 0.5 | 90 | V5 | 0.5 | 1.03 |

| 100 | 0.79 | ||||

| 135 | 0.33 | ||||

| 175 | 0.03 | ||||

| SPCC | 0.5 | 90 | V6 | 0.5 | 1.1 |

| 100 | 0.85 | ||||

| 135 | 0.35 | ||||

| 175 | 0.03 | ||||

| SPCC | 0.6 | 90 | V4 | 0.5 | 1.08 |

| 100 | 0.83 | ||||

| 135 | 0.35 | ||||

| 175 | 0.03 | ||||

| SPCC | 0.6 | 90 | V5 | 0.5 | 1.15 |

| 100 | 0.89 | ||||

| 135 | 0.37 | ||||

| 175 | 0.03 | ||||

| SPCC | 0.6 | 90 | V6 | 0.5 | 1.23 |

| 100 | 0.95 | ||||

| 135 | 0.39 | ||||

| 175 | 0.03 | ||||

| SPCC | 0.8 | 90 | V6 | 0.5 | 1.49 |

| 120 | 0.73 | ||||

| 135 | 0.47 | ||||

| 150 | 0.25 | ||||

| SPCC | 0.8 | 90 | V8 | 0 | 1.64 |

| 120 | 0.81 | ||||

| 135 | 0.52 | ||||

| 150 | 0.27 | ||||

| SPCC | 0.8 | 90 | V10 | 0 | 1.79 |

| 120 | 0.88 | ||||

| 135 | 0.57 | ||||

| 150 | 0.3 | ||||

| SPCC | 1 | 90 | V10 | 0 | 2.05 |

| 100 | 1.58 | ||||

| 120 | 1.01 | ||||

| 135 | 0.62 | ||||

| 175 | 0.06 | ||||

| SPCC | 1 | 90 | V8 | 0 | 1.9 |

| 100 | 1.47 | ||||

| 120 | 0.93 | ||||

| 135 | 0.6 | ||||

| 175 | 0.05 | ||||

| SPCC | 1 | 90 | V6 | 0 | 1.74 |

| 100 | 1.35 | ||||

| 120 | 0.86 | ||||

| 135 | 0.56 | ||||

| 175 | 0.05 | ||||

| SPCC | 1.2 | 90 | V10 | 1.4 | 2.31 |

| 100 | 1.78 | ||||

| 120 | 1.13 | ||||

| 135 | 0.73 | ||||

| 175 | 0.06 | ||||

| SPCC | 1.2 | 90 | V8 | 1.4 | 2.15 |

| 100 | 1.66 | ||||

| 120 | 1.06 | ||||

| 135 | 0.69 | ||||

| 175 | 0.06 | ||||

| SPCC | 1.2 | 90 | V6 | 1.4 | 2 |

| 100 | 1.55 | ||||

| 120 | 0.98 | ||||

| 135 | 0.64 | ||||

| 175 | 0.05 | ||||

| SPCC | 1.5 | 90 | V6 | 1.7 | 2.36 |

| 100 | 1.82 | ||||

| 120 | 1.16 | ||||

| 135 | 0.75 | ||||

| 175 | 0.06 | ||||

| SPCC | 1.5 | 90 | V12 | 1.7 | 2.8 |

| 100 | 2.17 | ||||

| 120 | 1.38 | ||||

| 135 | 0.89 | ||||

| 175 | 0.08 | ||||

| SPCC | 1.5 | 90 | V10 | 1.7 | 2.65 |

| 100 | 2.05 | ||||

| 120 | 1.31 | ||||

| 135 | 0.85 | ||||

| 175 | 0.07 | ||||

| SPCC | 1.5 | 90 | V8 | 1.7 | 2.5 |

| 100 | 1.94 | ||||

| 120 | 1.23 | ||||

| 135 | 0.8 | ||||

| 175 | 0.07 | ||||

| SPCC | 2 | 90 | V10 | 2 | 3.29 |

| 100 | 2.54 | ||||

| 120 | 1.62 | ||||

| 135 | 1.05 | ||||

| 175 | 0.09 | ||||

| SPCC | 2 | 90 | V12 | 2 | 3.44 |

| 100 | 2.66 | ||||

| 120 | 1.69 | ||||

| 135 | 1.1 | ||||

| 175 | 0.09 | ||||

| SPCC | 2.5 | 90 | V18 | 3.03 | 4.6 |

| 100 | 3.56 | ||||

| 120 | 2.26 | ||||

| 135 | 1.47 | ||||

| 175 | 0.12 | ||||

| SPCC | 2.5 | 90 | V12 | 3.03 | 4.15 |

| 100 | 3.21 | ||||

| 120 | 2.04 | ||||

| 135 | 1.32 | ||||

| 175 | 0.11 | ||||

| SPCC | 2.5 | 90 | V10 | 3.03 | 4 |

| 100 | 3.09 | ||||

| 120 | 1.97 | ||||

| 135 | 1.28 | ||||

| 175 | 0.11 | ||||

| SPCC | 3 | 90 | V18 | 3.133.13 | 5.22 |

| 100 | 4.03 | ||||

| 120 | 2.57 | ||||

| 135 | 1.66 | ||||

| 175 | 0.14 | ||||

| SPCC | 3 | 90 | V12 | 3.13 | 4.78 |

| 100 | 3.69 | ||||

| 120 | 2.35 | ||||

| 135 | 1.52 | ||||

| 175 | 0.13 | ||||

| SPCC | 3 | 90 | V10 | 3.13 | 4.63 |

| 100 | 3.58 | ||||

| 120 | 2.28 | ||||

| 135 | 1.48 | ||||

| 175 | 0.13 |

| Material | Thickness | Bending angle | V opening | Inner radius | Bends Allowance |

|---|---|---|---|---|---|

| SUS | 0.5 | 90 | 4 | 0.6 | 1.04 |

| 100 | 0.79 | ||||

| 120 | 0.48 | ||||

| 135 | 0.3 | ||||

| 175 | 0.04 | ||||

| SUS | 0.5 | 90 | 5 | 0.6 | 1.15 |

| 100 | 0.88 | ||||

| 120 | 0.54 | ||||

| 135 | 0.33 | ||||

| 175 | 0.04 | ||||

| SUS | 0.5 | 90 | 6 | 0.6 | 1.27 |

| 100 | 1.13 | ||||

| 120 | 0.59 | ||||

| 135 | 0.37 | ||||

| 175 | 0.04 | ||||

| SUS | 0.6 | 90 | 4 | 0.6 | 1.16 |

| 100 | 0.88 | ||||

| 120 | 0.54 | ||||

| 135 | 0.34 | ||||

| 175 | 0.04 | ||||

| SUS | 0.6 | 90 | 5 | 0.6 | 1.27 |

| 100 | 0.97 | ||||

| 120 | 0.59 | ||||

| 135 | 0.37 | ||||

| 175 | 0.04 | ||||

| SUS | 0.6 | 90 | 6 | 0.6 | 1.38 |

| 100 | 1.05 | ||||

| 120 | 0.64 | ||||

| 135 | 0.4 | ||||

| 175 | 0.05 | ||||

| SUS | 0.8 | 90 | 4 | 1.1 | 1.4 |

| 100 | 1.06 | ||||

| 120 | 0.65 | ||||

| 135 | 0.4 | ||||

| 175 | 0.05 | ||||

| SUS | 0.8 | 90 | 5 | 1.1 | 1.51 |

| 100 | 1.15 | ||||

| 120 | 0.7 | ||||

| 135 | 0.44 | ||||

| 175 | 0.05 | ||||

| SUS | 0.8 | 90 | 6 | 1.1 | 1.62 |

| 100 | 1.23 | ||||

| 120 | 0.75 | ||||

| 135 | 0.47 | ||||

| 175 | 0.06 | ||||

| SUS | 1 | 90 | 6 | 1.9 | 1.87 |

| 100 | 1.42 | ||||

| 120 | 0.87 | ||||

| 135 | 0.54 | ||||

| 175 | 0.07 | ||||

| SUS | 1 | 90 | 8 | 1.9 | 2.1 |

| 100 | 1.6 | ||||

| 120 | 0.98 | ||||

| 135 | 0.61 | ||||

| 175 | 0.07 | ||||

| SUS | 1.2 | 90 | 6 | 1.6 | 2.1 |

| 100 | 1.59 | ||||

| 120 | 0.97 | ||||

| 135 | 0.61 | ||||

| 175 | 0.07 | ||||

| SUS | 1.2 | 90 | 8 | 1.6 | 2.32 |

| 100 | 1.76 | ||||

| 120 | 1.08 | ||||

| 135 | 0.67 | ||||

| 175 | 0.08 | ||||

| SUS | 1.2 | 90 | 10 | 1.6 | 2.54 |

| 100 | 1.93 | ||||

| 120 | 1.18 | ||||

| 135 | 0.74 | ||||

| 175 | 0.09 | ||||

| SUS | 1.5 | 90 | 8 | 2.1 | 2.68 |

| 100 | 2.03 | ||||

| 120 | 1.24 | ||||

| 135 | 0.77 | ||||

| 175 | 0.09 | ||||

| SUS | 1.5 | 90 | 10 | 2.1 | 2.9 |

| 100 | 2.2 | ||||

| 120 | 1.35 | ||||

| 135 | 0.84 | ||||

| 175 | 0.1 | ||||

| SUS | 2 | 90 | 10 | 3.49 | |

| 100 | 2.65 | ||||

| 120 | 1.62 | ||||

| 135 | 1.01 | ||||

| 175 | 0.12 | ||||

| SUS | 2 | 90 | 12 | 3.7 | |

| 100 | 2.82 | ||||

| 120 | 1.72 | ||||

| 135 | 1.07 | ||||

| 175 | 0.13 |

| Material | Thickness | Bending angle | V opening | Inner radius | Bends Allowance |

|---|---|---|---|---|---|

| SPHC | 1 | 90 | V10 | 1.86 | 2.05 |

| 100 | 1.58 | ||||

| 120 | 1.01 | ||||

| 135 | 0.62 | ||||

| 175 | 0.06 | ||||

| SPHC | 1 | 90 | V8 | 1.86 | 1.9 |

| 100 | 1.47 | ||||

| 120 | 0.93 | ||||

| 135 | 0.6 | ||||

| 175 | 0.05 | ||||

| SPHC | 1 | 90 | V6 | 1.86 | 1.74 |

| 100 | 1.35 | ||||

| 120 | 0.86 | ||||

| 135 | 0.56 | ||||

| 175 | 0.05 | ||||

| SPHC | 1.2 | 90 | V10 | 1.44 | 2.31 |

| 100 | 1.78 | ||||

| 120 | 1.13 | ||||

| 135 | 0.73 | ||||

| 175 | 0.06 | ||||

| SPHC | 1.2 | 90 | V8 | 1.44 | 2.15 |

| 100 | 1.66 | ||||

| 120 | 1.06 | ||||

| 135 | 0.69 | ||||

| 175 | 0.06 | ||||

| SPHC | 1.2 | 90 | V6 | 1.44 | 2 |

| 100 | 1.55 | ||||

| 120 | 0.98 | ||||

| 135 | 0.64 | ||||

| 175 | 0.05 | ||||

| SPHC | 1.5 | 90 | V12 | 1.74 | 2.8 |

| 100 | 2.17 | ||||

| 120 | 1.38 | ||||

| 135 | 0.89 | ||||

| 175 | 0.08 | ||||

| SPHC | 1.5 | 90 | V10 | 1.74 | 2.65 |

| 100 | 2.05 | ||||

| 120 | 1.31 | ||||

| 135 | 0.85 | ||||

| 175 | 0.07 | ||||

| SPHC | 1.5 | 90 | V8 | 1.74 | 2.5 |

| 100 | 1.94 | ||||

| 120 | 1.23 | ||||

| 135 | 0.8 | ||||

| 175 | 0.07 | ||||

| SPHC | 2 | 90 | V12 | 2.01 | 3.44 |

| 100 | 2.66 | ||||

| 120 | 1.69 | ||||

| 135 | 1.1 | ||||

| 175 | 0.09 | ||||

| SPHC | 2 | 90 | V10 | 2.01 | 3.29 |

| 100 | 2.54 | ||||

| 120 | 1.62 | ||||

| 135 | 1.05 | ||||

| 175 | 0.09 | ||||

| SPHC | 2.5 | 90 | V18 | 3 | 4.6 |

| 100 | 3.25 | ||||

| 120 | 2.26 | ||||

| 135 | 1.47 | ||||

| 175 | 0.12 | ||||

| SPHC | 2.5 | 90 | V12 | 3 | 4.15 |

| 100 | 3.21 | ||||

| 120 | 2.04 | ||||

| 135 | 1.32 | ||||

| 175 | 0.11 | ||||

| SPHC | 2.5 | 90 | V10 | 3 | 4 |

| 100 | 3.09 | ||||

| 120 | 1.97 | ||||

| 135 | 1.28 | ||||

| 175 | 0.11 | ||||

| SPHC | 3 | 90 | V18 | 3.1 | 5.22 |

| 100 | 4.03 | ||||

| 120 | 2.57 | ||||

| 135 | 1.66 | ||||

| 175 | 0.14 | ||||

| SPHC | 3 | 90 | V12 | 3.1 | 4.78 |

| 100 | 3.69 | ||||

| 120 | 2.35 | ||||

| 135 | 1.52 | ||||

| 175 | 0.13 | ||||

| SPHC | 3 | 90 | V10 | 3.1 | 4.63 |

| 100 | 3.58 | ||||

| 120 | 2.28 | ||||

| 135 | 1.48 | ||||

| 175 | 0.13 |

| Material | Thickness | Bending angle | V opening | Inner radius | Bends Allowance |

|---|---|---|---|---|---|

| SECC | 1 | 90 | V10 | 1.9 | 2.05 |

| 100 | 1.58 | ||||

| 120 | 1.01 | ||||

| 135 | 0.62 | ||||

| 175 | 0.06 | ||||

| SECC | 1 | 90 | V8 | 1.9 | 1.9 |

| 100 | 1.47 | ||||

| 120 | 0.93 | ||||

| 135 | 0.6 | ||||

| 175 | 0.05 | ||||

| SECC | 1 | 90 | V6 | 1.9 | 1.74 |

| 100 | 1.35 | ||||

| 120 | 0.86 | ||||

| 135 | 0.56 | ||||

| 175 | 0.05 | ||||

| SECC | 1.2 | 90 | V10 | 1.4 | 2.31 |

| 100 | 1.78 | ||||

| 120 | 1.13 | ||||

| 135 | 0.73 | ||||

| 175 | 0.06 | ||||

| SECC | 1.2 | 90 | V8 | 1.4 | 2.15 |

| 100 | 1.66 | ||||

| 120 | 1.06 | ||||

| 135 | 0.69 | ||||

| 175 | 0.06 | ||||

| SECC | 1.2 | 90 | V6 | 1.4 | 2 |

| 100 | 1.55 | ||||

| 120 | 0.98 | ||||

| 135 | 0.64 | ||||

| 175 | 0.05 | ||||

| SECC | 1.5 | 90 | V12 | 1.7 | 2.8 |

| 100 | 2.17 | ||||

| 120 | 1.38 | ||||

| 135 | 0.89 | ||||

| 175 | 0.08 | ||||

| SECC | 1.5 | 90 | V10 | 1.7 | 2.65 |

| 100 | 2.05 | ||||

| 120 | 1.31 | ||||

| 135 | 0.85 | ||||

| 175 | 0.07 | ||||

| SECC | 1.5 | 90 | V8 | 1.7 | 2.5 |

| 100 | 1.94 | ||||

| 120 | 1.23 | ||||

| 135 | 0.8 | ||||

| 175 | 0.07 | ||||

| SECC | 2 | 90 | V12 | 2 | 3.44 |

| 100 | 2.66 | ||||

| 120 | 1.69 | ||||

| 135 | 1.1 | ||||

| 175 | 0.09 | ||||

| SECC | 2 | 90 | V10 | 2 | 3.29 |

| 100 | 2.54 | ||||

| 120 | 1.62 | ||||

| 135 | 1.05 | ||||

| 175 | 0.09 | ||||

| SECC | 2.5 | 90 | V18 | 3.03 | 4.6 |

| 100 | 3.56 | ||||

| 120 | 2.26 | ||||

| 135 | 1.47 | ||||

| 175 | 0.12 | ||||

| SECC | 2.5 | 90 | V12 | 3.03 | 4.15 |

| 100 | 3.21 | ||||

| 120 | 2.01 | ||||

| 135 | 1.32 | ||||

| 175 | 0.11 | ||||

| SECC | 2.5 | 90 | V10 | 3.03 | 4 |

| 100 | 3.09 | ||||

| 120 | 1.97 | ||||

| 135 | 1.28 | ||||

| 175 | 0.11 | ||||

| SECC | 3 | 90 | V18 | 3.13 | 5.22 |

| 100 | 4.03 | ||||

| 120 | 2.57 | ||||

| 135 | 1.66 | ||||

| 175 | 0.14 | ||||

| SECC | 3 | 90 | V12 | 3.13 | 1.78 |

| 100 | 3.69 | ||||

| 120 | 2.35 | ||||

| 135 | 1.52 | ||||

| 175 | 0.13 | ||||

| SECC | 3 | 90 | V10 | 3.13 | 4.63 |

| 100 | 3.58 | ||||

| 120 | 2.28 | ||||

| 135 | 1.48 | ||||

| 175 | 0.13 |

| Material | Thickness | Bending angle | V opening | Inner radius | Bends Allowance |

|---|---|---|---|---|---|

| AL | 0.8 | 90 | 4 | 0.6 | 1.15 |

| 100 | 0.81 | ||||

| 120 | 0.5 | ||||

| 135 | 0.36 | ||||

| 175 | 0.03 | ||||

| AL | 0.8 | 90 | 5 | 0.6 | 1.2 |

| 100 | 0.85 | ||||

| 120 | 0.52 | ||||

| 135 | 0.37 | ||||

| 175 | 0.03 | ||||

| AL | 0.8 | 90 | 6 | 0.6 | 1.25 |

| 100 | 0.88 | ||||

| 120 | 0.54 | ||||

| 135 | 0.39 | ||||

| 175 | 0.03 | ||||

| AL | 1 | 90 | 6 | 0.6 | 1.49 |

| 100 | 1.05 | ||||

| 120 | 6.5 | ||||

| 135 | 0.46 | ||||

| 175 | 0.04 | ||||

| AL | 1 | 90 | 8 | 0.6 | 1.59 |

| 100 | 1.13 | ||||

| 120 | 0.69 | ||||

| 135 | 0.5 | ||||

| 175 | 0.04 | ||||

| AL | 1.2 | 90 | 6 | 0.9 | 1.73 |

| 100 | 1.22 | ||||

| 120 | 0.75 | ||||

| 135 | 0.54 | ||||

| 175 | 0.04 | ||||

| AL | 1.2 | 90 | 8 | 0.9 | 1.82 |

| 100 | 1.29 | ||||

| 120 | 0.79 | ||||

| 135 | 0.57 | ||||

| 175 | 0.05 | ||||

| AL | 1.5 | 90 | 8 | 1.2 | 2.18 |

| 100 | 1.54 | ||||

| 120 | 0.95 | ||||

| 135 | 0.68 | ||||

| 175 | 0.06 | ||||

| AL | 1.5 | 90 | 10 | 1.2 | 2.28 |

| 100 | 1.61 | ||||

| 120 | 0.99 | ||||

| 135 | 0.71 | ||||

| 175 | 0.06 | ||||

| AL | 1.5 | 90 | 12 | 1.2 | 2.38 |

| 100 | 1.68 | ||||

| 120 | 1.03 | ||||

| 135 | 0.74 | ||||

| 175 | 0.06 | ||||

| AL | 2 | 90 | 14 | 1.6 | 3.07 |

| 100 | 2.17 | ||||

| 120 | 1.3 | ||||

| 135 | 0.93 | ||||

| 175 | 0.08 | ||||

| AL | 2 | 90 | 12 | 1.6 | 2.98 |

| 100 | 2.11 | ||||

| 120 | 1.34 | ||||

| 135 | 0.95 | ||||

| 175 | 0.08 | ||||

| AL | 2 | 90 | 18 | 1.6 | 3.25 |

| 100 | 2.3 | ||||

| 120 | 1.42 | ||||

| 135 | 1.01 | ||||

| 175 | 0.08 | ||||

| AL | 2.5 | 90 | 18 | 2.4 | 3.89 |

| 100 | 2.75 | ||||

| 120 | 1.7 | ||||

| 135 | 1.21 | ||||

| 175 | 0.1 | ||||

| AL | 3 | 90 | 18 | 2.5 | 4.5 |

| 100 | 3.18 | ||||

| 120 | 1.96 | ||||

| 135 | 1.4 | ||||

| 175 | 0.1 | ||||

| AL | 3.2 | 90 | 18 | 2.5 | 4.74 |

| 100 | 3.35 | ||||

| 120 | 2.06 | ||||

| 135 | 1.47 | ||||

| 175 | 0.12 | ||||

| AL | 4 | 90 | 40 | 4.6 | 6.77 |

| 100 | 4.79 | ||||

| 120 | 2.95 | ||||

| 135 | 2.11 | ||||

| 175 | 0.17 | ||||

| AL | 6.8 | 90 | 800 | 9.4 | 12.09 |

| 100 | 8.55 | ||||

| 120 | 5.27 | ||||

| 135 | 3.76 | ||||

| 175 | 0.31 |