Have you ever wondered about the weight of those patterned steel plates you see every day? In this blog post, we’ll dive into the fascinating world of checkered steel plates. As a mechanical engineer with years of experience, I’ll share my insights on how factors like material, thickness, and pattern shape influence the weight of these versatile plates. Get ready to learn something new and exciting!

The weight of a checkered steel plate depends on several key factors, including the plate’s material, thickness, and pattern shape. To calculate the weight of a standard steel plate, you can use the following formula:Weight (kg) = 7.85 x Thickness (mm)However, the theoretical weight will vary for different types of checkered plates based on their unique characteristics.

The theoretical weight per square meter for checkered plates can vary significantly based on the specific pattern shape and thickness:

Overall, the theoretical weight of checkered plates can range from as low as 1.6 kg/m² to 29.5 kg/m², depending on these factors. It’s essential to consider both the pattern shape and thickness when determining the expected weight of a checkered plate.

The material composition of a checkered plate plays a crucial role in determining its overall weight. The primary factor at play is the material’s density – the mass contained within a unit volume.

Density and Weight Relationship

In addition to density, the specific material used for the checkered plate will impact its theoretical base weight per square meter. Common materials include:

Even if two checkered plates have identical dimensions and thicknesses, they may have noticeably different weights in practice due to the inherent properties of their constituent materials. This highlights the importance of factoring in material choice when assessing the weight of checkered plates.

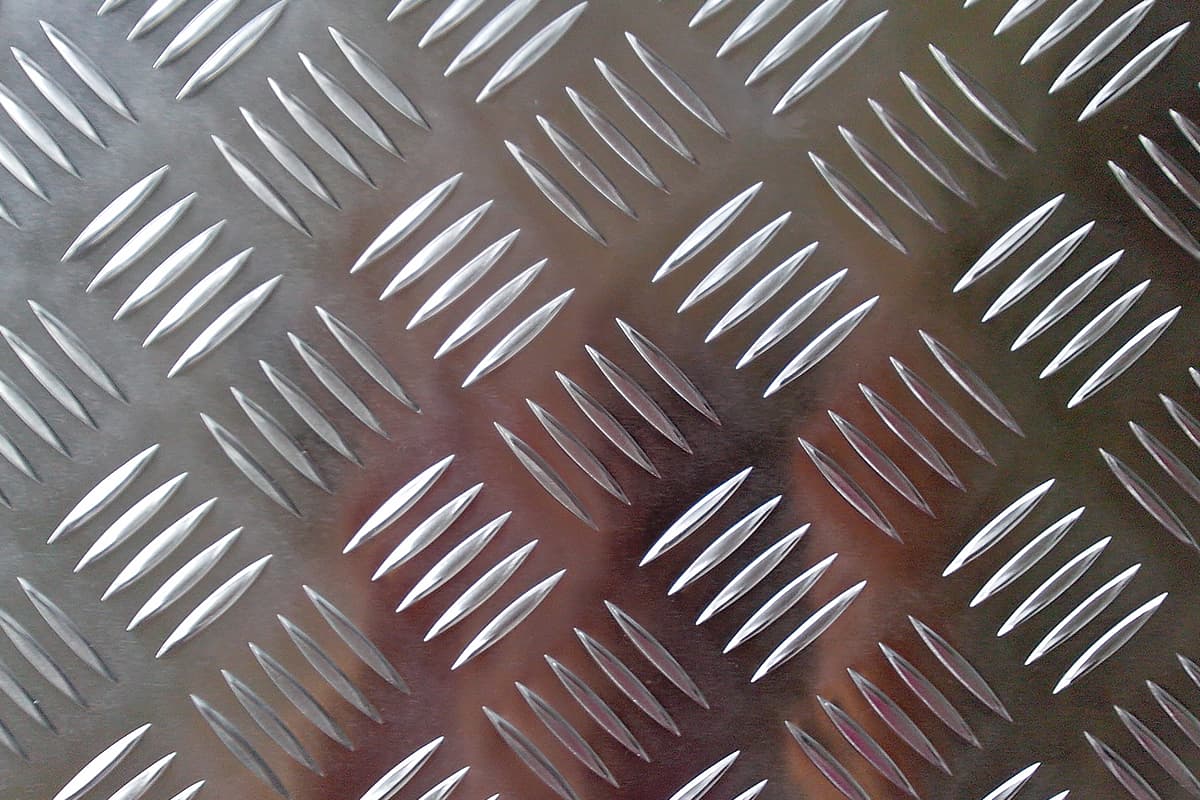

Another key consideration when evaluating the weight of a checkered plate is its pattern shape. The most common pattern shapes are:

Each of these distinct patterns will affect the overall weight of the checkered plate differently. As such, it’s crucial to account for both the material composition and the specific pattern shape to accurately assess the weight of a given checkered plate.By taking a comprehensive approach that includes material density, thickness, and pattern geometry, you can more precisely determine the expected weight of checkered plates for your specific applications.

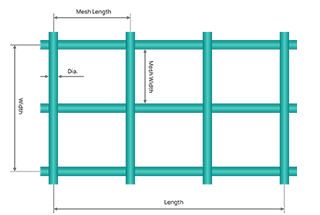

To simplify the process of determining the weight of checkered plates, you can use online calculators designed for specific materials. These calculators take into account factors such as pattern shape, thickness, width, length, and number of pieces to provide an estimated weight.

For checkered mild steel (MS) plates, use the following calculator:

Simply select the pattern shape (diamond, lentil, or round bean), input the thickness (2.5mm to 8mm), width, length, and number of pieces, and the calculator will display the estimated weight in kilograms.

Related calculator:

To calculate the weight of checkered aluminum plates, use this calculator:

Input the thickness (2.5mm to 8mm), width, length, and number of pieces to obtain the estimated weight in kilograms.

Important Considerations:

While these calculators provide a convenient way to estimate the weight of checkered plates, it’s crucial to keep in mind that the results are for reference purposes only. The actual weight of the plates may differ from the theoretical weight by an error margin ranging from 0.2% to 0.7%.

When using these calculated weights for transactions or other critical applications, exercise caution and verify the actual weight whenever possible to ensure accuracy.

For quick reference, consult these comprehensive weight charts for checkered steel plates in various thicknesses and pattern shapes.

| Thickness (mm) | Allowable deviation (mm) | Diamond (kg/m²) | Lentil (kg/m²) | Round bean (kg/m²) |

|---|---|---|---|---|

| 2.5 | ±0.3 | 21.6 | 21.3 | 21.1 |

| 3 | ±0.3 | 25.6 | 24.4 | 24.3 |

| 3.5 | ±0.3 | 29.5 | 28.4 | 28.3 |

| 4 | ±0.4 | 33.4 | 32.4 | 32.3 |

| 4.5 | ±0.4 | 38.6 | 38.3 | 36.2 |

| 5 | 0.4 | 42.3 | 40.5 | 40.2 |

| 5 | -0.5 | 42.3 | 40.5 | 40.2 |

| 5.5 | 0.4 | 46.2 | 44.3 | 44.1 |

| 5.5 | -0.5 | 46.2 | 44.3 | 44.1 |

| 6 | 0.5 | 50.1 | 48.4 | 48.1 |

| 6 | -0.6 | 50.1 | 48.4 | 48.1 |

| 7 | 0.6 | 59 | 58 | 52.4 |

| 7 | -0.7 | 59 | 58 | 52.4 |

| 8 | 0.6 | 66.8 | 65.8 | 56.2 |

| 8 | -0.8 | 66.8 | 65.8 | 56.2 |

| Thickness (mm) | Weight (kg/m²) |

| 2.5 | 22.6 |

| 3 | 26.6 |

| 3.5 | 30.5 |

| 4 | 34.4 |

| 4.5 | 38.3 |

| 5 | 42.3 |

| 6 | 50.1 |

| 8 | 66.8 |

Important Notes:

Use these weight charts as a handy guide when working with checkered steel plates. Remember to account for allowable deviations and to refer to the appropriate standards for steel grade and mechanical properties if required for your specific application.

The weight of checkered steel plates in kg/m² varies depending on the plate thickness and the specific pattern shape. Here’s a breakdown of the weights for common thicknesses and patterns:

2.5mm Thickness

3mm Thickness

3.5mm Thickness

4mm Thickness

4.5mm Thickness

5mm Thickness

5.5mm Thickness

6mm Thickness

7mm Thickness

8mm Thickness

Use this information to quickly determine the expected weight of checkered steel plates based on your required thickness and preferred pattern shape. This data can help you make informed decisions when selecting materials for your projects and estimating total weight for transportation and installation purposes.

Checkered steel plates are a versatile and widely used type of steel plate characterized by a distinctive patterned surface. These patterns can take various forms, such as:

Among these designs, lentil patterns are the most commonly found in the market.

Checkered steel plates offer several notable advantages that contribute to their popularity across diverse industries:

Due to their unique benefits, checkered steel plates find extensive use in a wide range of industries, including:

The mechanical properties required for checkered plates are generally not as stringent as those for other steel products. Instead, the quality of checkered plates is primarily determined by three key factors:

Checkered steel plates are commonly available in thicknesses ranging from 2.0mm to 8mm, with standard widths of 1250mm or 1500mm to suit a variety of applications.

When selecting a checkered steel plate for your project, consider the following factors to ensure you make the best choice:

To ensure the longevity and performance of your checkered steel plates, follow these maintenance and care guidelines:

By considering these factors and following proper maintenance and care practices, you can ensure that your checkered steel plates provide optimal performance, safety, and durability in your specific application.