Have you ever wondered how to accurately calculate the weight of wire mesh? In this blog post, we’ll explore various methods and factors to consider when determining wire mesh weight. Our resident mechanical engineering expert will guide you through the process, providing insights and practical examples. By the end of this article, you’ll have a clear understanding of how to estimate wire mesh weight for your specific needs.

The weight calculation method for wire mesh can be determined in various ways, depending on the material, structure of the wire mesh, and specific parameters needed for calculation. We can summarize several different calculation methods and factors to consider.

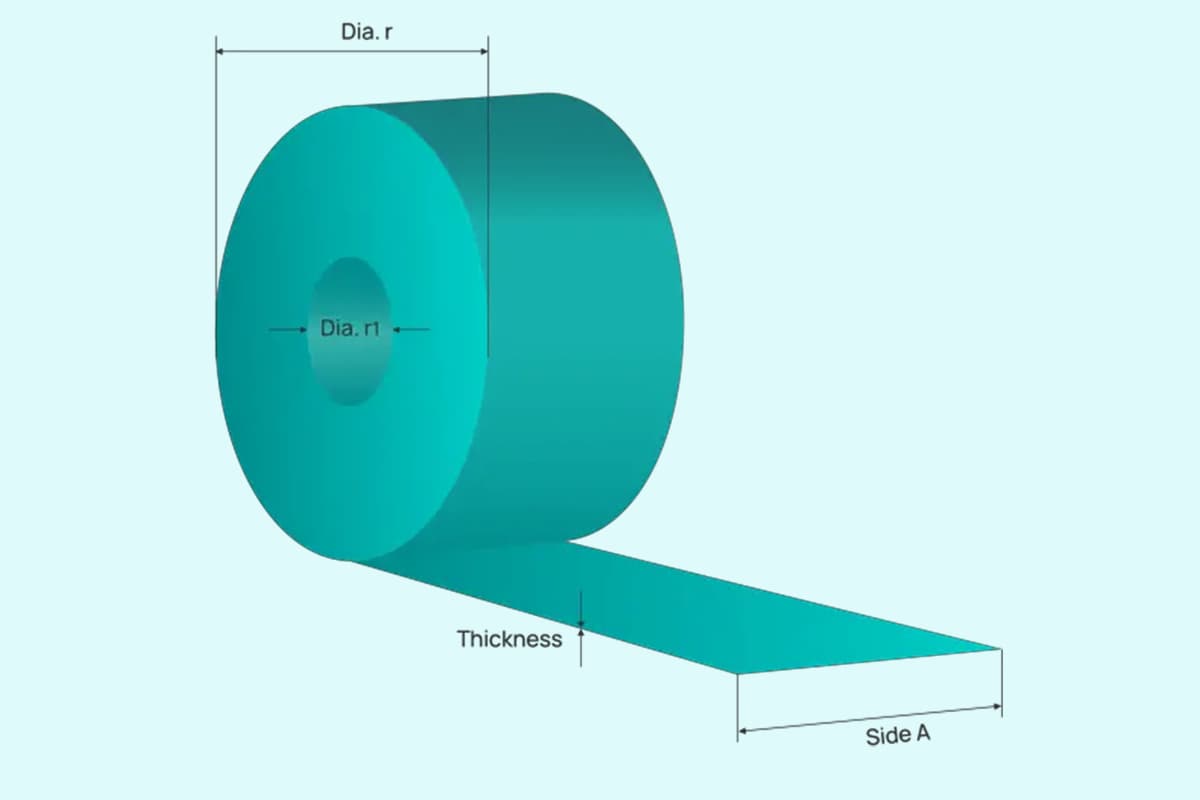

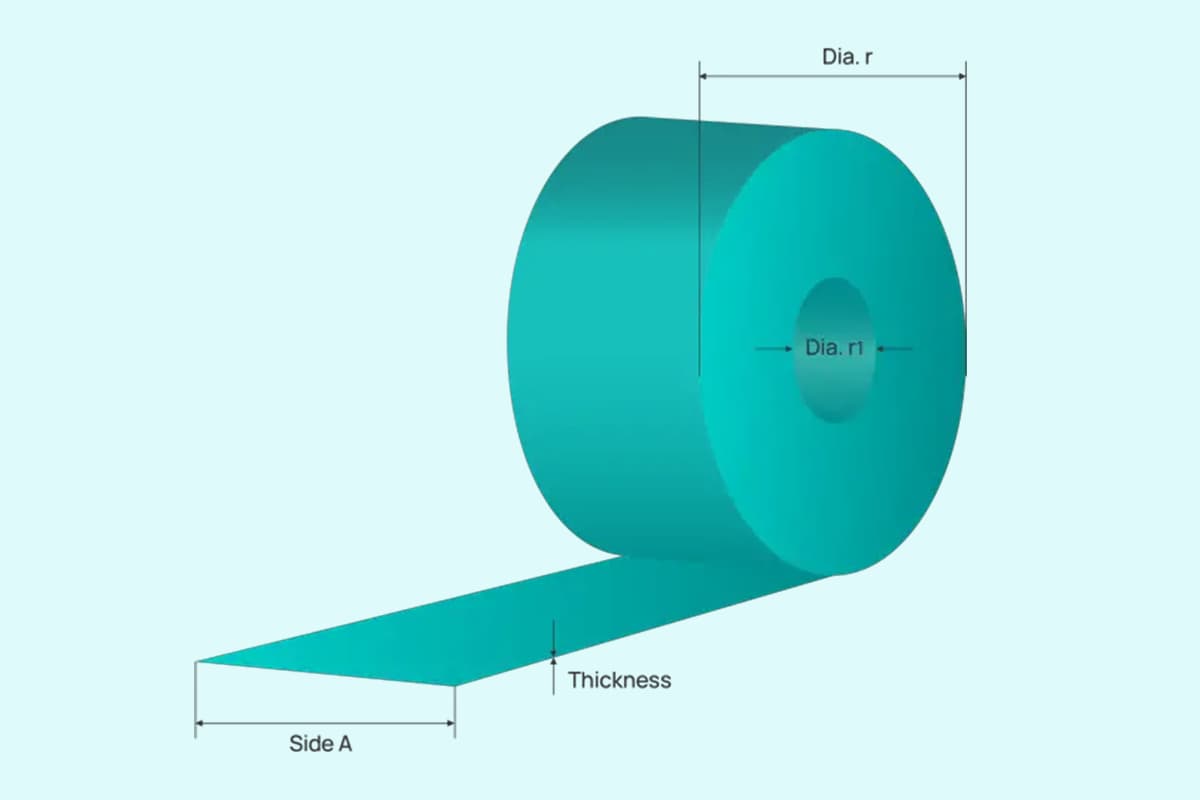

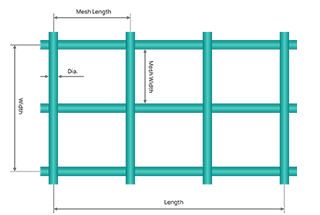

Firstly, a basic weight calculation method involves estimating by dividing the product of wire diameter, mesh count, mesh length, and mesh width by 2. This method is applicable for general wire mesh weight calculations, where the unit of wire diameter is millimeters (mm), and the units for mesh length and width are meters (m).

Additionally, for specific types of wire mesh, such as galvanized wire mesh, more detailed calculation methods can be employed. For instance, the weight of galvanized wire mesh can be calculated by measuring the length of wire per square meter (in meters) and the weight of wire per meter (in kilograms). This method provides a straightforward way to estimate the weight of the wire mesh.

Another method is to calculate the weight through the cross-sectional area and length of the wire, as well as the density of the material. This can be achieved through the formula “Weight(kg) = Cross-sectional Area(mm2) × Length(m) × Density(g/cm3) × 1/1000″. This method is suitable for situations where precise calculation of wire mesh weight is required, particularly when considering the density of different materials.

Just input the width, length, mesh width, mesh length, dia of the wire mesh in the calculator below, then you will get the result of wire mesh weight in both kg and lbs.

The following simplified formula can be used to calculate the weight of steel wire mesh.

Of course, if you need a more accurate calculation result, you can use our online calculator.

Weight (kg) = total length of raw materials * wire diameter² * coefficient (0.00617)

The following table lists the theoretical weight of steel wire mesh in kg/m². If your steel size is not in the table below, you can use our steel weight calculator to calculate online.

(1) Longitudinal reinforcing bar weight chart

| Grade | Longitudinal reinforcing bar | Theoretical weight | ||

| Dia. | Distance | Area per linear meter | ||

| (mm) | (mm) | (mm²/m) | (kg/m²) | |

| A18 | 18 | 200 | 1273 | 14.43 |

| A16 | 16 | 200 | 1006 | 12.34 |

| A14 | 14 | 200 | 770 | 10.49 |

| A12 | 12 | 200 | 566 | 8.88 |

| A11 | 11 | 200 | 475 | 7.46 |

| A10 | 10 | 200 | 393 | 6.16 |

| A9 | 9 | 200 | 318 | 4.99 |

| A8 | 8 | 200 | 252 | 3.95 |

| A7 | 7 | 200 | 193 | 3.02 |

| A6 | 6 | 200 | 142 | 2.22 |

| A5 | 5 | 200 | 98 | 1.54 |

| B18 | 18 | 100 | 2545 | 24.42 |

| B16 | 16 | 100 | 2011 | 18.89 |

| B14 | 14 | 100 | 1539 | 15.19 |

| B12 | 12 | 100 | 1131 | 10.9 |

| B11 | 11 | 100 | 950 | 9.43 |

| B10 | 10 | 100 | 785 | 8.14 |

| B9 | 9 | 100 | 635 | 6.97 |

| B8 | 8 | 100 | 503 | 5.93 |

| B7 | 7 | 100 | 385 | 4.53 |

| B6 | 6 | 100 | 283 | 3.73 |

| B5 | 5 | 100 | 196 | 3.05 |

| C18 | 18 | 150 | 1697 | 17.77 |

| C16 | 16 | 150 | 1341 | 14.98 |

| C14 | 14 | 150 | 1027 | 12.51 |

| C12 | 12 | 150 | 754 | 10.36 |

| C11 | 11 | 150 | 634 | 8.7 |

| C10 | 10 | 150 | 523 | 7.19 |

| C9 | 9 | 150 | 423 | 5.82 |

| C8 | 8 | 150 | 335 | 4.61 |

| C7 | 7 | 150 | 257 | 3.53 |

| C6 | 6 | 150 | 189 | 2.6 |

| C5 | 5 | 150 | 131 | 1.8 |

| D18 | 18 | 100 | 1545 | 28.86 |

| D16 | 16 | 100 | 2011 | 24.68 |

| D14 | 14 | 100 | 1539 | 20.98 |

| D12 | 12 | 100 | 1131 | 17.75 |

| D11 | 11 | 100 | 950 | 14.92 |

| D10 | 10 | 100 | 785 | 12.33 |

| D9 | 9 | 100 | 635 | 9.98 |

| D8 | 8 | 100 | 503 | 7.9 |

| D7 | 7 | 100 | 385 | 6.04 |

| D6 | 6 | 100 | 283 | 4.44 |

| D5 | 5 | 100 | 196 | 3.08 |

| E18 | 18 | 150 | 1697 | 19.25 |

| E16 | 16 | 150 | 1341 | 16.46 |

| E14 | 14 | 150 | 1027 | 13.99 |

| E12 | 12 | 150 | 754 | 11.84 |

| E11 | 11 | 150 | 634 | 9.95 |

| E10 | 10 | 150 | 523 | 8.22 |

| E9 | 9 | 150 | 423 | 6.66 |

| E8 | 8 | 150 | 335 | 5.26 |

| E7 | 7 | 150 | 257 | 4.03 |

| E6 | 6 | 150 | 189 | 2.96 |

| E5 | 5 | 150 | 131 | 2.05 |

| F18 | 18 | 100 | 2545 | 25.9 |

| F16 | 16 | 100 | 2011 | 21.7 |

| F14 | 14 | 100 | 1539 | 18 |

| F12 | 12 | 100 | 1131 | 14.8 |

| F11 | 11 | 100 | 950 | 12.43 |

| F10 | 10 | 100 | 785 | 10.28 |

| F9 | 9 | 100 | 635 | 8.32 |

| F8 | 8 | 100 | 503 | 6.58 |

| F7 | 7 | 100 | 385 | 5.03 |

| F6 | 6 | 100 | 283 | 3.7 |

| F5 | 5 | 100 | 196 | 2.57 |

(2) Transverse reinforcing bar weight chart

| Grade | Transverse reinforcing bar | Theoretical weight | ||

| Dia. | Distance | Area per linear meter | ||

| (mm) | (mm) | (mm²/m) | (kg/m²) | |

| A18 | 12 | 200 | 566 | 14.43 |

| A16 | 12 | 200 | 566 | 12.34 |

| A14 | 12 | 200 | 566 | 10.49 |

| A12 | 12 | 200 | 566 | 8.88 |

| A11 | 11 | 200 | 475 | 7.46 |

| A10 | 10 | 200 | 393 | 6.16 |

| A9 | 9 | 200 | 318 | 4.99 |

| A8 | 8 | 200 | 252 | 3.95 |

| A7 | 7 | 200 | 193 | 3.02 |

| A6 | 6 | 200 | 142 | 2.22 |

| A5 | 5 | 200 | 98 | 1.54 |

| B18 | 12 | 200 | 566 | 24.42 |

| B16 | 10 | 200 | 393 | 18.89 |

| B14 | 10 | 200 | 393 | 15.19 |

| B12 | 8 | 200 | 252 | 10.9 |

| B11 | 8 | 200 | 252 | 9.43 |

| B10 | 8 | 200 | 252 | 8.14 |

| B9 | 8 | 200 | 252 | 6.97 |

| B8 | 8 | 200 | 252 | 5.93 |

| B7 | 7 | 200 | 193 | 4.53 |

| B6 | 7 | 200 | 193 | 3.73 |

| B5 | 7 | 200 | 193 | 3.05 |

| C18 | 12 | 200 | 566 | 17.77 |

| C16 | 12 | 200 | 566 | 14.98 |

| C14 | 12 | 200 | 566 | 12.51 |

| C12 | 12 | 200 | 566 | 10.36 |

| C11 | 11 | 200 | 475 | 8.7 |

| C10 | 10 | 200 | 393 | 7.19 |

| C9 | 9 | 200 | 318 | 5.82 |

| C8 | 8 | 200 | 252 | 4.61 |

| C7 | 7 | 200 | 193 | 3.53 |

| C6 | 6 | 200 | 142 | 2.6 |

| C5 | 5 | 200 | 98 | 1.8 |

| D18 | 12 | 100 | 1131 | 28.86 |

| D16 | 12 | 100 | 1131 | 24.68 |

| D14 | 12 | 100 | 1131 | 20.98 |

| D12 | 12 | 100 | 1131 | 17.75 |

| D11 | 11 | 100 | 950 | 14.92 |

| D10 | 10 | 100 | 785 | 12.33 |

| D9 | 9 | 100 | 635 | 9.98 |

| D8 | 8 | 100 | 503 | 7.9 |

| D7 | 7 | 100 | 385 | 6.04 |

| D6 | 6 | 100 | 283 | 4.44 |

| D5 | 5 | 100 | 196 | 3.08 |

| E18 | 12 | 150 | 754 | 19.25 |

| E16 | 12 | 150 | 754 | 16.46 |

| E14 | 12 | 150 | 754 | 13.99 |

| E12 | 12 | 150 | 754 | 11.84 |

| E11 | 11 | 150 | 634 | 9.95 |

| E10 | 10 | 150 | 523 | 8.22 |

| E9 | 9 | 150 | 423 | 6.66 |

| E8 | 8 | 150 | 335 | 5.26 |

| E7 | 7 | 150 | 257 | 4.03 |

| E6 | 6 | 150 | 189 | 2.96 |

| E5 | 5 | 150 | 131 | 2.05 |

| F18 | 12 | 150 | 754 | 25.9 |

| F16 | 12 | 150 | 754 | 21.7 |

| F14 | 12 | 150 | 754 | 18 |

| F12 | 12 | 150 | 754 | 14.8 |

| F11 | 11 | 150 | 634 | 12.43 |

| F10 | 10 | 150 | 523 | 10.28 |

| F9 | 9 | 150 | 423 | 8.32 |

| F8 | 8 | 150 | 335 | 6.58 |

| F7 | 7 | 150 | 257 | 5.03 |

| F6 | 6 | 150 | 189 | 3.7 |

| F5 | 5 | 150 | 131 | 2.57 |

The influence of the material of a wire mesh on its weight primarily manifests in the density of different materials. The materials of wire ropes and wire meshes can be divided into steel wire, nickel-chromium steel, alloy steel, stainless steel, etc. These materials have different densities, thereby affecting their weight.

For instance, a wire mesh made of steel wire, exhibiting excellent strength and durability, is suitable for withstanding considerable tension and pressure, widely applied in the construction industry.

Additionally, the materials of protective meshes usually include steel wire, aluminum alloy, stainless steel, etc. The difference in density of these materials would also result in different weights. Thus, it can be concluded that the impact of the material of a wire mesh on its weight is primarily due to the density differences of various materials.

The selection of the appropriate calculation method depends on the type of wire mesh, such as galvanized wire mesh, stainless steel wire mesh, etc. We can summarize the following points:

For different types of wire meshes, their weight calculation formulas may vary. This indicates that the specific properties of different material wire meshes need to be considered in calculations.

The calculation of wire mesh pieces can be done by software automatically calculating the length according to the material, then multiplying by the width specified in the project. This method is applicable to various material wire meshes, including but not limited to galvanized wire mesh and stainless steel wire mesh.

In terms of construction welding, the calculation method for wire mesh piece specifications reflects in the production of multiple models, sizes, and style types. This means that when selecting the calculation method, the specific specifications and application requirements of the wire mesh need to be considered.

Choosing the appropriate calculation method first requires understanding the type and characteristics of the wire mesh. For galvanized wire mesh and stainless steel wire mesh, etc., the method of software automatically calculating the length and multiplying by the width can be used for calculation. This ensures the accuracy and applicability of the calculation results.

In real-world applications, choosing the most suitable method for calculating the weight of wire mesh requires first considering the specific type of mesh and its use. We can see that different types of mesh have different calculation formulas. For example, the weight calculation formulas for copper mesh and stainless steel mesh are as follows:

Weight calculation formula for copper mesh: Wire diameter × Wire diameter × Mesh count × Length × Width ÷ 2 × 1.07 = kg.

Weight calculation formula for stainless steel mesh: Wire diameter × Wire diameter × Mesh count × Length × Width ÷ 2 × 1.07 = kg.

This shows that the calculation methods for copper mesh and stainless steel mesh are similar, with the main difference being the density difference (1.07) caused by different materials.

For steel aluminum plate mesh, its weight calculation formula is: Mesh weight (kg): Mesh length ÷ 1/2 short section rectangle × Stem thickness × Stem width × Mesh width × 7.85. This formula involves multiple parameters such as mesh length, short section rectangle (hole width), stem thickness, stem width, and mesh width, and is suitable for accurately calculating larger areas or complex structures of wire mesh.

Therefore, when choosing the most suitable weight calculation method, it should be decided according to the specific type of wire mesh and its use. If it is copper mesh or stainless steel mesh, the general calculation formula mentioned above can be used. For special types of mesh such as steel aluminum plate mesh, a calculation formula specifically designed for that type of mesh should be used. In addition, cost calculation considerations, such as cost:= mesh weight × plate price + labor cost + circulation cost, are also one of the factors to consider when choosing a calculation method.