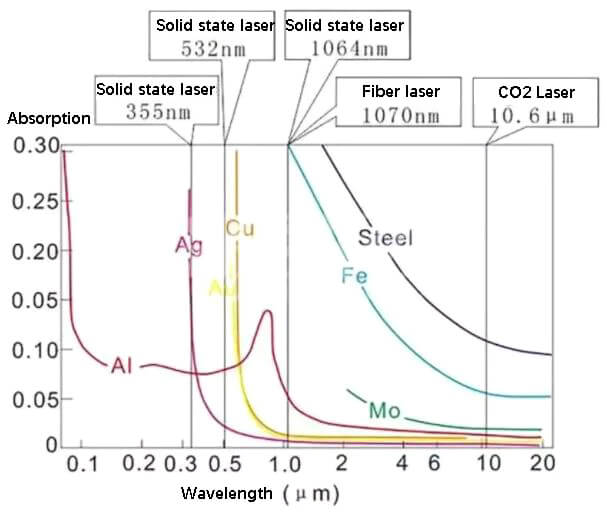

What is high reflection? Generally speaking, high reflection refers to the low resistance of processed materials, a smooth surface, and a low absorption rate of near-infrared lasers. The figure shows the absorption coefficient of common metal elements, which results in the emission of a large number of lasers. Additionally, in most laser use scenarios, the […]

Generally speaking, high reflection refers to the low resistance of processed materials, a smooth surface, and a low absorption rate of near-infrared lasers. The figure shows the absorption coefficient of common metal elements, which results in the emission of a large number of lasers.

Additionally, in most laser use scenarios, the material is perpendicular to the laser or at a small inclination angle.

As a result, the returned laser re-enters the output head, and even a portion of the return light is coupled into the energy transfer fiber and transmitted back into the laser, leading to continuous high temperatures in the core components of the laser.

In the process of processing high-reflection materials, the high-reflection laser can cause damage to the cutting or welding head and the laser source if it enters the laser source. This is especially true for high-power fiber laser products, where the return laser power is significantly higher and the risk of damage is greater. If the material is not penetrated during cutting, high-power return light can return to the inside of the laser and cause damage.

To address these issues, the R&D team at Raycus laser has designed a four-level anti-high reflection light protection design and added various return light monitoring functions to ensure real-time protection of the laser in case of abnormal processing.

The QBH, QD, and QP optical fiber output heads designed by Raycus laser are designed to effectively convert uncontrollable return light into absorbable light and heat, improving the heat absorption and dissipation capacity of the output head and minimizing the impact of return light on internal components.

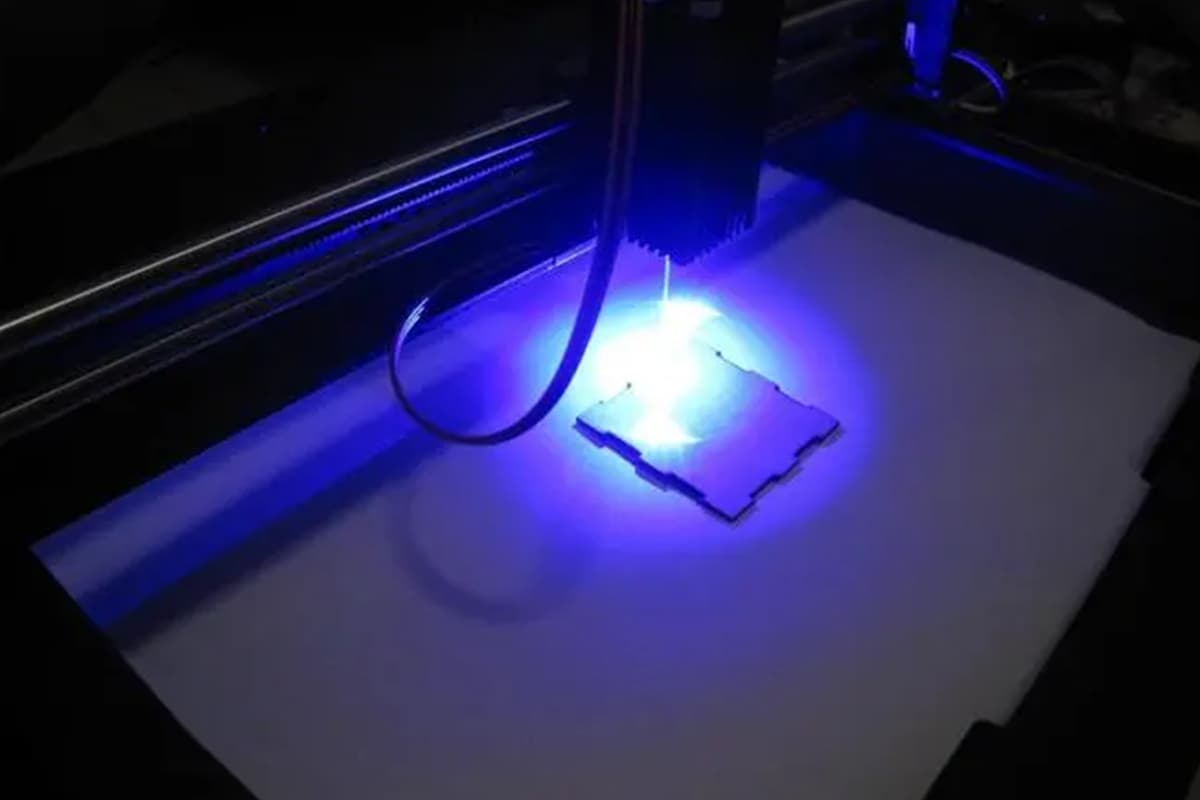

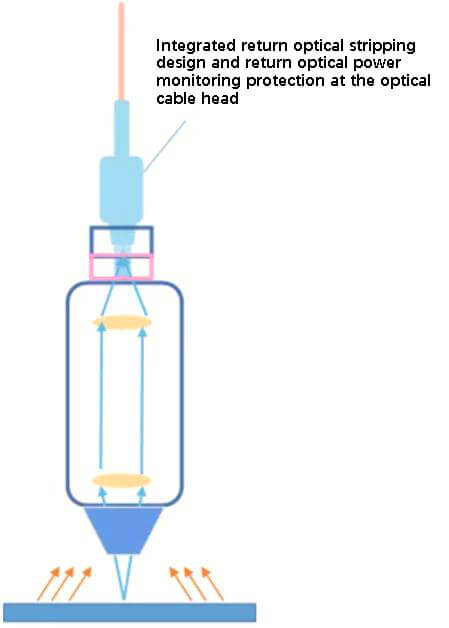

In the laser processing system, return laser can impact the output optical cable head and cause heating or damage. To ensure the safety of the output optical cable, a primary return light stripping device has been integrated into the output optical cable, as shown in the figure, on top of the original design.

The anti-high reflection design added to the end of the optical cable helps to reduce the damage to the internal optical structure of the laser by peeling off most of the returned laser immediately. This design, combined with a water-cooling system, effectively absorbs the stripped returned laser and eliminates its thermal impact on the output head of the optical cable.

Multi-module high-power laser products are primarily constructed using multiple unit modules in a beam combination.

When cutting high reflection materials, some light may still be transmitted backwards into the beam combination through the output optical cable even after passing through the primary anti-high reflection design at the cable.

Therefore, to ensure the safety and reliability of the optical devices and optical path design within the beam combination, a two-stage anti-high reflection protection design is added, as illustrated in the figure.

The step-by-step stripping of the return laser ensures the safety of the anti-high reflection protection optical devices and reduces the impact of the return laser on the optical path structure of the laser.

Due to the presence of an optical resonator within the unit module, when the low-power return laser enters and is repeatedly amplified by the resonator, it can seriously impact the laser’s optical stability and increase the likelihood of laser damage.

To enhance the stability and reliability of the laser during high-power reverse cutting, the unit module includes an anti-high reflection device, in conjunction with its optical path design, as illustrated in the figure.

High reflection software protection refers to the monitoring and protection mechanism that is activated when a strong retroreflection generated by the laser enters the laser optical system during processing of high reflection materials, leading to instability of laser operation or damage to optical devices.

While the anti-high reflection device can ensure that the laser continues to function without damage within a specific return laser power threshold, there is still a risk of damage if this threshold is exceeded. To ensure timely protection of the laser in the event of excessive return laser power, multiple high anti-software protection designs have been added in multi-module high-power laser products.

When the return optical power is high, some of the returned laser will travel back to the output optical cable along its original path, while the rest will directly impact the front of the output optical cable.

By conducting research on return laser transmission and monitoring function integration technology, we have integrated multiple detection functions, such as laser monitoring and return light monitoring, into the optical cable temperature monitoring for real-time monitoring of the return laser.

If the return laser power exceeds the laser’s capacity, the laser will turn off and an alarm will sound promptly to prevent damage. This also serves as a reminder to the customer that there is an issue with the processing.

Given that there are two types of return laser: core laser and cladding laser, in addition to the high anti-protection design of the output optical cable, we have also incorporated a high anti-detection module within the beam combination to monitor the reverse transmission laser power and track the return laser power in real-time.

This high reflection detection module can detect both core and cladding lasers, effectively reducing the risk of laser damage caused by the core return laser that might go undetected if only cladding return laser was being monitored.

In the event of a high return laser, the module will turn off the laser and trigger an alarm, ensuring the safety and reliability of the laser.

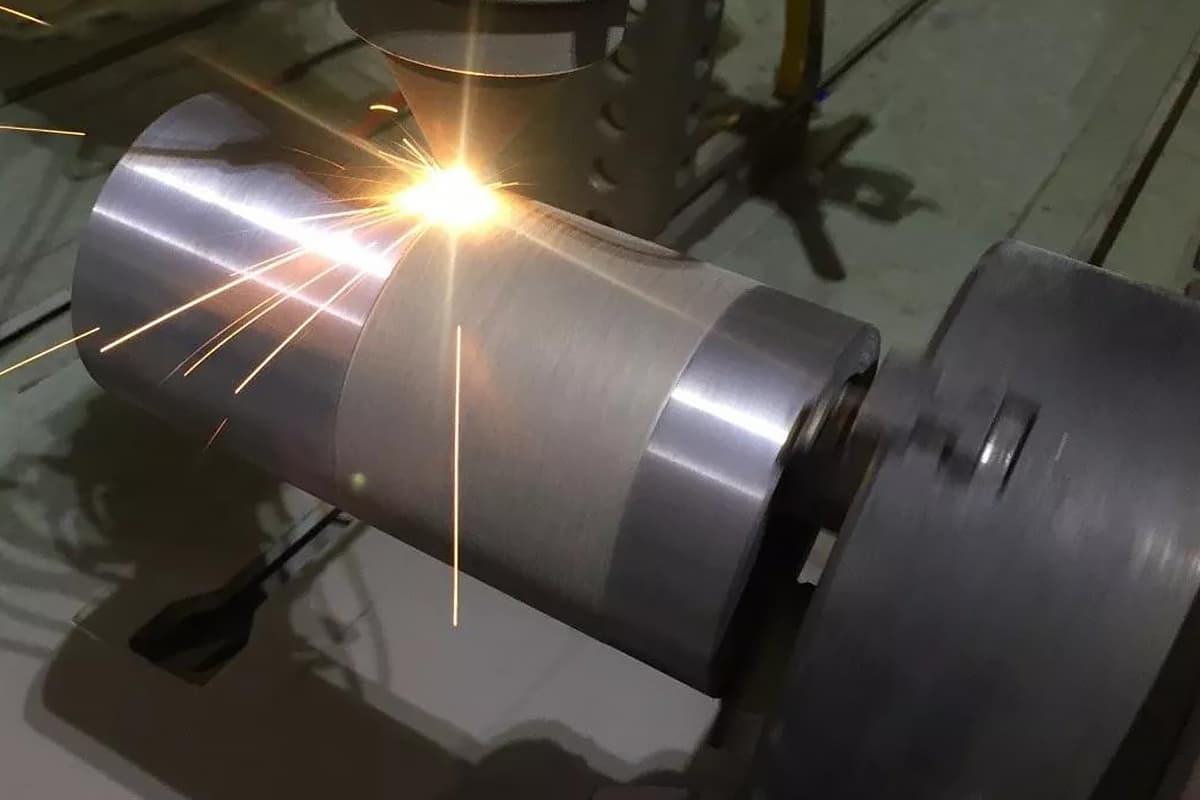

Due to the low laser absorbance and high thermal conductivity of red copper, the surface of red copper remains in a mirror state, causing a constant stream of laser to return to the optical fiber output head. This allows for the evaluation of the new optical fiber output head’s anti-high reflection capabilities.

Cutting red copper and abnormal cutting

With proper operation, the Raycus laser can effectively cut high reflection materials such as aluminum plates, brass, and red copper, resulting in efficient cuts and desirable cross-sectional effects.

The abnormal processing test of high reflection is conducted to assess the laser’s anti-high reflection capabilities.

By marking back and forth on a red copper plate, the laser does not penetrate the plate, resulting in a high return light. Despite this, the laser continues to function normally, demonstrating the Raycus laser’s strong anti-high reflection abilities.

Signal display

The high reflection test demonstrates that the high reflection monitoring signal can be transmitted to the display screen in real-time during the cutting process.

In the event of abnormal processing, the high reflection signal can be monitored, and its value remains within the laser threshold.

If the high reflection exceeds a certain threshold, the machine alarm will be activated to alert staff to check the operation for any errors.

The following suggestions are provided by the process engineer for cutting high reflection materials:

(1) When cutting brass, red copper, and other materials, it is advisable to maintain a moderate speed and leave some space, avoiding extremes.

(2) Red copper must be cut using oxygen, not nitrogen or air.

In the event of the following issues, the machine should be stopped for inspection immediately:

(1) Contamination of the lower protective mirror.

(2) Failure to penetrate the material during high reflection cutting.

(3) Penetration of the material during high reflection cutting, but failure to fully cut through.