Is the steel you’re using truly safe? The integrity of construction projects hinges on the quality of materials, making it crucial to identify counterfeit and substandard steel. This article reveals telltale signs of inferior steel, such as surface defects and irregular shapes, to help ensure the reliability and safety of your structures. By understanding these indicators, you can protect your projects from potential failures and hazards.

1. Substandard steel often exhibits folding. Folding refers to various fold lines formed on the surface of the steel, a defect that often runs longitudinally through the entire product.

This is caused by counterfeit manufacturers pursuing high efficiency, applying excessive reduction, and creating ears that fold during the next rolling process. Once folded, the product will crack when bent, significantly reducing the steel’s strength.

2. The surface of inferior steel often presents a pockmarked appearance. This irregularity is due to severe groove wear, causing an uneven surface. Since counterfeit steel manufacturers prioritize profit, they often roll beyond the standard capacity of the groove.

3. Inferior steel surfaces are prone to scarring. This is due to two reasons: a) the material of the counterfeit steel is uneven and contains many impurities; b) the protective equipment of the counterfeit manufacturers is rudimentary, leading to steel sticking and subsequent scarring after being bitten by the roll.

4. Inferior materials are susceptible to cracking on the surface. This occurs because their billets are made of earth blanks, which have many pores. During cooling, these earth blanks crack under thermal stress, and these cracks persist after rolling.

5. Counterfeit steel is easily scratched due to the rudimentary equipment of counterfeit manufacturers, which can create burrs that scratch the steel surface. Deep scratches reduce the steel’s strength.

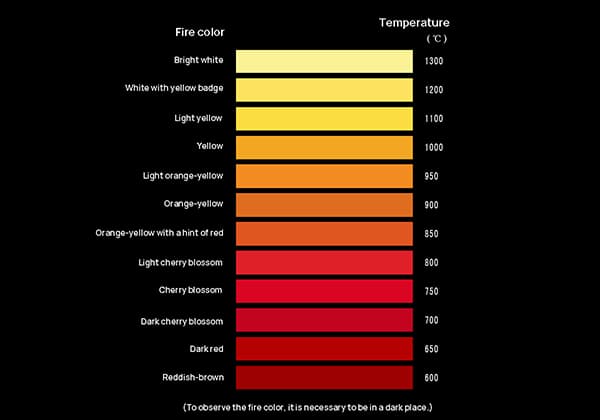

6. Counterfeit steel lacks a metallic luster and appears light red or similar to the color of raw iron. This is due to two reasons: a) the billet is an earth blank; b) counterfeit manufacturers do not adhere to standard rolling temperatures. They estimate the steel temperature visually, which prevents proper austenite region rolling, naturally leading to substandard steel performance.

7. The ribs of counterfeit steel are thin and low, often exhibiting underfilling. This is because manufacturers, aiming for a large negative tolerance, apply excessive reduction during the initial production stages, resulting in smaller iron shapes and underfilled hole shapes.

8. The cross-section of counterfeit steel is elliptical. This is due to manufacturers trying to save material and applying excessive reduction during the initial rolling stages. This significantly reduces the strength of such rebar and fails to meet the standard size for rebar profiles.

9. High-quality steel has a uniform composition, and the cold shear machine has high tonnage, resulting in a smooth and neat cut end face. Meanwhile, due to its inferior material, the cut end face of counterfeit steel often has a meat loss phenomenon, i.e., it is uneven and lacks a metallic luster. Furthermore, because counterfeit manufacturers cut fewer product ends, there will be large ears at the head and tail.

10. Inferior steel materials contain many impurities, resulting in low density and significant dimensional deviations. Therefore, in the absence of a vernier caliper, weight verification can be conducted. For example, for rebar 20, the national standard stipulates a maximum negative tolerance of 5%.

When the specified length is 9M, the theoretical weight of a single piece is 120 kilograms. Its minimum weight should be: 120 X (1-5%) = 114 kilograms.

If the actual weight of a single piece is less than 114 kilograms, it is considered inferior steel, because its negative tolerance exceeds 5%. Generally, a comprehensive weighing process yields better results, primarily due to cumulative errors and probability theory issues.

11. The inner diameter of inferior steel varies significantly due to unstable steel temperatures, uneven composition, and the use of rudimentary equipment leading to low foundation strength and significant mill bounce. This results in significant inner diameter changes within the same week, making the steel susceptible to uneven stress and potential fracturing.

12. High-quality materials have standardized trademarks and printing.

13. For large threaded steel bars with a diameter of 16 and above, the distance between two trademarks is always more than 1M.

14. The longitudinal ribs of rebar made from inferior steel often form a wave shape.

15. Manufacturers of inferior steel materials typically do not use overhead cranes, resulting in loosely packed bundles that appear elliptical when viewed from the side.