Imagine marking any surface with pinpoint accuracy and permanent results. Laser marking machines achieve this by using high-energy lasers to etch or vaporize material, creating precise and durable marks. This article dives into the various types of laser marking machines, their working principles, and their diverse applications. From CO2 to fiber lasers, each type offers unique advantages for marking metals, plastics, and other materials. Discover how laser technology is transforming manufacturing processes and what you need to know to leverage these powerful tools.

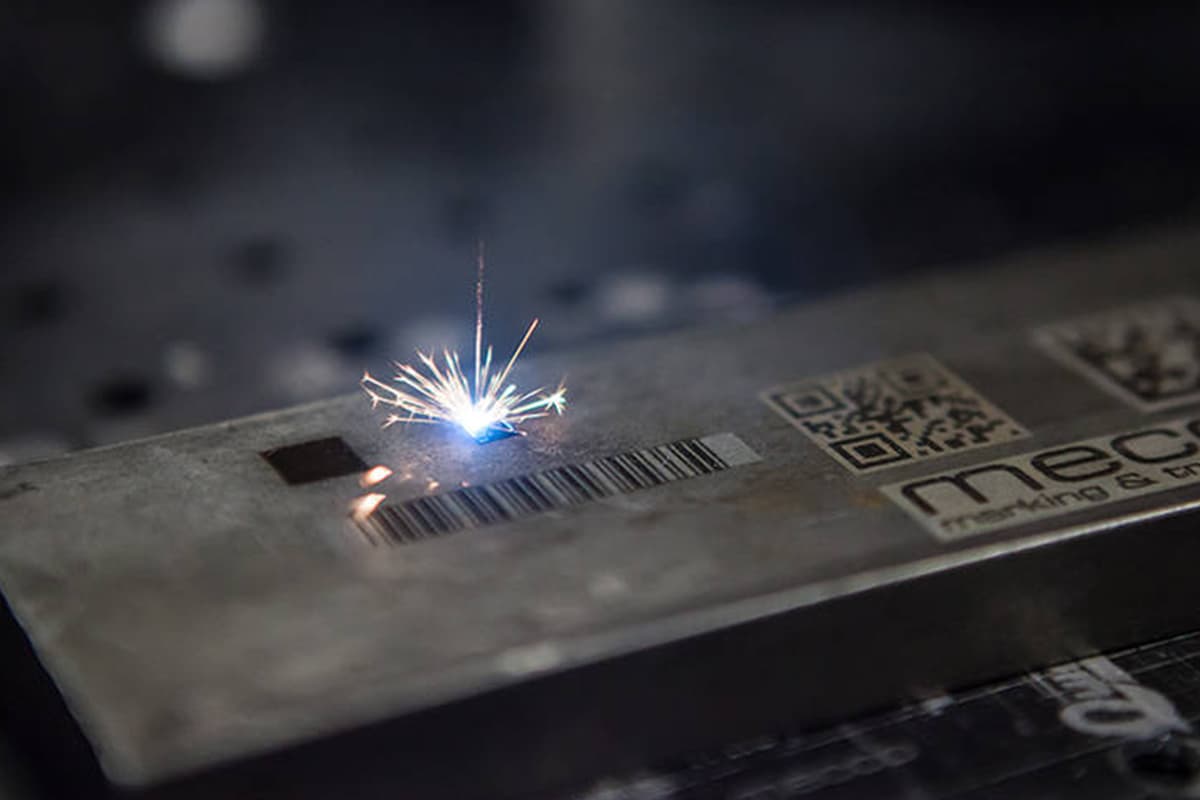

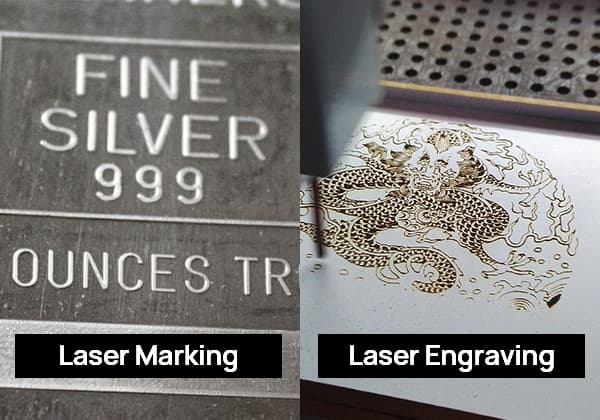

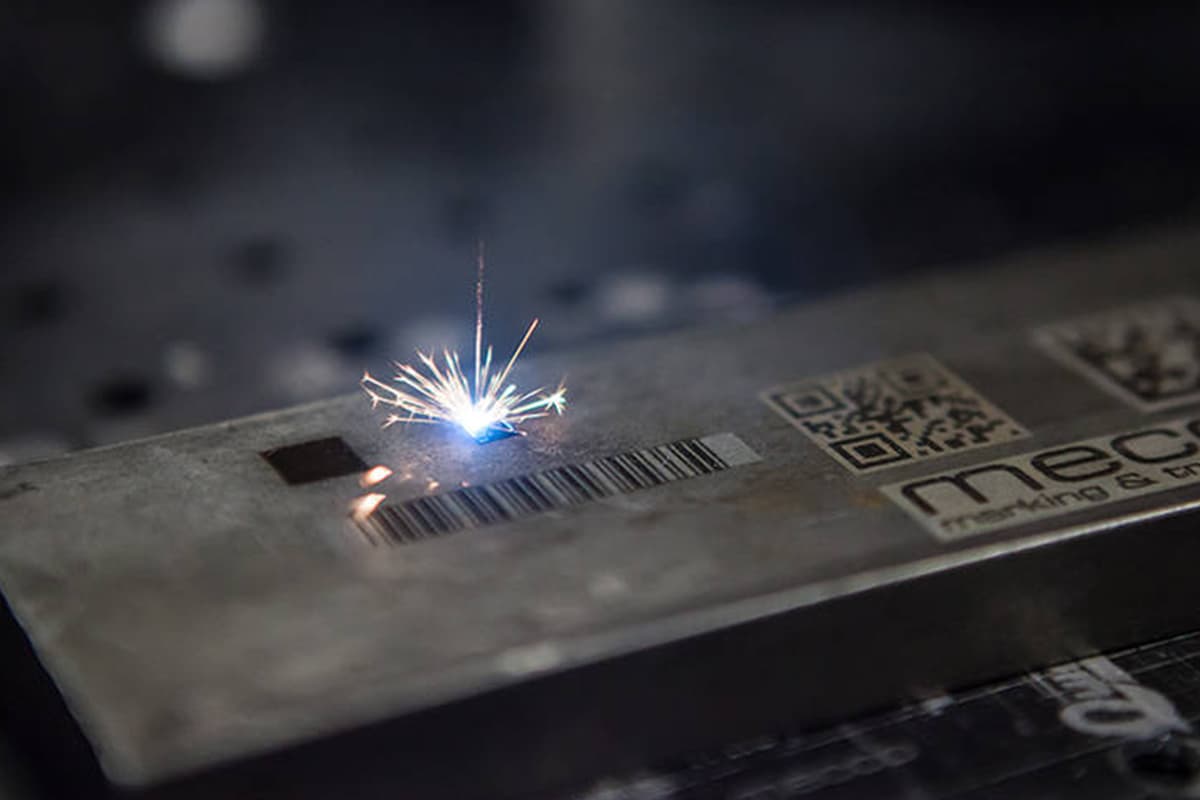

A laser marking machine employs high-energy density lasers to irradiate parts of a workpiece locally, causing surface material to vaporize or undergo color-changing chemical reactions, thereby leaving a permanent mark.

1. Based on the characteristics of material absorption of lasers, lasers can be divided into two main categories. One type uses lamp-pumped YAG (solid-state) lasers, while the other uses CO2 (carbon dioxide) lasers.

2. Based on different types of lasers, we can categorize into: CO2 laser marking machines, semiconductor laser marking machines, YAG laser marking machines, and fiber laser marking machines.

3. Classification according to laser visibility can be: ultraviolet laser marking machines (invisible), green laser marking machines (visible laser), and infrared laser marking machines (invisible laser).

4. According to different laser wavelengths, they can be grouped as: deep ultraviolet laser marking machines (266 nm), green laser marking machines (532 nm), lamp-pumped YAG laser marking machines (1064 nm), side-pumped semiconductor YAG laser marking machines, end-pumped semiconductor YAG laser marking machines (1064 nm), fiber laser marking machines (1064 nm), and CO2 laser marking machines (10.64 um).

1. Lamp-pumped YAG laser marking machine:

It uses a krypton lamp as an energy source (excitation source), and ND: YAG as the medium to produce the laser.

Emitting a specific wavelength can induce the working material to produce an energy level transition and release a laser. After amplifying the laser energy, a laser beam is formed for material processing.

2. CO2 Laser Marking Machine:

Utilizing CO2 gas as the working substance, the machine fills the discharge tube with CO2 gas, which serves as the laser-producing medium.

When a high voltage is applied to the electrode, the discharge tube generates a glow discharge, releasing laser from the gas molecules. After amplifying the laser energy, a laser beam is formed for material processing.

3. Semiconductor Side-Pumped YAG Laser Marking Machine:

This machine employs a semiconductor laser diode with a wavelength of 808nm to pump the Nd: YAG medium, leading to the formation of a large number of inverted particles.

Under the effect of the Q-switch, a giant pulse laser output with a wavelength of 1064nm is produced. This machine boasts high electro-optical conversion efficiency and is capable of marking both metal and non-metal materials.

4. Fiber Laser Marking Machine: This machine outputs the laser directly through the fiber.

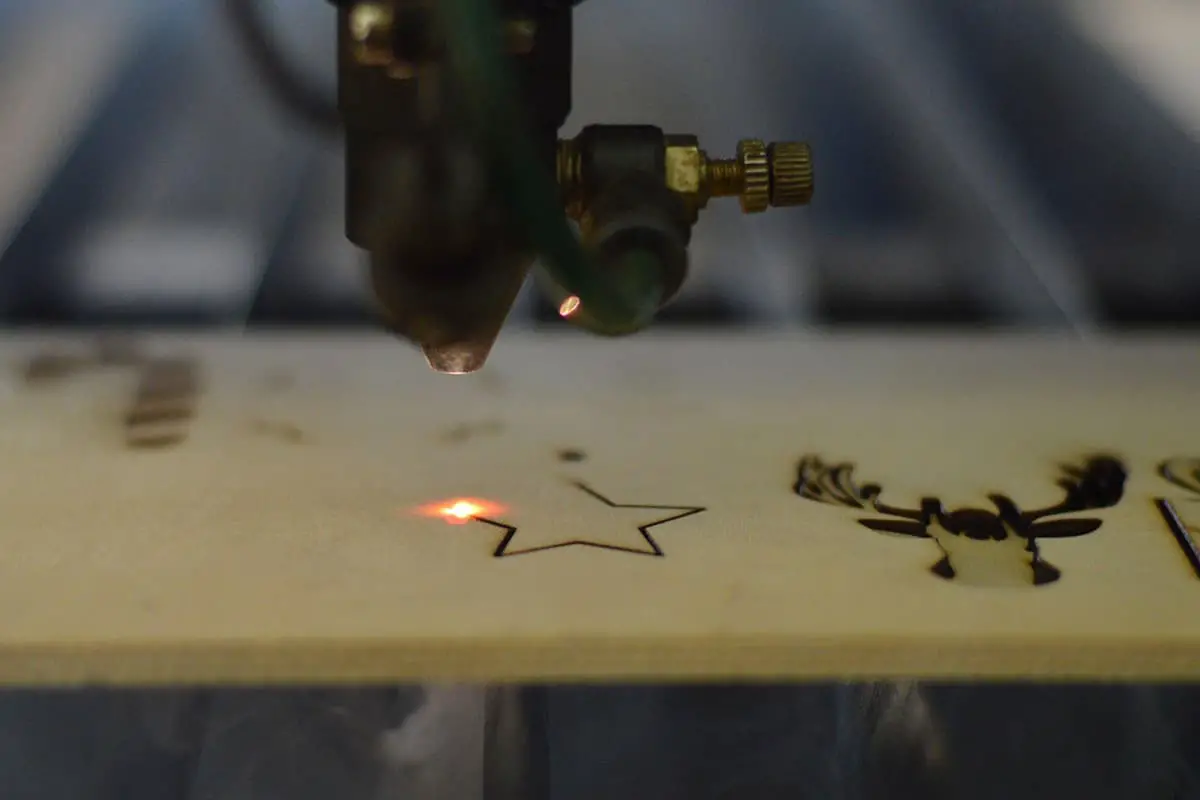

1. CO2 Laser Marking Machine:

This machine can engrave a wide range of non-metallic materials, such as paper, leather, wood, plastic, plexiglass, fabric, acrylic, bamboo, rubber, crystal, jade, ceramics, glass, and artificial stone.

It employs a CO2 gas laser tube, an expanding focusing optical system, and a high-speed galvanometer scanner. It is stable in performance, long-lasting, maintenance-free, and cost-effective.

Technical Parameters:

2. YAG Galvanometer Laser Marking Machine:

Suitable for a variety of materials including metals, metal oxides, glass, and plastics. Its high-speed scanning mirror can complete image scanning in a very short time, resulting in exquisite markings.

The design is rational, craftsmanship refined, and the appearance is premium. It can be equipped with a CNC rotary head, automatic fixtures, and loading/unloading production line according to user requirements.

3. Green Laser Marking Machine, Ultraviolet Laser Marking Machine:

Mainly used for ultra-fine IC products and other high-end applications. These machines are more expensive and are typically customized.

4. Fiber Laser Marking:

Primarily used in fields where high requirements for depth, smoothness, and precision are needed.

1. The marking remains intact over time because the surface material is peeled off. The information can be preserved permanently.

2. Lasers can mark products with unique serial numbers, facilitating product identification and traceability. The special effects of laser marking are difficult to mimic with traditional processes.

3. Laser processing is non-toxic and harmless, without the drawbacks of processes like silk-screening corrosion.

A one-dimensional barcode only expresses information in one direction (usually horizontal), and does not express any information in the vertical direction. Its height is usually for the convenience of the reader’s alignment.

Disadvantages:

A barcode that stores information in a two-dimensional space, both horizontally and vertically. It uses a particular geometric shape arranged according to certain rules on a plane (two-dimensionally). The alternating black and white shapes record the data symbol information.

The commonly used codes include Data Matrix, Maxi Code, Aztec, QR Code, Vericode, PDF417, Ultracode, Code 49, Code 16K, etc.

Advantages: