Imagine a tool so precise it can cut through metal with the finesse of a surgeon’s scalpel. Fiber lasers have revolutionized industries from manufacturing to medicine. This article delves into the mechanics behind fiber lasers, exploring how they harness the power of light through optical fibers to achieve unparalleled precision and efficiency. Readers will discover the various applications of this technology, the science that makes it possible, and the advancements shaping its future. Join us as we illuminate the cutting-edge world of fiber lasers.

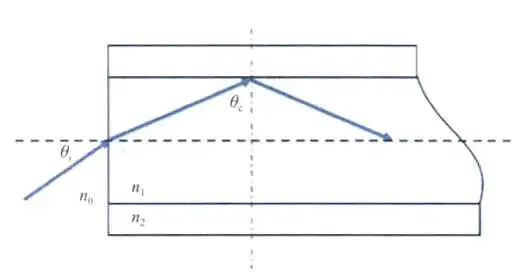

Optical fiber, also known as fiber optic, is a cylindrical waveguide used to transmit light. It uses the principle of total internal reflection to confine the light wave within the fiber core and guide it along the fiber axis.

The replacement of copper wires with optical fiber changed the world. As a medium for light transmission, optical fiber has been widely adopted since its proposal by Gao Kun in 1966 due to its numerous advantages such as high capacity, strong anti-interference capabilities, low transmission loss, long transmission distance, excellent security, strong adaptability, compact size, light weight, and abundant raw material resources.

Gao Kun, widely recognized as the “father of optical fiber,” was awarded the Nobel Prize in Physics in 2009.

The telecommunications industry has been transformed by the continuous improvement and practical applications of optical fiber. Optical fiber has largely replaced copper wire and is now a crucial part of modern communication.

The optical fiber communication system is a type of communication system that uses light as the carrier of information and optical fiber as the waveguide medium. When transmitting information, the electrical signal is converted into an optical signal and transmitted within the optical fiber.

As a new form of communication technology, optical fiber communication has displayed incomparable advantages from the outset, attracting widespread interest and attention.

The widespread use of optical fiber in communication has also spurred the rapid development of fiber amplifiers and fiber lasers. In addition to the field of communication, optical fiber systems are also commonly used in medicine, sensing, and other areas.

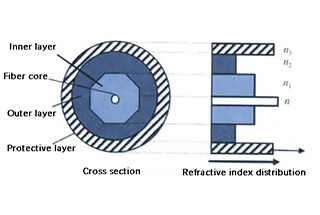

The active fiber serves as the gain medium in fiber lasers. It can be classified into single-mode fiber, double-clad fiber, and photonic crystal fiber based on its structure.

Single-mode fiber consists of a core, cladding, and coating. The refractive index (N1) of the core material is higher than that of the cladding material (N2). When the incident light’s angle of incidence is greater than the critical angle, the beam is completely emitted in the core, allowing the optical fiber to confine the beam to the core and transmit it.

However, the inner cladding of single-mode fiber cannot confine multi-mode pump light, and the core has a low numerical aperture. As a result, laser output can only be obtained by coupling single-mode pump light into the core.

Early fiber lasers utilized single-mode fiber, leading to low coupling efficiency and producing only milliwatt output power.

Transmission of light in optical fiber

In an effort to overcome the limitations of conventional single-mode, single-cladding Ytterbium-doped (Yb3+) fiber in terms of conversion efficiency and output power, R. Maurer first proposed the concept of double-cladding fiber in 1974. However, it wasn’t until E. Snitzer and others proposed cladding pumping technology in 1988 that high-power ytterbium-doped fiber laser/amplifier technology saw rapid development.

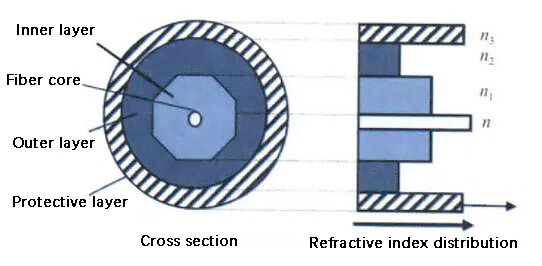

Double-clad optical fiber is a type of optical fiber with a unique structure. Compared to conventional optical fiber, it has an inner cladding made up of a coating layer, inner cladding, outer cladding, and doped core.

Cladding pumping technology is based on double-clad fiber and aims to transmit multi-mode pump light in the inner cladding and laser light in the fiber core, thereby greatly improving the pump conversion efficiency and output power of the fiber laser.

The structure of the double-clad fiber, the shape of the inner cladding, and the coupling mode of the pump light are crucial to this technology.

The double-clad fiber’s fiber coil is composed of silica (SiO2) doped with rare earth elements. In fiber lasers, it serves as both the laser medium and the laser signal transmission channel.

To ensure the output excitation is the fundamental transverse mode, the V parameter is reduced for the corresponding working wavelength by designing its numerical aperture and core diameter.

The inner cladding’s transverse dimension (tens of times larger than the conventional core diameter) and numerical aperture are much larger than the core’s, and its refractive index is lower than the core’s, which restricts the complete propagation of the laser in the core.

This creates an optical waveguide with a large cross-section and numerical aperture between the core and outer cladding, allowing high-power pump light with a large numerical aperture, cross-section, and multi-mode to be coupled into the optical fiber and limited to transmission within the inner cladding without diffusion. This helps maintain high-power density optical pumping.

The outer cladding of the double-clad fiber is composed of polymer materials with a refractive index lower than that of the inner cladding. The outermost layer is a protective layer made of organic materials.

The coupling area of the double-clad fiber to the pump light is determined by the size of the inner cladding, unlike traditional single-mode fiber, which is determined solely by the core.

This creates a double-layer waveguide structure for the double-clad fiber.

On one hand, it improves the power coupling efficiency of the fiber laser, allowing the pump light to excite the doped ions and emit laser light through the fiber core multiple times when conducted in the inner cladding.

On the other hand, the output beam quality is determined by the nature of the fiber core, and the introduction of the inner cladding does not negatively impact the output beam quality of the fiber laser.

Structural diagram of octagonal double clad fiber

Schematic diagram of various inner cladding structures

The specifically designed inner cladding of the double-clad fiber laser can greatly enhance the utilization efficiency of the pump light.

Initially, the inner cladding structure of the double-clad fiber was cylindrically symmetrical, making its manufacturing process relatively simple and easy to couple with the tail fiber of the pump laser diode (LD).

However, its perfect symmetry resulted in a large number of spiral rays in the pump light within the inner cladding, which would never reach the core area even after multiple reflections.

As a result, these rays could not be absorbed by the fiber core, leading to light leakage, making it difficult to improve conversion efficiency, even with the use of longer fibers.

Therefore, the cylindrical symmetry of the inner cladding structure must be disrupted.

In conventional double-clad fiber, the output laser power is determined by the size of the fiber core, and the numerical aperture determines the quality of the output laser beam.

However, the limitations of physical mechanisms such as nonlinear effects and optical damage in optical fiber make it impossible to meet the needs for single-mode operation of large mode field double-clad fiber at high power output through increasing the core diameter alone.

The advent of special optical fibers, such as photonic crystal fiber (PCF), offers an effective solution to this issue.

The concept of photonic crystals was first proposed by E. Yablonovitch in 1987. This involves dielectric materials with varying dielectric constants forming a periodic structure with the order of the light wavelength in one-dimensional, two-dimensional, or three-dimensional space. This creates photonic guide bands that allow for light propagation and photonic band gaps (PBG) that prohibit light propagation.

By altering the arrangement and distribution period of different media, numerous changes in the properties of photonic crystals can be achieved, enabling specific functions.

Photonic crystal fiber (PCF) is a two-dimensional photonic crystal, also referred to as a microstructure fiber or porous fiber.

In 1996, J.C. Knight and others created the first PCF, and its light guiding mechanism is similar to the total internal reflection light guiding mechanism in traditional optical fiber.

The first PCF based on the photonic band gap principle was invented in 1998.

After 2005, the design and preparation methods of large mode field PCF became diverse, with various shaped structures emerging, including leaky channel PCF, rod PCF, large spacing PCF, and multi-core PCF.

The mode field area of optical fibers also increased.

Microstructure of different photonic crystal fibers

Photonic crystal fiber (PCF) appears similar to traditional single-mode fiber, but has a complex hole array structure at the microstructure level.

These structural features grant PCF many unique advantages that traditional optical fibers cannot match, such as non-cutoff single-mode transmission, a large mode field area, adjustable dispersion, and low limiting loss, overcoming numerous problems in traditional lasers.

For instance, PCF can achieve single-mode operation with a large mode field area, significantly reducing the laser power density in the optical fiber, minimizing the nonlinear effect in the optical fiber, and improving the damage threshold of the optical fiber while preserving the beam quality.

It also allows for a large numerical aperture, resulting in better pump light coupling and higher power laser output.

These advantages of PCF have led to a surge in research worldwide, making it a new research focus in fiber lasers and playing an increasingly important role in high-power fiber laser applications.

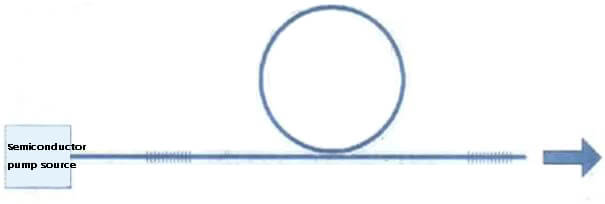

A laser with an optical fiber as the laser gain medium is called a fiber laser.

Like other laser types, it consists of a gain medium, pump source, and resonator.

The fiber laser uses the active fiber, doped with rare earth elements in the core, as the gain medium.

Typically, semiconductor lasers serve as the pump source, while the resonator is composed of mirrors, fiber end faces, fiber ring mirrors, or fiber gratings.

Based on the time-domain characteristics, fiber lasers can be divided into continuous fiber lasers and pulsed fiber lasers.

Based on the resonator structure, they can be divided into linear cavity fiber lasers, distributed feedback fiber lasers, and ring cavity fiber lasers.

Based on the different gain fiber and pumping mode, they can be divided into single cladding fiber lasers (core pumping) and double cladding fiber lasers (cladding pumping).

Structure principle of all fiber linear cavity fiber laser

In 1961, Snitzer discovered laser radiation in Nd-doped glass waveguides.

In 1966, Gao Kun thoroughly studied the main causes of optical attenuation in optical fibers and pointed out the key technical problems that needed to be addressed for the practical application of optical fibers in communication.

In 1970, Corning Company in the United States developed optical fibers with an attenuation of less than 20 dB/km, which laid the foundation for the development of optical communication and optoelectronic technology.

This technological breakthrough also greatly facilitated the development of fiber lasers.

In the 1970s and 1980s, the maturity and commercialization of semiconductor laser technology provided reliable and diverse pump sources for the development of fiber lasers.

At the same time, the advancement of chemical vapor deposition reduced the transmission loss of optical fibers.

Fiber lasers have rapidly diversified. Different rare earth elements, such as erbium (Er3+), ytterbium (Yb3+), neodymium (Nd3+), samarium (Sm3+), thulium (Tm3+), holmium (Ho3+), praseodymium (Pr3+), dysprosium (Dy3+), and bismuth (Bi3+), are doped into the fiber to achieve laser output of different wavelengths to meet various application requirements.

Emission spectrum range of quartz fiber doped with rare earth elements

The advantages of high-power fiber laser are as follows.

The waveguide structure of the fiber laser makes it easy to produce single transverse mode output and is not significantly impacted by external factors, leading to high brightness laser output.

Fiber lasers can achieve high optical-to-optical conversion efficiency by using a semiconductor laser whose emission wavelength matches the absorption characteristics of doped rare earth elements as the pump source.

For high-power ytterbium-doped fiber lasers, 915 nm or 975 nm semiconductor lasers are typically selected.

The simple energy level structure of Yb3+ leads to few phenomena such as up-conversion, excited state absorption and concentration quenching, and a long fluorescence life, making it effective for storing energy and achieving high-power operation.

The overall electro-optic efficiency of commercial fiber lasers can be as high as 25%, contributing to cost reduction, energy conservation, and environmental protection.

Fiber lasers utilize a slender rare earth-doped fiber as the laser gain medium, which boasts a large surface area and volume ratio. This is approximately 1000 times greater than that of solid-state block lasers and provides inherent advantages in terms of heat dissipation.

For low to medium power applications, special cooling of the optical fiber is not required. In high power scenarios, water cooling can effectively mitigate the decline in beam quality and efficiency caused by thermal effects in solid-state lasers.

The fiber laser’s use of a small and flexible fiber as the laser gain medium makes it ideal for reducing volume and reducing costs. The pump source, a semiconductor laser, also has a compact size and is easily modularized. Most commercial products can be output using tail fiber.

By incorporating optical fiber devices such as fiber Bragg gratings, an all-optical fiber system can be achieved through the fusion of these devices. This results in high immunity to environmental disturbances, high stability, and reduced maintenance time and costs.

High power fiber lasers also have insurmountable disadvantages:

First, it is easily restricted by nonlinear effects.

The fiber laser’s waveguide structure gives it a long effective length, resulting in a low threshold for various nonlinear effects. However, harmful nonlinear effects such as stimulated Raman scattering (SRS) and self-phase modulation (SPM) can lead to phase fluctuations, energy transfer in the spectrum, and even damage to the laser system, hindering the advancement of high-power fiber lasers.

The second is photon darkening effect.

The high doping concentration of rare earth in fiber lasers results in a gradual and irreversible decline in power conversion efficiency due to the photon darkening effect with prolonged pumping time. This limits the long-term stability and lifespan of high-power fiber lasers, particularly in the case of ytterbium-doped high-power fiber lasers.

However, advancements in high-brightness fiber-coupled semiconductor lasers and double-clad fiber technology have significantly improved the output power, optical conversion efficiency, and beam quality of high-power fiber lasers.

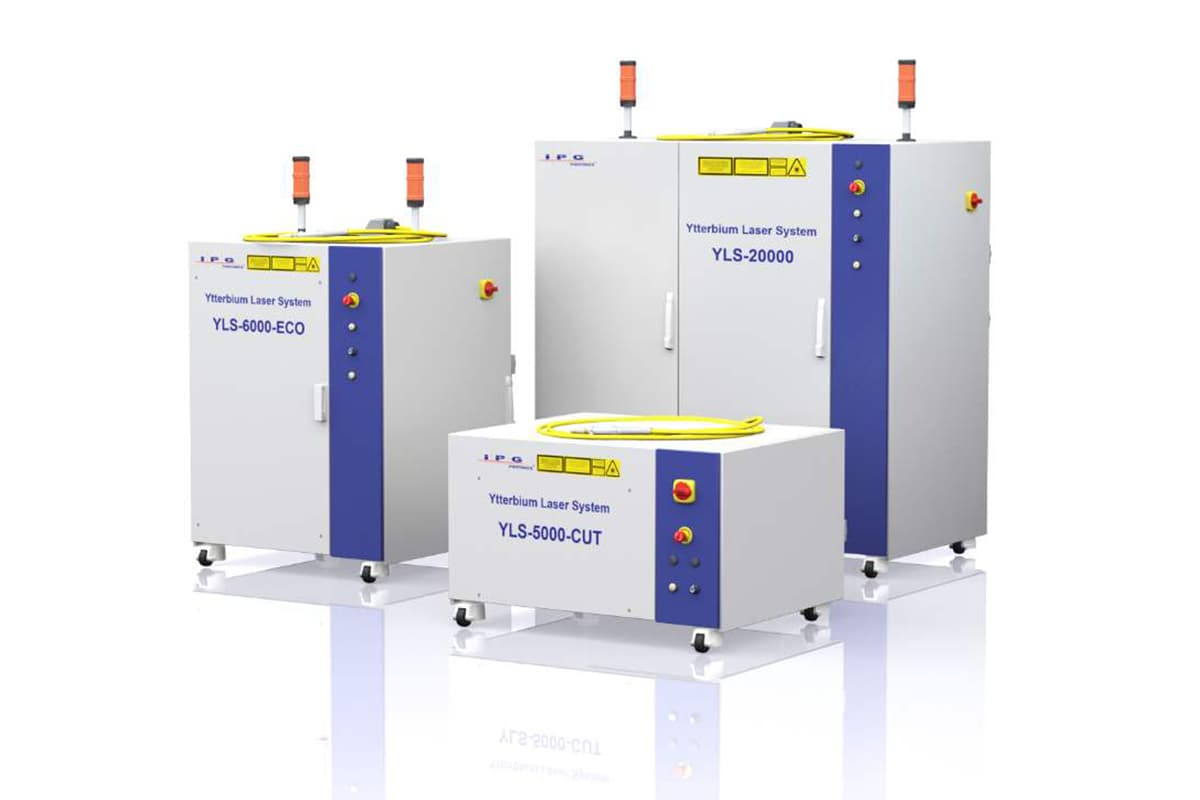

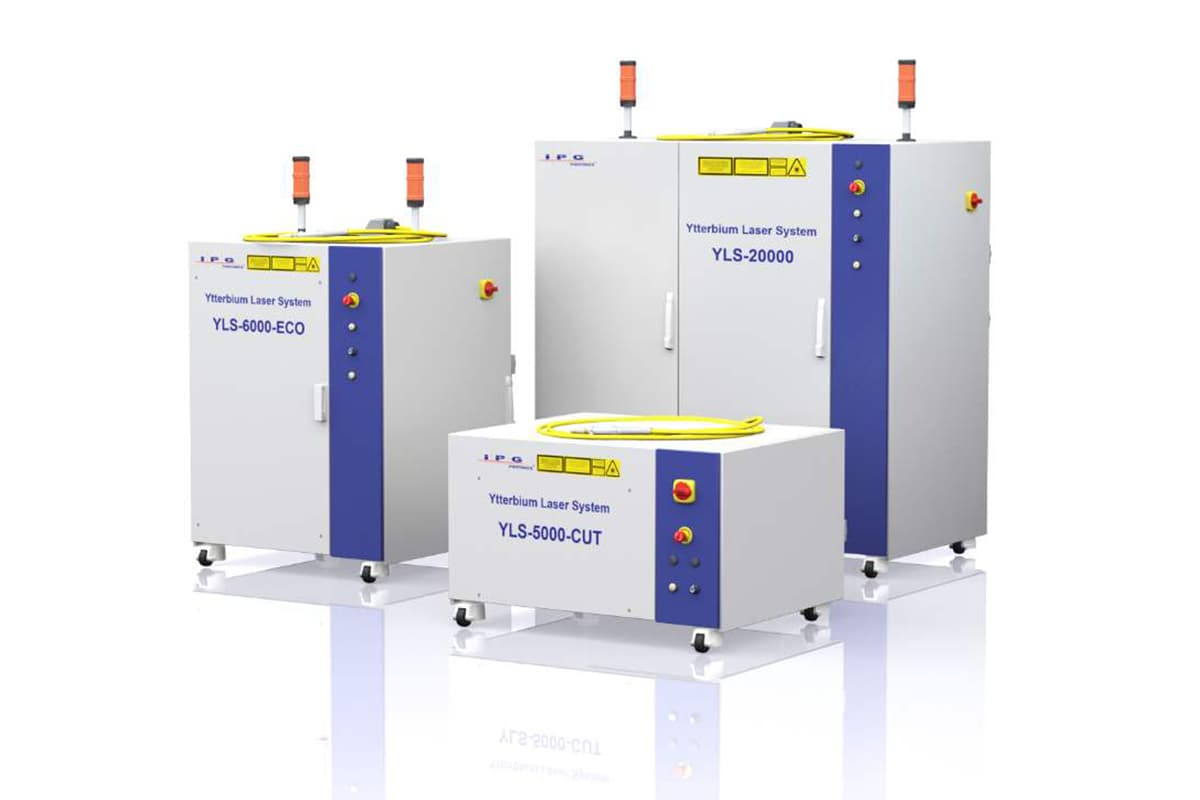

The huge demand for high-power fiber lasers in industrial processing, directional energy weapons, long-distance telemetry, lidar, and other fields has driven research efforts by companies such as IPG Photonics, Nufern, NLight, and the Trumpf Group, leading to the development of both continuous wave and pulse wave high-power fiber lasers with a diverse product line.

Academic institutions such as Tsinghua University, the University of National Defense Science and Technology, the Shanghai Institute of Optics and Precision Machinery, the Chinese Academy of Sciences, and the Fourth Research Institute of China Aerospace Science and Industry Group have also reported exciting results in this field.

The limitations of nonlinear effects, thermal effects, and material damage thresholds in fiber lasers result in a limited output power for single-channel fiber lasers, with a decrease in beam quality as power increases.

To improve beam quality, it is necessary to adopt mode control technology and design new fibers with special structures. J.W. Dawson and colleagues conducted a theoretical analysis of the output power limit of a single fiber. The calculations reveal that a broadband fiber laser can achieve a near-diffraction limit laser output with a maximum power of 36 kW, while a narrow linewidth fiber laser can reach a maximum power of 2 kW.

To further enhance the output power of fiber lasers and amplifiers, power synthesis of multi-channel fiber lasers through coherent synthesis technology is an effective method. This has become a widely researched topic in recent years.

Coherent synthesis system of fiber laser

The limitations imposed by nonlinear effects, thermal effects, and material damage thresholds in fiber lasers restrict the output power of single-channel fiber lasers and result in a decline in beam quality with increasing power.

To enhance beam quality, mode control technology and the design of special fiber structures must be utilized. J.W. Dawson and his colleagues conducted a theoretical analysis of the output power limit of a single fiber. The results show that a broadband fiber laser can produce a near-diffraction limit laser output with a maximum power of 36 kW, while a narrow linewidth fiber laser can reach a maximum power of 2 kW.

Coherent synthesis technology, which involves power synthesis of multiple fiber lasers, is an effective method for increasing the output power of fiber lasers and amplifiers. This approach has become a topic of significant research interest in recent years.

In addition to the unique advantages of fiber lasers and the demand for 100 kilowatt systems, various supporting devices, such as fiber-fused cone couplers, multi-core fibers, phase modulators with pigtails, and acousto-optic frequency shifters, have played a crucial role in the commercialization of optical fiber communication.

The fiber-fused cone coupler and multi-core fibers make passive phase control through laser energy injection coupling and evanescent wave coupling much more manageable.

The phase modulator with pigtails and acousto-optic frequency shifters allow for active phase control with a megahertz control bandwidth, enabling the control of phase fluctuations under high-power conditions and achieving phase-locked output.

Researchers have proposed numerous distinct coherent synthesis schemes, including spectral synthesis technology, an incoherent synthesis technology that uses one or more diffraction gratings to diffract multiple subbeams into the same aperture for a single aperture output and improved beam quality.

The spectral synthesis of fiber lasers makes full use of the wide gain bandwidth of ytterbium-doped fiber lasers to overcome the limitations of single fiber laser output power, resulting in high-power and high-beam quality laser output. This is one of the important technical avenues for high-power fiber lasers in the future.

Spectral synthetic fiber laser system

The Shanghai Institute of Optics and Mechanics has conducted extensive research on high-power fiber lasers and spectral synthesis in recent years, making significant breakthroughs in device preparation, key technologies, and spectral synthesis systems.

In terms of narrow linewidth and high-power fiber amplifiers, the Institute utilized self-developed core devices such as fiber Bragg gratings, high-power fiber combiners, and cladding optical filters in 2016. This was based on key technologies including fiber Bragg grating cascade filtering, linewidth control, amplification stage parameter control, and fiber mode control.

This breakthrough surpassed the single-mode output power limit of lasers with a linewidth of less than 50 GHz reported by the research group at Jena University in Germany. The Institute was able to achieve a near-diffraction limit fiber laser output with a power of 2.5 kW, a linewidth of 0.18 nm (50 GHz), and a center wavelength of 1064.1 nm.

The laser features a compact and stable all-optical fiber seed and a three-stage amplification structure, making it highly robust. The main amplifier utilizes a non-polarization-maintaining 20 μm/400 μm fiber, and increasing the available pump power could further improve the laser output power.

In terms of spectral synthesis, metal film reflective diffraction gratings have a low damage threshold and are unable to withstand the high-power laser irradiation, making it challenging to achieve high-power spectral synthesis. However, in August 2016, the Institute realized spectral synthesis of 11.27 kW high beam quality by using 7 narrow linewidth fiber lasers and high damage threshold polarization uncorrelated multilayer dielectric diffraction gratings (MLDG), making significant progress in the spectral synthesis of high-power fiber lasers.

Fiber lasers have excellent performance in a variety of fields such as industrial processing, medical treatment, remote sensing, security, and scientific research due to their good beam quality, high electro-optic efficiency, compact structure, and reliability.

In the industrial sector, fiber lasers can be classified into three categories based on their output power:

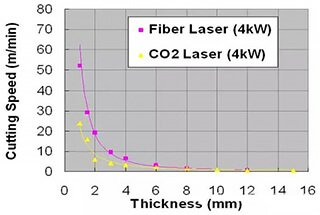

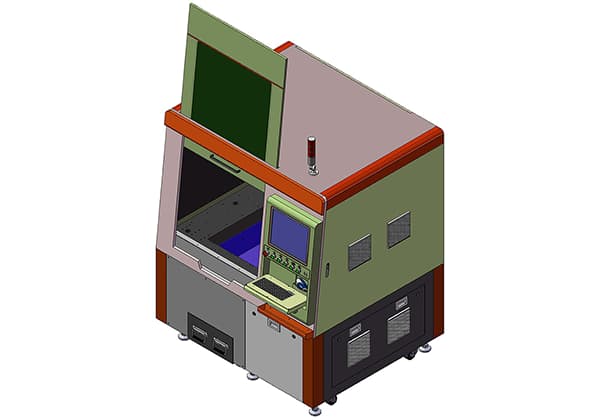

Low-power fiber lasers (< 50 watts) are mainly used for microstructure processing, laser marking, resistance adjustment, precision drilling, metal engraving, etc.

Medium-power fiber lasers (50 to 500 watts) are mainly utilized for drilling, welding, cutting, and surface treatment of thin metal plates.

High-power fiber lasers (> 1000 watts) are mainly used for cutting thick metal plates, metal surface coating, and three-dimensional processing of special plates, among others.

Fiber lasers have outstanding performance in various fields such as industrial processing, medical treatment, remote sensing, security, and scientific research due to their good beam quality, high electro-optic efficiency, compact design, and reliability.

In the industrial domain, fiber lasers can be grouped into three categories based on their output power:

Low-power fiber lasers (< 50 watts) are primarily used for microstructure processing, laser marking, resistance adjustment, precision drilling, metal engraving, etc.

Medium-power fiber lasers (50 to 500 watts) are predominantly used for drilling, welding, cutting, and surface treatment of thin metal plates.

High-power fiber lasers (> 1000 watts) are primarily utilized for cutting thick metal plates, metal surface coating, and three-dimensional processing of special plates, among other applications.

Fiber lasers have exceptional performance in various fields such as industrial processing, medical treatment, remote sensing, security, and scientific research due to their good beam quality, high electro-optic efficiency, compact design, and reliability.

In the industrial sector, fiber lasers can be classified into three categories based on their output power:

Low-power fiber lasers (< 50 watts) are primarily used for microstructure processing, laser marking, resistance adjustment, precision drilling, metal engraving, etc.

Medium-power fiber lasers (50 to 500 watts) are predominantly utilized for drilling, welding, cutting, and surface treatment of thin metal plates.

High-power fiber lasers (> 1000 watts) are primarily used for cutting thick metal plates, metal surface coating, and three-dimensional processing of special plates, among other applications.

Compared to other light sources, the smaller volume of fiber lasers contributes to high mobility on launch platforms, thereby improving adaptability and survivability in the battlefield.

In Afghanistan, the Spata company’s “Zeus” laser mine-sweeping system has been used to clear mines.

Since 2009, the U.S. Navy has successfully used fiber-optic laser systems to destroy UAVs, shells, and small ships. The system was installed on warships in 2014.

In 2012, German defense arm dealer Rheinmetall launched a 50 kW double-tube laser system that successfully intercepted and destroyed UAVs, shells, and other targets in a demonstration experiment.

The laser weapon is a rapidly developing new concept weapon.

It emits high-energy lasers at the speed of light onto the target surface, causing damage to key devices such as photoelectric detection, navigation, and guidance, or making the target “blind and deaf,” or burning through the moving object shell to shoot it down, or detonating fuel to explode it in the air, thereby completing the task of causing damage in a short amount of time.

It has the benefits of energy concentration, fast transmission speed, and repeatable use, as well as high cost-efficiency, fast fire transfer, and resistance to electromagnetic interference.

Since its inception, the development of laser weapons has had its share of ups and downs. However, the maturity of solid-state laser technologies, such as fiber lasers, has revitalized the development of laser weapons and become the focus of research for major military powers.

At present, countries such as the United States, Britain, Russia, Germany, and India have started the development of laser weapons and carried out relevant tests.

The entry of laser weapons into the battlefield is just around the corner.

In an effort to combat asymmetrical threats such as UAVs and stealth attack boats and enhance the ship’s close defense capabilities, the US Navy officially commenced development of the “Laser Weapon System” (LAWS) in 2010. The system was deployed on the amphibious dock transport ship “Ponce” in September 2014 for a one-year operational test and evaluation.

LAWS is led by Raytheon, with participation from Boeing and Lockheed Martin in certain aspects of the work. The system leverages existing commercial technologies and components to the greatest extent possible to minimize R&D and procurement costs.

The LAWS prototype consists of six industrial fiber lasers, which when operational, combine their laser beams to produce a 30 kW laser beam. The cost of using the laser weapon system is low, with a single shot estimated to cost just $1, in stark contrast to the tens of thousands or hundreds of thousands of dollars per missile.

In 2016, the US Naval Research Bureau initiated the development of a new ship-borne high-energy laser weapon system with an output power of 150 kW, which was five times more powerful than the previously tested laws system prototype. The project took 12 months and cost US $53 million to develop the “laser weapon system demonstration prototype” in three stages: the first stage was the initial design, the second stage was ground testing, and the third stage was testing on a Navy self-defense test ship.

In 2014, China Academy of Engineering Physics and the Shanghai Institute of Optics and Mechanics jointly developed the “Low Altitude Guard” system. In the demonstration and verification experiment, over 30 small aircraft, such as fixed-wing, multi-rotor, and helicopter, were successfully shot down with a 100% success rate. The system had a launch power of nearly 10,000 watts and an effective protection area of 12 square kilometers for low altitudes. It could accurately intercept a variety of aircraft, including fixed-wings, within a 2-kilometer radius and 360-degree airspace, within 5 meters. The system was fast, accurate, and free of collateral damage.

In 2015, Lockheed Martin used a 30 kW laser weapon called Athena to destroy a truck from a mile away. In March 2017, the company announced the completion of its research and development of a 60 kW laser weapon system, and its shipment to the U.S. Army Command Center in Alaska. The company’s chief technologist stated that the successful tests bring us closer to the development of portable laser weapon systems that can be deployed on military aircraft, helicopters, ships, and trucks. The research has shown that the high-energy directional laser is now compact, lightweight, and reliable enough to be used for defense on ground, sea, and air platforms.

In conclusion, the development of laser technology shows that fiber laser technology is the future direction of high-power and high-brightness lasers. The combination of waveguide fiber technology and semiconductor laser pumping technology leads to the creation of high-power fiber lasers which can cater to the pressing demand for high-power and high-efficiency lasers in advanced laser manufacturing and military defense.

This technology is of great strategic importance for both the national economy and security. Moreover, high-power fiber lasers have immense application potential in various fields such as energy exploration, large scientific devices, space science, environmental science, and more. It will serve as a powerful tool for humans to comprehend and shape the world.