Have you ever wondered which laser cutting technology truly reigns supreme? This article dives into the battle between fiber lasers and CO2 lasers, exploring their strengths, weaknesses, and the factors that make one better than the other. By the end, you’ll know which laser cutting machine suits your needs best.

It is only in recent years that fiber laser cutting technology has begun to be widely used in the industry.

Many companies have realized the advantages of fiber lasers.

With the development of cutting technology, fiber laser cutting has become one of the most advanced technologies in the industry.

In 2014, the fiber lasers surpassed CO2 lasers to occupy the most market share of laser sources.

Plasma, flame and laser cutting techniques are three common thermal cutting methods, while laser cutting can achieve the best cutting quality, especially for fine cutting and hole blanking with the diameter-to-thickness ratio less than 1:1.

Therefore, laser cutting technology is also the first choice of fine cutting.

Fiber laser cutting has drawn great attention in the industry because it provides both cutting speed and quality which is achievable by CO2 laser cutting, while significantly reducing maintenance and operating costs.

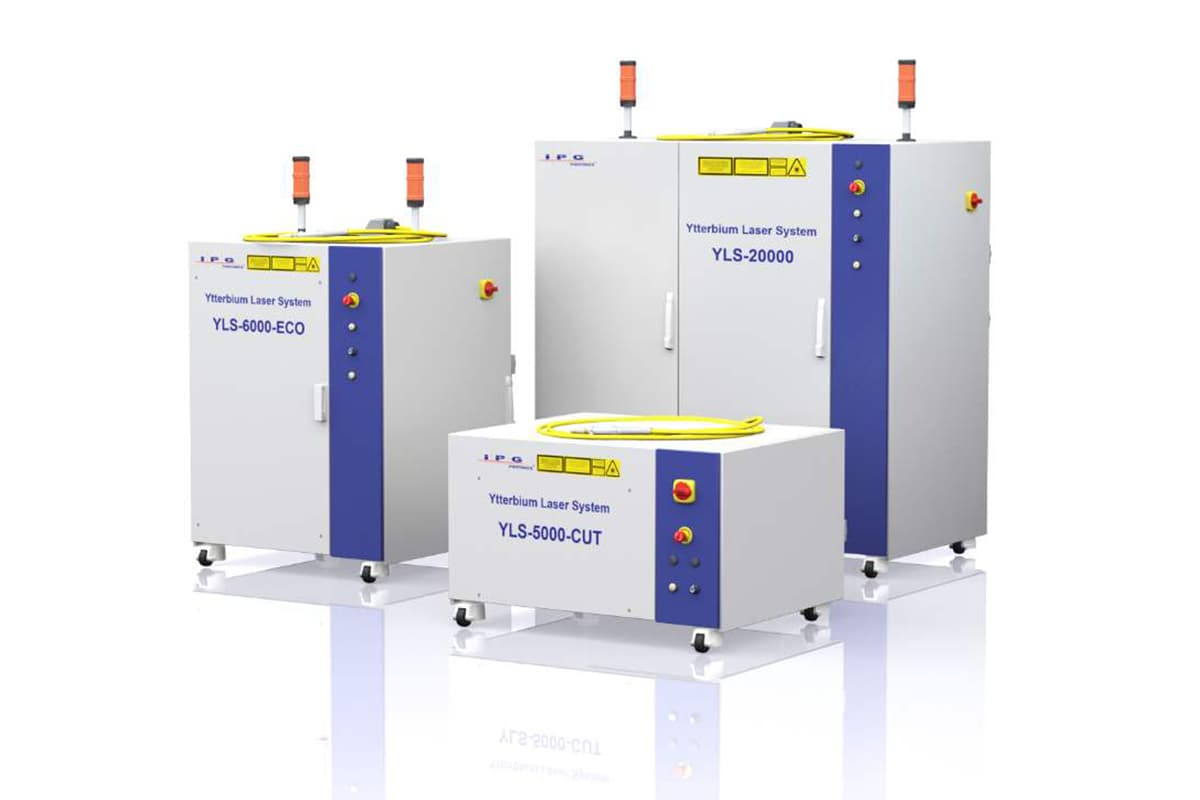

Currently, there are 2 main types of laser cutting machines for cutting metal sheets in the sheet metal processing industry.

One is a CO2 laser cutting machine that was converted from an industrial laser about 25 years ago, and the other is a fiber laser cutting machine that was officially converted from an industrial laser about 10 years ago.

From the number of laser cutting machines sold in China’s sheet metal equipment market in recent years, CO2 laser cutting machines account for 40% and fiber laser cutting machines account for 60%.

Although essentially 100% of laser cutters sold on the market in 2007 were CO2 laser cutters, we know that fiber laser cutters have gained momentum in recent years and are gaining market acceptance and the number of units sold is gradually expanding.

While the current market trend favors fiber laser cutters, are fiber laser cutters really the best choice?

Due to the different physical characteristics of CO2 laser and fiber laser, the laser processing process differs between the two.

Of course, the two actually have their own strengths and weaknesses, and each has advantages and disadvantages depending on the object being processed.

The CO2 laser is a gas beam obtained by excitation of carbon dioxide molecules, and its wavelength is 10.6μm, while the fiber laser is a solid laser obtained by placing a crystalline Yb (ytterbium) compound as a medium in optical fiber and irradiating the crystals with a light beam, and its wavelength is 1.08μm.

The physical characteristics of the different wavelengths have a significant impact on the processing characteristics of the two.

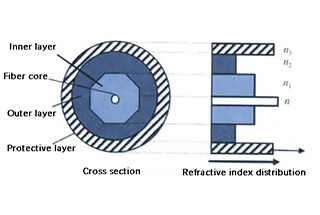

The original concept of the fiber laser was recognized because it was a laser that could propagate through fibers.

The reason for being able to propagate through the optical fiber is precise because of its wavelength of 1.08μm.

The advantage of using optical fibers for propagation is the long life of the optical components and the high reliability and low maintenance requirements.

CO2 laser cutting machines transmit laser light from the oscillator to the processing point with the aid of a reflective lens, generally in an optical path that is isolated from the outside air.

Although the inside of the optical path is filled with air free of common dust and foreign objects, the surface of the reflector may become covered with dirt even after prolonged use and needs to be cleaned.

In addition, the reflector itself will wear out from absorbing small amounts of laser energy and will need to be replaced.

To transmit the laser from the oscillator to the processing point, multiple reflectors are used to adjust the angle of the laser reflection.

Therefore, maintaining proper operations requires a certain amount of technical skills and management.

However, with fiber laser cutters, the laser is transmitted via a single fiber from the oscillator to the processing point. This fiber is commonly called a light guide fiber.

Since no optical components such as reflectors are required, and the laser is transmitted in a light-guiding fiber that is isolated from the outside air, the laser is virtually invisible.

Strictly speaking, however, the laser is transmitted repeatedly in the periphery of the optical fiber, so the optical fiber itself is somewhat depleted. Nevertheless, it will last several times longer compared to the reflectors used in CO2 laser cutters.

In addition, if the transmission path is above the minimum curvature of the guiding fiber, the path can be freely determined, making it easy to adjust and maintain.

The two also differ in the process of laser generation (laser oscillator construction).

A CO2 laser oscillator generates a laser by placing a gas mixed with CO2 in the discharge space. To ensure proper functioning of the resonance length derived from the laser output power, optical components are placed inside the oscillator, which need to be cleaned and replaced periodically.

In contrast, fiber laser oscillators generate the laser inside the fiber and are isolated from the outside air with no optical components. Therefore, there is little need for regular maintenance. The maintenance cycle for cleaning is set at approximately 4000 hours for CO2 laser oscillators and approximately 20,000 hours for fiber laser oscillators.

The aforementioned advantages make fiber laser cutters more durable and easier to maintain.

Additionally, we can compare them in terms of operating costs such as power consumption.

CO2 laser oscillators have a photoelectric conversion rate of about 10-15%, while fiber laser oscillators have a conversion rate of about 35-40%. This high photoelectric conversion rate of fiber laser cutters results in lower power consumption of cooling devices such as chillers, as less electrical energy is converted into heat dissipation.

Although the oscillator of a fiber laser cutter requires more accurate management of the cooling temperature than a CO2 oscillator, about 1/2 to 2/3 of the cooling capacity of a CO2 laser oscillator is sufficient for a fiber laser cutter with the same laser output power.

Therefore, a fiber laser cutting machine can be operated with about 1/3 of the power consumption of a CO2 laser cutting machine. This makes it a highly energy-efficient laser cutting machine.

Cutting speed

There is a significant difference between CO2 lasers and fiber lasers in their processing, mainly due to the difference in their respective wavelengths.

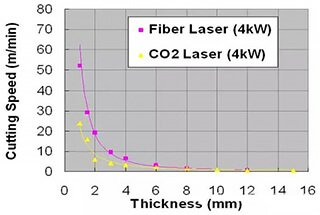

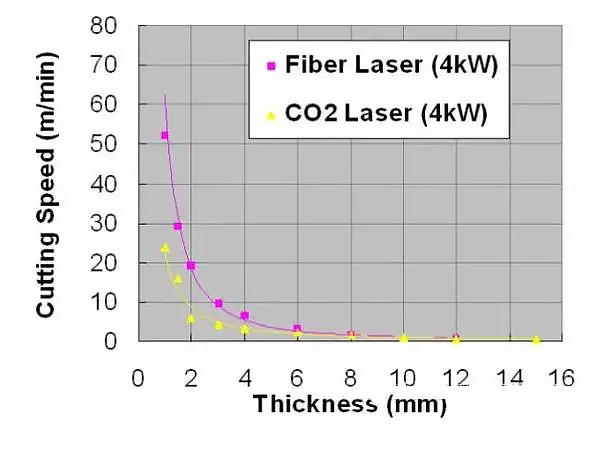

Comparison of processing speed between CO2 laser cutting machine and fiber laser cutting machine when processing stainless steel.

Both lasers have a 4kW output.

It can be observed that the fiber laser cutting machine is able to process at 2 to 3 times the cutting speed of the CO2 laser cutting machine in the field of plate thickness of 4.0mm or less.

Why is there such a big difference in processing speed, even with the same output power?

Firstly, the difference can be attributed to the large differences in the absorption rate of laser energy into metallic materials.

Due to the varying physical properties of matter, the absorption of light energy at different wavelengths of light differs. For example, stainless steel has an absorption rate of about 12% for CO2 lasers, while fiber lasers have an absorption rate of about 35%, which is about three times higher.

This high absorption rate results in a very short time for the laser to convert light energy into heat energy and melt the metal material after irradiation, enabling a very fast cutting process.

If you want to cut quartz glass with a laser cutter, you can use a CO2 laser cutter, but not a fiber laser cutter.

This is because quartz glass absorbs the wavelength of a CO2 laser, but not that of a fiber laser, which penetrates it.

Moreover, when cutting highly reflective materials such as aluminum and copper, fiber laser cutting has an advantage over CO2 laser cutting due to the principle that metal materials absorb the wavelength of the fiber laser better.

When comparing the processing speed of stainless steel materials, it can be observed that the two speeds are essentially the same for plate thicknesses over 6.0mm.

Cutting techniques

When cutting with a laser, it is more important to consider how to remove the molten metal efficiently than how to melt the metal instantly.

During laser cutting, an auxiliary gas (usually nitrogen, oxygen, etc.) is injected into the processing point while the laser is directed at the material to achieve optimal processing conditions.

Different auxiliary gases are used for different cutting materials. The primary function of the auxiliary gas is to isolate the molten metal from underneath the material.

For thick plates, an auxiliary gas is required to achieve optimal cutting conditions by isolating the melted metal from underneath the lower part of the material, ultimately increasing processing speed.

However, in terms of processing area and cutting quality, CO2 laser cutting machines are generally considered superior.

It has been approximately 30 years since the introduction of CO2 laser machines to the industry, and their features have been thoroughly studied, enabling them to process a wide range of materials, from thin to thick plates. Additionally, processing technology has become so mature that it can guarantee a certain processing quality.

We have not only developed the processing technology to cut various shapes but also to ensure a certain roughness of the cut surface.

However, ensuring the quality of cutting with fiber laser cutting machines still presents some challenges. In particular, for products processed with fiber laser cutting machines and a plate thickness greater than 3.0mm, there will be some noticeable small particles attached to the bottom of the cutting surface that are difficult to remove, known as scum. The cutting surface is also rougher compared to that of CO2 laser cutting machines. This phenomenon is caused by the high absorption property of metallic materials.

During laser processing, the laser reflects onto the surface of the material, and the metal melts and falls away. When a fiber laser reflects onto a metal surface with high absorption rates, back-absorption occurs, melting the metal on the cutting surface and resulting in a rough cut section after cutting.

Sample cut by CO2 laser cutting machine (20mm stainless steel)

Processing quality is one of the items that are difficult to quantify, so many customers do not pay much attention to it when choosing a laser cutter.

However, the aforementioned problem with scum is related to processing quality.

Fiber laser cutting machines can be used to control costs even at high speeds. After the laser cutting process, if there is a subsequent process such as scum removal, the total processing cost is about the same as that of a CO2 laser cutting machine.

Therefore, it is necessary to pay more attention to the processing quality of the laser cutter.

Although I used the concepts of fiber lasers and CO2 lasers to make a comparison, is it sufficient to rely solely on this when choosing a laser cutter?

The comparison of fiber optics and CO2 refers to the constituent oscillators of a laser cutter. In the composition system of a laser cutting machine, there are also X, Y, Z drive axes. The performance and control of the movement of these drive axes are also significant factors.

Laser cutting machines can process complex shapes, such as odd-shaped holes, wedges, and bumps, in addition to round, square, and rectangular holes.

Therefore, no matter how fast the machining speed is, if the kinematic performance of the XY drive axis, which determines the shape to be machined, is low, it is impossible to shorten the cutting time.

If the processing speed is 40m/min with a fiber laser machine and 20m/min with a CO2 laser cutting machine, the processing time of the fiber laser machine will not necessarily be twice as fast as the CO2 laser cutting machine, and the processing time of the CO2 laser cutting machine will not necessarily be half as fast when processing a certain shape, particularly if the machining shape is complex and the number of holes is high.

In order to clearly show the difference in processing speed, it is necessary to improve the kinematic performance of the drive shaft, particularly the acceleration and deceleration ability during cutting processing.

With high acceleration and deceleration performance, a strong, highly rigid frame is required to withstand its kinematic performance. In order to maintain the processing accuracy of the product, it is necessary to have an internal structure that can control high motion.

Maximizing the laser processing capability of the oscillator requires an increase in the overall capability of the laser cutting machine, including the driveshaft.

Because the components of a fiber laser cutter are relatively simple, it is possible to build a fiber laser cutter of a certain quality without laser processing technology when considering the design and manufacture of a laser cutter.

In addition, many components of a fiber laser cutting machine are available in the market and the processing capability of a cutter made by assembling these components is also good. This is one of the reasons why there has been a recent proliferation of manufacturers manufacturing and selling fiber laser cutters.

However, CO2 laser cutting machines require a lot of processing techniques, such as laser transmission, so it is easy for differences in characteristics and performance to occur between laser cutting machine manufacturers.

A true laser cutting machine manufacturer should have mature technology and the ability to design and manufacture CO2 laser cutting machines, as well as the processing technology accumulated from the production of CO2 laser cutting machines that can be used to design and manufacture fiber laser cutting machines.

Although machining accuracy and quality are difficult to express numerically, the best choice is a laser cutting machine that can consistently maintain a high level of accuracy and quality, as well as high kinematic performance. However, it is necessary to make a rational decision based on the processing materials.

If the material to be processed is thin, the production volume is high, and you want to control processing costs, a fiber laser cutter is the best choice. However, if thickness greater than 6.0mm is required in many cases or if a certain processing quality is required, a CO2 laser cutting machine is more suitable.

Separate follow-up operations are required, and the total processing cost is very high when done manually. When selecting a laser cutting machine, make comprehensive evaluations not only about the laser process but also about your product and manufacturing.

The technology provides both the cutting speed and quality that carbon dioxide laser cutting can achieve while significantly reducing the cost of maintenance and operation.

The most significant advantage of fiber cutting technology is its energy efficiency. For each power unit of carbon dioxide cutting system, the actual general utilization rate is about 8% to 10%. In contrast, the user can expect higher power efficiency with the fiber laser cutting system, which is about 25% to 30%.

In other words, the overall energy consumption of the fiber cutting system is about 3 to 5 times less than that of the carbon dioxide cutting system, resulting in increased energy efficiency to more than 86%.

Fiber lasers have short-wavelength characteristics that increase the absorption of the beam by the cutting material and can cut materials such as brass, copper, and non-conductive materials. A more focused beam produces a smaller focus and deeper focal depth, enabling the optical fiber laser to quickly cut thin materials and more efficiently cut materials of medium thickness.

When cutting materials up to 6mm thickness, the cutting speed of a 1.5kw fiber laser cutting system is equivalent to that of a 3KW carbon dioxide laser cutting system. As the operation cost of fiber cutting is lower than that of ordinary carbon dioxide cutting systems, this can be understood as increased output and decreased commercial cost.

There are also maintenance issues to consider. The CO2 laser system requires regular maintenance, including reflector maintenance and calibration, as well as regular maintenance of the resonant cavity. However, the fiber laser cutting solution requires virtually no maintenance.

The CO2 laser cutting system requires CO2 as the laser gas, and due to the purity issues of CO2 gas, the cavity can become contaminated and require regular cleaning. It costs at least $20,000 per year for a system of kilowatts of carbon dioxide. Additionally, many CO2 cuts require high-speed axial-flow turbines to deliver laser gas, and turbines require maintenance and renovation.

Finally, compared to CO2 cutting systems, fiber cutting solutions are more compact and have less impact on the environment, requiring less cooling and significantly reducing energy consumption. The features of less maintenance and higher efficiency make optical fiber laser cutting systems more environmentally friendly, emitting less carbon dioxide than CO2 laser cutting systems.

Fiber lasers have a wide range of applications, including laser fiber communication, industrial shipbuilding, automobile manufacturing, sheet metal processing, laser engraving, medical equipment, and more. As technology continues to develop, the range of applications for fiber lasers is expanding.

Definition of fiber laser:

A fiber laser is a type of laser that uses rare earth element-doped glass fiber as the gain medium. Fiber lasers can be developed based on fiber amplifiers.

Principle of fiber laser:

Under the action of pump light, a high power density can be formed in the optical fiber, leading to “particle number inversion” of the laser energy level of the laser working material. When the positive feedback loop (forming a resonator) is properly added, the laser oscillation output can be generated.

Applications of fiber laser:

Fiber lasers have a wide range of applications, including laser fiber communication, laser space long-distance communication, industrial shipbuilding, automobile manufacturing, laser engraving, laser marking, laser cutting, printing roller, metal and non-metal drilling/cutting/welding (brazing, quenching, cladding, and deep welding), military and national defense security, medical instruments and equipment, and large-scale infrastructure construction, as well as the pump source of other lasers.

Types of fiber laser:

Fiber lasers can be classified in many ways, among which the more common methods include classification by working mode, band range, and dielectric doped rare earth elements.

Fiber lasers can be classified in several ways, including:

By working mode:

By band range:

By doped rare earth elements:

Lasers are usually named based on one or more of these categories.

Fiber lasers have a wide range of applications, and different subdivisions of lasers have distinct characteristics and suitable application fields. For example:

An application diagram of laser subdivision classification corresponding to relevant industries can be useful for identifying suitable uses for specific types of lasers.

A CO2 laser is a type of molecular laser and is one of the most common high-power continuous wave (CW) lasers. Its primary material is carbon dioxide molecules.

The main structure of a CO2 laser includes a laser tube, an optical resonator, a power supply, and a pump. Its primary feature is high output power and continuous operation, but the structure is complex, and the laser is large in size and difficult to maintain.

Basic structure of CO2 gas laser

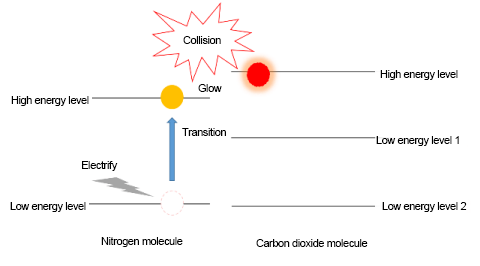

Realizing particle number inversion is key to the luminescence of a carbon dioxide laser.

The working substances in a carbon dioxide laser include carbon dioxide, nitrogen, and helium.

After DC power is supplied, nitrogen molecules in the mixed gas are excited by electron impact.

When the excited nitrogen molecules collide with carbon dioxide molecules, they transfer energy to the carbon dioxide molecules.

Thus, the carbon dioxide molecules transition from a low-energy level to a high-energy level, forming particle number inversion and emitting a laser.

① Nitrogen molecules collide with carbon dioxide molecules after excitation, so that carbon dioxide is excited separately.

② The excited carbon dioxide molecule jumps down and emits a laser

Optical fiber and CO2 laser have their own advantages, and different lasers should be selected according to different needs.

From the cutting technology widely used at present, fiber laser and CO2 laser have their own advantages and disadvantages in the face of specific application requirements.

They cannot completely replace each other but need to complement and coexist.

From the type of processing materials, due to the absorption effect, fiber lasers are not suitable for cutting non-metallic materials, while conventional CO2 lasers are not suitable for cutting high reflectivity materials such as copper and aluminum.

In terms of cutting speed, CO2 lasers have advantages in sheet thickness > 6mm, while fiber lasers cut sheet faster;

Workpiece penetration is required before laser cutting, and the perforation speed of CO2 is significantly faster than that of fiber laser;

In terms of cutting section quality, CO2 laser is better than fiber laser as a whole.

Comparison between fiber laser and carbon dioxide laser

| Fiber laser | CO2 laser | |

| Cutting material | Non metallic materials cannot be cut | High reflective materials have poor adaptability |

| Cutting speed | Obvious advantages below 3mm | >6mm, CO2 is more advantageous |

| Penetration efficiency | The speed is relatively slow | The greater the thickness, the more obvious the advantage |

| Section quality | Slightly worse | Better roughness and verticality |

Fiber laser has higher light conversion efficiency and lower use cost.

Based on the calculation, the cost of using fiber laser is 23.4 yuan per hour, while the cost of using carbon dioxide laser is 39.1 yuan per hour. Specifically, the power cost of fiber laser is 7 yuan per hour, water cooling cost is 8.4 yuan per hour, and other costs are 8 yuan per hour. Meanwhile, the power cost of carbon dioxide laser is 21 yuan per hour, water cooling cost is 12.6 yuan per hour, and other costs are 5.5 yuan per hour.

Cost comparison between fiber laser and CO2 laser

| Fiber Laser | CO2 Laser | |

| Power (kw) | 3 | 3 |

| Light conversion efficiency | 30% | 10% |

| Power consumption (kw) | 10 | 30 |

| Electricity price (yuan/kWh) | 1 | 1 |

| Load duration | 70% | 70% |

| Power cost (yuan/hour) | 7 | 21 |

| Water cooling equipment power (kw) | 12 | 18 |

| Electricity price (yuan/kWh) | 1 | 1 |

| Load duration | 70% | 70% |

| Water cooling cost (yuan/hour) | 8.4 | 12.6 |

| Consumables cost (yuan/hour) | 3 | 2.5 |

| Module consumption cost (yuan/hour) | 5 | |

| Media cost (yuan/hour) | 1 | |

| Conventional point solution (yuan/hour) | 2 | |

| Other costs (yuan/hour) | 8 | 5.5 |

| Use cost (yuan/hour) | 23.4 | 39.1 |