Deciding on the right Pittsburgh Lockformer machine for your duct manufacturing needs can be overwhelming, especially for newcomers. This guide simplifies the process by breaking down key considerations like voltage, machine weight, sheet thickness, and lock shape. You’ll learn the differences between light, conventional, and heavy-duty models, ensuring you choose the best machine for your specific applications. Discover how these factors impact your decision and ensure your investment meets your production demands efficiently. Dive in to make an informed purchase!

The Pittsburgh Lockformer machine, also referred to as a Lockformer machine or Rollformer machine, is a versatile machine.

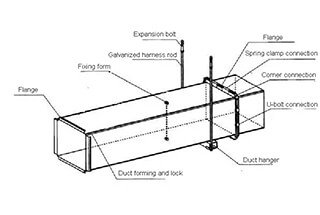

Mainly used for the lock processing of sheet connections and closed connections of circular ducts, the Pittsburgh Lockformer machine is well understood by experienced customers when it comes to purchasing the right machine.

However, for new customers entering the duct manufacturing industry, the decision of which lock forming machine to buy can be challenging.

Therefore, we are here today to provide a comprehensive guide on how to purchase a Lockformer machine.

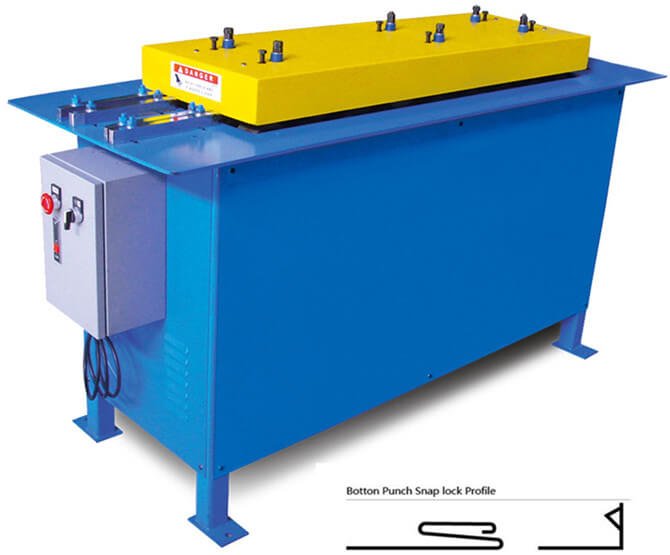

Additionally, there are two other types of Lockformer machines: the single flat mouth machine and the button lockformer machine. The single flat mouth machine is used for splicing plates by folding the remaining materials by 180 degrees to save materials.

It is also suitable for the joint seam in the middle of a round duct, which is similar to the stitching seam function of the joint angle machine. The difference is that the edge of the single flat mouth machine is slightly wider than that of the stitching seam machine.

The button lockformer machine is used for small air ducts and can only process galvanized sheets within 1.0mm due to its complicated forming process.