Have you ever struggled with achieving precise bends in sheet metal? This article demystifies the manual folding machine, a versatile tool essential for bending steel and nonferrous metals. By reading, you’ll learn step-by-step instructions on operating and adjusting this machine to ensure smooth and accurate results. Discover practical tips on maintenance to keep your equipment running efficiently, making it an indispensable guide for professionals and hobbyists alike.

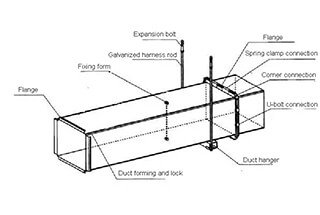

This series of manual folding machines are widely used in various industries for bending and folding steel plates, nonferrous metals, and stainless steel plates with a length of up to 2.5 meters and thickness of up to 2mm. They are particularly popular in the production of household appliances, stainless steel kitchen utensils, lighting fixtures, hardware furniture, ventilation systems, and air-conditioning equipment.

The machines feature full manual operation with a positioning device, making them ideal for mass-producing irregular workpieces with a fixed angle.

The folding process is achieved by using the upper and lower blades, ensuring that there is no relative movement or impact during the entire process. This results in a smooth and bright surface on the workpiece, making it particularly suitable for manufacturing stainless steel workpieces.

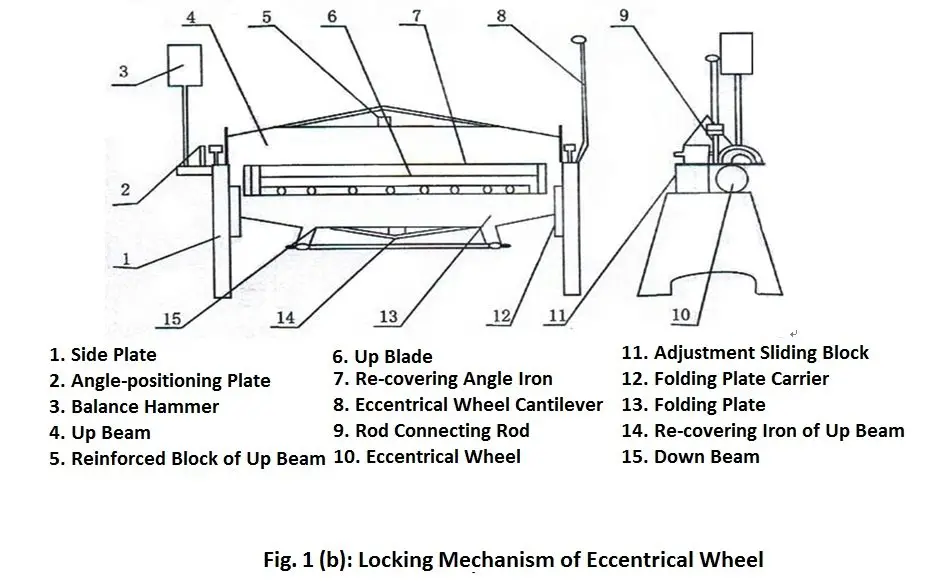

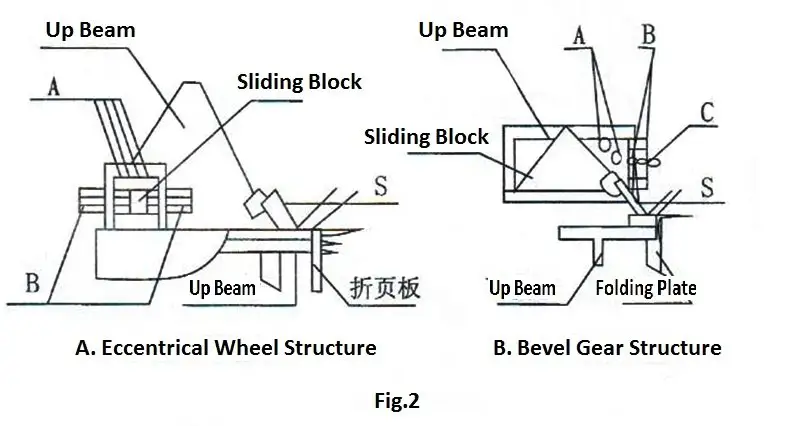

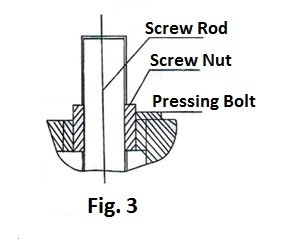

Locking is achieved through the use of bevel gears, screw rotation, or cams, providing smooth and reliable operation. The machines have a simple structure, making maintenance and adjustment easy.

| Portable-type ( bevel gear locking) | ||||||

| Model | Max. Plate Thickness | Max. Bending Width | Max. Bending Angle | Weight | Max. Workpiece Dimension | Toolings |

| WS1.5×1300 | 1.5 | 1300 | 60° | 320 | 1950×650×1500 | Segmented Blade |

| WS1.5×1500 | 1.5 | 1500 | 60° | 360 | 2150×650×1500 | Segmented Blade |

| WS1.5×2000 | 1.5 | 2000 | 60° | 450 | 2650×650×1500 | Segmented Blade |

| WS1.2×2500 | 1.2 | 2500 | 60° | 550 | 3150×650×1500 | Segmented Blade |

| TDF1.5×1300 | 1.5 | 1300 | 60° | 320 | 1950×650×1500 | Segmented Blade |

| TDF1.5×1500 | 1.5 | 1500 | 60° | 360 | 2150×650×1500 | Segmented Blade |

| TDF1.5×2000 | 1.5 | 2000 | 60° | 450 | 2650×650×1500 | Segmented Blade |

| TDF1.2×2500 | 1.2 | 2500 | 60° | 550 | 3150×650×1500 | Segmented Blade |

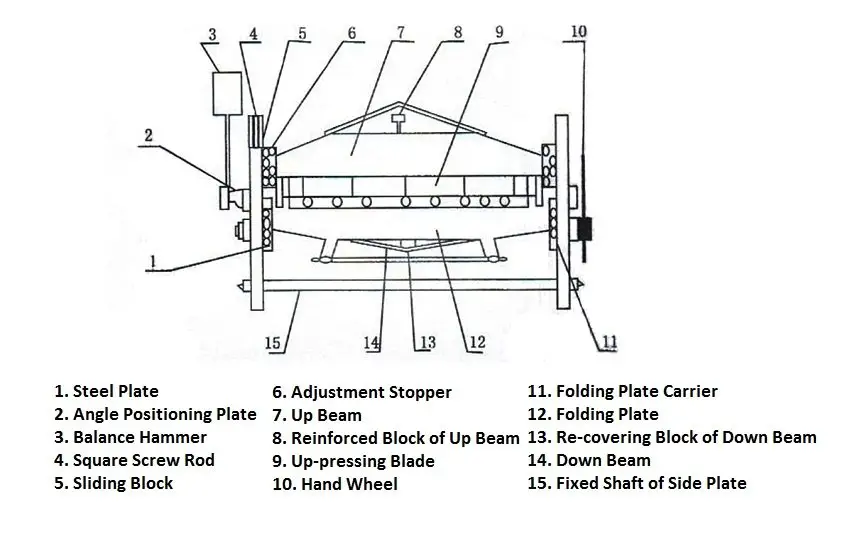

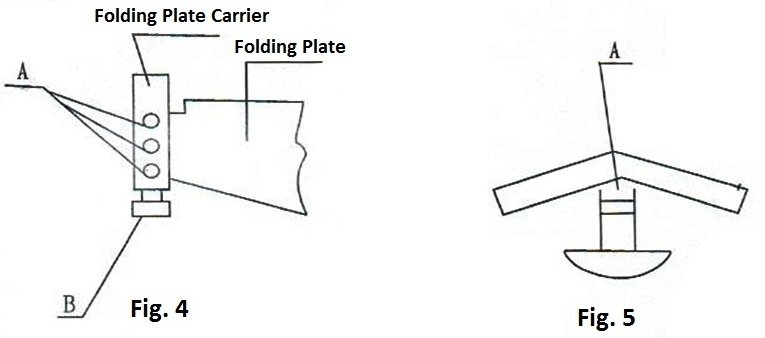

This series of manual folding machine tools, as shown in Figure 1, consists of upper and lower beams, plate-folding components, and blades. These three components have been adjusted to a rotational center, allowing users to adjust related parameters based on the machine specifications and plate thickness.

The adjustable parts of this series of the manual folding machine are as follows:

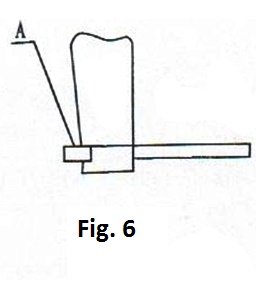

First, loosen bolt A connecting the folding plate and folding plate seat, then adjusts bilateral bolt B until the folding plate blade and beam blade are in the same line, and finally, re-locking bolt A.

All bearing points on the upper beam, lower beam, and folding plate are distributed at both ends, it is inevitable that some deflection will arise in the process of bending the plate, which directly affects the workpiece straightness, in order to overcome the shortcoming, the machine is equipped with the crowning device, through adjusting nut A to add some pre-stress on the center of the beam and folding plate (Max. adjustable height 0.5mm)for compensating the deflection deformation to guarantee the workpiece quality.

These manual folding machines are user-friendly and easy to operate.

To start, the user adjusts the upper beam and folding plate, places the plate between the beams, secures the angle positioning plate on the left shaft, and rotates the folding plate to the angle positioning position. Then, the required workpieces can be folded.

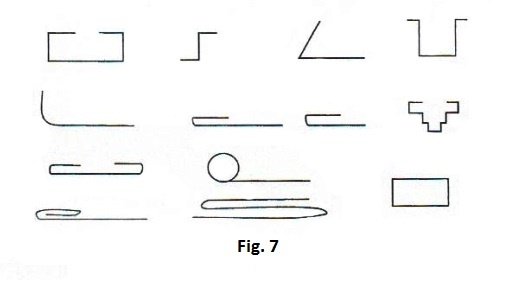

The upper beam comes in two types of blades: 35° and 55°. The 55° blade is a segmented blade that can be assembled into blades of varying lengths to accommodate different shaped boxes.

A typical example is shown in Figure 7.

Before using the machine, it is important to carefully inspect the blade clearance, as shown in Figure 2 (S valve). It is strictly prohibited to fold plates that are too large, as this can damage the blade.

It is recommended to use the machine at a moderate pace. No one should stand behind the balance hammer to avoid potential accidents.

Regular attention should also be paid to the bearing and lubrication positions.