Ever wondered how to determine the weight of a metal plate without a scale? This article reveals a simple yet effective method for calculating plate weight using mathematical formulas. You’ll discover how to apply these formulas to different materials and dimensions, making your projects more efficient and precise. Get ready to simplify your metalworking tasks with these practical tips!

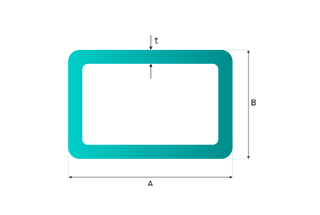

A steel plate is a plate-shaped steel material that is formed by pouring molten steel and then pressing it after cooling.

Steel plates are classified based on their thickness, with thin steel plates being less than 4 mm (with the thinnest being 0.2 mm), medium-thick steel plates being 4 to 60 mm, and extra-thick steel plates being 60 to 115 mm. They can also be divided into hot-rolled steel plates and cold-rolled steel plates based on the rolling process.

The width of thin plates ranges from 500 to 1500 mm, and the thickness ranges from 600 to 3000 mm. Thin plates can be further divided into various types, including ordinary steel, high-quality steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel, and industrial pure iron thin plates.

In terms of professional use, there are oil barrel plates, enamel plates, bulletproof plates, etc. The surface coating of the plates can also vary, including galvanized sheets, tin-plated sheets, lead-plated sheets, plastic composite sheets, etc.

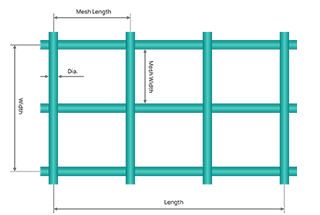

According to the “Hot Rolled Steel Plate and Strip Dimensions, Shape, Weight and Allowable Deviation” (GB/T 709-2006) and “Cold Rolled Steel Plate and Strip Dimensions, Shape, Weight and Allowable Deviation” (GB/T 708-2006), the theoretical weight calculation method for both hot-rolled steel plates and strips and cold-rolled steel plates and strips is the same.

In the market, steel plates can be delivered either based on their theoretical weight or actual weight, while steel strips are generally delivered based on their actual quantity. When the steel plate is delivered based on its theoretical weight, the density of carbon steel is 7.85 g/m3, and the densities of other steel types are specified in the corresponding standards.

A steel plate weight calculator can be used to calculate the weight of the steel plate.

Related Tool: Steel Weight Calculator

| Thickness | Weight |

| (mm) | (kg/m2) |

| 0.2 | 1.57 |

| 0.25 | 1.96 |

| 0.3 | 2.36 |

| 0.35 | 2.75 |

| 0.4 | 3.14 |

| 0.45 | 3.53 |

| 0.5 | 3.93 |

| 0.55 | 4.32 |

| 0.6 | 4.71 |

| 0.65 | 5.1 |

| 0.7 | 5.5 |

| 0.75 | 5.89 |

| 0.8 | 6.28 |

| 0.9 | 7.07 |

| 1 | 7.85 |

| 1.1 | 8.64 |

| 1.2 | 9.42 |

| 1.3 | 10.21 |

| 1.4 | 10.99 |

| 1.5 | 11.78 |

| 1.6 | 12.56 |

| 1.7 | 13.35 |

| 1.8 | 14.13 |

| 2 | 15.7 |

| 2.2 | 17.27 |

| 2.5 | 19.36 |

| 2.8 | 21.98 |

| 3 | 23.55 |

| 3.2 | 25.12 |

| 3.5 | 27.48 |

| 3.8 | 29.83 |

| 3.9 | 30.62 |

| 4 | 31.4 |

| 4.5 | 35.33 |

| 5 | 39.25 |

| 5.5 | 43.18 |

| 6 | 47.16 |

| 7 | 54.95 |

| 8 | 62.8 |

| 9 | 70.65 |

| 10 | 78.6 |

| 11 | 86.35 |

| 12 | 94.2 |

| 13 | 102.1 |

| 14 | 109.9 |

| 15 | 117.75 |

| 16 | 125.6 |

| 18 | 141.3 |

| 20 | 157 |

| 22 | 172.7 |

| 24 | 188.4 |

| 25 | 196.25 |

| 26 | 204.1 |

| 28 | 219.8 |

| 30 | 235.5 |

| 32 | 251.2 |

| 34 | 266.9 |

| 35 | 274.75 |

| 36 | 282.6 |

| 38 | 298.3 |

| 40 | 314 |

| 42 | 329.7 |

| 44 | 345.4 |

| 45 | 353.25 |

| 46 | 361.1 |

| 48 | 376.8 |

| 50 | 392.5 |

| 52 | 408.2 |

| 54 | 423.9 |

| 55 | 431.75 |

| 56 | 439.6 |

| 58 | 455.3 |