Have you ever needed to find the exact weight of a rectangular steel tube for your project? This article breaks down the process of calculating it, from understanding the key formula to using a handy online calculator. Whether you’re a seasoned engineer or just starting out, you’ll learn how to determine the weight of various tube sizes, enhancing your precision in design and manufacturing. Get ready to streamline your workflow with these essential calculations.

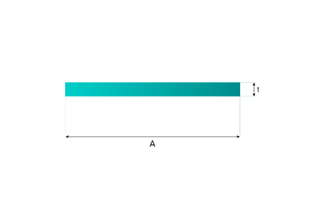

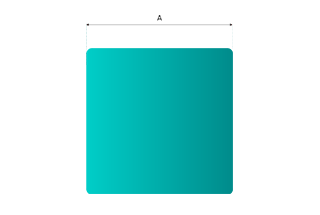

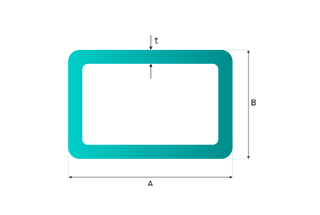

The weight calculation formula of rectangular tube is:

2[(a-d-2r+π(r+d/2)/2+(b-d-2r+π(r+d/2)/2)x7.85d(kg)

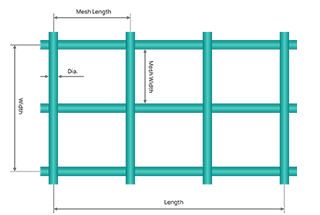

a, b is the length and width of the rectangular tube (m), r is the arc radius of the four corners of the inner cavity of the tube (m), and d is the wall thickness (mm).

According to GB/T 3094-2012, the typical length of a rectangular steel pipe is between 2000mm to 9000mm. The pipes can be supplied in fixed or double lengths.

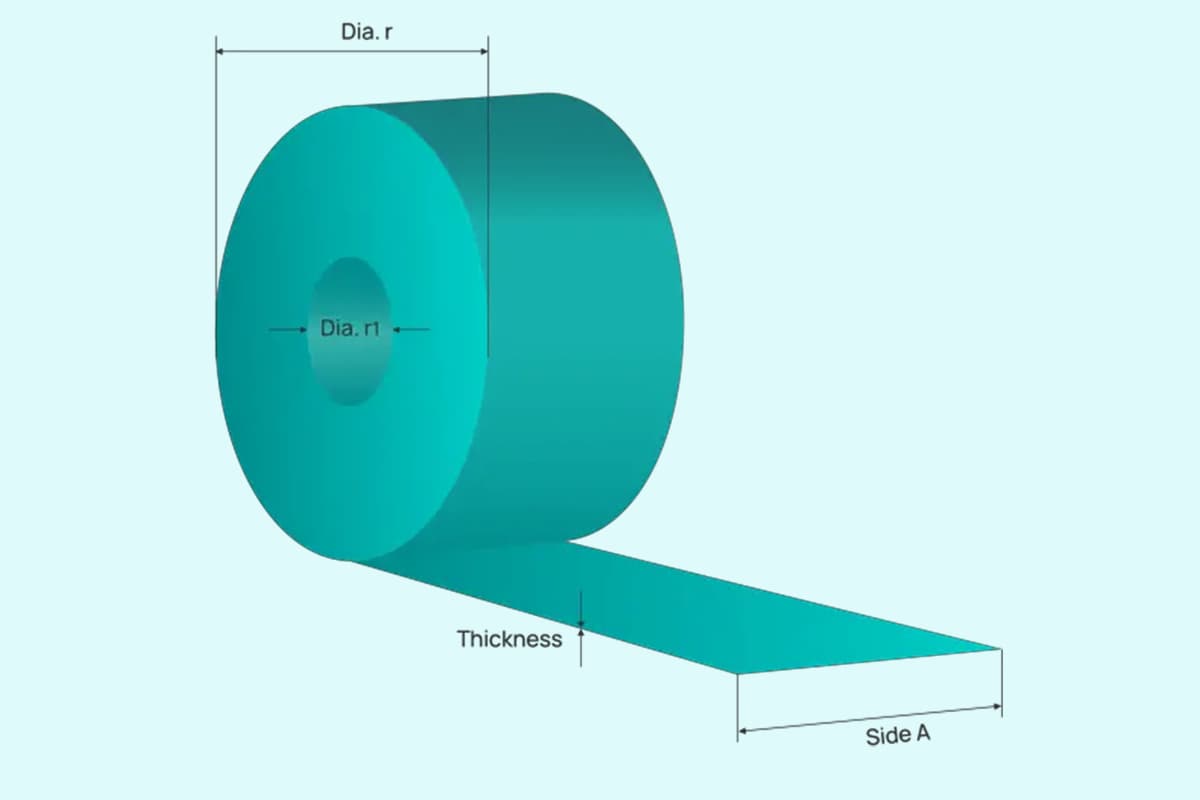

In the market, rectangular steel pipes can be supplied based on either actual weight or theoretical weight. When supplied based on theoretical weight, the density of the steel pipe is assumed to be 7.85g/cm3.

You can use a rectangular steel pipe weight calculator to determine the weight of the pipe.

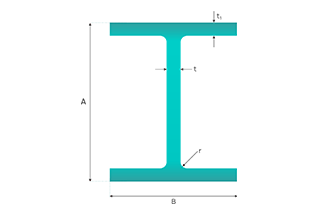

Related Tool: Steel Weight Calculator

| Size (mm) | Weight | ||

| b1(length) | b2(width) | t(thickness) | kg/m |

| 50 | 25 | 1.2 | 1.37 |

| 1.5 | 1.7 | ||

| 30 | 2.5 | 2.94 | |

| 3 | 3.49 | ||

| 4 | 4.52 | ||

| 60 | 30 | 2.5 | 3.34 |

| 3 | 3.96 | ||

| 4 | 5.15 | ||

| 40 | 2.5 | 3.73 | |

| 3 | 4.43 | ||

| 4 | 5.78 | ||

| 70 | 50 | 3 | 5.37 |

| 4 | 7.03 | ||

| 5 | 8.64 | ||

| 80 | 40 | 2.5 | 4.51 |

| 3 | 5.37 | ||

| 4 | 7.03 | ||

| 5 | 8.64 | ||

| 60 | 3 | 6.31 | |

| 4 | 8.29 | ||

| 5 | 10.21 | ||

| 90 | 40 | 3 | 5.84 |

| 4 | 7.66 | ||

| 5 | 9.42 | ||

| 50 | 3 | 6.31 | |

| 4 | 8.29 | ||

| 5 | 10.21 | ||

| 60 | 3 | 6.78 | |

| 4 | 8.92 | ||

| 5 | 10.99 | ||

| 100 | 50 | 3 | 6.78 |

| 4 | 8.92 | ||

| 5 | 10.99 | ||

| 120 | 60 | 3 | 8.2 |

| 4 | 10.8 | ||

| 5 | 13.35 | ||

| 6 | 15.83 | ||

| 80 | 3 | 9.14 | |

| 4 | 12.06 | ||

| 5 | 14.92 | ||

| 6 | 17.71 | ||

| 140 | 80 | 4 | 13.31 |

| 5 | 16.48 | ||

| 6 | 19.59 | ||

| 150 | 100 | 4 | 15.2 |

| 5 | 18.84 | ||

| 6 | 22.42 | ||

| 8 | 29.39 | ||

| 160 | 80 | 4 | 14.57 |

| 5 | 18.05 | ||

| 6 | 21.48 | ||

| 8 | 28.13 | ||

| 180 | 100 | 4 | 17.08 |

| 5 | 21.2 | ||

| 6 | 25.25 | ||

| 8 | 33.16 | ||

| 200 | 100 | 4 | 18.34 |

| 5 | 22.77 | ||

| 6 | 27.13 | ||

| 8 | 35.67 | ||

Rectangular tube is a light-weight, thin-walled steel tube with a hollow square section, also referred to as a steel cold-formed section.

The tube is made of Q235 hot-rolled or cold-rolled steel strip or coil plate as the base material.

The material undergoes cold bending and forming, followed by high-frequency welding to produce a square cross-sectional shape and size.

The wall thickness of hot-rolled extra thick wall square pipe is thicker, and its corner size and edge flatness even exceed the level of resistance welded cold formed square pipes.

Steel pipes can be classified into two types: seamless steel pipes and welded steel pipes (also known as seamless pipes).

Within the category of seamless pipes, there are hot-rolled seamless square pipes, cold-drawn seamless square pipes, extruded seamless square pipes. Welded square pipes are also available.

Welded square pipes can be further divided based on their manufacturing process:

Additionally, welded square pipes can be categorized based on the type of weld seam: