How does temperature affect measurement accuracy in engineering? This article delves into how temperature variations impact dimensional measurements, emphasizing the importance of maintaining consistent temperatures between objects and instruments. Readers will learn about the relationship between linear expansion coefficients and temperature changes, as well as methods to minimize errors, such as ensuring thermal equilibrium before measurements. Expect practical insights and formulas to enhance measurement precision in various engineering contexts.

In measurement conditions, factors such as temperature, humidity, vibration, dust, and corrosive gases can directly or indirectly impact measurement accuracy.

Among these factors, temperature changes have a significant effect on accuracy.

To ensure accurate results, the principle of maintaining equal temperatures between the measured object and the standard instrument is used, taking into consideration that different objects have varying expansion coefficients.

To guarantee the accuracy of test data, all metrology specialists must adhere to the temperature conditions specified by verification regulations.

Currently, the standard temperature for measurement rooms is 20℃.

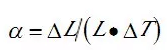

As per the manual, the relationship between the linear expansion coefficient (a), temperature change, and size change can be expressed by formula (1):

Where:

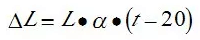

The change in size of a workpiece resulting from a deviation in temperature from 20℃ can be expressed by formula (2):

In this equation, “t” represents the temperature of the object.

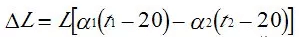

When the temperature of the workpiece and the measuring tool differ from the standard temperature, the error in measurement caused by temperature is the difference between the changes in size. This can be calculated using formula (3):

Where:

The linear expansion coefficient of an object is defined as the change in size of a unit length (1mm) in response to a 1℃ temperature change, and is specific to the material of the object.

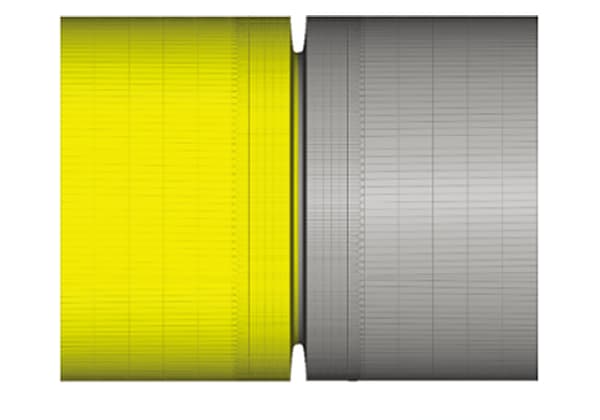

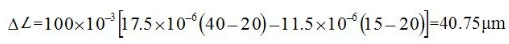

For example, consider a copper shaft with a diameter of 100mm whose temperature is 40℃, and a steel micrometer with an outer diameter of 15℃. If the linear expansion coefficients for the copper shaft and steel micrometer are 17.5 x10-6 and 11.5 x10-6 respectively, then the change in dimension (△L) can be calculated as follows:

It is evident that temperature has a significant impact on the size of the workpiece and can result in numerous errors.

Therefore, when using measuring instruments, it is advisable to balance the temperature of the workpiece and measuring tool before measurement to reduce temperature-related errors.

The required temperature balance time for each measuring tool during verification is specified in corresponding verification regulations and calibration specifications.

Note: The process of bringing the temperature of the bolted measuring tool and the standard measuring tool to consistency under specified conditions (such as a room temperature of (20 ± 6)℃) is referred to as temperature balance.

(1) Measure the temperature when it is close to the standard temperature.

In our work, we strictly abide by relevant regulations to ensure accuracy. Before verification or calibration, we require customers to provide the measuring instruments and the temperature of the measuring room.

Customers often require immediate measurement data, and it is important that the temperature is taken into consideration when obtaining this data.

(2) When conducting field measurements, do not remove the standard for measurement. Instead, place the standard and workpiece together on a large, flat surface and measure after they have reached thermal equilibrium.

(3) To prevent the influence of hand temperature on the workpiece and measuring tools, take necessary precautions. For example, when using a micrometer, hold it with a heat-insulating pad. If you suspect that your hand heat has been transferred to the micrometer, let it sit for a period of time before using or verifying it.

(4) When measuring large objects outdoors, it is necessary to compensate for the temperature of the material being measured to minimize temperature errors. Use a measuring instrument specifically designed for this purpose.