Have you ever wondered how to choose the best cutting tool for your CNC milling machine? This article dives into the essential properties and types of cutting tool materials, explaining how each choice impacts productivity, tool longevity, and machining quality. By the end, you’ll understand the key factors that make a cutting tool material suitable for your specific needs, ensuring both efficiency and precision in your metalworking projects.

In the metal cutting process, the cutting part of the tool is directly responsible for the cutting work. Therefore, the material of the cutting part of the tool is usually referred to as the tool material.

The reasonable choice of tool material is an important part of the cutting process, as it largely determines the level of cutting productivity, tool consumption and processing costs, as well as the size of the machining accuracy and surface quality.

The development of cutting tool materials is also promoted and influenced by the development of workpiece materials.

Today, I will share with you the basics of cutting tool materials, as well as methods for selecting them.

During the cutting process, the cutting tool is subjected to great cutting pressure, friction, and impact force, resulting in a high cutting temperature.

The tool works in such a high-temperature, high-pressure, and severe friction environment. The use of inappropriate materials will quickly wear down or break the tool.

Therefore, the tool material should be able to meet some basic requirements.

Hardness is a fundamental characteristic that tool materials should possess.

To cut chips from a workpiece, the tool’s hardness must be greater than that of the workpiece material.

The cutting edge of tools used to cut metal materials generally has a hardness above 60HRC.

For carbon tool steel materials, the hardness should be above 62HRC at room temperature.

The hardness of high-speed steel is 63-70HRC, while the hardness of carbide tools is 89-93HRC.

Wear resistance refers to the tool material’s ability to resist wear.

In general, the higher the hardness of the tool material, the better the wear resistance.

The wear resistance depends on the hardness of the hard points (such as carbides, nitrides, etc.) in the metallographic structure of the tool material, the number of these points, their particle size, and their uniformity of distribution, as well as the chemical composition, strength, microstructure, and temperature of the friction zone of the tool material.

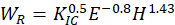

If the quality of the material is taken into consideration and the temperature in the friction zone and chemical wear are not considered, the following method can be used to express the wear resistance WR of the material:

Where:

To enable the tool to work under significant pressure, as well as withstand the impact and vibration that usually occur during the cutting process without chipping or breaking, the tool material must have sufficient strength and toughness.

In general, the greater the toughness of the tool material, the more cutting force it can withstand.

Heat resistance is the primary indicator used to measure the cutting performance of tool materials.

It is usually measured by the tool’s ability to maintain high hardness, wear resistance, strength, and toughness at high temperatures, also known as thermal hardness.

The higher the high-temperature hardness of the tool material, the better its heat resistance. The tool will have higher high-temperature resistance to plastic deformation and wear resistance, as well as a higher allowable cutting speed.

In addition to high-temperature hardness, the tool material should also be able to resist oxidation at high temperatures and possess good anti-bonding and anti-diffusion capabilities.

This characteristic is known as chemical stability.

The better the thermal conductivity of the tool material, the more easily the cutting heat is conducted from the cutting area. This reduces the temperature of the cutting part of the tool material, thereby reducing tool wear.

Cutting tools are often subjected to significant thermal shocks when used intermittently or when cutting fluid is applied. As a result, cracks can occur inside the tools and cause fractures.

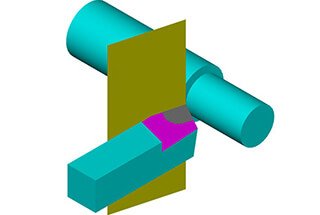

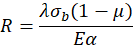

The ability of the tool material to resist thermal shock can be expressed by the thermal shock coefficient R:

Where:

The greater the thermal conductivity of the tool material, the easier the heat is transferred out. This reduces the temperature gradient on the tool surface.

A small coefficient of thermal expansion can reduce thermal deformation.

A small elastic modulus can reduce the amplitude of alternating stress caused by thermal expansion.

Tool materials with good thermal shock resistance can use cutting fluid in the cutting process.

The cutting tool should not only have good cutting performance, but it should also be easy to manufacture.

This requirement necessitates that tool materials have better process properties, such as forging performance, heat treatment performance, welding performance, grinding performance, and high-temperature plastic deformation.

Economy is one of the essential indicators of tool materials.

The development of tool materials should consider the country’s resource situation, which has significant economic and strategic significance.

Although some tools are expensive per piece, their long service life means that the cost allocated to each part is not necessarily high. Therefore, the economic effect should be considered when selecting a tool.

Moreover, advanced processing systems (such as cutting processing automation systems and flexible manufacturing systems) require the cutting performance of the tool to be stable, reliable, predictable, and have high reliability.

Table 1 lists the physical and mechanical properties of different tool materials. The physical and mechanical properties of materials are different, and their uses are also different.

Table 1 Physical and mechanical properties of various tool materials

| Type of material Performance | High-speed steel | Cemented carbide | TC(N)-based carbide substrate | Ceramics | PcBN | PCD | |||

|---|---|---|---|---|---|---|---|---|---|

| K-system (WC-Co) | P-system (WC-TIC-TaC-Co) | Al2O3 | Al2O3– TiC | Si3N4 | |||||

| Density (g/cm3) | 8.7-8.8 | 14-15 | 10-13 | 5.4-7 | 3.90-3.98 | 4.2-4.3 | 3.2-3.6 | 3.48 | 3.52 |

| HRA | 84-85 | 91-93 | 90-92 | 91-93 | 92.5-93.5 | 93.5-94.5 | 1350-1600HV | 4500HV | >9000HV |

| Flexural strength /MPa | 2000-4000 | 1500-2000 | 1300-1800 | 1400-1800 | 400-750 | 700-900 | 600-900 | 500-800 | 600-1100 |

| Compressive strength /MPa | 2800-3800 | 3500-6000 | 3000-4000 | 3500-5500 | 3000-4000 | 2500-5000 | 7000-8000 | ||

| Fracture toughness KIC /(MPa·m1/2) | 18-30 | 10-15 | 9-14 | 7.4-7.7 | 3.0-3.5 | 3.5-4.0 | 5-7 | 6.5-8.5 | 6.89 |

| Elastic modulus /MPa | 210 | 610-640 | 480-560 | 390-440 | 400-420 | 360-390 | 280-320 | 710 | 1020 |

| Thermal conductivity (W/(m·K)) | 20-30 | 80-110 | 25-42 | 21-71 | 29 | 17 | 20-35 | 130 | 210 |

| Coefficient of thermal expansion /(×10-6/K) | 5-10 | 4.5-5.5 | 5.5-6.5 | 6.5-7.5 | 7 | 8 | 3.0-3.3 | 4.7 | 3.1 |

| Heat resistance /℃ | 600-700 | 800-900 | 900-1000 | 1000-1100 | 1200 | 1200 | 1300 | 1000-1300 | 700-800 |

| Material Type | Relative Density | Hardness HRC (HV) | Bending Strength/GPa | Impact Toughness / (MJ / m2) | Thermal Conductivity / (W/m·K) | Heat Resistance / °C | Approximate Cutting Speed Ratio | |

| Tool Steel | Carbon Tool Steel | 7.6~7.8 | 60 ~ 65(81.2~84) | 2.16 | ≈41. 87 | 200~250 | 0. 32 ~ 0. 4 | |

| Alloy Tool Steel | 7.7~7.9 | 60 ~ 65(81. 2~84) | 2.35 | ≈41. 87 | 300~ 400 | 0. 48 ~ 0. 6 | ||

| High-Speed Tool Steel | 8.0~8.8 | 63 ~ 70(83 ~ 86. 6) | 1. 96 ~4. 41 | 0. 098 ~0. 588 | 16. 75 ~ 25. 1 | 600~ 700 | 1 ~ 1. 2 | |

| Cemented Carbide | Tungsten Cobalt Class | 14. 3 ~ 15. 3 | (89~91.5) | 1. 08 ~ 2. 16 | 0. 019 ~ 0. 059 | 75. 4~87. 9 | 800 | 3. 2 ~ 4. 8 |

| Tungsten Titanium Cobalt Class | 9. 35 ~ 13. 2 | (89 ~92.5) | 0. 882 ~ 1. 37 | 0. 0029 ~ 0. 0068 | 20. 9 ~ 62. 8 | 900 | 4 ~ 4.8 | |

| Class Containing Tantalum Carbide, Niobium | (~92) | ~ 1. 47 | 1000 ~ 1100 | 6~10 | ||||

| Titanium Carbide Base Class | 5. 56 ~ 6. 3 | (92 ~ 93. 3) | 0. 78 ~ 1. 08 | 1100 | 6~10 | |||

| Ceramic | Alumina Ceramic | 3.6~4. 7 | (91~95) | 0. 44 ~ 0. 686 | 0. 0049 ~0. 0117 | 4. 19 ~ 20. 93 | 1200 | 8~12 |

| Mixed Alumina Carbide Ceramic | 0. 71 ~ 0. 88 | 1100 | 6~10 | |||||

| Superhard Material | Cubic Boron Nitride | 3. 44~3. 49 | (8000 ~9000) | ≈0. 294 | 75.55 | 1300~1500 | ||

| Synthetic Diamond | 3. 47 ~3. 56 | -10000 | 0. 21 ~ 0. 48 | 146. 54 | 700~ 800 | ≈25 | ||

Commonly used tool materials can be divided into four categories:

Carbon tool steel and alloy tool steel are only suitable for some hand tools and tools with low cutting speeds due to their poor heat resistance.

Ceramic, diamond, and cubic boron nitride are only used in limited applications.

Currently, the most widely used tool materials are high-speed steel and cemented carbide.

High-speed steel (HSS) is a high-alloy tool steel that contains more alloying elements such as tungsten (W), molybdenum (Mo), chromium (Cr), and vanadium (V).

It was invented by American mechanical engineer Taylor and metallurgical engineer White in 1898.

The composition at that time was C 0.67%, W 18.91%, Cr 5.47%, V 0.29%, Mn 0.11%, and the remainder was iron.

It can withstand a cutting temperature of 550-600℃, and a cutting speed of 25-30m/min can be used for cutting general steel. This increases its processing efficiency by more than 215 times compared to that of alloy tool steel.

High-speed steel is a tool material with better comprehensive performance and the widest range of applications, and it has good thermal stability. It can still be cut at high temperatures of 500-600℃.

Compared to carbon tool steel and alloy tool steel, cutting speed is increased by 1-3 times, and tool durability is increased by 10-40 times, or even more. As a result, it can process a wide range of materials from non-ferrous metals to high-temperature alloys.

High-speed steel has high strength and toughness and has a certain degree of hardness and wear resistance. Its bending strength is 2-3 times that of general cemented carbide, 5-6 times that of ceramics, and has a hardness of 63-70HRC.

Therefore, it is suitable for various cutting tools and can also be used for processing on machines with poor rigidity.

Additionally, the manufacturing process of high-speed steel tools is relatively simple. They are easy to sharpen, and the cutting edge can be forged. This is critical for manufacturing tools with complex shapes. Therefore, high-speed steel occupies an essential position in the manufacture of complex tools, such as drills, taps, forming tools, broaches, and gear tools.

The performance of high-speed steel is more stable than that of cemented carbide and ceramics, making it more reliable to use on automatic machine tools.

Based on the above factors, high-speed steel still accounts for a large proportion of current tool materials, despite various new tool materials continuously appearing.

However, due to the worldwide shortage of resources for the main elements such as W and Co in HSS tools, they have become increasingly depleted, and their content is only sufficient for 40 to 60 years.

The proportion of HSS tools in tool materials is gradually decreasing, shrinking at a rate of 1% to 2% per year.

It is expected that the proportion of high-speed steel will continue to decline in the future.

The development direction of HSS cutting tools includes the following aspects:

According to different uses, high-speed steel can be divided into:

According to different process methods, high speed steel can be divided into:

The mechanical properties of several commonly used high-speed steels are shown in Table 2.

Table 2 Physical and mechanical properties of commonly used high-speed steel grades

| Types | Grades | Hardness (HRC) | Flexural strength σM/GPa | Impact toughness αK/(MJ·m-2) | |||||

|---|---|---|---|---|---|---|---|---|---|

| YB12-77 grade | American AISI code | Related China’s factory code | Room temperature | 500 oC | 600 oC | ||||

| General HHS | W18Cr4V (T1) | 63-66 | 56 | 48.5 | 2.94-3.33 | 0.176~0.314 | |||

| W6Mo5C4V2 (M2) | 63-66 | 55-56 | 47-48 | 3.43-3.92 | 0.294~0.392 | ||||

| W9Mo3Cr4V | 65-66.5 | __ | __ | 4-4.5 | 0.343-0.392 | ||||

| high performance steel | high vanadium | W12C4V4Mo (EV4) | 65~67 | __ | 51.7 | ≈3.136 | =0.245 | ||

| W6Mo5Cr4V3 (M3) | 65~67 | __ | 51.7 | ≈3.136 | ≈0.245 | ||||

| cobaltiferous | W6Mo5Cr4V2Co5 (M36) | 66-68 | __ | 54 | ≈2.92 | ≈0.294 | |||

| W2Mo9Cr4VCo8 (M42) | 67~70 | 60 | 55 | 2.665~3.72 | 0.225-0.294 | ||||

| aluminiferous | W6Mo5Cr4V2Al (M2A1)(501) | 67~69 | 60 | 55 | 2.84-3.82 | 0.225-0.294 | |||

| W10Mo4Cr4V3Al (5F6) | 67-69 | 60 | 54 | 3.04-~3.43 | 0.196~0.274 | ||||

| W6Mo5Cr4V5SiNbAl (B201) | 66~68 | 57.7 | 50.9 | 3.53~3.82 | 0.255-0.265 | ||||

1. General high-speed steel

General HSS is the most widely used, accounting for about 75% of the total HSS.

The carbon content of general high-speed steel is 0.7% to 0.9%.

According to the different tungsten content in steel, it can be divided into:

The cutting speed of general high-speed steel tools is typically not too high. It is usually not higher than 40-60m/min when cutting ordinary steel materials.

(1) Tungsten steel

The typical steel grade of tungsten steel is W18 steel.

The advantage of W18 steel is its low tendency to overheat during quenching. Because the vanadium content is small, the grinding workability is good. Due to the higher carbide content, the plastic deformation resistance is greater.

The disadvantage of this steel is that carbide distribution is often uneven, and its strength and toughness are not strong enough. The thermoplasticity is poor, so it is not suitable to be made into large-section tools.

Due to the above-mentioned shortcomings and other reasons, W18 steel is now gradually being used less frequently in domestic settings and is rarely used abroad.

(2) Tungsten-molybdenum steel

Tungsten-molybdenum steel is made by replacing a portion of the tungsten with molybdenum.

If the molybdenum in tungsten-molybdenum steels is not more than 5%, tungsten is not less than 6%, and meets [wW + (1.4~1.5)wMo] = 12%~13%, then molybdenum can improve the strength and toughness of steel without compromising its thermal stability.

The typical steel for tungsten-molybdenum steel is W6Mo5Cr4V2 (referred to as M2).

The advantage of this steel is that it reduces the unevenness of the number and distribution of carbides.

Compared to W18 steel, M2’s flexural strength is increased by 10%-15%, and toughness is increased by more than 40%.

Moreover, large cross-section tools also have the same strength and toughness and can be manufactured in larger sizes with larger impact forces.

The thermoplasticity of tungsten-molybdenum steel is particularly good, and the grinding workability is also excellent, which makes it a general-purpose high-speed steel used in many countries.

Tungsten-molybdenum steels have slightly lower thermal stability than W18 steels. When cutting at higher speeds, their cutting performance is slightly inferior to that of W18 steel, but there is no significant difference between the two when cutting at low speeds.

The disadvantage of tungsten-molybdenum steel is the tendency of heat treatment decarburization, easier oxidation, narrow quenching temperature range, and slightly worse high-temperature cutting performance compared to W18.

Another tungsten-molybdenum series steel produced in China is W9Mo3Cr4V1 (abbreviated as W9).

Its flexural strength, impact toughness, and thermal stability are all higher than M2. Its thermoplasticity, tool durability, grinding workability, and decarburization tendency during heat treatment are also higher than M2.

2. High-performance high-speed steel

High-performance high-speed steel is a new type of steel formed by adding carbon and vanadium content and alloying with cobalt, aluminum, and other elements to ordinary high-speed steel. Types include high-carbon high-speed steel, high-vanadium high-speed steel, cobalt high-speed steel, super-hard high-speed steel, etc.

High-performance high-speed steel is also known as high thermal stability high-speed steel due to its excellent heat resistance. At a high temperature of 630-650℃, it can maintain a high hardness of 60HRC, making it suitable for processing difficult-to-machine materials such as austenitic stainless steel, high-temperature alloys, titanium alloys, and ultra-high-strength steels. Its tool durability is 1.5 to 3 times that of ordinary high-speed steel.

The disadvantage of this type of steel is that its strength and toughness are lower than those of ordinary high-speed steel, and high-vanadium high-speed steel has poor grinding workability. Different grades of this type of steel can only achieve good cutting performance when used under their prescribed cutting conditions. The characteristics of various high-performance high-speed steels limit their use only within a certain range.

Typical steel grades include high-carbon high-speed steel 9W6Mo5Cr4V2, high-vanadium high-speed steel W6Mo5Cr4V3, cobalt high-speed steel W6Mo5Cr4V2Co5, and super-hard high-speed steel W2Mo9Cr4VCo8, W6Mo5Cr4V2Al, etc.

In recent years, high-speed steel grades have rapidly developed, especially high-performance high-speed steel developed to improve cutting efficiency.

The proportion of high-performance high-speed steel used abroad has exceeded 20% to 30%.

Traditional W18Cr4V high-speed steel has been basically eliminated and replaced by cobalt-containing high-speed steel and high-vanadium steel.

The use of high-performance high-speed steel in China only accounts for 3% to 5% of the total use of high-speed steel.

(1) W2Mo9Cr4VCo8 (M42 for short)

This is one of the most widely used cobalt-containing super-hard high-speed steels with good comprehensive properties and a hardness of 67~70HRC.

The high-temperature hardness at 600℃ is 55HRC, allowing for higher cutting speeds.

This steel has certain toughness and a low vanadium content, resulting in good grinding workability.

The presence of cobalt increases the tempering hardness and thermal conductivity of the steel and reduces the coefficient of friction.

Tools made of this steel have significantly improved durability compared to those made of W18 and M2 steel when processing heat-resistant alloys and stainless steel. The greater the hardness of the processed material, the more significant the effect.

This steel is more expensive due to its higher cobalt content.

(2) W6Mo5Cr4V2Al (abbreviated as 501)

This is an aluminum-containing super-hard high-speed steel, which is a high-performance high-speed steel developed by China based on the national conditions.

Aluminum can increase the solubility of tungsten, molybdenum, and other elements in steel and can prevent grain growth.

Therefore, aluminum high-speed steel has higher high-temperature hardness, thermoplasticity, and toughness.

Aluminum can form an aluminum oxide film on the surface of the tool under the influence of cutting temperature, reducing friction and bonding with chips.

Aluminum high-speed steel has excellent cutting performance.

The heat treatment process requirements of this kind of steel are stricter.

3. Powder metallurgy high speed steel

Powder metallurgy high-speed steel is molten high-speed steel that is atomized by high-pressure argon or pure nitrogen to directly obtain fine high-speed steel powder.

The powder is then made into a dense steel billet under high temperature and high pressure, and finally the steel billet is forged and rolled into high-speed steel of steel or a tool.

Powder metallurgy high-speed steel was first successfully developed by Sweden in the 1960s, and domestic powder metallurgy high-speed steel was first tried in the 1970s.

High-speed steel manufactured by powder metallurgy has the following advantages:

There is no carbide segregation, which improves the strength, toughness and hardness of steel, and the hardness value reaches 69-70HRC.

It ensures material isotropy and reduces internal stress and deformation during heat treatment.

The grinding processability is good, and the grinding efficiency is 2-3 times higher than that of melting high-speed steel.

Good abrasion resistance, which can be increased by 20-30%.

This type of steel is suitable for manufacturing tools for cutting difficult-to-machine materials, large-size tools (such as hobs and gear shapers), precision tools, and complex tools with a large amount of grinding.

With the advancement of industrial production, high-speed steel cutting tools no longer meet the requirements for efficient machining, high-quality machining, and various difficult-to-machine materials.

Therefore, tungsten-cobalt-titanium cemented carbide was invented between the 1920s and 1930s. Its room temperature hardness is as high as 89-93 HRA, it can withstand cutting temperatures above 800-900℃, the cutting speed can reach 100m/min, and the cutting efficiency is 5-10 times that of high-speed steel. The production of cemented carbide has grown extremely fast worldwide, and it has become one of the main tool materials.

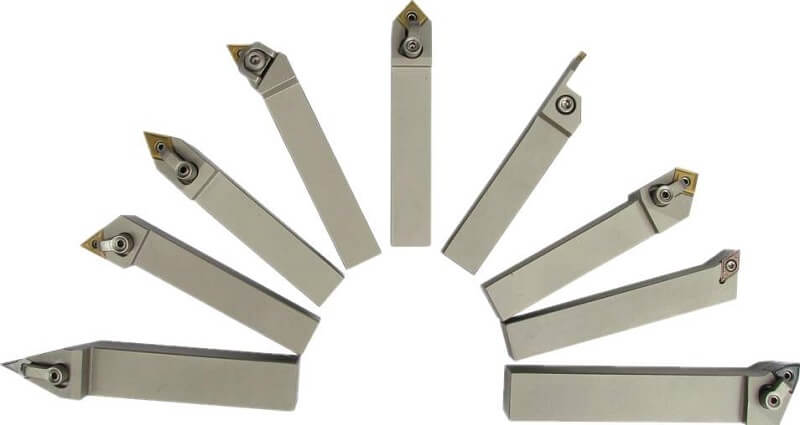

Carbide cutting tools are the main products of CNC machining tools. In some countries, more than 90% of turning tools and more than 55% of milling cutters are made of cemented carbide, and this trend is increasing.

1. Performance characteristics of cemented carbide

Cemented carbide is made of refractory metal carbides (such as TiC, WC, TaC, NbC, etc.) and metal binders (such as Co, Ni, etc.) through powder metallurgy.

The performance characteristics of cemented carbide tools are as follows:

(1) High Hardness

Cemented carbide has a high carbide content, high melting point, and, therefore, high hardness at room temperature.

The commonly used cemented carbide has a hardness of 89-93 HRA, which is much higher than that of high-speed steel. At 540℃, the hardness can still reach 82-87 HRA, equivalent to the hardness of high-speed steel at room temperature (83-86 HRA).

The hardness of cemented carbide depends on the type and quantity of carbide, the thickness of powder particles, and the content of the binder. The higher the carbide’s hardness and melting point, the better the thermal hardness of the cemented carbide.

When the binder content is higher, the hardness is lower. The finer the carbide powder, and the binder content is constant, the hardness is higher.

(2) Flexural Strength and Toughness

The commonly used cemented carbide has a bending strength of 0.9-1.5 GPa, which is much lower than the strength of high-speed steel. Its bending strength is only 1/3-1/2 of high-speed steel, and its impact toughness is also poor, only 1/30-1/8 of high-speed steel.

As a result, cemented carbide tools are not as capable of withstanding large cutting vibrations and shock loads as high-speed steel. When the binder content is higher, the bending strength is higher, but the hardness is lower.

(3) Thermal Conductivity

The thermal conductivity of TiC is lower than that of WC. Therefore, the thermal conductivity of WC-TiC-Co alloy is lower than that of WC-Co alloy, and it decreases with the increase of TiC content.

(4) Thermal Expansion Coefficient

The thermal expansion coefficient of cemented carbide is much smaller than that of high-speed steel. The coefficient of linear expansion of WC-TiC-Co alloy is greater than that of WC-Co alloy, and it increases with the increase of TiC content.

(5) Cold Welding Resistance

The cold welding temperature of cemented carbide and steel is higher than that of high-speed steel. Additionally, the cold welding temperature of WC-TiC-Co alloy and steel is higher than that of WC-Co alloy.

2. Classification and designation rules of cemented carbide for cutting tools

Cemented carbide grades for cutting tools are divided into six categories: P, M, K, N, S, and H, according to different fields of use, as listed in Table 3.

Each category is further divided into several groups to meet different usage requirements and based on the different wear resistance and toughness of the cemented carbide materials for cutting tools. These groups are represented by double-digit numbers such as 01, 10, and 20.

When necessary, a supplementary group number can be inserted between the two group numbers, represented by 05, 15, and 25, etc.

Table 3 Cemented carbide types for cutting tools

| Types | Field of use |

| P | Processing of long-cut materials such as steel, cast steel, long-cut malleable cast iron, etc. |

| M | General alloy for processing stainless steel, cast steel, manganese steel, malleable cast iron, alloy steel, alloy cast iron, etc. |

| K | Machining of short-cut materials such as cast iron, chilled cast iron, short-cut malleable iron, grey cast iron, etc. |

| N | Processing of non-ferrous metals and non-metallic materials, such as aluminum, magnesium, plastics, wood, etc. |

| S | Processing of heat resistant and high quality alloys such as heat resistant steel, alloys containing nickel, cobalt, titanium, etc. |

| H | Machining of hard cutting materials, such as hardened steel, chilled cast iron, etc. |

3. The basic composition and mechanical performance requirements of each grade of cemented carbide

Table 4 lists the basic composition and mechanical performance requirements of each group of cemented carbide for cutting tools (extracted from GB/T 18376.1-2008).

Table 4 Basic mechanical performance requirements of cemented carbide

| Groups | Main components | Mechanical properties | |||

|---|---|---|---|---|---|

| Types | Group number | Rockwell hardness HRA, ≥ | Vickers Hardness HV, ≥ | Flexural strength /MPa Ru, ≥ | |

| P | 01 | Alloys/coating alloys based on TNC and WC with Co (N+Mo, Ni+Co) as binder | 92.3 | 1750 | 700 |

| 10 | 91.7 | 1680 | 1200 | ||

| 20 | 91 | 1600 | 1400 | ||

| 30 | 90.2 | 1500 | 1550 | ||

| 40 | 89.5 | 1400 | 1750 | ||

| M | 01 | Take WC as the base, Co as the binder, and add a small amount of TiC (TaC, NbC) alloy/coating alloy. | 92.3 | 1730 | 1200 |

| 10 | 91 | 1600 | 1350 | ||

| 20 | 90.2 | 1500 | 1500 | ||

| 30 | 89.9 | 1450 | 1650 | ||

| 40 | 88.9 | 1300 | 1800 | ||

| K | 01 | Take WC as the base, Co as the binder, or add a small amount of TaC, NbC alloy/coating alloy. | 92.3 | 1750 | 1350 |

| 10 | 91.7 | 1680 | 1460 | ||

| 20 | 91 | 1600 | 1550 | ||

| 30 | 89.5 | 1400 | 1650 | ||

| 40 | 88.5 | 1250 | 1800 | ||

| N | 01 | Take WC as the base, Co as the bonding agent, or add a small amount of TaC, NbC or CrC alloy/coating alloy. | 92.3 | 1750 | 1450 |

| 10 | 91.7 | 1680 | 1580 | ||

| 20 | 91 | 1600 | 1650 | ||

| 30 | 90 | 1450 | 1700 | ||

| S | 01 | Take WC as the base, Co as the binder, or add a small amount of TaC, NbC or TiC alloy/coating alloy. | 92.3 | 1730 | 1500 |

| 10 | 91.5 | 1650 | 1580 | ||

| 20 | 91 | 1600 | 1650 | ||

| 30 | 90.5 | 1550 | 1750 | ||

| H | 01 | Take WC as the base, Co as the binder, or add a small amount of TaC, NbC or TiC alloy/coating alloy. | 92.3 | 1730 | 1000 |

| 10 | 91.7 | 1680 | 1300 | ||

| 20 | 91 | 1600 | 1650 | ||

| 30 | 90.5 | 1520 | 1500 | ||

| Note: 1. Choose one of Rockwell hardness and Vickers hardness; 2. The above data are requirements for non-coated cemented carbide, and the coated products can be reduced by 30-50 according to the corresponding Vickers hardness. | |||||

4. Commonly used cemented carbide and its properties

ISO classifies carbides for cutting into three categories:

Related reading: Ferrous vs Non-ferrous Metals

(1) Tungsten and cobalt (WC+Co)

The alloy code is YG, which corresponds to the national standard K category. This type of alloy is composed of WC and Co.

The commonly used brands produced in China are YG3X, YG6X, YG6, YG8, etc. The number indicates the percentage of Co, and X indicates fine grains.

YG cemented carbide has coarse grains, medium grains, and fine grains. Generally, cemented carbides (such as YG6, YG8) are medium-grained.

Fine-grained cemented carbide (such as YG3X, YG6X) has higher hardness and wear resistance than medium-grain when the cobalt content is the same, but the bending strength and toughness are lower.

Fine-grained cemented carbide is suitable for processing some special hard cast irons, austenitic stainless steels, heat-resistant alloys, titanium alloys, hard bronzes, hard wear-resistant insulating materials, etc.

The WC grains of ultra-fine grained cemented carbide are 0.2-1 μm, most of which are below 0.5 μm. Since the hard phase and the bonding phase are highly dispersed, the bonding area is increased. When the cobalt content is appropriately increased, high flexural strength can be obtained at higher hardness.

The higher the cobalt content of this alloy, the better the toughness, suitable for rough machining. Low cobalt content is suitable for finish machining. This type of alloy has good toughness, grinding properties, and thermal conductivity, and is more suitable for processing brittle materials that produce chipping chips and have impact cutting forces acting near the cutting edge.

It is mainly used for processing brittle materials such as cast iron and bronze but is not suitable for processing steel materials. Severe adhesion occurs at 640℃, which causes the tool to wear out and the durability to decrease.

(2) Tungsten Titanium Cobalt (WC+TiC+Co)

The alloy code is YT, which corresponds to the national standard P category. In addition to WC, the hard phase in this type of alloy also contains 5%-30% TiC.

The commonly used grades are YT5, YT14, YT15, and YT30, with a TiC content of 5%, 14%, 15%, and 30%, and the corresponding cobalt content is 10%, 8%, 6%, and 4%.

This type of alloy has higher hardness and heat resistance. Its hardness is 89.5-92.5 HRA, and its bending strength is 0.9-1.4 GPa.

It is mainly used to process plastic materials such as steel parts with strip-shaped chips. If the TiC content in the alloy is high, the wear resistance and heat resistance are improved, but the strength is reduced. Therefore, rough processing generally chooses grades with less TiC content, and finish processing chooses grades with more TiC content.

It is mainly used for processing steel and non-ferrous metals. It is generally not used for processing Ti-containing materials because the affinity between the titanium component in the alloy and the titanium element in the processing material will cause a serious sticking phenomenon and make the tool wear faster.

(3) Tungsten, titanium, tantalum (niobium) and cobalt [WC+TiC+TaC(Nb)+Co]

The alloy code is YW, which corresponds to the national standard M class. This is achieved by adding a certain amount of TaC(Nb) to the above cemented carbide composition.

The commonly used grades are YW1 and YW2. Adding a certain amount of TaC(Nb) to the components of YT cemented carbide can improve its bending strength, fatigue strength, and impact toughness, increase the high-temperature hardness and strength of the alloy, and improve the oxidation and wear resistance.

This type of cemented carbide is not only suitable for semi-finishing machining of chilled cast iron, non-ferrous metals, and alloys but also for semi-finishing and finishing of high manganese steel, hardened steel, alloy steel, and heat-resistant alloy steel. It is known as general cemented carbide.

If the cobalt content of this alloy is appropriately increased, the strength can be very high. It can withstand mechanical vibration and thermal shock caused by periodic temperature changes and can be used for intermittent cutting.

The main components of the above three types of cemented carbide are WC, so they can be collectively referred to as WC-based cemented carbide.

(4) TiC (N) base (WC+TiC+Ni+Mo)

The alloy code is YN, which is a TiC-Ni-Mo alloy with TiC as the main component (some of which are added with other carbides and nitrides). The hardness of this type of alloy is very high, 90-94 HRA, reaching the level of ceramics.

It has high abrasion resistance and crater wear resistance, high heat resistance and oxidation resistance, good chemical stability, low affinity with working materials, low friction coefficient, and strong anti-adhesive ability.

Therefore, the tool durability can be improved several times more than WC-based cemented carbide. TiC(N)-based cemented carbides are generally used for finishing and semi-finishing.

It is especially suitable for large and long parts or parts with high machining accuracy but is not suitable for rough machining and low-speed cutting with impact load.

5. New cemented carbide

(1) Fine-grained and ultra-fine-grained cemented carbide

The grain size of WC in ordinary cemented carbide is several microns, and the average grain size of fine-grained alloy is about 1.5 μm.

The grain size of ultra-fine grain alloys is 0.2-1 μm, most of which are below 0.5 μm.

In the fine-grained alloy, the hard phase and the bonding phase are highly dispersed, which increases the bonding area and improves the bonding strength. Therefore, its hardness and strength are higher than alloys of the same composition.

Hardness increases by 1.5-2 HRA, bending strength increases by 0.6-0.8 GPa. Moreover, the high-temperature hardness can also be improved, which can reduce the edge chipping phenomenon generated during low and medium speed cutting.

In the production process of ultra-fine grain alloys, in addition to the use of fine WC powder, trace inhibitors should also be added to control grain growth. The cost of the advanced sintering process is higher.

Ultra-fine grain cemented carbide is mostly used in YG alloys. Its hardness and wear resistance have been greatly improved, and its bending strength and impact toughness have also been improved, which is close to high-speed steel.

It is suitable for small size milling cutters, drills, etc., and can be used to process high-hardness and difficult-to-process materials.

(2) Coated cemented carbide

Coated cemented carbide tools are another major development in the application of cemented carbide tool materials. It organically combines tough materials and wear-resistant materials through coatings, thereby changing the comprehensive mechanical properties of cemented carbide blades and increasing their service life by 2 to 5 times.

Its development is quite rapid. In some developed countries, its use has accounted for more than half of the total use of cemented carbide tool materials.

China is currently actively developing this type of cutting tool, and CN15, 1N25, CN35, CN16, CN26, and other coated carbide blades have been used in production.

(3) High-speed steel-based cemented carbide

It uses TiC or WC as the hard phase (30% to 40%) and high-speed steel as the bonding phase (70% to 60%), which is made by powder metallurgy. Its performance is between high-speed steel and cemented carbide. It can be forged, cut, heat treated, and welded. The hardness at room temperature is 70-75 HRC, and the wear resistance is 6-7 times higher than that of high-speed steel. It can be used to manufacture complex tools such as drills, milling cutters, broaches, hobs, and to process stainless steel, heat-resistant steel, and non-ferrous metals.

High-speed steel-based cemented carbide has poor thermal conductivity, is easy to overheat, and has worse high-temperature performance than cemented carbide. It requires sufficient cooling during cutting and is not suitable for high-speed cutting.

(1) When processing ordinary material workpieces, ordinary high-speed steel and cemented carbide are generally used. High-performance and new tool material grades can be selected when processing difficult-to-machine materials. CBN and PCD inserts should only be considered when processing high-hard materials or when conventional tool materials in precision processing cannot meet the processing accuracy requirements.

(2) It is difficult to fully consider the strength, composition, hardness, and wear resistance of any cutting tool material. When selecting the tool material grade, the machinability and processing conditions of the workpiece material should be considered. Wear resistance is usually considered at first, and the problem of chipping should be solved with reasonable geometric parameters of the tool as much as possible. Only when the tool material is too brittle and causes chipping, reducing the wear resistance requirements, and choosing a grade with better strength and toughness is necessary.

Under normal circumstances, when cutting at low speeds, the cutting process is not stable and chipping is easy to occur. It is advisable to choose a tool material grade with good strength and toughness. In high-speed cutting, the cutting temperature has the greatest impact on the wear of tool materials. It is recommended to select tool material grades of durable consumer goods with good grinding properties.