Ever wondered why washers are indispensable in mechanical assemblies? This article explores the various types, specifications, and weight charts of washers, explaining their crucial roles in distributing loads and preventing damage to surfaces. By the end, you’ll understand how to select the right washer for your project, ensuring durability and efficiency. Dive in to learn about the unsung heroes of fasteners!

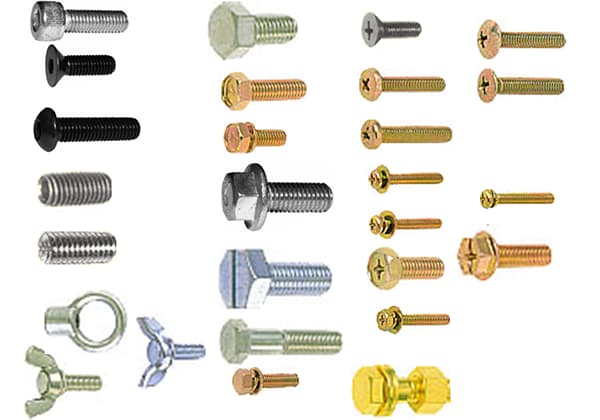

A washer is a component that sits between the connected part and the nut.

Typically, it is a flat metal ring used to protect the surface of the connected part from being scratched by the nut and to distribute the pressure exerted by the nut on the connected part.

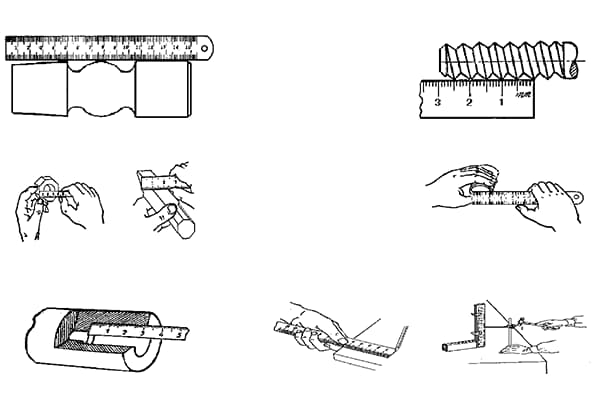

Washers are classified into:

| Nominal Diameter (Thread Diameter) | d | B | H | GB852-66 I-beam square sloped washer | GB853-66 Channel square sloped washer | ||

| H1 | Weight per thousand (Kg) | H1 | Weight per thousand (Kg) | ||||

| 6 | 7 | 16 | 2 | 4.7 | 5 | 3.6 | 4 |

| 8 | 9 | 18 | 2 | 5 | 6 | 3.8 | 5 |

| 10 | 11 | 22 | 2 | 5.7 | 10 | 4.2 | 6 |

| 12 | 13 | 28 | 2 | 6.7 | 15 | 4.8 | 14 |

| 16 | 17 | 35 | 2 | 7.7 | 25 | 5.4 | 19 |

| -18 | 20 | 40 | 2 | 9.7 | 66 | 7 | 48 |

| 20 | 22 | 40 | 3 | 9.7 | 60 | 7 | 32 |

| -22 | 24 | 40 | 3 | 9.7 | 65 | 7 | 37 |

| 24 | 26 | 50 | 3 | 11.3 | 100 | 8 | 62 |

| -27 | 29 | 50 | 3 | 11.3 | 104 | 8 | 90 |

| 30 | 32 | 60 | 3 | 13 | 180 | 9 | 130 |

| 36 | 38 | 70 | 3 | 14.7 | 250 | 10 | 200 |

| Nominal Diameter (Thread Diameter) | d | GB859-66 Light-duty | GB93-66 | |||

| S | b | Weight per thousand (Kg) | S(b) | Weight per thousand (Kg) | ||

| 4 | 4.1 | 0.8 | 1.2 | 0.13 | 1.2 | 0.18 |

| 5 | 5.1 | 1 | 1.2 | 0.19 | 1.6 | 0.41 |

| 6 | 6.2 | 1.2 | 1.6 | 0.36 | 2 | 0.75 |

| 8 | 8.2 | 1.6 | 2 | 0.8 | 2.5 | 1.53 |

| 10 | 10.2 | 2 | 2.5 | 1.56 | 3 | 2.82 |

| 12 | 12.3 | 2.5 | 3.5 | 3.41 | 3.5 | 4.63 |

| -14 | 14.3 | 3 | 4 | 5.39 | 4 | 6.85 |

| 16 | 16.3 | 3.2 | 4.5 | 7.36 | 4 | 7.75 |

| -18 | 18.3 | 3.5 | 5 | 10 | 4.5 | 11 |

| 20 | 20.5 | 4 | 5.5 | 14.1 | 5 | 15.2 |

| -22 | 22.5 | 4.5 | 6 | 18.9 | 5 | 16.5 |

| 24 | 24.5 | 4.8 | 6.5 | 23.7 | 6 | 26.2 |

| -27 | 27.5 | 5.5 | 7 | 32.3 | 6 | 28.2 |

| 30 | 30.5 | 6 | 8 | 45.4 | 6.5 | 37.6 |

| 36 | 36.6 | – | – | – | 7 | 51.8 |

| 42 | 42.6 | – | – | – | 8 | 78.7 |

| 48 | 49 | – | – | – | 9 | 114 |

| Nominal Diameter (Thread Diameter) | d | D | S | Weight per thousand (Kg) | ||||||

| Small washers | Washers | Large circle washers | Small washers | Washers | Large circle washers | Small washers | Washers | Large circle washers | ||

| 4 | 4.2 | 8 | 10 | 12 | 0.5 | 1 | 1.2 | 0.14 | 0.51 | 0.89 |

| 5 | 5.5 | 10 | 12 | 14 | 0.8 | 1.5 | 1.5 | 0.35 | 1.05 | 1.46 |

| 6 | 6.5 | 12 | 14 | 18 | 0.8 | 1.5 | 1.5 | 0.5 | 1.42 | 2.51 |

| 8 | 8.5 | 16 | 18 | 22 | 1 | 1.5 | 2 | 1.12 | 2.33 | 4.9 |

| 10 | 10.5 | 18 | 22 | 28 | 1 | 2 | 3 | 1.32 | 3.98 | 12.1 |

| 12 | 12.5 | 22 | 25 | 35 | 1.5 | 2 | 3 | 3.25 | 5.76 | 18.7 |

| -14 | 14.5 | 25 | 28 | 38 | 1.5 | 3 | 4 | 3.84 | 10.61 | 29.8 |

| 16 | 16.5 | 28 | 32 | 45 | 2 | 3 | 4 | 6.31 | 13.9 | 42.3 |

| -18 | 19.5 | 30 | 35 | 50 | 2 | 3 | 4 | 6.44 | 15.9 | 51.7 |

| 20 | 21 | 35 | 38 | 55 | 2.5 | 4 | 5 | 11.99 | 24.71 | 79.2 |

| -22 | 23 | 38 | 42 | 60 | 2.5 | 4 | 5 | 14 | 30.44 | 94.4 |

| 24 | 25 | 40 | 45 | 65 | 2.5 | 4 | 6 | 15 | 34.51 | 131 |

| -27 | 28 | – | 50 | 70 | – | 5 | 6 | – | 52.87 | 150 |

| 30 | 31 | – | 55 | 80 | – | 5 | 6 | – | 63.59 | 198 |

| 36 | 38 | – | 76 | – | – | 6 | – | – | 117.6 | – |

| 42 | 44 | – | 80 | – | – | 6 | – | – | 165.1 | – |

| 48 | 50 | – | 90 | – | – | 8 | – | – | 276.1 | – |