Why is welding high carbon steel such a challenge? This article delves into the unique difficulties associated with this material, such as its tendency to form brittle martensite, leading to potential cracks. You’ll learn about the specialized welding techniques required and the preventative measures necessary to ensure structural integrity. Discover how to manage weldability issues and what precautions can be taken to achieve successful welds with high carbon steel. Read on to gain a deeper understanding of these critical welding considerations.

High carbon steel refers to a type of carbon steel with a carbon (c) content higher than 0.6%.

It is more prone to hardening compared to medium carbon steel and forms high-carbon martensite, which is prone to the formation of cold cracks.

The martensite structure formed in the welding heat-affected zone has hard and brittle properties, leading to a significant decrease in the plasticity and toughness of the joint. As a result, the weldability of high carbon steel is poor, and a specialized welding process must be used to maintain the performance of the joint.

Due to its poor weldability, high carbon steel is not commonly used in welding structures.

High carbon steel is primarily used in machine parts that require high hardness and wear resistance, such as rotating shafts, large gears, and couplings.

To conserve steel and simplify processing technology, these machine parts are often joined using welding.

The manufacture of heavy machinery may also involve welding high carbon steel parts.

When developing the welding process for high carbon steel components, it is important to thoroughly analyze possible welding defects and implement appropriate welding process measures.

High carbon steel is primarily utilized in structures requiring high hardness and wear resistance, and is typically welded using electrode arc welding, brazing, or submerged arc welding.

Welding high carbon steel does not necessarily require the joint and base metal to have equal strength.

For electrode arc welding, low hydrogen electrodes with strong desulfurization capabilities, low diffusible hydrogen content in the deposited metal, and good toughness are typically used.

If the strength of the weld metal and base metal is required, a low hydrogen electrode of the appropriate grade should be selected.

However, if the strength of the weld metal and base metal is not required, a low hydrogen electrode with a strength level lower than the base metal should be selected.

It is important to avoid selecting an electrode with a strength level higher than the base metal.

If preheating of the base metal is not possible during welding, an austenitic stainless steel electrode can be used to prevent cold cracks in the heat-affected zone, resulting in an austenitic structure with good plasticity and crack resistance.

To limit the carbon content in the weld metal, the fusion ratio should be reduced. As a result, U-shaped or V-shaped grooves are commonly used during welding. It is important to clean any oil stains and rust within 20mm on both sides of the groove.

When welding with structural steel electrodes, preheating is necessary and must be performed before welding. The preheating temperature should be controlled within the range of 250°C to 350°C.

In multi-layer and multi-pass welding, the first pass is typically performed using a small diameter electrode and low current.

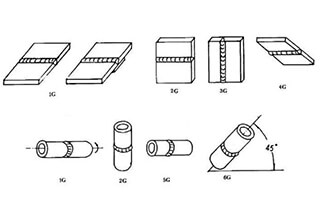

The workpiece is usually positioned in semi-vertical welding, or the welding rod is used to swing laterally, allowing the entire heat-affected zone of the base metal to be heated quickly, thereby achieving the effects of preheating and heat preservation.

Immediately after welding, the workpiece should be placed in a heating furnace and subjected to thermal insulation at 650°C for stress relief annealing.

High carbon steel has a strong tendency to harden, making it susceptible to both hot cracks and cold cracks during welding.

(1) Control of Weld Chemical Composition

It is important to strictly control the content of sulfur and phosphorus, and to increase the manganese content appropriately to improve the weld structure and reduce segregation.

(2) Control of Weld Section Shape

The aspect ratio should be slightly larger to avoid segregation at the center of the weld.

(3) Weldments with High Rigidity

For weldments with high rigidity, appropriate welding parameters, sequence, and direction should be selected.

(4) Preheating and Slow Cooling Measures

If necessary, preheating and slow cooling measures should be implemented to prevent hot cracks.

(5) Increase in Electrode or Flux Alkalinity

Increasing the alkalinity of the electrode or flux can reduce impurities in the weld and enhance segregation.

(1) Preheating and Slow Cooling

Preheating before welding and slow cooling after welding can reduce the hardness and brittleness of the heat-affected zone and accelerate the diffusion of hydrogen in the weld.

(2) Selection of Appropriate Welding Measures

(3) Adoption of Proper Assembly and Welding Sequence

To reduce restraint stress in the welded joints and improve the stress state of the weldments, a proper assembly and welding sequence should be employed.

(4) Appropriate Selection of Welding Materials

The welding rod and flux should be dried and used immediately before welding.

(5) Removal of Contaminants

Prior to welding, water, rust, and other contaminants on the base metal surface surrounding the groove should be thoroughly removed to reduce the diffusible hydrogen content in the weld.

(6) Dehydrogenation Treatment

Immediate dehydrogenation treatment should be performed prior to welding to ensure that hydrogen is fully removed from the welded joint.

(7) Stress Relief Annealing

Immediately after welding, a stress relief annealing treatment should be performed to promote the diffusion of hydrogen in the weld.