What makes 321 stainless steel stand out in demanding environments? This article delves into the unique composition and properties of 321 stainless steel, highlighting its superior resistance to intergranular corrosion and high temperatures. You’ll discover how the addition of titanium enhances its performance, making it ideal for use in high-stress, high-temperature applications like aerospace and chemical processing. Learn about its specific mechanical and physical properties, and explore the diverse applications where 321 stainless steel excels.

321 stainless steel is a Ni-Cr-Ti austenitic stainless steel used in the manufacture of acid-resistant containers and wear-resistant equipment linings and pipelines.

321 stainless steel is created by adding a titanium element to the base composition of 304 stainless steel. Its performance is highly similar to that of 304 stainless steel.

The addition of titanium results in exceptional resistance to acid and alkali corrosion. Even a small amount of titanium (around 1%) added to stainless steel can significantly enhance its rust resistance.

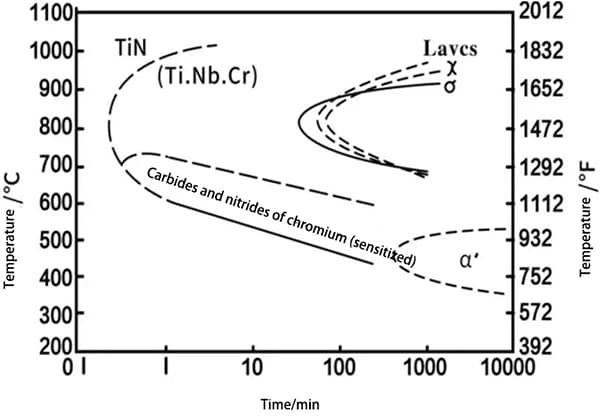

Austenitic stainless steel is prone to sensitization when exposed to temperatures between 450 ℃ and 850 ℃.

During sensitization, carbides, mainly chromium carbide (C23C6), precipitate along grain and twin boundaries, which results in damage to the neighboring alloy elements. This leads to intergranular corrosion in specific corrosive environments.

321 stainless steel is capable of withstanding the formation of chromium carbide between 426 ℃ and 815 ℃ due to the addition of titanium as a stabilizing element. As a result, it exhibits better resistance to intergranular corrosion, high temperature performance, and higher resistance to creep and stress fractures than 304 and 304L.

Furthermore, 321 also has excellent low-temperature toughness, formability, and welding properties. It does not require annealing after welding.

The characteristic of 321 stainless steel is the presence of Ti as a stabilizing element.

However, it is also a heat-resistant steel variety with a much better high-temperature aspect compared to 316L.

In different concentrations and temperatures of organic and inorganic acids, especially in oxidizing media, 321 stainless steel exhibits excellent wear and corrosion resistance. It’s used in the manufacture of wear-resistant acid containers, linings, and pipelines.

321 stainless steel is a Ni-Cr-Ti type of austenitic stainless steel. Its performance is very similar to 304, but the addition of the metal titanium gives it better intergranular corrosion resistance and high-temperature strength. The addition of titanium effectively controls the formation of chromium carbide.

321 stainless steel has excellent high-temperature stress rupture and high-temperature creep resistance. Its stress mechanical properties are superior to 304 stainless steel.

| Standard | GB/T20878 | ASTM A276 | JIS G4303 | DIN EN10088-3 |

| Grade | 06Cr18Ni11Ti(0Cr18Ni10Ti) | S32100321 | SUS 321 | X6CrNiTi18-101.4541 |

| C | ≤0.08 | ≤0.08 | ≤0.08 | 0.08 |

| Si | 1.00 | 1.00 | ≤1.00 | 1.00 |

| Mn | ≤2.00 | ≤2.00 | 2.00 | ≤2.00 |

| P | 0.045 | 0.045 | 0.045 | 0.045 |

| S | ≤0.030 | ≤0.030 | ≤0.030 | 0.030 |

| Ni | 9.00~12.00 | 9.00~12.00 | 9.00~13.00 | 9.00~12.00 |

| Cr | 17.0~19.0 | 17.0~19.0 | 17.0~19.0 | 17.0~19.0 |

| Ti | 5C~0.70 | 5(C+N)~0.70 | >5×C% | 5×C~0.70 |

| Density (g/cm3) 20 ℃ | 8.03 | |

| Melting point (℃) | 1398~1427 | |

| Specific heat capacity [kJ/(kgK)] 0~100 ℃ | 0.50 | |

| Thermal conductivity [W/(m-K)] | 100℃ | 16.3 |

| 500℃ | 22.2 | |

| Linear expansion coefficient (10-6/K) | 0~100℃ | 16.6 |

| 0~500℃ | 18.6 | |

| Resistivity (Ωmm2/m) 20 ℃ | 0.72 | |

| Longitudinal elastic modulus (kN/mm2) 20 ℃ | 193 | |

| Magnetic | Slightly magnetic after cold deformation | |

Mechanical Properties

The addition of titanium to 321 stainless steel enhances its suitability for high-temperature applications, making it a better choice than 304 stainless steel, which can experience sensitization reactions, and 304L stainless steel, which may not have sufficient high-temperature strength.

Common uses for 321 stainless steel plate and tube products include thermal expansion joints, corrugated pipes, components for aircraft exhaust systems, casings for heating elements, furnace body components, and heat exchangers.

Besides, it can be used in areas where high anti-grain boundary corrosion resistance is required, such as in the chemical, coal, and petroleum industries, for outdoor machinery exposed to the elements, heat-resistant building materials, and parts that are difficult to heat-treat, such as:

Dimensions and permissible deviations of 321 stainless steel.

| Deviation Grade | Allowable Deviation of Standardized Outer Diameter |

| D1 | ±1.5%, with a minimum of ±0.75 mm. |

| D2 | ±1.0%, with a minimum of ±0.5 mm. |

| D3 | ±0.75%, with a minimum of ±0.30 mm. |

| D4 | ±0.50%, with a minimum of ±0.10 mm. |

The weight formula for stainless steel pipes: [(Outer Diameter – Wall Thickness) * Wall Thickness] * 0.02491 = kg/m (weight per meter).

Heat Treatment Specifications:

1) Solution heat treatment at 920-1150℃ with rapid cooling;

2) Stabilization treatment can be performed upon request at a heat treatment temperature of 850-930℃, but it must be specified in the contract.

3) The solution temperature should not exceed 1066℃. If it does, a stabilization treatment must be performed to prevent chromium precipitation.

Microstructure:

Characterized by an austenitic structure.

Delivery Condition: The product is generally delivered in a heat-treated condition. The type of heat treatment is specified in the contract. If not specified, the product is delivered in an untreated condition.

Both 304 and 321 belong to the 300 series of stainless steel and show little difference in corrosion resistance.

However, under heat resistant conditions of 500-600 degrees Celsius, 321 stainless steel is mostly used. A type of heat-resistant steel called 321H, with a slightly higher carbon content than 321, akin to China’s 1Cr18Ni9Ti, has been specially developed overseas.

A moderate amount of Ti is added to stainless steel to enhance its intergranular corrosion resistance.

This was due to the inability to reduce the carbon content in steel at the beginning of stainless steel production due to low smelting technology, so the method of adding other elements was used.

With technological advancement, low carbon and ultra-low carbon stainless steel varieties can now be produced, hence the widespread use of 304 material.

At this point, the heat resistance characteristics of 321, 321H, or 1Cr18Ni9Ti become apparent.

304 is 0Cr18Ni9Ti, and 321 is 304 with added Ti to improve intergranular corrosion tendencies.

The Ti in 321 stainless steel acts as a stabilizing element, but it is also a heat-strength steel type, much better at high temperatures than 316L.

321 stainless steel has excellent wear resistance in different concentrations and temperatures of organic acids, especially in oxidizing media, and is used to manufacture wear-resistant acid containers and wear-resistant equipment linings, and transport pipes.

321 stainless steel is a Ni-Cr-Mo austenitic stainless steel, its performance is very similar to 304, but the addition of titanium metal gives it better intergranular corrosion resistance and high-temperature strength.

The addition of titanium metal effectively controls the formation of chromium carbide.

321 stainless steel exhibits superior high-temperature stress rupture and high-temperature creep resistance mechanical properties than 304 stainless steel.

The main components of both 304 stainless steel and 304L stainless steel contain 18% chromium (Cr) and 8% nickel (Ni); their main difference is that 304L stainless steel is low carbon 304 steel, under normal conditions, the corrosion resistance of 304L stainless steel is similar to that of 304 stainless steel, but after welding or stress relief, 304L stainless steel has excellent intergranular corrosion resistance.

In terms of price, 304L stainless steel is higher than 304 stainless steel. 304L stainless steel is low carbon stainless steel, mainly suitable for welding processes. During welding, using 304L stainless steel can effectively reduce welding corrosion.

According to hardness standards, 304 stainless steel is superior to 304L stainless steel because the carbon content directly affects the hardness of stainless steel. There is also the 304H stainless steel series, where H signifies high carbon content.

304L is a variant of 304 stainless steel with a lower carbon content, used for welding occasions.

The lower carbon content reduces the carbides precipitated in the heat-affected zone near the weld to a minimum, and the precipitation of carbides may cause intergranular corrosion (weld decay) of stainless steel in certain environments.

Stainless Steel 304 vs 321

304 and 321 are both austenitic stainless steels, and their appearance and physical properties are very similar. The only slight difference lies in their chemical composition:

Firstly, 321 stainless steel requires trace amounts of titanium (Ti) element (according to ASTM A182-2008 standard its Ti content should be no less than 5 times the carbon (C) content, but not more than 0.7%. Note, both 304 and 321 have a carbon (C) content of 0.08%), while 304 does not contain titanium (Ti).

Secondly, the requirements for nickel (Ni) content are slightly different, with 304 between 8% and 11%, and 321 between 9% and 12%.

Thirdly, the requirements for chromium (Cr) content are slightly different, with 304 between 18-20%, and 321 between 17-19%.