Have you ever wondered how the strength of stainless steel is measured so precisely? This article explores the fascinating world of stainless steel hardness testing. You’ll learn about the different methods used, including Brinell, Rockwell, and Vickers tests, and discover why hardness testing is becoming the go-to method over traditional tensile testing. Get ready to uncover the secrets behind the durability of stainless steel!

(National Standard, United States, Japan)

Stainless steel products can be classified by delivery shape into stainless steel plates, strips, pipes, rods, wires, and so forth.

If classified according to metallographic structure, they can be divided into the following five types: austenitic stainless steel, ferritic stainless steel, austenitic-ferritic stainless steel, martensitic stainless steel, and precipitation-hardened stainless steel.

Various stainless steel materials are supplied in different heat treatment states such as annealing, tempering, solution treatment, quenching, or tempering.

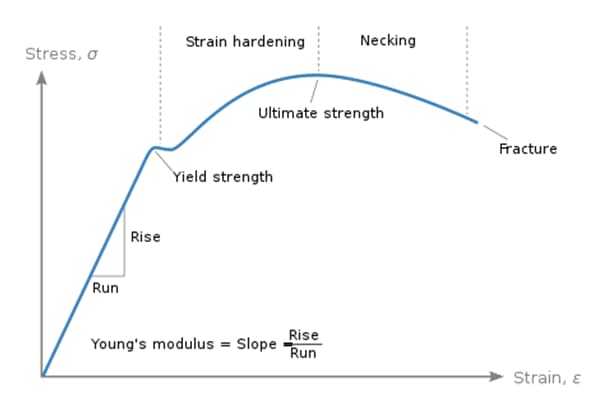

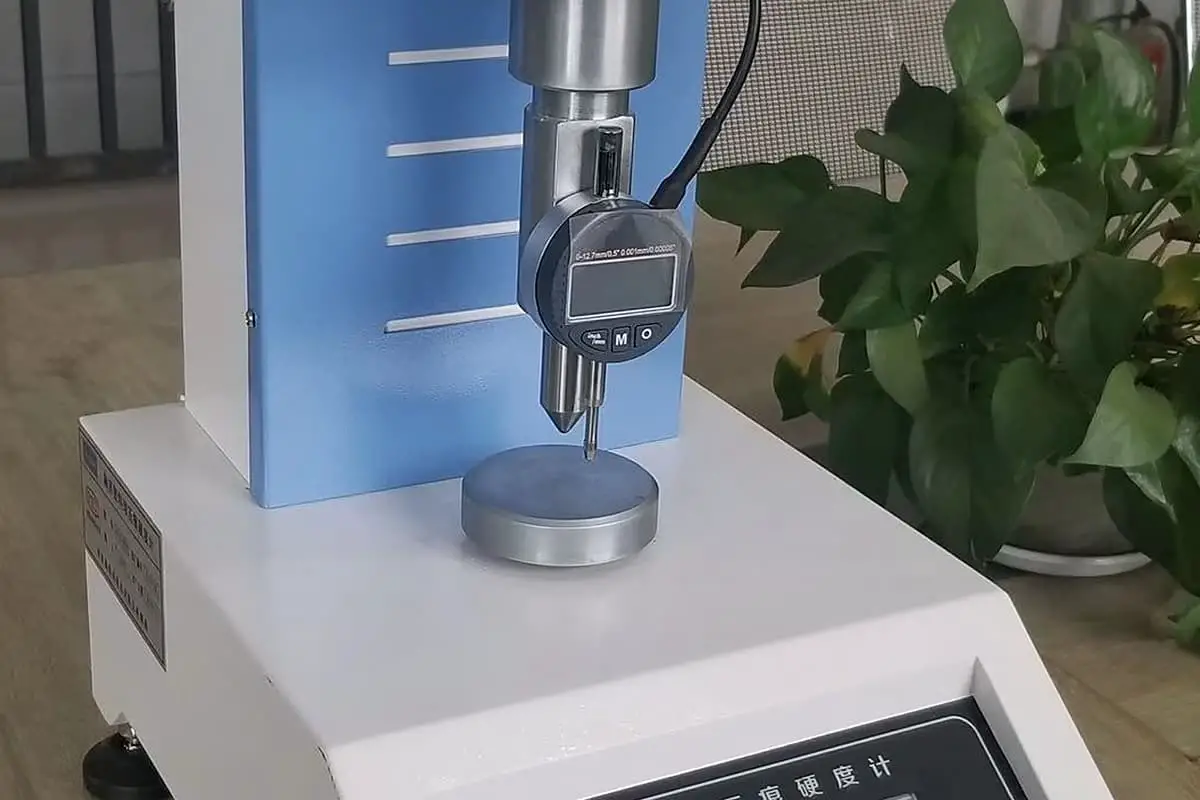

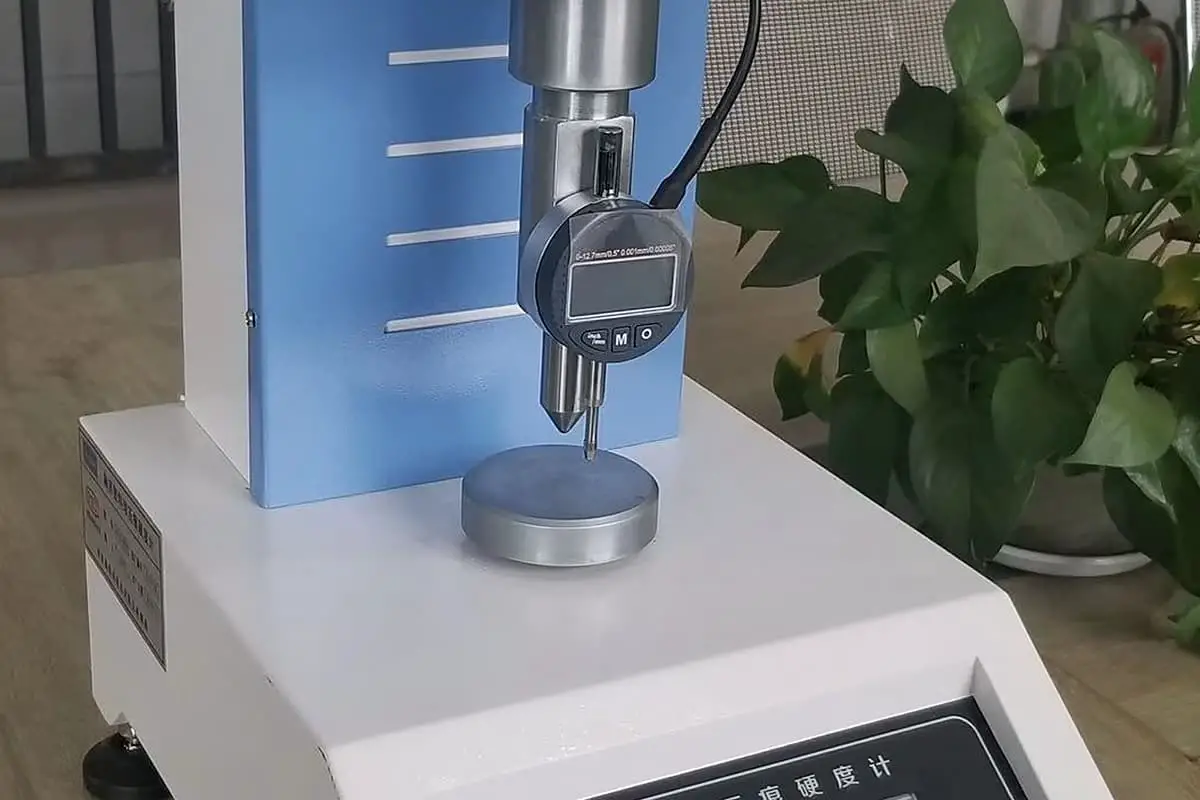

Hardness testing involves slowly pressing a hard indenter into the surface of a sample under specified conditions and then measuring the depth or size of the indentation to determine the hardness of the material.

It is the simplest, quickest, and most easily implemented method in material mechanical property testing.

Hardness testing is non-destructive, and there is an approximate conversion relationship between hardness values and tensile strength values.

Due to the inconvenience of tensile testing and the ease of converting hardness to strength, people are increasingly testing material hardness and less frequently testing its strength.

Especially with the continuous progress and innovation in hardness testing technology, some materials that could not be directly tested for hardness in the past, such as stainless steel pipes, stainless steel wire, extremely thin stainless steel plates, and stainless steel strips, can now be directly tested for hardness.

Therefore, there is a trend for hardness testing to gradually replace tensile testing.

In stainless steel standards, three hardness testing methods, Brinell, Rockwell, and Vickers, are typically stipulated, measuring HB, HRB (or HRC), and HV hardness values respectively.

It is specified that just one of the three hardness values needs to be measured for stainless steel hardness testing.

In the American metal material standards, a prominent feature regarding hardness testing is the preference for the Rockwell hardness test, supplemented by the Brinell hardness test, and seldom using the Vickers hardness test.

The American view is that the Vickers hardness test should mainly be used for metal research and testing of thin, small parts.

Both Chinese and Japanese standards simultaneously use three hardness tests. Users can choose one of these tests based on the thickness and condition of the material, as well as individual circumstances, to test stainless steel materials.

The Japanese stainless steel standards regarding tensile testing and hardness testing align closely with the corresponding Chinese standards in both methodology and numerical values, indicating that the Chinese standards have been influenced by those of Japan.

The Rockwell hardness tester is an exceptionally suitable instrument for stainless steel hardness testing.

Its simplicity and ease of use make it an efficient tool that does not require a professional inspector and can directly read hardness values, making it highly suitable for factory use.

The Rockwell hardness tester is typically used for testing the hardness of stainless steel, with the standards generally only specifying the HRC and HRB scales.

For annealed stainless steel materials, each type of stainless steel grade is expected to have a hardness value not exceeding a certain HRB value, typically within the range of 88-96 HRB.

For quenched and tempered martensitic stainless steel, each grade’s hardness value should not be less than a certain HRC value, typically within the range of 32-46 HRC.

While only the HRB and HRC scales of the Rockwell hardness tester are specified in the stainless steel standards, the surface Rockwell hardness tester can also be effectively used for testing stainless steel.

Its principle is identical to the Rockwell hardness tester, but it exerts lesser force. Its hardness values can conveniently be converted to HRB, HRC, Brinell hardness HB, or Vickers hardness HV.

The conversion tables can be found on our company’s website, sourced from the American Standard ASTM or International Standard ISO.

The surface Rockwell hardness tester is particularly handy for testing thin-walled stainless steel pipes, thin stainless steel plates, thin stainless steel strips, and thin stainless steel wires.

Especially, our company’s latest development, the portable surface Rockwell hardness tester and pipe Rockwell hardness tester, can perform rapid and accurate hardness testing on stainless steel plates and strips as thin as 0.05mm and stainless steel pipes as slender as 4.8mm, solving issues that were previously difficult to overcome domestically.

Stainless steel plates include hot-rolled and cold-rolled plates. For stainless steel plates or strips thicker than 1.2mm, the Rockwell hardness tester is used to test HRB and HRC hardness.

For plates or strips with a thickness between 0.2mm and 1.2mm, a surface Rockwell hardness tester is used to test HRT or HRN hardness.

For plates or strips thinner than 0.2mm, a surface Rockwell hardness tester paired with a diamond indenter is used to test HR30TM hardness.

For annealed stainless steel plates and strips with a thickness between 0.3mm and 13mm, a Vickers hardness tester can also be used.

This instrument is extremely quick and straightforward, making it very suitable for rapid quality inspection of annealed stainless steel materials.

Stainless steel pipes include welded stainless steel pipes and cold-drawn stainless steel pipes. For those with an inner diameter greater than 30mm and a wall thickness greater than 1.2mm, a Rockwell hardness tester is used to test HRB or HRC hardness.

For pipes with an inner diameter greater than 30mm but a wall thickness less than 1.2mm, a superficial Rockwell hardness tester is used to test HRT or HRN hardness.

For pipes with an inner diameter less than 30mm but greater than 4.8mm, a specialized Rockwell hardness tester for pipes is used to test HR15T hardness.

When the pipe inner diameter exceeds 26mm, the inner wall hardness can also be tested using Rockwell or superficial Rockwell hardness testers.

For annealed stainless steel pipes with an inner diameter greater than 6.0mm and a wall thickness less than 13mm, a W-B75 Webster hardness tester can be used.

This tool provides fast, convenient testing and is suitable for quick, non-destructive qualification tests on stainless steel pipes.

For stainless steel rods with a diameter less than 50mm, a Rockwell hardness tester can be used to test the HRB or HRC hardness.

For stainless steel wire with a diameter greater than 2.0mm, a superficial Rockwell hardness tester can be used to test HRT or HRN hardness.