Ever wondered which aluminum alloy suits your project better, 6061 or 7075? Both are popular choices, but they have key differences. In this article, you’ll discover the distinct properties of each alloy, including their strength, corrosion resistance, and applications. By the end, you’ll understand which alloy fits your needs, whether it’s for high-stress aerospace parts or versatile industrial components. Dive in to make an informed decision that optimizes your project’s performance and longevity.

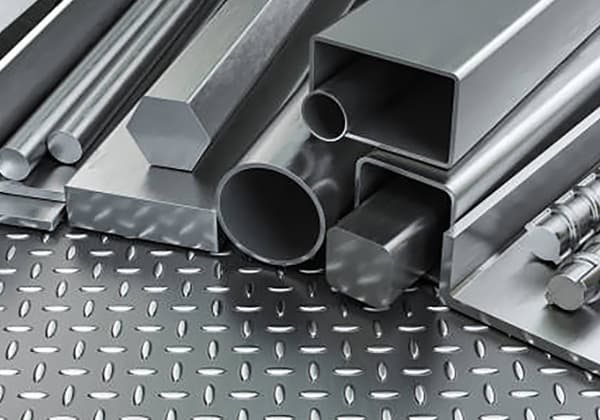

The main alloying elements of the 6000 series aluminum alloy represented by 6061 are magnesium and silicon. It has moderate strength, good corrosion resistance, weldability, and good oxidation effect.

It is widely used in various industrial structural parts that require certain strength and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, railway vehicles, furniture, etc.

The main chemical composition of 6061 aluminum alloy is: Cu 0.15-0.4, Si 0.4-0.8, Fe 0.7, Mn 0.15, Mg 0.8-1.2, Zn 0.25, Cr 0.04-0.35, Ti 0.15. They are aluminum alloys represented by four digits, with magnesium and silicon as the main alloying elements and Mg2Si as the strengthening phase.

The first digit is used to distinguish between groups. The last two digits are used to distinguish between different material numbers within the same series and have no special meaning.

The first digit of the four-digit numerical system and the four-character system number represent the category of aluminum and aluminum alloys as follows:

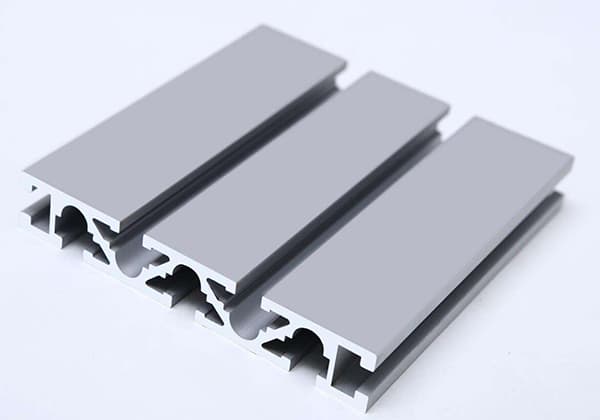

6061 aluminum alloy is a heat-treatable, strengthenable alloy that has good formability, weldability, and machinability, as well as moderate strength. It can maintain good workability even after annealing.

The main alloying elements of 6061 aluminum alloy are magnesium and silicon, which form the Mg2Si phase. If a certain amount of manganese and chromium is added, it can neutralize the adverse effects of iron.

Sometimes, a small amount of copper or zinc is added to increase the strength of the alloy without significantly reducing its corrosion resistance. A small amount of copper is also added to conductive materials to counteract the adverse effects of titanium and iron on conductivity.

Zirconium or titanium can refine the grain size and control the recrystallization structure. Lead and bismuth can be added to improve machinability. When Mg2Si is dissolved in aluminum, the alloy has artificial aging hardening function.

6061-T651 is the main alloy of 6061 aluminum alloy, which is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with the 2XXX or 7XXX series, it has many characteristics of magnesium and silicon alloys.

It has excellent processing performance, excellent welding characteristics, good electroplating properties, good corrosion resistance, high toughness, no deformation after processing, dense and defect-free materials, easy polishing, easy film coloring, and excellent oxidation effect.

The chemical composition range of 6061 aluminum alloy is 0.4-0.8% Si, 0.70% Fe max, 0.15-0.40% Cu, 0.15% Mn max, 0.80-1.20% Mg, 0.04-0.35% Cr, 0.25% Zn max, 0.15% Ti max. The maximum content of each additional element is 0.05%, and the total maximum content of all additional elements is 0.15%. The remaining balance is aluminum.

| Aluminum alloy grades and temper | Coefficient of thermal expansion (20- 100℃)μm/m·k | Melting point range (℃) | Electrical conductivity 20℃(68℉) (%IACS) | Electrical resistivity 20℃(68℉) Ωmm2/m | Density (20℃) (g/cm3) |

| 2024-T351 | 23.2 | 500-635 | 30 | 0.058 | 2.82 |

| 5052-H112 | 23.8 | 607-650 | 35 | 0.050 | 2.72 |

| 5083-H112 | 23.4 | 570-640 | 29 | 0.059 | 2.72 |

| 6061-T651 | 23.6 | 580-650 | 43 | 0.040 | 2.73 |

| 7050-T7451 | 23.5 | 490-630 | 41 | 0.0415 | 2.82 |

| 7075-T651 | 23.6 | 475-635 | 33 | 0.0515 | 2.82 |

| Aluminum alloy grades and temper | Tensile strength(25°C MPa) | Yield strength (25°C MPa) | Hardness 500kg load 10mm dia. ball | Elongation 1.6mm(1/16in) thickness |

| 5052-H112 | 175 | 195 | 60 | 12 |

| 5083-H112 | 180 | 211 | 65 | 14 |

| 6061-T651 | 310 | 276 | 95 | 12 |

| 7050-T7451 | 510 | 455 | 135 | 10 |

| 7075-T651 | 572 | 503 | 150 | 11 |

| 2024-T351 | 470 | 325 | 120 | 20 |

7075 aluminum sheet is a super-hard aluminum alloy belonging to the Al-Zn-Mg-Cu system. It has been widely used in the aviation industry since the late 1940s and remains a popular choice for manufacturing aircraft due to its high strength and deformation resistance.

The alloy has good plasticity after solid solution treatment and excellent strengthening effect after heat treatment. It exhibits high strength below 150℃ and excellent low-temperature strength.

However, its welding performance is poor and it has a tendency to stress corrosion cracking. To use it, it must undergo protective treatment such as cladding with aluminum or other methods.

The alloy’s stress corrosion cracking resistance can be improved with a two-stage aging treatment. In its annealed and quenched states, it has slightly lower plasticity than 2A12 and slightly better static fatigue properties than 7A04.

It is sensitive to notches and has better stress corrosion resistance than 7A04, with 7075T651 being considered the highest quality product in the aluminum alloy family, with superior strength that far exceeds that of mild steel.

This alloy has excellent mechanical properties and anodic reaction and is a typical aluminum alloy for aerospace applications.

| Tensile strength /MPa | Yield strength /MPa | Elongation /% | Coefficient of thermal expansion m3(.m3.k)ˉ1 | Volume electrical conductivity at 20℃ /IACS | Resistivity at 20℃ /NΩ.M | Elastic modulus E/Gpa | Hardness /HB | Density /kg.mˉ1 |

| 524 | 462 | 11 | 68*10ˉ6 | 33 | 52.2 | 71 | 150 | 2810 |

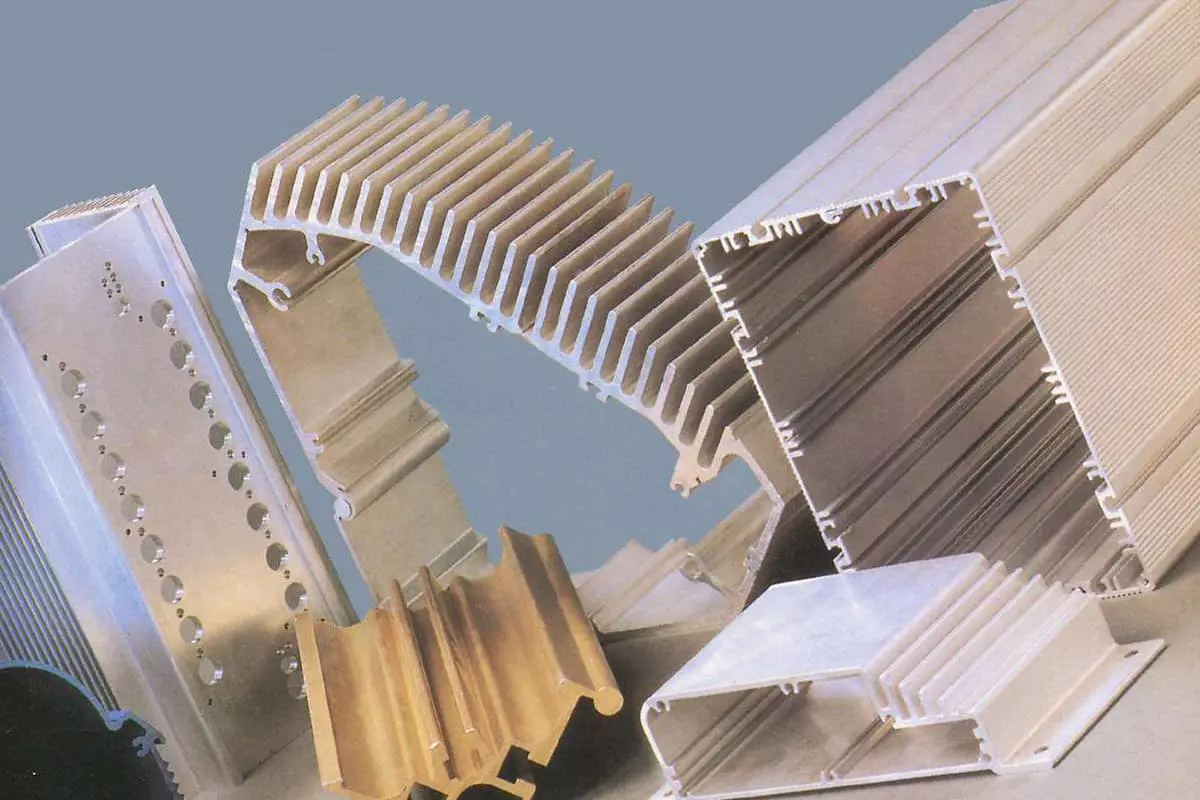

7075 aluminum sheet is available in various forms including sheet, plate, stretched tube, extruded tube, bar, profile, wire, rolled or cold-processed bar, and cold-processed wire. It is also available in various conditions including O, T6, T651, T6511, T73, T7351, T7651, T76511, and H13.

Typical applications of 7075 aluminum sheet include aerospace and aviation industries, blow molding (bottle) molds, ultrasonic plastic welding molds, high-end golf heads, shoe molds, paper-plastic molds, foaming molds, investment casting molds, fixtures, mechanical equipment, and other high-stress structural components that require corrosion resistance.

Zinc is the main alloying element in 7075 aluminum, and the addition of magnesium to the alloy containing 3% – 7.5% zinc can form MgZn2, which significantly enhances the strengthening effect and improves the heat treatment effect of the alloy compared to aluminum-zinc binary alloys.

Increasing the zinc and magnesium content in the alloy further improves its tensile strength, but its resistance to stress corrosion and peeling corrosion decreases accordingly.

After heat treatment, the alloy can achieve extremely high strength properties. 7075 materials generally contain small amounts of copper, chromium, and other alloys. Among them, A7075 aluminum alloy is particularly high-quality and is considered the best product in the aluminum alloy family due to its high strength, which far exceeds that of any mild steel.

In aluminum alloys, the grade has a representative meaning. Taking the 7075T651 aluminum sheet grade as an example, the first 7 represents the aluminum and aluminum alloy group – aluminum-zinc-magnesium series alloy. The aluminum and aluminum alloy group are divided into nine categories:

The 0 represents the control situation of the limit content of alloy elements or impurities: 0 represents the original alloy, indicating that there is no special control over the limit content of impurities, 1-9 are modified alloys, indicating that there is special control over the limit content of one or more individual impurities or alloy elements.

The 24 represents different alloys: indicating the last two digits after the decimal point in the minimum aluminum alloy content. For example, the aluminum content of 1050 aluminum is 99.50%, and the two digits have no special meaning, but are used to identify different alloys in the same group.

T651 represents heat treatment. Generally, there is one or more digits after T, such as T6, indicating that it has undergone T6 heat treatment. Different digits represent different heat treatments. 51 represents the state of eliminating internal stress.

In conclusion, both Al 6061 and 7075 are popular aluminum alloys used in various industries. While both alloys offer high strength-to-weight ratios and excellent corrosion resistance, they differ in terms of their tensile strength, hardness, and machinability.

Al 6061 is a versatile alloy that is suitable for a wide range of applications, while Al 7075 is a high-strength alloy that is commonly used in aerospace and defense applications.

Choosing the right alloy for a specific application depends on a variety of factors, including the required strength, weight, and cost. Ultimately, both alloys have their own unique properties and advantages, and the choice between the two will depend on the specific requirements of the application.