Have you ever wondered how different materials affect sheet metal bending? In this insightful article, a seasoned mechanical engineer shares their expertise on the impact of material types, thickness, and other factors on bending calculations. Discover valuable insights that can help you optimize your sheet metal fabrication processes and achieve precise results. Read on to learn from an industry expert and take your bending knowledge to the next level!

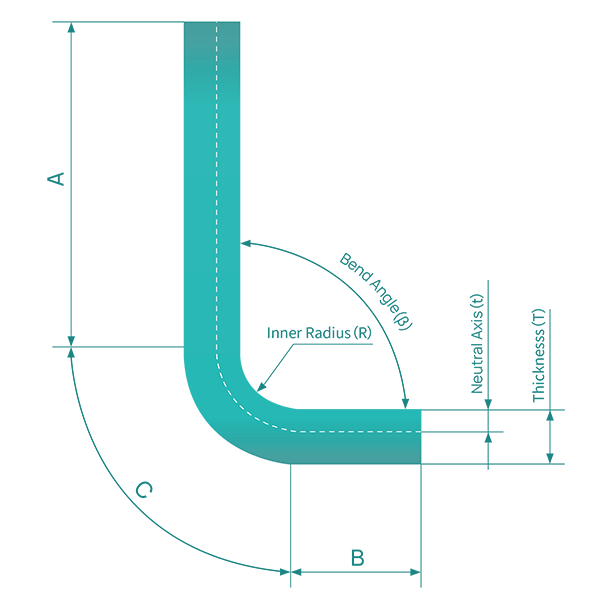

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into:

Instructions for Optimal Use:

Leverage this powerful calculator to enhance your sheet metal fabrication process, improve accuracy, reduce material waste, and streamline your production workflow.

Related reading:

In sheet metal bending calculations, the impact of different material types on the bending factor is significant and multifaceted, influencing the accuracy, quality, and efficiency of the bending process. The key areas affected include:

Material Properties:

Different materials exhibit varying mechanical properties such as yield strength, tensile strength, and elastic modulus. These properties directly influence the material’s behavior during bending, affecting the spring back phenomenon and the required bending force. For instance, high-strength steels typically require a larger bending factor compared to mild steels due to their increased resistance to plastic deformation.

Grain Structure and Anisotropy:

The crystalline structure and grain orientation of metals play a crucial role in bending behavior. Materials with a pronounced grain structure, like certain aluminum alloys, may exhibit anisotropic properties, leading to different bending factors depending on the direction of bending relative to the grain orientation. This can result in inconsistent spring back and potential defects if not properly accounted for in calculations.

Work Hardening Characteristics:

Materials with different work hardening rates, such as austenitic stainless steels versus low-carbon steels, require distinct approaches to bending factor calculations. Work hardening during the bending process can significantly alter the material’s properties, affecting the final shape and dimensional accuracy.

Thermal Expansion Coefficients:

For processes involving heat, such as hot bending or subsequent heat treatment, the material’s thermal expansion coefficient becomes a critical factor. Materials with higher coefficients may require compensation in the bending factor to account for dimensional changes during cooling.

Surface Condition and Treatments:

Surface treatments like anodizing, galvanizing, or case hardening can alter the material’s surface properties, affecting friction during bending and potentially changing the required bending factor. The presence of oxide layers or coatings must be considered in precise bending calculations.

Thickness Variations:

While material thickness itself is a key factor, the consistency of thickness across the sheet is equally important. Materials prone to thickness variations, such as certain rolled alloys, may require adaptive bending factors or more conservative calculations to ensure consistent results across the workpiece.

Strain Rate Sensitivity:

Some materials, particularly certain aluminum alloys and high-strength steels, exhibit strain rate sensitivity. This means the bending factor may need to be adjusted based on the speed of the bending operation, with faster bending potentially requiring different calculations than slower, more controlled processes.

Residual Stress State:

The presence of residual stresses in the material, which can vary based on the material type and previous processing history, can significantly impact the bending behavior. Materials with high levels of residual stress may require stress relief treatments or adjusted bending factors to achieve accurate results.

To optimize bending operations for different material types, it’s crucial to:

By carefully considering these material-specific impacts on the bending factor, manufacturers can achieve higher precision, reduce scrap rates, and optimize their sheet metal bending processes across a wide range of materials.