Imagine the power of a spring that is compact yet incredibly strong. Rectangular springs, with their unique shape and high stiffness, outperform ordinary round wire springs in demanding applications. They are essential in precision machinery, offering greater durability and resilience. In this article, you’ll discover the distinct advantages of rectangular springs and understand why they are the preferred choice for high-load environments. Dive in to learn how these springs enhance mechanical performance and reliability.

In recent years, the industrial automation industry has experienced rapid development. One very representative product in the spring series is the rectangular spring. Its research and development speed is increasing, and its application fields are becoming more extensive.

The rectangular spring is known for its prominent features such as large stiffness, long service life, and small volume. To understand the difference between the rectangular spring and an ordinary spring, one needs to consider various factors from multiple angles.

Rectangular springs are typically made of chromium alloy steel, which is known for its high rigidity, high temperature resistance, and strong working stability.

Using chromium alloy steel for rectangular springs not only maintains their existing advantages, but also adds benefits such as strong elasticity, high precision, and a visually appealing appearance.

To differentiate the bearing capacity of rectangular springs with different specifications, manufacturers use color-coded surface coatings.

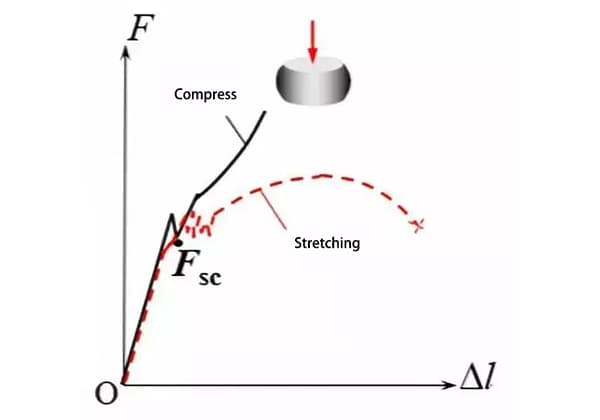

Ordinary springs are typically made of round wire with a circular cross-section, while rectangular springs are made of square wire with a square cross-section. Springs made of square wire rods have a greater spring force than ordinary springs and better performance in resisting deformation and fracture.

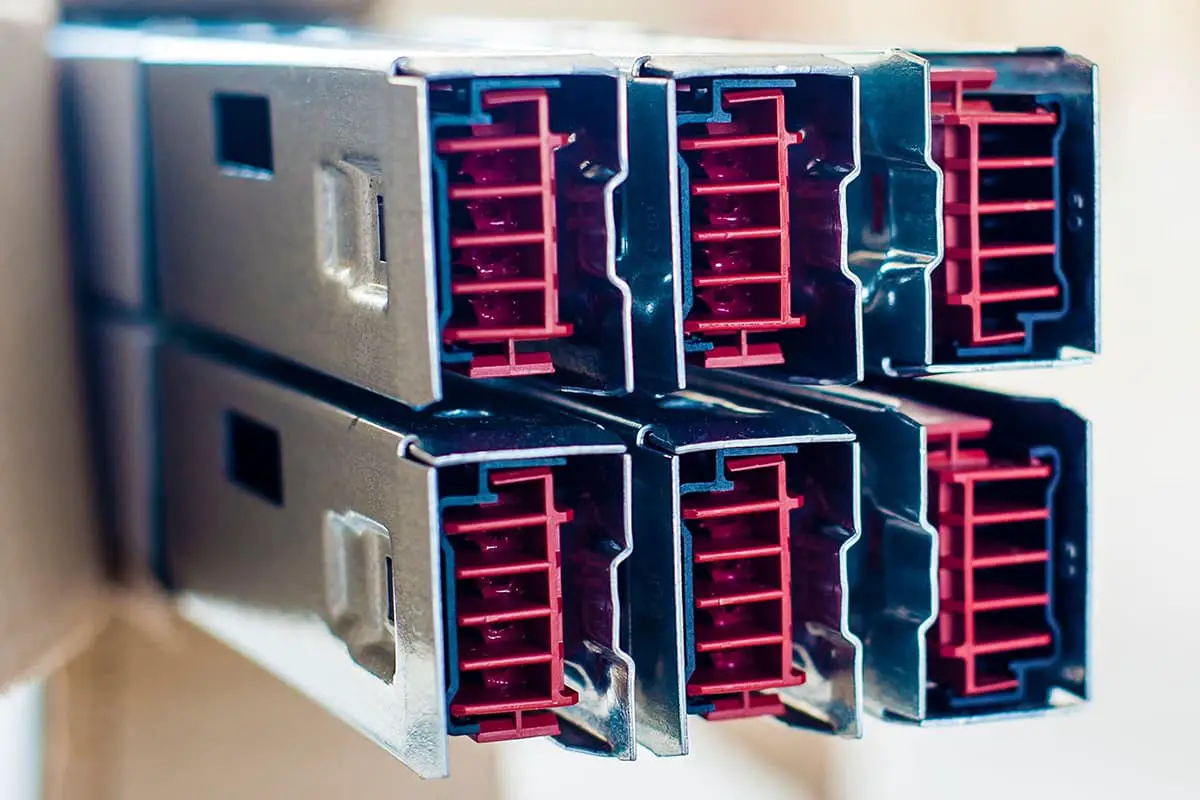

As a result, rectangular springs are widely used in stamping dies, die-casting dies, plastic dies, and other precision mechanical equipment that requires elastic motion.

Because of its significant role in the field of mold making, the rectangular spring is also known as a mold spring. Rectangular springs are commonly used in high-load situations with limited installation space. The small size of the rectangular spring makes it suitable for use in holes or on shafts, while still meeting the requirements for high-speed compression and overweight loads.

Although the rectangular spring is only one type of spring product, its importance in various fields cannot be ignored. It plays a crucial role in starting and resetting, ensuring that the entire mechanical equipment runs smoothly. Without the auxiliary function of rectangular springs, the durability and applicability of the equipment would be greatly reduced.

In summary, the quality of rectangular spring products reflects the manufacturing capacity of the entire manufacturing industry.