Have you ever marveled at the versatility of springs in mechanical engineering? From automotive suspensions to precision instruments, these unsung heroes play a crucial role. In this blog post, we’ll delve into the fascinating world of springs, exploring their types, applications, and design principles. Join us as we uncover the secrets behind these essential components that keep our machines and devices running smoothly.

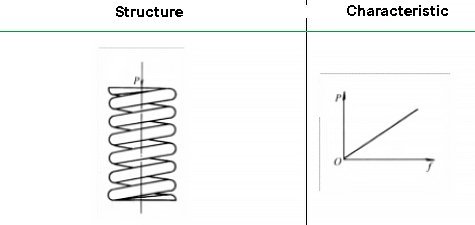

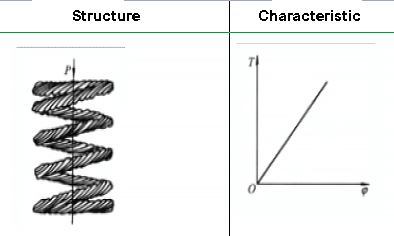

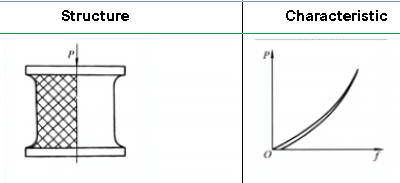

The characteristics of the line are linearity, stable stiffness, a simple structure, convenient manufacture, and widespread applicability.

It is primarily utilized as a buffer, for vibration reduction, energy storage, and motion control in mechanical equipment.

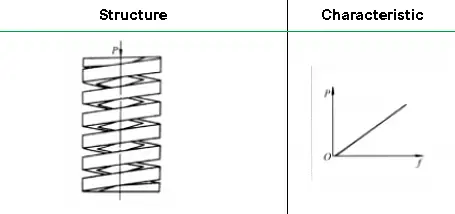

Under equivalent space constraints, a rectangular section cylindrical helical compression spring exhibits higher stiffness and can absorb more energy compared to a cylindrical helical compression spring with a circular section.

Its characteristic curve is more linear and its stiffness is more constant.

Compared to the cylindrical spiral compression spring with a circular section, the cylindrical spiral compression spring with a flat section has the advantage of having a large energy storage capacity, low compression height, and large compression capability.

As a result, it is commonly used in engine valve systems, clutches, automatic transmissions, and other devices that have limited space for installation.

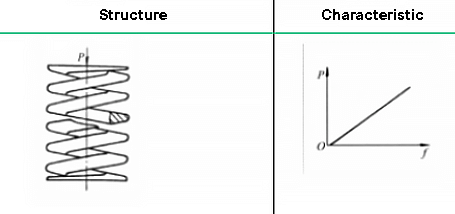

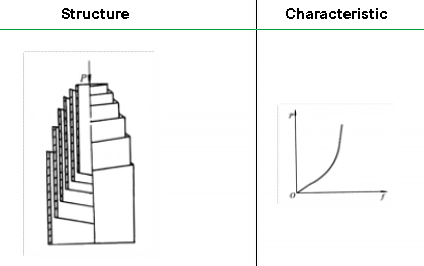

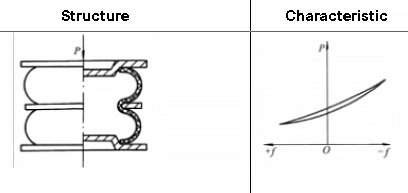

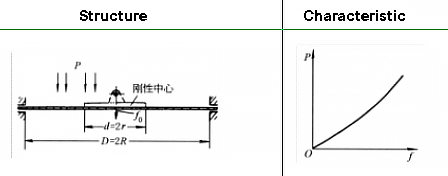

As the load increases to a certain extent, the spring gradually tightens from a small pitch, causing the stiffness to increase and the characteristic line to change from linear to incremental. As a result, the natural frequency becomes variable, allowing for better elimination or mitigation of resonance. This feature makes it a popular choice for use in high-speed load changing mechanisms.

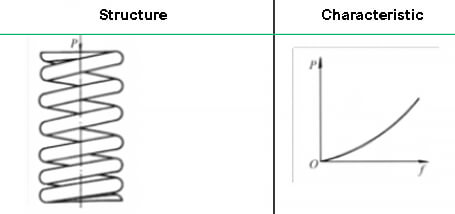

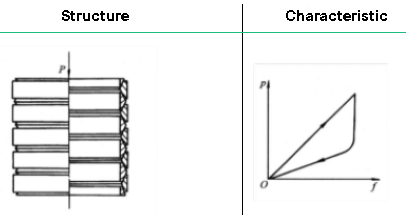

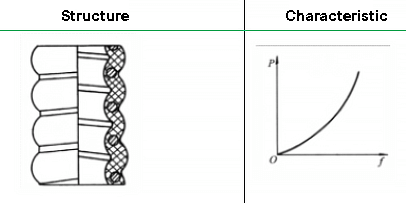

The material used for a multi-stranded cylindrical spiral compression spring is steel wire rope twisted with thin steel wire.

When not under load, the contact between the wires in the wire rope is relatively loose. However, when an external load reaches a certain level, the contact tightens and the spring rigidity increases, causing a break point in the characteristic line of the multi-stranded spiral spring.

Compared to an ordinary cylindrical spiral spring made from the same section material, the multi-stranded cylindrical spiral compression spring has greater strength and a stronger damping effect.

It is commonly used in weapons and aeronautical engines.

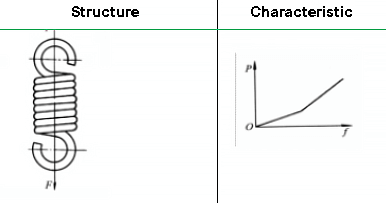

The performance and characteristics of cylindrical helical tension springs are similar to those of cylindrical helical compression springs with circular sections.

These springs are primarily utilized in applications that require tensile loading, such as in overload safety devices for couplings and as pawl return tension springs in ratchet mechanisms.

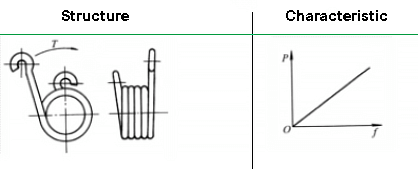

A cylindrical helical torsion spring is designed to withstand torsional loads and is commonly used for pressing, energy storage, and as an elastic link in transmission systems. With a linear characteristic line, it is widely employed in various applications, such as dynamometers and forced air valve closing mechanisms.

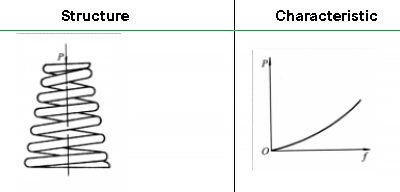

The function of a conical coil spring is similar to that of an unequal pitch coil spring. When a load reaches a certain level, the spring gradually tightens, starting from the larger coil to the smaller coil, until the coils begin to make contact.

The characteristic line is non-linear, the stiffness increases gradually, and the natural vibration frequency is a variable value. This makes it ideal for eliminating or reducing resonance and makes it have a stronger anti-resonance ability compared to equal pitch compression springs.

This type of spring is known for its compact structure and stability. It is commonly used to support heavy loads and reduce vibrations, such as in suspension springs for heavy vibrating screens and in Dongfeng automobile transmissions.

Compared to other springs, volute coil springs have the ability to absorb more energy in a compact space. Additionally, the friction between its plates can effectively reduce vibration.

Volute coil springs are commonly utilized in piping systems that require absorbing thermal expansion deformation and Yin Ni vibration, as well as components related to piping systems such as steam and water piping systems in thermal power plants.

However, the volute coil spring has some limitations, including a small gap between plates that makes quenching difficult and shot blasting impossible. Furthermore, the manufacturing accuracy of the spring may not be high enough.

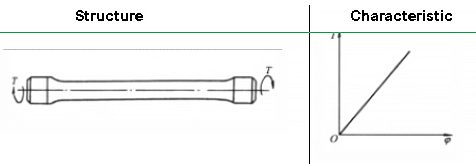

The design of torsion bar springs is straightforward, however, the demands for material quality and manufacturing precision are high.

It is primarily utilized as a suspension spring in automobiles and light vehicles, as well as an auxiliary spring for valves in internal combustion engines, air springs, and pressurizers.

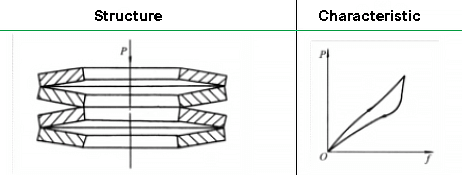

Ordinary Belleville springs exhibit strong capacities for load-bearing, cushioning, and shock absorption.

By using different combinations, various characteristic lines can be obtained.

These springs can be utilized in various applications, including pressure safety valves, automatic conversion devices, reset devices, clutches, and more.

Ring springs are commonly utilized in applications that require the absorption of significant amounts of energy within limited space constraints, including: springs in locomotive traction devices, buffer springs for cranes and cannons, damping springs for forging hammers, and braking springs in aircraft, among others.

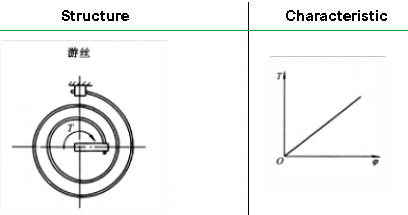

The hairspring is a flat, coiled spring made from a small metal belt. It can serve as both a measuring element (known as a measuring hairspring) and a pressing element (referred to as a contacting hairspring).

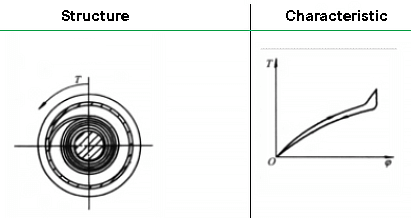

The spring serves mainly as an energy storage component.

Clockwork is dependable and straightforward to maintain.

It is commonly utilized in timing devices and time control instruments such as clocks, recording instruments, household appliances, etc., and as a source of power in motorized toys.

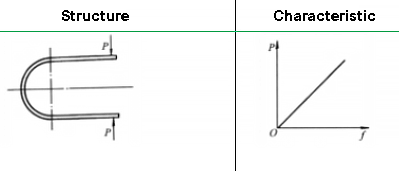

Leaf spring is a type of metal sheet with a rectangular section, primarily used in applications with low load and deformation. It can serve as a sensitive element in detection instruments or automatic devices, an electric contact point, the pawl in a ratchet mechanism, a pressure spring for a positioner, or a support or guide rail.

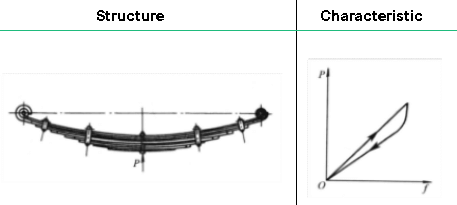

The steel plate spring consists of several spring steel plates.

It is commonly utilized as a suspension component in automobiles, tractors, and trains to provide cushioning and reduce vibrations.

Additionally, it is employed as a vibration dampening device in several mechanical products due to its high rigidity.

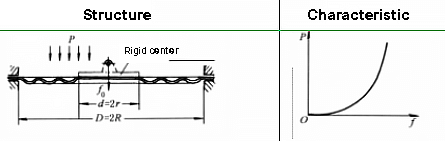

The rubber spring has a small elastic modulus, allowing for significant elastic deformation, making it easy to achieve the desired nonlinear characteristics. Its shape is unrestricted and its stiffness can be freely selected to meet design requirements in any direction.

Additionally, the rubber spring is capable of bearing multiple loads simultaneously, simplifying the overall system structure. The use of rubber springs in mechanical equipment is rapidly growing.

The characteristic curve of a rubber-metal spiral composite spring is increasing.

Compared to a rubber spring, this composite spring has greater rigidity and damping compared to a metal spring.

As a result, it has the benefits of high load-bearing capacity, effective vibration damping, and improved wear resistance.

It is suitable for suspension systems in mining equipment and heavy vehicles.

An air spring is a non-metallic type of spring that utilizes the compressibility of air to provide an elastic effect. When used in a vehicle’s suspension system, it can significantly enhance the vehicle’s dynamic performance and running comfort, making it a widely adopted technology in cars and trains.

It is utilized to assess non-linear quantities related to pressure, including the flow of liquids or gases in pipelines and the speed and altitude of aircraft.

It is utilized as the sensitive component in the instrument, serving to isolate two distinct substances. For instance, it functions as a flexible sealing device that deforms in response to changes in pressure or vacuum.

Two identical diaphragms are connected into a box shape along the periphery.

Under the influence of fluid pressure, the end of the pressure spring tube experiences displacement, which is then transmitted to the pointer through a transmission mechanism. This mechanism is utilized in various instruments such as pressure gauges, thermometers, vacuum gauges, liquid level gauges, and flowmeters.