Have you ever wondered how to accurately calculate the weight of metal objects? In this blog post, we’ll explore a handy tool called the Metal Weight Calculator. Developed by experienced mechanical engineers, this calculator simplifies the process of determining the weight of various metals based on their dimensions and properties. Whether you’re a professional or a curious DIY enthusiast, this article will provide you with valuable insights to streamline your metalworking projects.

Weight (kg) = Sectional Area (mm2) × Length (mm) × Density (ρ, g/cm3)

Related reading:

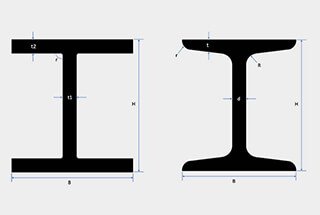

By using our online metal weight calculator, you can quickly and easily calculate the weight of over 20 different metals, including Carbon Steel, Alloy Steel, Stainless Steel, Iron, Aluminum, Magnesium, Copper, Brass, Bronze, Zinc, Titanium, Tungsten, Adamantium, Nickel, Cobalt, Tin, Lead, and Silicon. The calculator can handle various metal shapes such as sheet, plate, pipe, square tube, rectangle tube, flat bar, round bar, square bar, rectangle bar, hexagonal bar, octagonal bar, ring, circle, and coil.

Regarding the density of different metals and alloys, you can refer to the Metal Density Table.