How can handheld laser welders manage the intense heat generated during operation? This article explores the cutting-edge heat dissipation technologies, such as air cooling and water cooling, crucial for maintaining laser performance and longevity. By reading, you’ll understand the principles behind these methods and their impact on the efficiency and portability of laser welding equipment.

With the increasing use of fiber lasers in various fields, their reliability has become an important concern. This includes the reliability of laser output performance, electronic components, optical devices, and systems, which are all closely related to the thermal characteristics of the laser itself.

Temperature has a significant impact on the laser’s performance, especially on its output power and stability. The heat generated by a fiber laser mainly comes from the pump source and the gain cavity.

The conversion efficiency of the pump source is around 50%, meaning that heat is generated in the form of energy equivalent to the output optical power. If this heat is not dissipated quickly enough, the temperature of the internal chip will rise rapidly, causing the central wavelength of the laser to drift.

In the gain cavity, only part of the pump light is converted into laser output, and the rest is converted into heat energy. This thermal energy increases the temperature of the gain medium, causing the fluorescence spectrum to broaden and the lifetime of spontaneous emission to shorten, ultimately reducing the energy conversion efficiency.

Therefore, effective heat management is crucial for fiber lasers. Currently, air cooling and water cooling are the two most commonly used heat management technologies.

Air cooling is suitable for low-power pulse and continuous-wave lasers, while water cooling is the main heat dissipation method used in medium and high-power fiber lasers.

As the name suggests, water cooling is a method that uses water to dissipate heat through a heat exchanger, such as a water cooling plate.

The principle behind water cooling is simple: cold water from a chiller flows through a water pipe and into the heat exchanger, then exits through the other port of the heat exchanger and returns to the chiller via the water pipe. This continuous circulation helps to dissipate heat from inside the laser.

Water cooling and heat dissipation are straightforward in structure and easy to maintain. By using a chiller with greater cooling capacity, the laser’s cooling performance can be improved due to the strong heat dissipation capacity and good temperature uniformity.

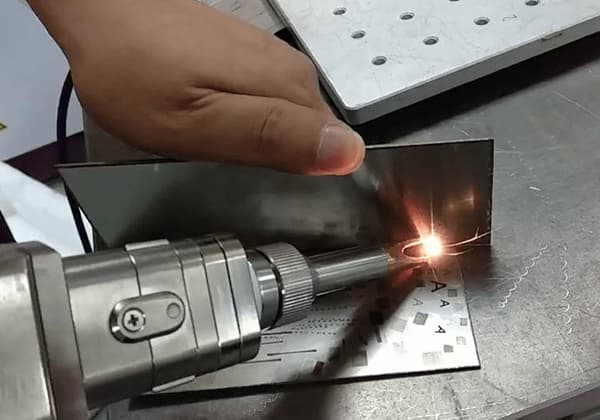

Currently, on the market, over 500 manufacturers integrate and sell handheld laser welding machines that generally use water cooling.

However, in addition to the laser itself, a hand-held laser welding machine with water cooling and heat dissipation requires a separate water cooler and water, which significantly increases the overall volume and weight of the equipment and limits its use environment.

In a broad sense, air cooling refers to the use of fans to enhance air convection and facilitate heat exchange inside the machine.

Thanks to technological advancements, major laser manufacturers have now ventured into the domain of air cooling and heat dissipation.

Last June, the global fiber laser giant, Company I, released the air-cooled LightWELD 1500W handheld laser welding product.

In August, the first air-cooled A1500W intelligent laser welder was launched in China.

Air cooled fiber laser: reci, IPG, GW

These three lasers are mainly designed for the handheld laser welding market segment.

Air-cooled lasers provide greater flexibility and portability in work environments.

All three lasers use air-cooled heat dissipation, eliminating the need for additional water-cooling equipment. This reduces equipment costs and significantly decreases the volume and weight of the equipment.

Despite sharing the “air-cooled” classification, each laser uses a different heat dissipation scheme. These include fan heat dissipation, heat pipe radiator heat dissipation, and compressor refrigeration heat dissipation.

(1) Fan cooling

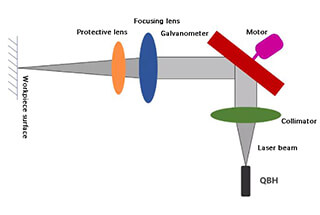

In lasers, substrates with good thermal conductivity such as copper, aluminum nitride, etc., are utilized to export the heat generated in the pump source and gain cavity, and then dissipate it by convection. This method is known as convective heat dissipation.

Convective heat transfer is classified into two types based on the different driving forces of fluid flow- natural convection and forced convection heat dissipation.

When fluid flows spontaneously and conducts heat transfer solely by the temperature difference of the fluid, it is referred to as natural convection, and it occurs without any external force.

On the other hand, forced convection occurs when there is an external driving force that rapidly flows the fluid by fans, pumps, or other components, to remove heat.

Since natural convection has a slow heat dissipation rate and poor effect, it cannot fully meet the heat dissipation requirements of the laser.

Hence, it is essential to add fans to the entire cooling system to accelerate the flow of air and convert natural convection into forced convection.

Cooling principle of fan

(2) Heat pipe radiator

Heat dissipation in a heat pipe radiator is achieved through the transfer of heat via the phase change of its internal working liquid. The liquid has a low boiling point and is highly volatile.

One end of the heat pipe is the evaporation end, which is connected to the heat sink inside the laser, while the other end is the condensing end, connected to an external heat sink and fan. The tube wall is equipped with a liquid absorption core made up of capillary porous materials.

When the laser generates heat, the evaporation end is heated, causing the working liquid to rapidly evaporate. The resulting steam flows to the condensation end under a pressure difference and releases heat, which is then discharged through the fan.

At the same time, the steam recondenses into liquid, which flows back to the evaporation section through the suction core. (In a gravity heat pipe, there is no suction core, and the liquid adheres to the pipe wall and flows back to the bottom evaporation section due to gravity).

This cycle continues, enabling the transfer of heat from inside the laser to the outside.

Heat dissipation principle of heat pipe radiator

The lightWELD 1500 handheld laser welding system from IPG company incorporates a heat pipe radiator for heat dissipation.

The design and manufacturing of lightWELD is characterized by its compact size and lightweight, leading to a new generation of handheld laser welding machines.

Apart from welding, it also offers a dual function of handheld laser welding and cleaning.

The lightWELD handheld laser welding machine employs an air-cooled mechanism, eliminating the need for additional cooling water equipment and associated power consumption.

It eliminates the need for pipes, components, controls, and maintenance links of the chiller, reducing costs, enhancing portability, and improving the system’s overall reliability.

LightWELD 1500 handheld laser welding system

(3) Refrigeration and heat dissipation of compressor

Refrigeration and heat dissipation principle of compressor: the compressor compresses the refrigerant to turn the refrigerant into high-temperature and high-pressure gas and flow to the external condenser.

High-temperature and high-pressure gas condenses into low-temperature and high-pressure liquid. The heat generated by liquefaction is discharged out of the machine with the help of a fan.

The low-temperature and high-pressure liquid refrigerant changes into a low-temperature and low-pressure state after depressurization through the expansion valve, and then flows into the internal evaporator.

The evaporator absorbs heat to reduce the internal temperature of the laser, achieving the cooling effect. Subsequently, the refrigerant vaporizes into a gas with high temperature and low pressure.

The refrigerant gas evaporated by the evaporator is compressed again by the compressor and circulates back and forth to dissipate the heat inside the machine.

Refrigeration and heat dissipation principle of compressor

The A1500w intelligent air-cooled handheld welding machine uses the scheme of compressor refrigeration and heat dissipation.

1500w intelligent air-cooled handheld welder

The structure of fan cooling is relatively simple as it diffuses the heat from the heat sink to the ambient air using the temperature difference between the heat sink and the surrounding air through forced convection by the fan.

However, in summer when the ambient temperature is high, the temperature difference between the heat sink and air decreases resulting in reduced heat dissipation capacity. This limits its ability to dissipate heat and makes it sensitive to environmental factors, making temperature control difficult.

Despite its limitations, fan cooling has the advantage of being simple in overall equipment and control system.

On the other hand, a heat pipe radiator has a more complex structure with multiple heat pipes. It relies on the evaporation and condensation of the working material to quickly transfer the heat from the heat sink to the ambient air through the fan, making it more efficient than simple fan cooling.

Passive heat dissipation is unable to accurately control the temperature and is greatly affected by the surrounding temperature, and it is also a part of it.

On the other hand, the compressor’s refrigeration and heat dissipation scheme falls under active heat dissipation. The compressor and expansion valve’s existence enables precise temperature control by regulating the refrigerant’s flow and pressure.

Additionally, the refrigerant’s temperature in the condenser is higher than that of the heat sink, allowing for quick heat transfer to the air. Its control system must be more complex as a result.

However, due to its significantly more complicated design than the previous two schemes, the equipment’s size and weight are also correspondingly increased.

Traditional fiber lasers typically use water cooling to dissipate heat. The water is first cooled by a compression mechanism, and then used to cool the laser.

In contrast, air-cooled heat dissipation directly uses the compression mechanism to cool the laser, eliminating the need for water and reducing the intermediate heat transfer link. This results in higher heat dissipation efficiency and smaller volume and weight.

In our laboratory, we use a constant temperature and humidity test chamber to simulate a high-temperature service environment in summer by setting the temperature to 35 ℃.

We tested the change of internal gain fiber temperature in a laser operating at full power (1500W) using different air cooling schemes over time. The experimental data showed that the optical fiber temperature increased exponentially in the first few minutes and stabilized after about 10 minutes.

Due to the compressor’s refrigeration function, the laser can be actively cooled, and the temperature can be controlled below 60 ℃ with relatively stable temperature changes.

On the other hand, the other two schemes rely on passive heat dissipation, resulting in slightly higher internal temperatures than the compressor refrigeration scheme. The heat pipe has higher heat transfer efficiency and can efficiently export heat from inside the laser, resulting in a lower internal temperature than the pure fan, and gentler temperature rise.

Variation of temperature with time when laser with different air cooling schemes outputs 1.5KW laser

(laboratory data may deviate from actual field use)